Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

06361.X211TS31000X1317 - ASME Summary of NDE Levels-Rev C

Caricato da

ngoinhanhoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

06361.X211TS31000X1317 - ASME Summary of NDE Levels-Rev C

Caricato da

ngoinhanhoCopyright:

Formati disponibili

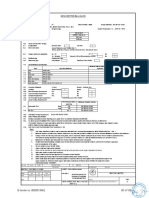

File Ref.: SHEET REV.

DATE BY APPROVED

06361.X211TS31000X1217_Appendix14

1 of 6 B Feb 08 B. Robb D. I. Anderson

C May’08 B.Robb D.I.Anderson

TITLE: SUMMARY OF N.D.E. LEVELS.

ASSEMBLY ACTIVITY M.P.I. D.P.I. ULTRASONIC RAIOGRAPHY

B.S.R. A.S.R. B.S.R. A.S.R. B.S.R. A.S.R. B.S.R. A.S.R.

GENERAL NOTES

NOTE 1: Butt welds are considered to be in contact with furnace gases when in a zone where the design temperature of these gases exceeds 850 oF (494oC). Such welds

require 100% mandatory radiography when exceeding NPS 6 (168mm O/D) or wall thickness ¾” (19mm). In radiant boilers this may occur in cage and

economiser headers. In heat recovery steam generators this may occur in all headers and in some integral pipe to header nozzle welds.

NOTE 2: Butt welds are considered to be subject to radiation from the furnace when in a portion of a tube which has less than five rows of tubes between it and the

furnace. Such welds require 100% mandatory radiography when exceeding NPS 4 (114mm O/D) or wall thickness ½” (12.7mm). This condition could occur

only in large radiant boilers, but the tube sizes in DB designed boilers are almost invariably less than the sizes quoted.

NOTE 3: When performing percentage N.D.E., if one or more welds is revealed as not being acceptable then two additional welds of the same type of that welder’s work

shall be examined, for each rejected weld. If the additional welds are acceptable then the initial percentage may be retained. If one or more of the additional

welds are not acceptable then a further two welds shall be examined for each rejected weld, and shall be repeated until a satisfactory quality of welding is

achieved.

NOTE 4 : Initial testing rate will be 10% ensuring that the first of each welder’s work are tested, until it is agreed that satisfactory quality of welding has been achieved

when the percentage may be reduced. If an unsatisfactory repair rate exists, percentages may be increased as per note 3 above.

SHEET REV. DATE BY APPROVED

2 of 6 C Feb 08 B. Robb D.I. Anderson

TITLE: SUMMARY OF N.D.E. LEVELS.

ASSEMBLY ACTIVITY M.P.I. D.P.I. ULTRASONIC RAIOGRAPHY

B.S.R. A.S.R. B.S.R. A.S.R. B.S.R. A.S.R. B.S.R. A.S.R.

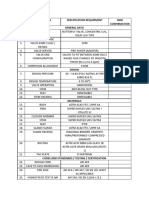

HEADER / MANIFOLD Butt Welds (Water Carrying):

C, CMn, 1% Cr and 2 ¼% Cr NPS > 10 (273.05mm O/D) or T > 1 1/8” (29mm) 100% B - - - - - 100% M -

Material

(Non-stress relieved) All other sizes in contact with furnace gases 100% B - - - - - 100% M -

C, CMn, 1% Cr Material (Note 1)

(Stress relieved

All other sizes not in contact with furnace gases - - - - - - - -

Butt Welds (Steam Carrying):

NPS > 16 (406mm O/D) or T > 1 5/8” (41mm) 100% B - - - - - 100% M -

All other sizes in contact with furnace gases 100% B - - - - - 100% M -

(Note 1)

All other sizes not in contact with furnace gases - - - - - - - -

Branch Welds, O/D ≥ 100mm and T ≥ 6mm 100% B - - - 100% B - - -

Load Carrying Support Lug Attachment Welds 100% B - - - - - - -

Non-Load Carrying Attachment Welds 10%B - - - - - - -

Surface after removal of Welding Aids 100% M - - - - - - -

SHEET REV. DATE BY APPROVED

3 of 6 C Feb 08 B. Robb D I Anderson

TITLE: SUMMARY OF N.D.E. LEVELS.

ASSEMBLY ACTIVITY M.P.I. D.P.I. ULTRASONIC RAIOGRAPHY

B.S.R. A.S.R. B.S.R. A.S.R. B.S.R. A.S.R. B.S.R. A.S.R.

HEADER / MANIFOLD Butt Welds (Water Carrying):

2 ¼ % Cr and 9% Cr Material NPS > 10 (273.05mm O/D) or T > 1 1/8” (29mm) - 100% B - - - - - 100% M

(Stress relieved)

All other sizes in contact with furnace gases - 100% B - - - - - 100% M

(Note 1)

All other sizes not in contact with furnace gases - 10% B - - 10% B or 10% B

Butt Welds (Steam Carrying):

NPS > 16 (406mm O/D) or T > 1 5/8” (41mm) - 100% B - - - - - 100% M

All other sizes in contact with furnace gases - 100% B - - - - - 100% M

(Note 1)

All other sizes not in contact with furnace gases - 10% B - - 10% B or 10% B -

Branch Welds, O/D ≥ 100mm and T ≥ 6mm - 10% B - - - 100% B - - -

Load Carrying Support Lug Attachment Welds 100% B 20% B - - - - - -

Non-Load Carrying Attachment Welds - - - - - - - -

Surface after removal of Welding Aids 100% M - - - - - - -

SHEET REV. DATE BY APPROVED

4 of 6 C Feb 08 B. Robb D. I. Anderson

TITLE: SUMMARY OF N.D.E. LEVELS.

ASSEMBLY ACTIVITY M.P.I. D.P.I. ULTRASONIC RAIOGRAPHY

B.S.R. A.S.R. B.S.R. A.S.R. B.S.R. A.S.R. B.S.R. A.S.R.

PIPE / ATTEMPERATOR Butt Welds (Water Carrying):

C, CMn, 1% Cr and 2 ¼% Cr NPS > 10 (273.05mm O/D) or T > 1 1/8” (29mm) - 100% B - - - - 100% M (Note B)

Material (Note A)

(Non-stress relieved) NPS > 6 (168mm O/D) or T > 3/8” (9.5mm) in - 100% B - - - - 100% M (Note B)

C, CMn, 1% Cr, 2 ¼% Cr and Contact with furnace gases (Note 1) (Note A) - -

9% Cr Material

(Stress relieved) All other sizes - - - - - - - -

Butt Welds (Steam Carrying):

NPS > 16 (406mm O/D) or T > 1 5/8” (41mm) - 100% B - - - - 100% M (Note B)

(Note A)

NPS > 6 (168mm O/D) or T > 3/8” (9.5mm) in - 100% B - - - - 100% M (Note B)

Contact with furnace gases (Note 1) (Note A)

All other sizes - - - - - - - -

Branch Welds, O/D ≥ 100mm and T ≥ 6mm - - - - - - - -

Load Carrying Support Lug Attachment Welds 100% B 100% B - - - - - -

(Note A)

Non-Load Carrying Attachment Welds - - - - - - -

Surface after removal of Welding Aids 100% M - - - - - - -

SHEET REV. DATE BY APPROVED

5 of 6 C Feb 08 B. Robb D I Anderson

TITLE: SUMMARY OF N.D.E. LEVELS.

ASSEMBLY ACTIVITY M.P.I. D.P.I. ULTRASONIC RAIOGRAPHY

B.S.R. A.S.R. B.S.R. A.S.R. B.S.R. A.S.R. B.S.R. A.S.R.

MEMBRANE PANELS Tube Butt Welds T ≥ ½” (12.7mm) subject to - - - - - 100% M -

Radiation from furnace (see note 2)

All other tube butt welds - - - - - - 10% B -

Attachment Welds - - - - - - - -

Arc Welded Membrane to Tube - - - - - - - -

ELEMENTS AND LOOSE Tube Butt Welds, T ≥ ½” (12.7mm) subject to - - - - - - - 100% B

TUBES Radiation from furnace (see note 3)

2 ¼% Cr and 9 % Cr Material

(Stress relieved) Tube Butt Welds, T < ½” (12.7mm) subject to 100% B

Radiation from furnace (see note 3)

Tube Butt Welds, T ≥ ½” (12.7mm) - - - - - - 10% B

(note 4)

Tube Butt Welds, T < ½” (12.7mm) 10% B

(note 4)

Attachment Welds - 10% B - - - - - -

ELEMENTS AND LOOSE Tube Butt Welds, T ≥ ½” (12.7mm) subject to - - - - - - 100% M -

TUBES Radiation from furnace (see note 3)

All Materials

(Non-Stress relieved) Tube Butt Welds, ≥ T ½” (12.7mm) - - - - - - 5% B -

Attachment Welds - - - - - - - -

PIPE BENDS Inspect first off of each material type, diameter

and thickness as follows:

Ultrasonic Test extrados and intrados for cracks

M.P.I. extrados for cracks

SHEET REV. DATE BY APPROVED

6of 6 C Feb 08 B. Robb D I Anderson

TITLE: SUMMARY OF N.D.E. LEVELS.

ASSEMBLY ACTIVITY M.P.I. D.P.I. ULTRASONIC RAIOGRAPHY

B.S.R. A.S.R. B.S.R. A.S.R. B.S.R. A.S.R. B.S.R. A.S.R.

STEAM DRUM – SHELL AND LONGITUDIANL AND CIRCUMFERENTIAL

DISHED HEAD WELD PREPARATION AND WELD SEAMS

Welding edges for shell , dished head and test 100% - - - - - - -

plates after machining ( before welding)

All weld seams(Longitudinal, Circumferential 100% 100% - -- 100% 100% 100% -

seams)

BRANCH /NOZZLES ON Checking of Drilled Holed edges 100% - - - - - - -

SHELL AND DISHED HEAD

-

Outside of machined stub surfaces - - 100% - - - - -

Weld seams of stubs (For all stubs) 100% 100% - - - - - -

Weld seams of stubs ( For stub ID > 150mm) 100% 100% - - 100% - - -

Other parts welded to steam drum 100% OR 100% - - - - -

(Note C) (Note C)

INTERNALS Welded to drum plate and dished head 100% OR 100%

(Note C) (Note C)

Note A: M.P.I. A.S.R. applies only to 2 ¼% Cr and 9% Cr material

Note B: In the case of 2 ¼% Cr and 9% Cr material, radiography shall be carried out after PWHT

Note C: MPI or DPI can be performed

Potrebbero piacerti anche

- Summary of ASME Section VIIIDocumento3 pagineSummary of ASME Section VIIIAMALENDU PAUL100% (2)

- Elastomeric Bearings: 6 (1) Design Load On BearingsDocumento8 pagineElastomeric Bearings: 6 (1) Design Load On BearingsCivil MexNessuna valutazione finora

- Bearing DesignDocumento5 pagineBearing DesignAussen RistNessuna valutazione finora

- 9) Api 510 Day 1Documento109 pagine9) Api 510 Day 1nivrutti2012100% (14)

- En 1090 2 Ex3 PDFDocumento1 paginaEn 1090 2 Ex3 PDFlai nguyenNessuna valutazione finora

- Specification Aa10109 1440410164 PDFDocumento5 pagineSpecification Aa10109 1440410164 PDFParthi NatarajNessuna valutazione finora

- Bearing DesignDocumento5 pagineBearing DesignSaurav KumarNessuna valutazione finora

- PipingDocumento8 paginePipingRajkumar ANessuna valutazione finora

- Test CertificateDocumento1 paginaTest CertificateViswa BhuvanNessuna valutazione finora

- FabricationDocumento50 pagineFabricationashishghadiya75% (16)

- Api 510Documento109 pagineApi 510Jerry Man Utd100% (4)

- API 510 - Day 1: G T Technical & Management Institute PVT - LTD.Documento109 pagineAPI 510 - Day 1: G T Technical & Management Institute PVT - LTD.fathiNessuna valutazione finora

- CSA 165.1 Specifications & General Specifications Notes: Canadian Concrete Masonry Producers' AssociationDocumento17 pagineCSA 165.1 Specifications & General Specifications Notes: Canadian Concrete Masonry Producers' AssociationZebNessuna valutazione finora

- 182268644-CW-Pump-CalculationDocumento18 pagine182268644-CW-Pump-CalculationPinak ProjectsNessuna valutazione finora

- D070Q Agr CatDocumento4 pagineD070Q Agr CatRuben ManuelNessuna valutazione finora

- Inspection Report: Cu Flexibles For SWGR and TRF End. (Qty. 36 Nos.)Documento4 pagineInspection Report: Cu Flexibles For SWGR and TRF End. (Qty. 36 Nos.)sanjayprakash1979Nessuna valutazione finora

- Nina ClubhouseDocumento24 pagineNina ClubhousenagulshareefNessuna valutazione finora

- Ce 14444 Lab7Documento5 pagineCe 14444 Lab7Owen Francis Arles MaongatNessuna valutazione finora

- Astm A746 PDFDocumento19 pagineAstm A746 PDFCristian OtivoNessuna valutazione finora

- Departement de Technologies de Construction Industrielle: Duty 2Documento6 pagineDepartement de Technologies de Construction Industrielle: Duty 2Kassi CharlesNessuna valutazione finora

- CuNi NUFITDocumento16 pagineCuNi NUFIT9823458877Nessuna valutazione finora

- Fabrication Tolerances 51G14r1Documento7 pagineFabrication Tolerances 51G14r1Selvakpm06100% (1)

- BPCL Volume IIIDocumento196 pagineBPCL Volume IIIPaul PhiliphsNessuna valutazione finora

- A318 - A319 - A320 - A321 - AMM - 01-Feb-2020 - 72-21-20-210-802-A - Visual Inspection of The Fan BladeDocumento30 pagineA318 - A319 - A320 - A321 - AMM - 01-Feb-2020 - 72-21-20-210-802-A - Visual Inspection of The Fan Bladesaid PalaoNessuna valutazione finora

- ExcalDocumento85 pagineExcalhameed6101986Nessuna valutazione finora

- ProcessTap Temperature - Dualam - AC Plastic PipeDocumento2 pagineProcessTap Temperature - Dualam - AC Plastic PipeXarly Polite Jr.Nessuna valutazione finora

- Sis Book1Documento99 pagineSis Book1Hamza AlamNessuna valutazione finora

- Datasheet Anchor FlangeDocumento1 paginaDatasheet Anchor FlangeHafiz Ashadi100% (1)

- Specification Sheet: Case I Case Ii Operating ConditionsDocumento1 paginaSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNessuna valutazione finora

- Cairo 97Documento27 pagineCairo 97Karen LealNessuna valutazione finora

- One Way SlabDocumento23 pagineOne Way SlabmeerahNessuna valutazione finora

- B70 Rock Breaker Care Operation Manual For TH86Documento21 pagineB70 Rock Breaker Care Operation Manual For TH86Latifa EngineeringNessuna valutazione finora

- Flume 1 84inchParshallSpecDocumento3 pagineFlume 1 84inchParshallSpecnupurNessuna valutazione finora

- R.C.C Pier Design of BridgeDocumento42 pagineR.C.C Pier Design of BridgeMd BIN HASAN100% (1)

- Beam Column ConnectionDocumento2 pagineBeam Column ConnectionHAZIRACFS SURATNessuna valutazione finora

- AD 2000 HesapDocumento11 pagineAD 2000 HesapBaşarŞenNessuna valutazione finora

- Generalcons Tructionnot ES: General NotesDocumento10 pagineGeneralcons Tructionnot ES: General NotesJejomar MotolNessuna valutazione finora

- Burner CalculationDocumento6 pagineBurner CalculationAbul QasimNessuna valutazione finora

- Topic 7 Oil and Gas Pipeline SolutionsDocumento17 pagineTopic 7 Oil and Gas Pipeline SolutionsImranMajidli100% (1)

- NASH TC Twostage enDocumento4 pagineNASH TC Twostage enErivertonNessuna valutazione finora

- Grinnell Mechanical Products Flexible Coupling Technical Data General DescriptionDocumento4 pagineGrinnell Mechanical Products Flexible Coupling Technical Data General DescriptionСергей КолесниковNessuna valutazione finora

- K.P.Mondal & Sons: Quality Assurance PlanDocumento1 paginaK.P.Mondal & Sons: Quality Assurance PlanTanmoy DuttaNessuna valutazione finora

- 074010-M06 - GRP Pipe Butt - Wrap JointDocumento1 pagina074010-M06 - GRP Pipe Butt - Wrap Jointaug27june16Nessuna valutazione finora

- Asme Sec Viii Closed QB (106-120)Documento15 pagineAsme Sec Viii Closed QB (106-120)slxanto100% (1)

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocumento4 pagineOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNessuna valutazione finora

- Usab Feed Tanks 09092015Documento16 pagineUsab Feed Tanks 09092015DenishmakvanaNessuna valutazione finora

- Mechanical BOQ and EstimateDocumento4 pagineMechanical BOQ and EstimatePoojaashish TripathiNessuna valutazione finora

- Moding 3 Pattern Moding 3 Detail: 10mmø Lateral Ties Spaced 2@0.05, 3@0.10, REST @0.175Documento1 paginaModing 3 Pattern Moding 3 Detail: 10mmø Lateral Ties Spaced 2@0.05, 3@0.10, REST @0.175Felix Albit Ogabang IiiNessuna valutazione finora

- Bio Gas Excel Calculation SheetDocumento5 pagineBio Gas Excel Calculation SheetsrivarmaNessuna valutazione finora

- Project: Proposed Additional Storey (Residential Building) Location: Pasig City Owner: Mr. Arsenio BustillosDocumento7 pagineProject: Proposed Additional Storey (Residential Building) Location: Pasig City Owner: Mr. Arsenio BustillosjologscresenciaNessuna valutazione finora

- Sample DS-1Documento1 paginaSample DS-1Sachin KumarNessuna valutazione finora

- RCC31R Rigorous One-Way SlabsDocumento389 pagineRCC31R Rigorous One-Way SlabsCioabla BogdanNessuna valutazione finora

- FlowmeterDocumento22 pagineFlowmeterAnandNessuna valutazione finora

- DS-01 - LR BendsDocumento1 paginaDS-01 - LR BendsMecon LtdNessuna valutazione finora

- Datasheet For Butterfly ValveDocumento3 pagineDatasheet For Butterfly ValvevishnuvarthanNessuna valutazione finora

- SMP - Boiler Prs Part-R02Documento41 pagineSMP - Boiler Prs Part-R02Kathir Siva100% (1)

- Fault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureDa EverandFault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureMarion Y. ThomasNessuna valutazione finora

- Steel and Its Heat Treatment: Bofors HandbookDa EverandSteel and Its Heat Treatment: Bofors HandbookValutazione: 2.5 su 5 stelle2.5/5 (3)

- RMP ContractDocumento181 pagineRMP ContractHillary AmistosoNessuna valutazione finora

- Cis MSCMDocumento15 pagineCis MSCMOliver DimailigNessuna valutazione finora

- Me N Mine Science X Ist TermDocumento101 pagineMe N Mine Science X Ist Termneelanshujain68% (19)

- DR Hoon Park III - Indigenous Microorganism (IMO)Documento33 pagineDR Hoon Park III - Indigenous Microorganism (IMO)neofrieda79100% (1)

- Geography - Development (Rural - Urban Settlement)Documento32 pagineGeography - Development (Rural - Urban Settlement)jasmine le rouxNessuna valutazione finora

- What To Do Following A Workplace AccidentDocumento5 pagineWhat To Do Following A Workplace AccidentMona DeldarNessuna valutazione finora

- Business PlanDocumento17 pagineBusiness PlanChester Cortez50% (2)

- Method Statement For Installation of Chilled Water Pump & Condenser Water PumpDocumento14 pagineMethod Statement For Installation of Chilled Water Pump & Condenser Water Pump721917114 47Nessuna valutazione finora

- Complement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksDocumento2 pagineComplement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksYASMINANessuna valutazione finora

- Safety AuditDocumento9 pagineSafety AuditRobena Nagum BagasNessuna valutazione finora

- Missoula County Fairgrounds Phase 2Documento10 pagineMissoula County Fairgrounds Phase 2Olivia IversonNessuna valutazione finora

- Dryer Regenerative Blower Purge DBP 02250195 405 R00 PDFDocumento84 pagineDryer Regenerative Blower Purge DBP 02250195 405 R00 PDFjennyNessuna valutazione finora

- Emission Estimation Technique Manual: For Mining and Processing of Non-Metallic MineralsDocumento84 pagineEmission Estimation Technique Manual: For Mining and Processing of Non-Metallic MineralsAbdelaziem mahmoud abdelaalNessuna valutazione finora

- Checklist For Surge Arrester Rev00Documento3 pagineChecklist For Surge Arrester Rev00Santhosh Kumar VinayagamNessuna valutazione finora

- BR Interlock Pallet Racking System 2009 enDocumento8 pagineBR Interlock Pallet Racking System 2009 enMalik Rehan SyedNessuna valutazione finora

- Chapter 8 - Lipids and Proteins Are Associated in Biological Membranes - Part 1Documento44 pagineChapter 8 - Lipids and Proteins Are Associated in Biological Membranes - Part 1Tommy RamazzottoNessuna valutazione finora

- Of Periodontal & Peri-Implant Diseases: ClassificationDocumento24 pagineOf Periodontal & Peri-Implant Diseases: ClassificationruchaNessuna valutazione finora

- As Level Chemistry Practical Paper 3 - GCE GuideDocumento1 paginaAs Level Chemistry Practical Paper 3 - GCE GuideJamal AldaliNessuna valutazione finora

- Frequency Inverter: User's ManualDocumento117 pagineFrequency Inverter: User's ManualCristiano SilvaNessuna valutazione finora

- Mdp36 The EndDocumento42 pagineMdp36 The Endnanog36Nessuna valutazione finora

- Hospital - Data Collection & Literature StudyDocumento42 pagineHospital - Data Collection & Literature StudyNagateja MallelaNessuna valutazione finora

- Lesson 49Documento2 pagineLesson 49Андрій ХомишакNessuna valutazione finora

- 2020 Q2 CushWake Jakarta IndustrialDocumento2 pagine2020 Q2 CushWake Jakarta IndustrialCookiesNessuna valutazione finora

- Biomedical Admissions Test 4500/12: Section 2 Scientific Knowledge and ApplicationsDocumento20 pagineBiomedical Admissions Test 4500/12: Section 2 Scientific Knowledge and Applicationshirajavaid246Nessuna valutazione finora

- Measurement of Bioreactor K ADocumento18 pagineMeasurement of Bioreactor K AAtif MehfoozNessuna valutazione finora

- Calao Deliquente Diadi River SystemDocumento15 pagineCalao Deliquente Diadi River SystemJason MalamugNessuna valutazione finora

- Resume Massage Therapist NtewDocumento2 pagineResume Massage Therapist NtewPartheebanNessuna valutazione finora

- (Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)Documento4 pagine(Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)nguyen duong trungNessuna valutazione finora

- E10b MERCHANT NAVY CODE OF CONDUCTDocumento1 paginaE10b MERCHANT NAVY CODE OF CONDUCTssabih75Nessuna valutazione finora

- CASE DIGEST GAISANO CAGAYAN vs. INSURANCE COMPANY OF NORTH AMERICADocumento3 pagineCASE DIGEST GAISANO CAGAYAN vs. INSURANCE COMPANY OF NORTH AMERICAclaireNessuna valutazione finora