Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Phase Diagrams

Caricato da

Sajeed ShaikDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Phase Diagrams

Caricato da

Sajeed ShaikCopyright:

Formati disponibili

Phase Diagrams

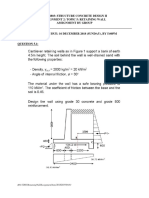

Phase diagram equilibrium (annealing) Phase diagram consists of temperature, composition, and phases One-two-one phase diagram: Nickel-Copper (Ni-Cu) Liquidus line, solidus line, tie line, lever rule A tie line is a horizontal line, extends across the twophase region and terminate at the phase boundary lines on either side. Binary eutectic phase diagram: Lead-Tin (Pb-Sn) Solvus line: the solid solubility limit line separating the and + phase regions Hypo-eutectic composition, eutectic composition, and hyper-eutectic composition Iron-iron carbide (Fe-Fe3C) phase diagram: Fe-C Allotropic transformation- -Fe, -Fe, -Fe Ferrite (-Fe) -- BCC solid solution, maximum 0.0218%C Austenite (-Fe) FCC solid solution 912oC 1394oC maximum 2.11%C (1674oF- 2541oF) -ferrite (-Fe) BCC solid solution 1394oC-1538oC maximum 0.09%C (2541oF-2800oF) Cementite (Fe3C) intermetallic compound, contains 6.67%C, is extremely hard and brittle Pearliteferrite + cementite Eutectoid temperature 727oC, eutectoid point 0.77%C Hypo-eutectoid composition, hyper-eutectoid composition Cast Irons: 2.11-4.5%C, ~3.5%Si Types of cast irons: Gray cast irons: graphite in flakes, low strength and low ductility, good damping resistance (vibration) used for machine tool bases and structures

Ductile cast irons (nodular cast irons): spheroidal graphite particle, somewhat ductile and shock resistance. White cast irons: massive amounts of cementite (no graphite), hard and brittle, good wear resistance. Malleable cast irons: heat treatment of white cast irons. Forming clusters of graphitesimilar to ductile cast irons. Improved ductility, strength, and shock resistance. Compacted graphite cast irons: short, thick, interconnected graphite flakes, the properties lie between gray cast irons and ductile cast irons. Time-temperature-transformation (TTT) diagrams, a.k.a. isothermal transformation (IT) diagrams Dynamic cooling Different structures: Spheroidites (spherical particles) 700oC several hours Bainites (ferrite + cementite) 250-500oC, upper bainitesfeathery plates; lower bainites dark needles Martensites: below 250oC, lath shape Hardenability: The capability of an alloy to be hardened by heat treatment, measured by the depth of hardness Jominy test: a round 100 mm long and 25mm in diameter test bar is end-quenched with a water stream at 24oC (hardness measurements along its length should be performed) Heat treatment of nonferrous metals: Solution treatment, precipitation hardening, case hardening

ANSI-SAE designations for steels

ANSI: American Iron and Steel Institute SAE: Society of Automotive Engineers 10XX carbon steel 11XX Resulfurized carbon steel 12XX Rephosphorized and resulfurized carbon steel 13XX Manganese steel (manganes 1.75%) 41XX Chromium-molybdenum steels 43XX Nickel-chromium-molybdenum steels (nickel 1.83%) 44XX Molybdenum steels (molybdenum 0.53%) 50XX Chromium steels (chromium 0.40%) 51XX Chromium steels (chromium 0.80, 0.88, 0.93, 0.95%) 51XXX Chromium steels (chromium 1.03%) 52XXX Chromium steels (chromium 1.45%) . Types of stainless steels: Austenitic (200-300 series): are hardened by cold working Ferritic (400 series): are hardened by cold working not heat treatable, up to 27% chromium. Martensitic (400 and 500 series): heat treated, no nickel Precipitation hardening (PH): many elements, high strength at elevated temperature Duplex structure: a mixture of austenite and ferrite. Types of tool steels: High speed: M, T Cold work: D, A, O Mold steels: P Water hardening:W

Hot work: H Shock resisting: S Special purpose: L, F

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 12 Desalination Advance Water Treatment Economics FinancingDocumento169 pagine12 Desalination Advance Water Treatment Economics FinancingFlavia ZanetteNessuna valutazione finora

- Nitoprime 28: Epoxy Based Primer For Steel SurfacesDocumento2 pagineNitoprime 28: Epoxy Based Primer For Steel SurfacesVenkata Raju KalidindiNessuna valutazione finora

- Solvent Improvement For Separating C4 With ACNDocumento9 pagineSolvent Improvement For Separating C4 With ACNBacNessuna valutazione finora

- Concrete Mix Design - Weight Method, SI Units, Non-Air-Entrained Concrete PDFDocumento10 pagineConcrete Mix Design - Weight Method, SI Units, Non-Air-Entrained Concrete PDFThomas CroweNessuna valutazione finora

- New Energy Efficient Car Built With 3d PrintingDocumento3 pagineNew Energy Efficient Car Built With 3d PrintingKarthi KNessuna valutazione finora

- Chapter Sixteen Cell SignalingDocumento96 pagineChapter Sixteen Cell SignalingRu LiliNessuna valutazione finora

- Practical Process Plant Layout and Piping DesignDocumento136 paginePractical Process Plant Layout and Piping Designgonvic7411Nessuna valutazione finora

- Ficha Técnica Válvula CompuertaDocumento2 pagineFicha Técnica Válvula CompuertaMiguel RondinelNessuna valutazione finora

- Assignment Retaining Wall - QuestionDocumento4 pagineAssignment Retaining Wall - QuestionAidaFarzanaNanaNessuna valutazione finora

- Hille B-Second Edition (For Printing)Documento617 pagineHille B-Second Edition (For Printing)matuskacarlosNessuna valutazione finora

- Chap 6 Numhyd Riemann 1Documento13 pagineChap 6 Numhyd Riemann 1rickyspaceguyNessuna valutazione finora

- ISO 3071 2020 Textiles-Determination of PH of Aqueous Extract BZ-244Documento12 pagineISO 3071 2020 Textiles-Determination of PH of Aqueous Extract BZ-244tsing takNessuna valutazione finora

- Oil Free Process Gas Screw CompressorsDocumento16 pagineOil Free Process Gas Screw CompressorsAndresoMartinecNessuna valutazione finora

- Vanadio NMRDocumento7 pagineVanadio NMRsergioodin4851Nessuna valutazione finora

- CTSB For Service RoadDocumento31 pagineCTSB For Service RoadAkash SarkarNessuna valutazione finora

- Absorbance and Fluorescence Spectroscopies of Green Fluorescent ProteinDocumento24 pagineAbsorbance and Fluorescence Spectroscopies of Green Fluorescent ProteinMadel Tutor ChaturvediNessuna valutazione finora

- 1251 Weighing On An Analytical BalanceDocumento6 pagine1251 Weighing On An Analytical Balancenonick18Nessuna valutazione finora

- Kaplan and Pelton QuestionsDocumento13 pagineKaplan and Pelton Questionstixy2013Nessuna valutazione finora

- Nagendra G M: Teaching ExperienceDocumento3 pagineNagendra G M: Teaching Experiencenagendra_gmNessuna valutazione finora

- Unified Council: National Level Science Talent Search ExaminationDocumento4 pagineUnified Council: National Level Science Talent Search ExaminationAnwesha SatpathyNessuna valutazione finora

- Lab Report Experiment 1Documento5 pagineLab Report Experiment 1Jessica NicholsonNessuna valutazione finora

- TLC SprayerDocumento4 pagineTLC SprayerShaanNegiNessuna valutazione finora

- Astm ADocumento32 pagineAstm AKhaled FatnassiNessuna valutazione finora

- Genetic Linkage & Mapping (Article) - Khan AcademyDocumento22 pagineGenetic Linkage & Mapping (Article) - Khan Academy嘉雯吳Nessuna valutazione finora

- Combustion Analysis Extra Problems KeyDocumento2 pagineCombustion Analysis Extra Problems KeyJoselyna GeorgeNessuna valutazione finora

- Worksheet Xi 4 - 9-23-8-9-23 - 02092023 - 194444Documento4 pagineWorksheet Xi 4 - 9-23-8-9-23 - 02092023 - 194444Adithya PramodNessuna valutazione finora

- Backwards Heat Equation InfoDocumento1 paginaBackwards Heat Equation InfoMelissa Marie HernandezNessuna valutazione finora

- Soal Pas Genap - Big Xi - k13 - Revisi2Documento16 pagineSoal Pas Genap - Big Xi - k13 - Revisi2citraNessuna valutazione finora

- 10) - Filter Sand Gravel 2352Documento2 pagine10) - Filter Sand Gravel 2352Charitha KandageNessuna valutazione finora

- Calcium Hypochlorite MSDS: Section 1: Chemical Product and Company IdentificationDocumento6 pagineCalcium Hypochlorite MSDS: Section 1: Chemical Product and Company IdentificationMohamed MaghawryNessuna valutazione finora