Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pulleys - Beginners Guide - Design Considerations

Caricato da

Marisamy PalrajTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pulleys - Beginners Guide - Design Considerations

Caricato da

Marisamy PalrajCopyright:

Formati disponibili

Beginners Guide

3. Design Considerations for Pulleys The proce dure for se le cting pulle ys for a conve yor for any give n application involve s the e valuation of a num be r of factors pe rtine nt to the installation. This se ction of the Handbook outline s the m ain factors affe cting pulle y de sign howe ve r, for a m ore com pre he nsive de sign proce dure , consult the pulle y design section. C onside ration should be give n to the following :a) A pplication / Environment The spe cific application for which the pulle y is re quire d should be unde rstood. A conve yor m ay re quire a se lf-cle aning be nd pulle y for a trippe r or a gravity tak e -up pulle y. Short conve yors are som e tim e s de signe d with crowne d pulle ys rathe r than flat pulle ys, to assist with training of the be lt while long ove rland conve yor drive pulle ys m ust be lagge d and the drive is a shaft-m ounte d unit. Having liste d the diffe re nt pulle ys on the proje ct, the de signe r should conside r the e nvironm e nt in which the pulle ys are to ope rate . Pontoon-m ounte d drive pulle ys found on a dusty ash dum p for e x am ple , m ay re quire spe cial be arings and se als com pare d to a pulle y on a conve yor in a fe rtilize r plant whe re the e nvironm e nt is e x tre m e ly corrosive and m ay re quire a stainle ss ste e l pulle y. The choice of whe the r or not pulle y lagging is re quire d is ofte n de pe ndant of whe the r the pulle y and be lt is to ope rate in a we t, m oist or dry condition. This affe cts the friction be twe e n the be lt and pulle y which in turn affe cts the de cision to include lagging or not. b) Conveyor design For e ach conve yor the e ngine e r is re quire d to unde rtak e a com ple te de sign. The outputs from this de sign spe cify the be lt width, the drive se le ction, the conve yor profile , the location and arrange m e nt of the pulle ys and tak e -up, the te nsions in the be lting and the be lt se le ction, e tc. As far as the de sign and se le ction of pulle ys is conce rne d, the following inform ation is ge ne rally re quire d from the conve yor de sign and application :Belt The be lt width will dictate the m inim um face width of the pulle y. The following width: table indicate s standard be lt and pulle y face widths. Be lt W idth (m m ) Pulle y Face W idth (m m ) 450 500 600 750 900 1050 1200 1350 1500 1650 1800 2100 2400 550 600 700 900 1050 1200 1350 1500 1700 1850 2000 2300 2600

Irre spe ctive of whe re the pulle y is locate d in a conve yor syste m , the pulle y

Irre spe ctive of whe re the pulle y is locate d in a conve yor syste m , the pulle y Belt will have to be de signe d with the be lt te nsions in m ind. tensions: Be lt te nsions will affe ct the she ll de sign as we ll as the shaft de sign, be aring se le ction and orie ntation of the te nsions re lative to the support structure for the be aring m ounts. Be lt te nsion calculations should include the te nsions base d on a dynam ic analysis of the conve yor unde r load. This issue be com e s a significant conside ration whe n longe r conve yors are de signe d. For e x am ple s of the thum bnails. force s applie d to pulle ys, click on the following

ConveyorThe se le ction of be arings include s a calculation to de te rm ine the life duty: e x pe ctancy of the be arings. The duty of the conve yor i.e . hours ope rate d pe r ye ar and load conve ye d will affe ct the pulle y be aring de sign and life . In addition to this, the de sign of the pulle y shaft, she ll, lock ing e le m e nt, e tc. re quire s an unde rstanding of the duty of the conve yor and he nce pulle y. Belt The type and class of conve yor be lting to be use d on a conve yor has a selection:dire ct be aring on the diam e te r of a pulle y. The m inim um pulle y diam e te rs re com m e nde d by be lt m anufacture rs should be obse rve d in orde r to pre ve nt ove r-stre ssing of the be lt. A ngle The de sign will spe cify the angle of wrap of the be lt around the drive pulle y(s). of This angle of wrap is re quire d to e nsure that the full torque can be introduce d Wrap:to the be lt through the drive pulle y. The angle of wrap affe cts the load se e n by the pulle y and the re sultant force which the shaft support be arings and plum m e r block s m ust be de signe d for and the orie ntation of the be aring housings. c) Standardisation The clie nt m ay have spe cifie d a pre fe rre d pulle y type and de sign and the com pone nts to be use d i.e . pulle y she ll dim e nsions, lock ing e le m e nts, e tc. m ay be spe cifie d in orde r to standardise on the spare s holding re quire m e nts at the site , and for inte rchange ability. Such inform ation is e sse ntial and m ay affe ct the de sign of the ne w conve yor and its com pone nts. In the case of pulle ys, the drive m ay re quire two 55 k W drive s and pulle ys to be installe d rathe r than a single 110 k W drive through one pulle y. The shaft de tail m ay be affe cte d by the type of drive unit and the m ounting de tail for e x am ple , a hollow shaft-m ounte d re duce r ve rsus a fle x ible low spe e d coupling. d) Specifications The clie nts' standard spe cifications m ay call for spe cific de sign proce dure s and se le ction crite ria to be applie d to pulle y de sign. Factors of safe ty or the allowable de fle ction in the shaft which the clie nt wishe s to pre scribe , m ust be tak e n into conside ration whe n de signing a pulle y. e) Layout

The particular layout of the conve yor m ay affe ct the de sign of a pulle y asse m bly. In a case whe re acce ss is e x tre m e ly re stricte d, the discharge chute at the he ad pulle y m ay re quire the pulle y be arings to be close r toge the r than the standard width so that the chute can be narrowe r. Anothe r e x am ple could be the ne e d to install two drive units onto one pulle y, rathe r than a single drive unit m ounte d onto one pulle y. This m ay be ne ce ssary to standardise on a particular drive size .

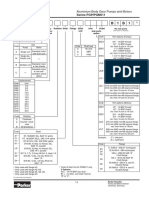

f) Pulley design The de sign of the pulle y and its com pone nts m ust tak e into conside ration a num be r of factors liste d be low :Dimensions:Standard pulle y dim e nsions should be obse rve d whe re ve r possible , in the inte re sts of standardisation in the industry. The following dim e nsions. chart provide s a guide line for the standard pulle y

Be lt width Face width C hute plate s I/S W 450 500 600 750 900 1050 1200 1350 1500 1650 1800 2100 2400 Le ge nd:F 550 600 700 900 1050 1200 1350 1500 1700 1850 2000 2300 2600 A 650 700 800 1000 1150 1300 1450 1600 1850 2000 2150 2450 2750

Be aring W ide B 1000 1050 1150 1350 1550 1700 1850 2050 2300 2450 2600 2900 3200

ce ntre s C le arance s for wide ce ntre s Se e le ge nd be low Narrow C D E G 760 225 50 50 810 225 50 50 1020 225 50 50 1170 225 75 50 1370 250 75 50 1520 250 75 50 1680 250 75 50 1830 275 75 50 1980 300 100 75 2130 300 100 75 2280 300 100 75 2580 300 100 75 2880 300 100 75

D = Pulle y face to ce ntre -line be aring housing. E = Pulle y face to be lt e dge . G = Pulle y face to inside chute plate . A ccessories:Lock ing e le m e nts, be arings and plum m e r block s are off-the -she lf com pone nts m anufacture d in standard size s and for ce rtain lim itations. The de sign of pulle ys and shafts m ust tak e this into conside ration.

C lick the following to vie w som e table s of standard e quipm e nt for pulle ys. PIC x 3 Drive The transm ission of torque from the drive unit to the be lting through the friction:drive pulle y is a furthe r factor which affe cts the de sign of the pulle y. The following table provide s the re com m e nde d friction factor for pulle ys unde r diffe re nt ope rating conditions :PIC Materials:The m ate rials of m anufacture m ay affe ct the de sign of the shaft, hubs, she lls and e nd plate s. If an application re quire s a pulle y to m anufacture d in stainle ss ste e l for e x am ple , this m ay have a be aring on the she ll thick ne ss, fabrication te chnique , re inforcing, e tc. The de taile d de sign of pulle ys and the ir com pone nt se le ction should thus be unde rtak e n by e x pe rie nce d e ngine e rs and e quipm e nt supplie rs.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- VB Script ReferenceDocumento27 pagineVB Script ReferenceRajkumarNessuna valutazione finora

- Project AgreementDocumento6 pagineProject AgreementRowin DizonNessuna valutazione finora

- EMOC 208 Installation of VITT For N2 Cylinder FillingDocumento12 pagineEMOC 208 Installation of VITT For N2 Cylinder Fillingtejcd1234Nessuna valutazione finora

- Lecture10 Combined FootingsDocumento31 pagineLecture10 Combined FootingsGopalram Sudhirkumar100% (3)

- Portal Info StubDocumento11 paginePortal Info Stubzamanqomaru8Nessuna valutazione finora

- JNTUA B Tech 2018 1 2 May R15 ECE 15A54201 Mathematics IIDocumento2 pagineJNTUA B Tech 2018 1 2 May R15 ECE 15A54201 Mathematics IIMRUDULA KULAKARNINessuna valutazione finora

- Ex-Cell XR2750 Pressure Washer Operation ManualDocumento16 pagineEx-Cell XR2750 Pressure Washer Operation Manualj_wilson85Nessuna valutazione finora

- Efficia Infant WarmingDocumento8 pagineEfficia Infant WarmingNurhidayat MursalinNessuna valutazione finora

- Optimizing Technique-Grenade Explosion MethodDocumento18 pagineOptimizing Technique-Grenade Explosion MethodUday Wankar100% (1)

- Ude My For Business Course ListDocumento51 pagineUde My For Business Course ListShehroz BhuttaNessuna valutazione finora

- Trade List 13 Mar 2019Documento74 pagineTrade List 13 Mar 2019Bharat JainNessuna valutazione finora

- Elevator Traffic Analysis - Passanger Elevators Option-1Documento5 pagineElevator Traffic Analysis - Passanger Elevators Option-1Amit GuptaNessuna valutazione finora

- ElectronicsDocumento3 pagineElectronicsashishkumar218Nessuna valutazione finora

- Programming Bayes Rule OptionalDocumento17 pagineProgramming Bayes Rule OptionalajuhaseenNessuna valutazione finora

- IBM System Storage DS8000 - A QuickDocumento10 pagineIBM System Storage DS8000 - A Quickmuruggan_aNessuna valutazione finora

- PG 511 B 1 B 1: Ordering Code Series PGP/PGM511Documento7 paginePG 511 B 1 B 1: Ordering Code Series PGP/PGM511Four SticksNessuna valutazione finora

- Material Safety Data Sheet: Roduct Ompany DentificationDocumento6 pagineMaterial Safety Data Sheet: Roduct Ompany DentificationArgade GVNessuna valutazione finora

- Sec VlanaclsDocumento10 pagineSec VlanaclsTry FajarmanNessuna valutazione finora

- SdccmanDocumento126 pagineSdccmanGustavo A. Sarache MillanNessuna valutazione finora

- Curriculum Vitae: Augusto Javier Puican ZarpanDocumento4 pagineCurriculum Vitae: Augusto Javier Puican Zarpanfrank_d_1Nessuna valutazione finora

- ITIL Quick ReferenceDocumento3 pagineITIL Quick ReferenceKalyaan KrushnaNessuna valutazione finora

- Teradata Installation: Installation Steps For WindowsDocumento4 pagineTeradata Installation: Installation Steps For WindowsjupudiguptaNessuna valutazione finora

- Selenium-75 Sources and Source Holders: ApplicationsDocumento2 pagineSelenium-75 Sources and Source Holders: ApplicationsTanpreet SinghNessuna valutazione finora

- BPSK SimulinkDocumento13 pagineBPSK SimulinkpootommyNessuna valutazione finora

- Quantity Surveying Division Assessment of Professional Competence Final Assessment 2014 Practice Problems / Part Ii Written TestDocumento31 pagineQuantity Surveying Division Assessment of Professional Competence Final Assessment 2014 Practice Problems / Part Ii Written TestjackyNessuna valutazione finora

- Opc PDFDocumento20 pagineOpc PDFnirajNessuna valutazione finora

- Trial Manufacture of A Fluid-Type Static Induction TransistorDocumento4 pagineTrial Manufacture of A Fluid-Type Static Induction TransistorStanley ClermontNessuna valutazione finora

- Supplier GPO Q TM 0001 02 SPDCR TemplateDocumento6 pagineSupplier GPO Q TM 0001 02 SPDCR TemplateMahe RonaldoNessuna valutazione finora

- 01 GeoStrucAnal Cylinder Elastic PDFDocumento12 pagine01 GeoStrucAnal Cylinder Elastic PDFSiddhant KaushikNessuna valutazione finora

- Manual PC Soundcard Scope 1.4.5Documento17 pagineManual PC Soundcard Scope 1.4.5NatashaKillerNessuna valutazione finora