Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Subgrades and Sub-Bases

Caricato da

Katrik_89Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Subgrades and Sub-Bases

Caricato da

Katrik_89Copyright:

Formati disponibili

1.1.

Subgrade The support that a subgrade can give to a rigid pavement is one of the main factors which must be evaluated and taken into account when designing a concrete slab. The most important property of the sui grade which must be known is whether or not it will provide uniform support throughout the life of the pavement, then the slab can probably be laid directly on the prepared in situ soil and there will be no need to construct a sub-base. If the subgrade soil conditions are poor, then it will be necessary to interpose a sub-base between the slab and the subgrade. As discussed later, the thickness design of rigid pavements is still very much at the empirical stage. In Great Britain, for instance, as in most other countries of the world, "design" primarily consists of specifying a particular combination of slab and sub-base thickness according to the design traffic and existing subgrade conditions. From a structural aspect, the only information regarding the subgrade which is required for design purposes in Great Britain is classification identifying whether it is very stable, normal or susceptible to non-uniform movement. As defined in this classification, a heavy clay is one which has a plasticity index greater than 40 while a well-graded sandy gravel is non-plastic and has a California Bearing Ratio value greater than 60 when it is poorly drained. The subgrade classifications given above are of course very wide, and numerous soils of varying stabilities can be included in each category. For instance, this system allows all well-drained soils having CBR values between 4 and 59 or poorly-drained soils having CBR values between 3 and 19 to be classified as normal soils. In practice, however, these wide groupings are generally quite adequate for design purposes. This can be explained by considering the manner in which a concrete slab distributes the wheel loads applied by the traffic. Concrete used in road construction is normally required to have a crushing strength of more than 4000 lb/in2 after 28 days. This material usually has a flexural strength of more than 450 lb/in2, which indicates that it has significant beam strength. Its modulus of elasticity is in the order of 5x106 lb/in2; this means that the concrete slab has a high degree of rigidity. Because of these properties of rigidity and beam strength, the wheel loads which are applied to a concrete slab are distributed over a large area and so deflections are small and unit pressures on the subgrade very low. The important thing to note that, for instance, an applied unit pressure of 106 lb/in2 could be reduced to subgrade pressure of only 3 to 7 lb/in2 by the slab distributing the applied load over an area of the subgrade more than 20 ft in diameter.! Thus it can be seen that concrete pavements do not necessary require strong subgrades; what is more important is that a subgrade should provide uniform support, and continue to do so throughout its design life.

1.2. Sub-base As has been established, a loaded concrete slab transmits very-low unit pressures to the subgrade and so it is not normally necessary in rigid pavements to utilize the thick subbase which is so often fundamental to the structural integrity of a flexible pavement. Where they are used beneath concrete road slabs, sub-bases are in fact rarely more than 6 in. thick. British practice with respect to sub-base re commends zero thickness for subbaae for a very stable subgrade, 3 in. for normal subgrade and 3 to 6 in. for the subgradeg which are very sus ceptible to non-uniform movement or for the parts of the roads with a water-table rising to within 2 ft of the slab. The function of a sub-base in a rigid pavement is not so much to increase the structural stability of the pavement as to counteract or correct unsatisfactory subgrade conditions which could lead to nonuniform support for the slab. Particular instances where sub-bases are used to provide uniform, stable and permanent support for concrete slabs are when damage is anticipated from one or more of the following causes: 1. Frost action 2. Poor drainage 3. Mud-pumping 4. Swell and shrinkage of high-volume-change soils. 5. Construction traffic

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- ShipyardsDocumento27 pagineShipyardsimran5705074Nessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Entec ETR300R - DNP - Device ProfileDocumento67 pagineEntec ETR300R - DNP - Device Profiledmoralesj_01Nessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Devon, Its Moorlands, Streams and Coasts by Northcote, RosalindDocumento233 pagineDevon, Its Moorlands, Streams and Coasts by Northcote, RosalindGutenberg.org100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- RISA Training ManualDocumento352 pagineRISA Training ManualSergey100% (1)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Microsoft Software License Terms Windows Vista ServiceDocumento4 pagineMicrosoft Software License Terms Windows Vista ServiceonisajoNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Kahn Order IsDocumento2 pagineKahn Order IswhadayacallitNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Is 12894: 1990Documento6 pagineIs 12894: 1990mukaslam100% (7)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Curriculum Vitae: Vikash KumarDocumento3 pagineCurriculum Vitae: Vikash Kumarkumarvikash29Nessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Design of A Low Resistance Grounding System For A Hydro-Electric Plant Located On Highly Resistive SoilsDocumento9 pagineDesign of A Low Resistance Grounding System For A Hydro-Electric Plant Located On Highly Resistive SoilsJose Jorge FontalvoNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- 15780Documento16 pagine15780uddinnadeemNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- NHB PDFDocumento43 pagineNHB PDFrohitkb09100% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Slab CulvertDocumento1 paginaSlab CulvertSivaramakrishnaNalluri100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- MichaelangeloDocumento14 pagineMichaelangeloBien BasbasNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Salesforce Analytics Rest ApiDocumento289 pagineSalesforce Analytics Rest Apicamicami2Nessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Seismic Design To S16-09 PDFDocumento13 pagineSeismic Design To S16-09 PDFDarryn McCormickNessuna valutazione finora

- RS232 Wiring DiagramsDocumento14 pagineRS232 Wiring DiagramsIsmail KırbaşNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- SPUN PILE WikaDocumento3 pagineSPUN PILE WikaCalvin SandiNessuna valutazione finora

- Art Deco Polemics and SynthesisDocumento15 pagineArt Deco Polemics and SynthesisStephann Abreu de FrançaNessuna valutazione finora

- Geetest InstallationDocumento4 pagineGeetest InstallationNarutõ UzumakiiNessuna valutazione finora

- AMDocumento31 pagineAMfebbyNessuna valutazione finora

- LCS Architecture For LTE EPSDocumento3 pagineLCS Architecture For LTE EPSgare69Nessuna valutazione finora

- Ab Initio TutorialsDocumento1 paginaAb Initio Tutorialsj_jeevan_jNessuna valutazione finora

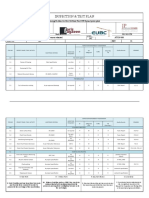

- Inspection & Test PlanDocumento2 pagineInspection & Test PlanKhaled GamalNessuna valutazione finora

- Dremel Catalog 2013Documento70 pagineDremel Catalog 2013wdowiuueNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Little Explorer 2012Documento2 pagineThe Little Explorer 2012Meg McKenzieNessuna valutazione finora

- TDDDocumento34 pagineTDDKaylen WheelerNessuna valutazione finora

- MS440209PM 48G6+ - 207PM 48G6Documento8 pagineMS440209PM 48G6+ - 207PM 48G6victor mauricio colonia rangelNessuna valutazione finora

- JA SteinDocumento69 pagineJA SteinNishant Sharma100% (1)

- Telnet Technical ModemDocumento2 pagineTelnet Technical ModemHà MậpNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Sand Trap LouversDocumento7 pagineSand Trap LouversAslam SageerNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)