Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Group 4 Section D End Term Paper

Caricato da

Ashish MukherjeeDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Group 4 Section D End Term Paper

Caricato da

Ashish MukherjeeCopyright:

Formati disponibili

Business Environment Analysis of Dempo Shipbuilding and Engineering Pvt Ltd

3/19/2011 Section D/ Group 4 Ashish Mukharjee Prathamesh Joshi Suhail Thakur Veera Redkar Vikash Kumar

2010189 Email id: ashishmk1@gmail.com Ph. No: 9823252709 2010218 2010230 2010235 2010237

Business Environment Analysis of Shipbuilding and Engineering Pvt Ltd

Abstract Through this report, we have tried to analyse both internal as well as external business environment of Dempo. The report explains various external factors that affect the internal workings and revenues of an organization. It analyses the internal environment with respect to the administration, production, its major products, organizational structure and financial measures. This has been compared with the external environment and how it influences the company. For this purpose a study of the regulatory requirements, taxation , competitors and future plans was carried out. The report also has utilised statistical techniques to understand and predict the sales, costs and revenues of the firm. Through a simple regression we have been able to establish the significant effect of steel prices on the companys profitability. We have also incorporated the time series in the model.1

Acknowledgement:

We would like to thank Dempo, for allowing us to gain an insight of their operations and business environment. We would specifically like to thank Mr. S S Kanekar (GM) from Dempo for patiently answering all our queries and helping us when needed. We would also like to thank Professor Joy Chaudhary and Professor Amarendu Nandy for providing their invaluable guidance during the course of preparing this paper. Finally, we would also like to thank our batchmates for helping us as and when required.

1

DEMPO THE GROUP The Dempo Group of Companies has been a leader in the field of Trade, Commerce, Industry, Education, Sports and Social Service right from the inception in the year 1941. This company was built from Souza Mineralia Pvt. Company. The group has diversified business activities like mining and export of iron ore, manufacturing of Calcined Petroleum Coke, Pig Iron, Shipbuilding, Food Processing, Real Estate, Sports and Media. The group has consolidated annual turnover of about Rs. 1000 crores. The group has global presence spanning from Europe to Far East and South East Asia. The brand name of Dempo has been an inseparable part of the era of industrialization in the State of Goa. A lineage dating back to the 17th Century, Dempo today is a name that symbolizes excellence, trust and commitment to the society.

DEMPO SHIPBUILDING AND ENGINEERING PVT LTD Dempo Shipbuilding and Engineering Pvt. Ltd. is a premier shipyard in Goa. The Group's other traditional mainstay has been ship building and ship repair, two areas in which it has proved to be an anchor of reliability and innovativeness along the Western coast of India. Located on the banks of the picturesque Mandovi River, just 8 Kms. off the Arabian sea, the yard is spread over a area of 25,000 square meters and is strategically placed between the National Highway and the river navigation channel. The yard has requisite facilities and expert work force to provide International quality services at competitive rates. It is certified to be conforming to ISO Standard 9001:2008 in respect of ship design, ship building and ship repair operations. Quality is the key and Excellence is the norm, at Dempo Shipbuilding. The shipyard also has another yard on the banks of the Zuari River at Undir, Ponda, just 10 Kms. Off the Arabian sea. The yard is spread over an area of 20,000 square meters with a side lunching facilities and an outfitting bay. A Dry Dock of size 100 mts X 20 mts is proposed to be constructed at this facility in 2010.

FACILITIES AT THE YARD The yard has Slip Way of the size120 mts X 20 mts. The yard also has a Side Launching Bay 110 mts X 20 mts and 80 mts X 16 mts. There are Dry Docks which, 2 in number, of the size 93 mts X 18 mts (maximum docking draft 2.5 mts) having the facilities for Blasting, Painting, Steel Renewals, Stern Gear, Propulsion, Deck Machinery, Piping, Plumbing, Repairs and Overhaul and all types of Mechanical and Electrical jobs. The Outfitting Quay if 120 mts. In length The Mechanical, Electrical and Steel Workshop is fully equipped The Fabrication Bay both covered and open with monthly throughput of over 150 tons per yard. The yard has a full-fledged CAD Centre for a conceptual and detailed design, production drawing, naval architectural calculations etc. The yard has a Quality Control Department for on line quality assurance and liasions with third party inspection agencies and statutory authorities. Custom Bonded Warehouses CNC Cutting and CO2 Welding Machines

Shipbuilding has historically witnessed a robust growth in demand for new vessels. Though the short. Term demand has seen peaks and troughs; overall the sector has shown a healthy rising trend in demand. The overall CAGR between 1980 and 2005 is around 6 percent, which is higher than most Manufacturing industries. At present, the sector is amidst an unprecedented boom, unseen in the last three decades. At the end of 2007, the global order book had swelled to 457 mn DWT having quadrupled in the last 5 years. The key reason is the rapid increase in new orders which has outgrown in the increase in global shipyard capacity. Average delivery in the last 5 years has been around 60 mn DWT whereas new orders in the same period have been around 100 mn DWT per annum.

INDIA SHIP REPAIR INDUSTRY

NEED FOR SHIP REPAIR Ship repair is done for following reasons Routine maintenance and Regulatory Inspection Damage Repair Conversion and Reconstruction

There are various categories of repair Hull Repair: constitutes mainly structural work. Machinery Repair: Mainly repair of main engine, propeller shaft, auxiliary engine etc. Accommodation Repair: Repair of equipments found in accommodation area, air conditioning and ventilation etc. Electrical/Instrumental Repair: Repair of any electrical or instrumentation on ship. Painting: Painting plays a very major role in preventing structural member and pipelines to decay while operating in saline water.

Ship repair industry has to consider the following things: Trade operations existing near ship repair yard. Transportation facilities for getting raw materials and equipment. List of ship size operating in that particular region. Environmental conditions prevalent at the site. Draft available for channel. List of sub-contractors and availability of skilled labour locally. Proper and standard management of repair activity. Equipments used should be standardized. Availability of advanced cutting, welding and outfit machineries. Advance detail design layout for machineries and dry dock facilities. Selection of dry dock.

Research report on dock days of dry dock. Shipyard should be able to cater to the future growth.

Costs involved in ship repairing can be divided as Direct cost a. Dry docking cost b. Labour cost c. Spares cost d. Structural work cost Indirect cost e. Revenue loss f. Operational expenses g. Mobilisation expenses h. De-Mobilisation expenses

Demand and supply growth in ship repair Major component in ship repair is the requirements that are derived from dry docking survey undertaken to satisfy the regulations of classification societies. Other demand comes from damage repair, technological changes/ ship conversions. Because of economies of scale size of ships are increasing and to accommodate those bigger vessels port capacity is also being increased. Increasing world trade is also another major demand influencer of the ship market. Demand influencers International regulations Technological changes/ ship conversions Age of fleet Accidental damage Increasing trade Related developments (port sector)

Supply influencers Ship repair capacity Low cost and productivity. Subcontracting capabilities. Repair subsidies. Ancillary industry. Ship repair technology IT enablement and process integration

INTERNAL ENVIRONMENT Mining activities in Goa commenced in the early 1940s when it was still a Portuguese colony .The key players in the market at that time who were given permission to operate in the mining business were family owned firms who had found favor with the colonial governments. These included the Dempos , Salgaocars and Chowgules. Initially the transportation of ore on the inland waterways from the mines to the bulk carriers out at sea was unorganized. It was carried out manually using small boats and canoes. This was feasible as the operations were at a small scale level and did not suffer from the absence of better methods. But 1950 onwards as the demand for Goan ore increased in the international market the companies started procuring small 100-150 DWT barges second hand from abroad to meet this demand. This can be considered as when the industry took its first steps to becoming and group of organized businesses. Dempo Ship Building and Engineering Pvt. Ltd opened its first yard in Goa in the late 1950-s to meet the service and repair requirements of the vessels the Dempos had procured from abroad to aid in their ore export business. This yard was primarily a repair and maintenance yard which looked after these activities in the monsoons when the mining activities were suspended due to bad weather. The organization employed and trained locals to work in this yard so as to provide an employment avenue to the local population. For this it invested a major amount in training and developmental activities. But very soon it realized that the employees and the work force in general was underutilized as they had a major chunk of work in the monsoon season and for the rest of the year there was hardly and work. Thus in

Dempo Shipbuilding and Engineering Pvt Ltd

orders to better utilize the work force they decided to venture into the barge building industry. For this they hired new engineers and drew up contracts with ships design firms in Mumbai. The first vessels constructed at the yard were of 750DWT and for personal use by the Dempo Mining industries Geographical constraints The geography of Goa is a major constraint for further development of ship building activities in the inland waterways. This is due the tidal nature of the rivers and a very small tidal difference of less than 2.6 meters. This constrains the size of vessels that can be built at any location on any inland shipyard. Also the draft capacity of the Mandovi (on which the Old Goa shipyard is located) and of the Zuari( on which the Undir-Ponda shipyard is located) is very less because of which ships with a very large draft requirement cannot be constructed. There is also a limitation with respect to air draft which is the height to which a ship can be constructed. Due to the presence of road and rail bridges along the Mandovi and Zuari the maximum air draft possible is just 9.5 meters in the Mandovi and 12.5 meters in the Zuari

Organizational Structure Dempo Shipbuilding and Engineering Pvt. Ltd is primary divided into two main divisions Production Administrative

Production looks after the actual construction and repair work of vessels. They are further divided into Mechanical Engineering: Look after the engineering aspects of repair and production. This includes interpreting designs, drawing up production plans, raw material requirements, assembly of parts, testing, certification etc. Electrical Engineering: Look after internal electrical and electronic installation and planning. These are required in all modern vessels according to regulatory requirements. They are also responsible for finding vendors for components which will be required in the vessels such as navigational equipment, electrical fixtures etc.

Dempo Shipbuilding and Engineering Pvt Ltd

Fabrication: They are primarily involved with fabrication of parts which are required and outsourcing jobs which cannot be carried out at the yard itself. They thus are also responsible for checking quality of outsourced parts that they get and maintaining that all parts are within the specified limits of tolerance

Carpentry: They are responsible for providing any wood work related equipment required in the vessels. Most of the work is outsourced though some of it is also carried out in house

The administrative duties involve human resource management, accounting, legal documentation and marketing. In 1990 the company shifted to a contract based labor system to better utilize funds and also better use their. The human resource department today primarily looks at whether contractors follow the required regulations with respect to registration, Employment security, PF schemes, PAN card requirements and other such labor regulations. They also install mechanism to keep their permanent staff numbering between 55-60, motivated and design the remuneration schemes and plans for them. Finance and accounting look after day to day financial activities. They deal with payments to contractors, petty cash payments, internal auditing, arranging for loans and financing, bank guarantees and if required communicating with the Dempo group financing head for any extra financial aid if required. An important thing to be noted is that the balance sheet is not prepared individually for each company under the Dempo group of industries and a consolidated balance sheet is prepared for the whole group comprising the assets and liabilities if the whole Dempo group. Hence the finance and accounting department are answerable to the CFO of the Dempo group.

Operations The company has a well-defined set of operational regulations and places high importance on process capability and quality. Dempo Ship Building and Engineering Pvt Ltd is an ISO 9001:2008 certified organization and thus implements stringent measures and works to a great extent on its quality management systems. The company does on have its own design team and relies on design consultants for vessel design with 2 consultants in Goa and Mumbai each and 1 in Singapore. Depending on

Dempo Shipbuilding and Engineering Pvt Ltd

customer requirements they outsource their design requirements and choose the best design available depending on what the customer desires and the price negotiated. The company is also highly concerned and sensitive to the issue of continuous improvement to as to remain competitive in the market and provide highly quality services and vessels to all customers. They believe that the best way of remaining in the business is by improving continuously and obtaining re-orders from their customers. The organization also uses ERP systems to better utilize its resources. At present it is using a self-developed system called Shipyard Management System but with expansion and growth in mind, they are planning to implement SAP within the next year for which the pre-implementation training programs have already commenced The operations in the marketing department follow a fixed procedure and involve the following steps Customer enquiry Preliminary design Negotiation on price and design Design modification Design Approval Final negotiation Legal documentation

The payment schedules for the vessels taken as projects are as follows 7.5 lakh rupees on projects acceptance 20% of price on commencing construction 20% of price on keel laying 20% on completion of hull construction 10% on vessel launch Balance on delivery

The usual time taken to construct a 2000DWT barge is between 4.5-5 months

Dempo Shipbuilding and Engineering Pvt Ltd

Products The company caters to a wide variety of customer requirements. Their major products include Barges up to 4500DWT Pilot launches Mini Bulk Carriers Off shore supply vessel Hopper barges Multi Utility craft Jack-up platforms

The company functions with the aim of maximizing the value provided to its customers. Because of this focus they have been able to maintain a steady number of orders from their customers and the yard is booked to capacity till the end of 2012. Apart from this the major highlights of the company are No capacity underutilization in the last 5 years 90% of the workforce consists of migrants They provide wages above the industry average in order to retain and draw the best talent in the industry

EXTERNAL ENVIRONMENT The Dempo Group has embarked on a major restructuring exercise involving all its businesses in the group, which include Mining, Calcined Petroleum Coke, Pig Iron, Shipbuilding, Food, Travel and Media, Dempo Football Club and its interests in Education. As a part of this restructuring, the Dempo Group has sold V S Dempo & Company Private Limited (VSD), which houses the Group's Goa mining assets, to Sesa Goa Limited. The major customers of Dempo are o Dempo Industries o United Shippers Mumbai

Dempo Shipbuilding and Engineering Pvt Ltd

o Adani Shipping Pvt Ltd o M Pallonji & Co. Pvt ltd o Vespan o Mundra port & SEZ The Shipbuilding at Dempo is aimed at the domestic market only. The external factors have a very minimal effect on the company. Hence Dempo was not affected by the recent economic recession and the other global factors. Raw materials The companys requirement for steel is fulfilled by either importing steel from outside or by the indigenous market only. They have special Bond Arrangements with customs and are exempted from import duties on the incoming steel for their companys requirement. The engines that are needed by the company are either imported aor bought from the local company Kirloskar Cummins. As all these things are bought with a bond arrangement in place, hence the scrap value is closely monitored. They use high end navigational equipment and gearboxes which is imported from abroad.

Market Segment catered to Dempo Shipyard caters primarily to the domestic market only. Hence it does not have a large market outside its domestic reach, because of this factor they have a large number of loyal customers and they get repeat orders from them. They don not compete with EOU( export oriented units) e.g. Bharati shipyard and Chowgule shipyard who deals with the international market.

Competitive Advantage The market that deals with shipyard is basically an unorganized sector and Dempo is one of the few organized company in this sector. Hence it has an edge over the others. As they have been established for the past 40 years and cater majorly to the domestic market only, they have a powerful goodwill. The Dempo name is highly respected and reputed in the state and also outside state, so this name is very beneficial for the company. As the company is dealing

Dempo Shipbuilding and Engineering Pvt Ltd

in many other businesses and is successful in each of them. This gives them better financial credibility and it is much easier for them to raise funds. Dempo gained from being first movers in industry because today land prices and laws regarding starting similar ventures are very stringent.

Dempo has been rated highly for Quality and Timely delivery in the recent IRS (Indian revenue services) reports. The pricing of the company is slightly higher compared to the competitors but despite of this they have repeat customer orders because of a strong and loyal customer base. Based on repeat orders the customer satisfaction level at Dempo is found to be 95%.

Taxes Dempo pays a 5% VAT on new vessels up from 4% earlier. The excise duty was exempted for the company due to the bond agreement but according to the new rules the company is required to pay at 1.06%. They have special customs bond with special permissions to import metal from abroad.

Regulatory Compliance According to the regulatory bodies the vessel is constructed abroad and brought to India. Hence they keep a constant tab on use of steel which is imported. This is done by customs officials posted to their office. The scrap levels of the machines are also measured from time to time and the maximum allowable is limit is 3.5%. This also helps improve processes and keep strict control. A strict fine is imposed an case any of the rule is not followed e.g. any increase in scrap level leads to a fine .The company has no benefit from the government of Goa. The company have not faced any major opposition or problem from local environmentalist etc due to this regulatory compliance. They follow the reuired statutory ruling i.e. CRZ-1993 etc. which is a coastal regulation zone.

Dempo Shipbuilding and Engineering Pvt Ltd

Work Culture Dempo Shipyard believes in keeping proper paperwork. Work culture throughout dempo industries is standardized and properly maintained. 99% paperwork is always in order and ready for inspection SWOT ANALYSIS Strength Situated at major shipping line between east and west. Skilled as well as unskilled workforce. Low cost and cheap labour. English speaking people. Experienced labour force. Manufacturing hub. Robust financial system.

Weakness Opportunities Growth in trade Increase in Port capacity Growth of Indian Fleet size Increase in exploration and production of oil in Indian subcontinent region Old age profile of Indian Domestic fleet Boom in ship building Lack of research and development in ship repair sector. Lack of dedicated ship repair yard. Lack of capacity. Low labour productivity and high labour unrest. Lack of well-developed ancillary industries in India. Old age employees. Old and outmoded facilities and lack of trained and qualified manpower. Exchange rate fluctuation.

Dempo Shipbuilding and Engineering Pvt Ltd

Threats Increasing labour cost without much improvement in productivity. Environmental regulation in ship repair. Attrition of young and talented people to gulf. Over supply if ship repair yard.

PEST Political Government support. o Goa government does not provide it support for expansion so Dempo is planning to move to gujrat. Gujrat government is providing it support required for expansion. Economic Policy initiatives o Dry docks will be given deemed export oriented unit (EOU) status. o Policy will encourage FDI in ship building and repair industry. Infrastructural initiatives o In house design and research activities will be promoted by giving budgetary support and fiscal initiative. o The new dry docking policy will encourage creation of ship repair units adjacent to the ports to be able to repair/dry dock large sized ships. Financial and fiscal initiatives o Taxation in ship building and repair activity including customs and central excise would be brought on par with EOU units. o Capital goods imported for ship building/repair facilities would be exempt from customs duty. o The industry gets excise and sales tax exemption for steel procured indigenously.

Dempo Shipbuilding and Engineering Pvt Ltd

Social Have not faced any major opposition or problem from locals or environmentalist. Follow required statutory ruling, and CRZ-1993 coastal regulation zone Believe in keeping proper paperwork. Work culture throughout dempo industries. 99% paperwork is always in order and ready for inspection. They provide higher than average salary considering high cost of lib=ving in GOA and to retain employees.

Technology Dempo uses ERP system but soon it will be migrating to SAP. With increased business using IT tool like SAP is advisable because of its features like: o Ability to make basic planning based on initially assessed volume of repair work. o Flexible for re-planning because of emerging additional work found necessary to attend or cancellation work. o Ability to take up issues regarding procurement planning and indent generation.

Dempo Shipbuilding and Engineering Pvt Ltd

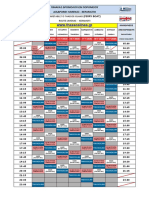

QUANTITATIVE ANALYSIS The first regression was done to check the improvement in productivity. Manufacturing expenses varies directly with sales and repair revenue. Time was introduced as a dependent variable to gauge the improvement in productivity over time. As per Exhibit 1(a), R square is 0.995. So the dependent variables can explain the 99.5% change in manufacturing expenses. The F is 417.187 and the significance is .00. So the model is significant. As claimed by the company that over the years they have improved their productivity. We observe that time has a negative slope, which shows that manufacturing expenses have not increased proportionately with sales and repair revenue, thereby generating more profits for the company. The significance of time is just above 0.05. This could be because of less number of data points and data modifications by the company. Regression Equation: Manufacturing Expenses = 16999430.77 - 3058077*Time + .252*Sales Revenue+ .364*Repair Revenue

The Second regression was done to gauge the effect of steel prices on profitability of the company. The profitability ratio was taken as independent and steel prices were taken as the dependent variable. The profitability ratio was taken as (sales+ repair revenue)/manufacturing expenses. As shown in Exhibit 2(a) The F Value is 27.21 and the significance is .001. So the model is significant. The R square is .773 so; the steel prices can explain the 77.3% variation in profitability. Steel is the main input to the manufacturing and profitability depends quite a bit on steel price. Regression Equation:

Profitability Ratio = 1.246 + 8.32E-005*Steel Price

Dempo Shipbuilding and Engineering Pvt Ltd

FUTURE PLANS Dempo Shipbuilding and Engineering Pvt Ltd In 2004 opened their second yard in UndirPonda. This yard was started with an initial expense of just 1.5 crore rupees and in the last 6 years has been highly profitable. The company now plans to expand this facility by investing between 8-10 crore. This investment would be used to construct a new jetty, a new metal workshop, a new CNC facility and an office. The company also feels that its operations in Goa have reached a saturation level and for growth prospects they must look outside the state. The only improvements possible are in the form of additional automation at the yards and optimizing the processes. The company is thus looking at expanding its operations to Gujarat where is plans a new yard capable of building vessels of 25000DWT. For this they have outline three strategies which are Partnership with an existing yard Direct purchase of an existing yard An altogether new Green field project

Of the 3 options the first two have an advantage that if chosen then operations can begin within a year. The Green filed project on the other hand will require at least 4 to 5 years before becoming fully operational due to the infrastructure development that will be required first. The company has also signed an MOU with the Gujarat government who have agreed to aid and support in whatever way they can. The new yard will target a different set of customers and as it will be able to provide much larger vessels. Also it will look at targeting the export market as well which right now is not a priority for the company. Also the new yard will have advanced dry dock and repair facilities which will make it lucrative for a lot more customers and with the Indian shipping industries future looking bright and growth oriented this venture is expected to be a very big profit generator for the company

Dempo Shipbuilding and Engineering Pvt Ltd

KEY FINDINGS AND RECOMMENDATIONS: The company is recession proof in terms of the order book, as the clientele is primarily domestic, whereas EOUs face fluctuations in their revenues.

The custom bonded facility offers them the advantage of duty exemptions on imported steel, but it also calls for strict supervision with regards to the amount of scrap and usage of steel. This in turn increases their productivity.

As per our quantitative analysis, the companys profitability is heavily influenced by fluctuating steel prices. To weather-proof themselves form the uncertainty of steel prices, they could think about entering in hedging agreements. Also the steel is mostly imported so even the exchange rates influence the profitability.

With the plans of expansion in headway, the company should analyse the macroenvironment in various states, in which it plans to operate by conducting market research studies on regular basis, through experts. This will help increase control over both internal and external environment to an extent, as well as will give the company time to prepare for unpredicted situations.

As the company is planning to implement SAP, the need for which arose because of the expansion plan, we recommend them to provide training to the employees for better and quicker acceptance.

To improve productivity in terms of repairing Ships, the company could do feasible repairs in layup berth. This will save time and cost as no additional compensation have to be borne by the company. This is a best practise followed by international Shipyards.

Dempo Shipbuilding and Engineering Pvt Ltd

LIMITATIONS: As the company is not listed, we had to rely on financial data provided by the company. This data was modified to a certain extent as dictated by company policy Most of the findings expressed are based on our primary research, due to lack of previous study and lack of information on the Web The short duration of the research carried out did not allow for extensive analysis of the company and the industry We were unable to find a comparative listed company, that would add to our findings and analysis

Dempo Shipbuilding and Engineering Pvt Ltd

EXHIBITS 1(a)

Model Summary Std. Error of the Estimate 4432491.38404

Model 1

R .998(a)

R Square .995

Adjusted R Square .993

A Predictors: (Constant), Repair, Sales, Time

1(b)

1(c)

Dempo Shipbuilding and Engineering Pvt Ltd

2(a)

2(b)

2(c)

Dempo Shipbuilding and Engineering Pvt Ltd

Dempo Shipbuilding and Engineering Pvt Ltd

REFERENCES: (The Dempo Group, Home, Shipbuilding) (KPMG, Shipbuilding Sector in India, 2007) (KPMG, Indian Maritime Industry, 2009) (Kanekar, 2011)

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- 815 F.2d 918 1987 A.M.C. 1521Documento11 pagine815 F.2d 918 1987 A.M.C. 1521Scribd Government DocsNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Imo Msc1 Circ1473 Policy On Use of Ais AtonDocumento7 pagineImo Msc1 Circ1473 Policy On Use of Ais AtonBă AnduleNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- : Πινακασ Δρομολογιων Πορθμειου Διαδρομη Λιμενασ - Κεραμωτη (Ferry Boat)Documento2 pagine: Πινακασ Δρομολογιων Πορθμειου Διαδρομη Λιμενασ - Κεραμωτη (Ferry Boat)Adrianna LenaNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- EC 49StateCatalog08Documento347 pagineEC 49StateCatalog08Lee Prine0% (1)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Skid ResistanceDocumento5 pagineSkid ResistanceMoyashi Desu100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Price ListDocumento14 paginePrice ListRavi MakhijaNessuna valutazione finora

- Assignment #1 422 PDFDocumento5 pagineAssignment #1 422 PDFhelo_gobuNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Hydrarchy - GasworksDocumento2 pagineHydrarchy - GasworksnicolaceliawrightNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Focus Group DiscussionDocumento4 pagineFocus Group DiscussionUsman LatifNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Rini - Operating Table RiEye Mk2 (Edited)Documento2 pagineRini - Operating Table RiEye Mk2 (Edited)jalan jalanNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Text 1 The Wright BrothersDocumento3 pagineText 1 The Wright BrothersputrisuardaniNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Reach Truck RRE140M 160M 1400 1600kgDocumento4 pagineReach Truck RRE140M 160M 1400 1600kgesmail aliNessuna valutazione finora

- LF Ebook PC S S H-L 2012 inDocumento330 pagineLF Ebook PC S S H-L 2012 in11tata100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- 09 Durango1Documento1 pagina09 Durango1GoodBikesNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- DDL Nop Since 60 DaysDocumento200 pagineDDL Nop Since 60 DaysSO Savlaj 1 MSEDCLNessuna valutazione finora

- IbrahimDocumento1 paginaIbrahimرضوان بن فروقNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- ABB-VTR..4 Approval LetterDocumento4 pagineABB-VTR..4 Approval LetterGerson NevesNessuna valutazione finora

- Cycleroutes DKDocumento33 pagineCycleroutes DKlucaswxyzNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Surface TolerancesDocumento9 pagineSurface Tolerancesshrinivast100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- TP Puteri Shahirah NazihahDocumento8 pagineTP Puteri Shahirah Nazihahapi-439348424Nessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Tad740-1032-1630-1631 & TWD740-1210-1232-1630Documento68 pagineTad740-1032-1630-1631 & TWD740-1210-1232-1630Rath Asypaden100% (1)

- Westside Subway Final EIR ReleaseDocumento3 pagineWestside Subway Final EIR ReleaseMetro Los AngelesNessuna valutazione finora

- Trafigura Corporate Brochure en 141218011728 Conversion Gate01Documento44 pagineTrafigura Corporate Brochure en 141218011728 Conversion Gate01Uma SubbiahNessuna valutazione finora

- Supplement No. AFS-AW139-IBF-FMS: 17891 Chesterfield Airport Road Chesterfield, MO 63005Documento13 pagineSupplement No. AFS-AW139-IBF-FMS: 17891 Chesterfield Airport Road Chesterfield, MO 63005Abdallah MhairatNessuna valutazione finora

- DNV RulesDocumento23 pagineDNV RulesDorin Sava100% (1)

- Filter Cross RefferenceDocumento2 pagineFilter Cross RefferenceVicente TanNessuna valutazione finora

- Public Baths Ny History ScribdDocumento43 paginePublic Baths Ny History ScribdDavid Bellel100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Master (Unlimited) Orals Report - 2023-11 - Frood - PassDocumento5 pagineMaster (Unlimited) Orals Report - 2023-11 - Frood - PassAnish MohandasNessuna valutazione finora

- QRH 02-Aug-22Documento154 pagineQRH 02-Aug-22aashesh puriNessuna valutazione finora

- Linde ManualDocumento6 pagineLinde ManualArnaldo AndréNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)