Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Quick N Dirty Oars

Caricato da

Alphamatrix01Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Quick N Dirty Oars

Caricato da

Alphamatrix01Copyright:

Formati disponibili

Quick-N-Dirty Oars

file:///C:/Users/Main/Desktop/Boat%20Plans%20June%205%202008/...

QUICK-AND-DIRTY OARS

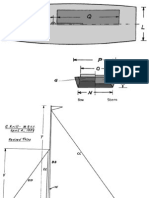

By David Goodchild A few years ago I built a small, pram, sailing-dinghy just for fooling around. Last summer, I wanted to introduce my young grand-niece and grand-nephew (ages nine and six respectively) to small boat sailing. The dinghy however is just a tad under 8-feet overall, and the best oars for this boat are also 8 feet long. This of course means that they will not fit into the boat comfortably,--especially when anyone is in it. This calls out then for two-piece oars. These are on the market but they are very pricey. I made these in just under an hour for absolutely ZIP! Of course, I did have the scrap just laying around to use, but even if you have to buy the PVC, it won't be more than a few dollars! The entire materials list consists of: 2 scraps of plywood about 20" by 7" 2 sections of 1 1/2" PVC plumbing pipe (usually 10' long) About 6' of 1 1/2" closet rod or dowel 18 galvanized, 1 1/4" deck (drywall) screws And that's it! These oars won't win any prizes for beauty but they will do the job. In fact, they will do two jobs! Here's how they go together. First cut each piece of PVC pipe into two pieces, one 48" long and the other 38" long. If you have 10' sections this will leave an extra piece of 34" and if you have 8' sections you will have a piece 10" long. You will not need this again, so put them aside. The 38" long piece is for the lower portion of the loom and the 48" piece the upper. Cut the closet pole into four sections; two of them 2-feet in length and 2 of them 1-foot in length. These are the insert joiners (the 2-foot ones) and the oar handles (the 1-foot ones). Either with a band-saw or a jig-saw cut a slot about 3/4" in width up one end of each of the 38" pieces. Make the slot about 10" long. Take the scrap plywood and draw out the blades. Mine taper from about 6 1/2" at the tip to about 4" where they meet the loom. The dimensions are not critical. Grab any two different-sized cans of paint from the shop and draw them out. Whatever you have that's the size and shape you want to achieve. That's what I did! Connect the dots, (well, ok, the radii) and you have the outline for the blades which you will then cut out on the band-saw or with the jig-saw. Now for final assembly. Drill three sets of holes on EACH side of the PVC at three points: 1. where the blade will fit in. 2. where the joining insert fits in. 3. where the handle fits in. You need to drill the PVC because the deck screws won't drill their own holes very well through this material. Stagger the holes, so that you have maximum grip. Insert blade in slot. Insert screws in holes. Drive home! Insert joining insert dowel half-way into other end of blade section. Insert screws in holes. Drive home! Insert oar handle half-way into end of 48" long piece. Insert screws in holes. Drive home! Insert handle section into blade section and drill a small (3/16-1/4"?) hole right through the whole assembly about 4" up from where they meet. This will be where you insert a pin to hold the oars together when they are in use and prevent the handle section from twisting around the blade section. Your oars are finished! A couple of notes: You may need to sand down the dowel pieces a little to fit into the PVC. You just want a snug fit; not too loose and obviously not too tight. You can use anything for a pin to hold the two sections together. I used a couple of 6d galvanized, common nails I had on hand. Worked fine! Now, as to the two uses. These make great paddles as well as oars. As oars they are a good length and I find that there is a little bend to the PVC which seems to provide a little snap at the end of the stroke. Terrific! The blade section also works great as a paddle. Sometimes you won't want to put the oars together, but just paddle around to the end of the dock or something. Just use the blade section as it is for a paddle. Also terrific!

1 of 1

2/10/2010 8:52 PM

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Hovercraft PlansDocumento104 pagineHovercraft Plansarqmiguelpereyrab100% (2)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The 23.5ft Light Schooner Full PlansDocumento7 pagineThe 23.5ft Light Schooner Full PlansAlphamatrix01100% (1)

- ST Michaels Sailing ScowDocumento6 pagineST Michaels Sailing ScowAlphamatrix01100% (3)

- Micro Auray PuntDocumento9 pagineMicro Auray PuntAlphamatrix01Nessuna valutazione finora

- One Sheet SampanDocumento5 pagineOne Sheet Sampanleather_nunNessuna valutazione finora

- Archive Purge Programs in Oracle EBS R12Documento7 pagineArchive Purge Programs in Oracle EBS R12Pritesh MoganeNessuna valutazione finora

- LESSON PLAN IN wRITING A REPORTDocumento2 pagineLESSON PLAN IN wRITING A REPORTMarkaton Dihagnos100% (4)

- A Summer Training Project Report OnDocumento79 pagineA Summer Training Project Report OnAnkshit Singhal100% (2)

- ZipperDocumento3 pagineZipperAlphamatrix01Nessuna valutazione finora

- Super Sunray PlansDocumento7 pagineSuper Sunray PlansAlphamatrix01Nessuna valutazione finora

- Wacky LassieDocumento4 pagineWacky LassieAlphamatrix01Nessuna valutazione finora

- Two DoriesDocumento10 pagineTwo DoriesAlphamatrix01Nessuna valutazione finora

- Sea HawkDocumento19 pagineSea HawkAlphamatrix01100% (1)

- Polysail International Boat Designs From The 1940'S: Treasures From The PastDocumento5 paginePolysail International Boat Designs From The 1940'S: Treasures From The PastAlphamatrix01Nessuna valutazione finora

- South Haven Dory PlansDocumento9 pagineSouth Haven Dory PlansAlphamatrix01Nessuna valutazione finora

- Plywood RowboatDocumento7 paginePlywood RowboatAlphamatrix01Nessuna valutazione finora

- Dory StoryDocumento10 pagineDory StoryAlphamatrix01100% (3)

- Plans For A Catamaram Sail-BoatDocumento10 paginePlans For A Catamaram Sail-BoatAlphamatrix01100% (3)

- P590Documento10 pagineP590Alphamatrix010% (1)

- DolphinDocumento5 pagineDolphinAlphamatrix01Nessuna valutazione finora

- This Little Gem Is From A 1950 Edition of Boat Builder's Annual. Hi Sibley May Have Foreseen The Bolger Box Boat Movement! You Think?Documento3 pagineThis Little Gem Is From A 1950 Edition of Boat Builder's Annual. Hi Sibley May Have Foreseen The Bolger Box Boat Movement! You Think?Alphamatrix01Nessuna valutazione finora

- Individual Development Plans: A. Teaching Competencies (PPST) Objective 13, KRA 4 Objective 1, KRA 1Documento2 pagineIndividual Development Plans: A. Teaching Competencies (PPST) Objective 13, KRA 4 Objective 1, KRA 1Angelo VillafrancaNessuna valutazione finora

- Nursing Philosophy Apa PaperDocumento7 pagineNursing Philosophy Apa Paperapi-449016836Nessuna valutazione finora

- Carr v. NH State Prison, Warden - Document No. 2Documento5 pagineCarr v. NH State Prison, Warden - Document No. 2Justia.comNessuna valutazione finora

- Silent Reading With Graph1Documento2 pagineSilent Reading With Graph1JonaldSamueldaJoseNessuna valutazione finora

- General Request Form Graduate School, Chulalongkorn University (Only Use For Educational and Research Scholarship, Graduate School)Documento2 pagineGeneral Request Form Graduate School, Chulalongkorn University (Only Use For Educational and Research Scholarship, Graduate School)Kyaw Zin PhyoNessuna valutazione finora

- Pegasus W200Documento56 paginePegasus W200Aleixandre GomezNessuna valutazione finora

- Comparative DegreeDocumento25 pagineComparative DegreeAgung PriyanaNessuna valutazione finora

- Sample CVDocumento3 pagineSample CVsam_mad00Nessuna valutazione finora

- Grade Three U3l2Documento84 pagineGrade Three U3l2Mohamed ElsisyNessuna valutazione finora

- Individual Assignment 1 (TPT630)Documento7 pagineIndividual Assignment 1 (TPT630)MUHAMMAD HABIB HARRAZ ABDUL RAHMANNessuna valutazione finora

- Jurnal Arang AktifDocumento7 pagineJurnal Arang AktifSurya KrisNessuna valutazione finora

- Syntax 1Documento35 pagineSyntax 1galcarolina722202100% (1)

- Physicochemical, Phytochemical, Mineral Analysis and Invitro Anti-Oxidant Activity of Shatavari Ghrita (Polyherbal Formulation)Documento11 paginePhysicochemical, Phytochemical, Mineral Analysis and Invitro Anti-Oxidant Activity of Shatavari Ghrita (Polyherbal Formulation)International Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- 2014 Price ListDocumento17 pagine2014 Price ListMartin J.Nessuna valutazione finora

- Working Capital Management by Birla GroupDocumento39 pagineWorking Capital Management by Birla GroupHajra ShahNessuna valutazione finora

- Top German AcesDocumento24 pagineTop German AcesKlaus Richter100% (1)

- 01.performing Hexadecimal ConversionsDocumento11 pagine01.performing Hexadecimal ConversionsasegunloluNessuna valutazione finora

- Po PCitesDocumento81 paginePo PCitessigit nian prasetyoNessuna valutazione finora

- Nail DisordersDocumento123 pagineNail DisordersyaraamadoNessuna valutazione finora

- Micro Fibra Sintetica at 06-MapeiDocumento2 pagineMicro Fibra Sintetica at 06-MapeiSergio GonzalezNessuna valutazione finora

- Form A HypothesisDocumento2 pagineForm A Hypothesismrshong5bNessuna valutazione finora

- UCCP Magna Carta For Church WorkersDocumento39 pagineUCCP Magna Carta For Church WorkersSilliman Ministry Magazine83% (12)

- Jacksonville's Taste 2012Documento100 pagineJacksonville's Taste 2012Ali KhanNessuna valutazione finora

- Week 4Documento5 pagineWeek 4عبدالرحمن الحربيNessuna valutazione finora

- Baby Romper Pattern and Sewing Tutorial 2014Documento18 pagineBaby Romper Pattern and Sewing Tutorial 2014Carolina Ribeiro100% (1)

- Direct Method (Education) : Navigation SearchDocumento5 pagineDirect Method (Education) : Navigation Searcheisha_91Nessuna valutazione finora

- IGCSE-Revision-Booklet-Part-1-2018-2019 - (New-Spec)Documento69 pagineIGCSE-Revision-Booklet-Part-1-2018-2019 - (New-Spec)MaryamNessuna valutazione finora