Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Plant Utility and Maintanance Assisgnment

Caricato da

NethiyaaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Plant Utility and Maintanance Assisgnment

Caricato da

NethiyaaCopyright:

Formati disponibili

PLANT UTILITY AND MAINTANANCE

Plant utility is the main utility in all industry to design a project or run a industry work. It is heart of the plant serving all kinds of life blood to the complex system. Therefore, without any of this equipment the industry could not perform in the global level. So without utilities, the equipment inside the plant cannot operate. In a plant, the utilities are dividing into a few scopes which are: I. II. III. IV. V. VI. VII. VIII. Water system Steam system Fuel gas system Plant and instrument air Nitrogen Product storage or transfer Electrical supply and distribution system Feed stock storage

All the scopes have their own function. All this commodities are very important to run a plant. In different industries, the function might be quite different. 1. Water system Water system is an important industry requirement .Water system consist of mainly of Water tower Pump tank

A water tower is an incredibly simple device. It is also called elevated water tank. Although water towers come in all shapes and sizes, they all do the same thing. A water tower is simply a large, elevated tank of water. Water towers are tall to provide pressure. Each foot of height provides 0.43 PSI (pounds per square Inch) of pressure. A typical municipal water supply runs at between 50 and 100 PSI because major appliances require at least 20 to 30 PSI. The water tower must be tall enough to supply that level of pressure to all of the appliances in the area of the tower. So water towers are typically located on high ground, and they are tall enough to provide the necessary pressure. In hilly regions, a tower can sometimes be replaced by a simple tank located on the highest hill in the area. A water tower's tank is normally quite large. A typical water tower might hold 50 times the water in a normal swimming pool. Typically, a water tower's tank is sized to hold about a day's worth of water for the community served by the tower. If the pumps fail, for example,

during a power failure, the water tower holds enough water to keep things flowing for about a day.

One of the big advantages of a water tower is that it lets a municipality size its pumps for average rather than peak demand. Say that the water consumption for a pumping station averages 500 gallons of water per minute or 720,000 gallons over the course of a day, there will be times during the day when water consumption in the industry is much greater than 500 gallons per minute. Because of the water tower, the municipality can purchase a 500gallon-per-minute pump and let the water tower handle the peak demand. At night, when demand normally falls to practically zero, the pump can make up the difference and refill the water tower. The water is treated in a water treatment plant to remove sediment (by filtration and settling) and bacteria (with ozone, ultraviolet light and chlorine). The output from the water treatment plant is clear, germ-free water. A high-lift pump pressurizes the water and sends it to the water system's primary feeder pipes. If the pump is producing more water than the water system needs, the excess flows automatically into the tank. If the factory is demanding more water than the pump can supply, then water flows out of the tank to meet the need.

Ground water tank is made of lined carbon steel, it may receive water from water well or from surface water allowing a large volume of water to be placed in inventory and used during peak demand cycles.

2. Steam system

A steam system is a complex arrangement of equipment and piping that works together to produce and circulate steam at a variety of pressures and temperatures. Since steam is used in so many industrial applications most chemical plants and refineries have their own steam generation facilities. In a closed steam system, a condensate return header is used to remove slugs of water or condensate from the live steam line. This treated water collects in low points in the system where devices called steam traps direct flow back toward the boiler. A vessel called a deaerator is used to collect fluid from the condensate return header. The deaerator is designed to

remove excess air from the system. Demineralized makeup water is often added to the deaerator. The cooled condensate is fed back into the boiler where it is changed into steam. A typical steam Boiler Steam header system (fire system will include tube (low, the or medium and following water high equipment: tube) pressure)

Condensate return system Deaerator system 3. Condensate Recovery System

(steam traps, valves, piping, pumps)

The condensate recovery system is separated into clean and suspect (dirty) condensate sections. Clean condensate is routed to the deaerator. Suspect condensate is collected from steam users where the process side pressure is higher than the steam pressure. This condensate is considered to be suspect because a mechanical failure, such as tube leakage or failure could cause contamination, and reuse of contaminated condensate could seriously damage the steam generators and turbines. Suspect condensate collected in a drum is closely monitored for hydrocarbon contaminations. Depending upon the results of analysis, the condensate is pumped either through a carbon filter and then routed to the deaerator. 4. Fuel Gas System Most industrial manufacturers purchase natural gas (NG) from suppliers. A highpressure pipeline generally delivers gas to the plant (Figure 13.7-1). A pressure letdown station located near one of the plant entrances meters flow to the plant. The letdown station consists of multiple control valves, two of which are normally in service for backup. Additional valves are provided for peak loads such as unit startups. The letdown/meter control valve is in operation at all times. A second valve opens when the flow rate is high and closes at low flow rates, thereby making possible more accurate metering of the gas flow. The plant natural gas distribution header normally runs around 200 to 250 psig. Each process unit has its own pressure-control station that usually maintains the unit pressure between 60 and 100 psig. Natural gas is used to supplement the fuel gas produced at a unit in order to meet furnace and boiler demands. Natural gas is also used as a purge medium in unit startup and shutdown. Fuel gas generally consists of plant-produced process gas that is augmented with purchased natural gas to satisfy the units energy demand. Fuel gas required is typically produced internally during normal unit operations. During a startup mode or emergency mode, where no internal fuel gas is available, gas is imported; the imported gas is measured in a meter

station before entering the unit. During normal operation, any excess fuel gas produced is exported by a compressor system. 5. Plant and Water System For this system, air is supplied by air compressor that is driven by steam turbine or a motor. The air will be compressed and dried before distributing the air to the plant. Example of company using this system is METSO Automation.

6. Nitrogen Nitrogen gas is usually generated in the plant or purchased from a supply company. If purchased, it is usually delivered by high-pressure pipeline. Pipeline pressures run from 300 to 600 psig. The supplier may own and operate the meter station, which forms the billing basis for the purchase of nitrogen. High-pressure nitrogen is delivered to the individual units in a plant (Figure 13.6-2). The pressure is reduced at each unit to the desired working pressure, which is usually 120 to 150 psig. Nitrogen is used primarily as an inert gas for blanketing vessels and lines or for conveying combustible materials and sometimes as a backup for instrument air. Nitrogen hose connections are located at utility stations in the process units. These connections are used for nitrogen only and are different from the connections used for air, water, or steam. The nitrogen connections (Natural Standard Coupling) are welded to prevent them from being changed to other types of fittings, namely air or water. 1. 7. Product Storage and Feed Stock Transfer

Example of company using this utilities is CCG International Inc. This company is involving with bio-fuel. Bio-fuel must be derived from feedstock produced with much lower life-cycle greenhouse-gas emissions than traditional fossil fuels .

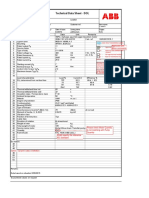

7. Electrical Supply and Distribution System The power received from electric supply companies is generally at voltage levels of 100 to 160 kV. At many plants, this is transformed down to 13.8 kV for distribution within the plant. At the units, the 13.8 kV is stepped down to 4160 V for use on large motors (200-10,000 hp). The 13.8 kV is also transformed to 480 V, the most common voltage in many plants, and finally to 240 V and 120 V for heating, lighting and fractional horsepower motors.

CONCLUSION The good plant should have good plant utilities. Every scope of plant utilities have its own importance and if one of it is not functioning well it can effect the operation of the plant. Just the organ in human body. If one organ is disrupt the whole function of the body is disrupt. So the utilities should be maintained at good condition.

REFERENCES I. II. III. http://ccgconsultinginc.com/2010sym_general.aspx http://www.industrialgasplants.com/cryogenic-nitrogen-plant.html http://valveproducts.metso.com/jamesbury/ApplicationReports/en/ABGP01%201205.pdf

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- JKR Specs L-S1 Specification For Low Internal Electrical Installation May-2011 Rev.2Documento114 pagineJKR Specs L-S1 Specification For Low Internal Electrical Installation May-2011 Rev.2Leong Km86% (7)

- Lab Report Marcet Boiler Segi UniversityDocumento6 pagineLab Report Marcet Boiler Segi Universityendra79Nessuna valutazione finora

- Internship Final Project ReportDocumento28 pagineInternship Final Project ReportDAS VICKY MANOJBHAI80% (5)

- Civil Civil Civil: Qaqc Qaqc QaqcDocumento18 pagineCivil Civil Civil: Qaqc Qaqc QaqcNethiyaaNessuna valutazione finora

- Retake Form of GBIF ExaminationDocumento1 paginaRetake Form of GBIF ExaminationNethiyaaNessuna valutazione finora

- Health, Safety and Environment (HSE) Monthly Report: Please Refer Calculation of LTI in Safety StatisticDocumento4 pagineHealth, Safety and Environment (HSE) Monthly Report: Please Refer Calculation of LTI in Safety StatisticNethiyaaNessuna valutazione finora

- UPSR SJKC English Paper 2 Section ADocumento47 pagineUPSR SJKC English Paper 2 Section Ajklim100% (1)

- Colin Coa Peng Project Manager: Safety, Health & Environment Committee Chart Signature TowerDocumento1 paginaColin Coa Peng Project Manager: Safety, Health & Environment Committee Chart Signature TowerNethiyaaNessuna valutazione finora

- Client Client Client: Rfa/ Submittal Rfa/ Submittal Rfa/ SubmittalDocumento17 pagineClient Client Client: Rfa/ Submittal Rfa/ Submittal Rfa/ SubmittalNethiyaaNessuna valutazione finora

- Vegetarian Men2Documento1 paginaVegetarian Men2NethiyaaNessuna valutazione finora

- Brosur Env Tech MNGMT - Compressed.compressedDocumento4 pagineBrosur Env Tech MNGMT - Compressed.compressedNethiyaaNessuna valutazione finora

- CHAPTER 8 Hazop StudyDocumento7 pagineCHAPTER 8 Hazop StudyNethiyaa50% (2)

- China State Construction EngineeringDocumento2 pagineChina State Construction EngineeringNethiyaaNessuna valutazione finora

- Equivalent Velocity Head Method: P F Length, M Diameter, M K Volume, L/S Gravitational Force, N/M2 P, KpaDocumento4 pagineEquivalent Velocity Head Method: P F Length, M Diameter, M K Volume, L/S Gravitational Force, N/M2 P, KpaNethiyaaNessuna valutazione finora

- Selecting A Distillation Column Control StrategyDocumento4 pagineSelecting A Distillation Column Control StrategyNethiyaaNessuna valutazione finora

- Automatic Solar Tracker: Presented byDocumento12 pagineAutomatic Solar Tracker: Presented byKomal RanvirNessuna valutazione finora

- Assignment 1Documento5 pagineAssignment 1Teoh Wong WeiNessuna valutazione finora

- KBU1010 DatasheetDocumento3 pagineKBU1010 DatasheetpandilzoNessuna valutazione finora

- ECS1 - Lecture 7 - Passive Solar HeatingDocumento74 pagineECS1 - Lecture 7 - Passive Solar HeatingJawhar ShahNessuna valutazione finora

- What Is A Fuel CellDocumento54 pagineWhat Is A Fuel CellHLSSummerInstituteNessuna valutazione finora

- Rondo CatalogDocumento3 pagineRondo CatalogRivo RudissaarNessuna valutazione finora

- Presentation For DownloadDocumento134 paginePresentation For DownloadPhon Phanna100% (1)

- ElectromechDocumento5 pagineElectromechramyachandarNessuna valutazione finora

- Solar Panel CleanerDocumento25 pagineSolar Panel CleanerE7011 BHAVYA PRATAP SINGHNessuna valutazione finora

- Power Theft Detection System-IJAERDV04I0272177Documento3 paginePower Theft Detection System-IJAERDV04I0272177Editor IJAERDNessuna valutazione finora

- A Combustion Phasing Control Oriented Model Applied To An - 2018 - IFAC PapersOnDocumento6 pagineA Combustion Phasing Control Oriented Model Applied To An - 2018 - IFAC PapersOnRochelle LopezNessuna valutazione finora

- CO2 Heat Pumps PotentialDocumento3 pagineCO2 Heat Pumps PotentialAnonymous ub0Yzv1PCNessuna valutazione finora

- Manual Do Sepam 10 PDFDocumento260 pagineManual Do Sepam 10 PDFLucas DoreaNessuna valutazione finora

- Simulink Test Bench Hybrid B-SDocumento4 pagineSimulink Test Bench Hybrid B-SRadoy CristyNessuna valutazione finora

- (Colored) Refrigerant 134a P-H Diagram (SI Units)Documento1 pagina(Colored) Refrigerant 134a P-H Diagram (SI Units)Mc Jason LaureteNessuna valutazione finora

- 11kw Motor DocumentDocumento5 pagine11kw Motor DocumentArun KumarNessuna valutazione finora

- MOV-14DxxK Series - Metal Oxide VaristorDocumento4 pagineMOV-14DxxK Series - Metal Oxide VaristorRESUL OTEBASNessuna valutazione finora

- Biofuel AssignmentDocumento29 pagineBiofuel AssignmentBerry BadariNessuna valutazione finora

- Ups UriDocumento12 pagineUps UriBerghiu CatalinNessuna valutazione finora

- Deep Submersible Hayward MotorsDocumento33 pagineDeep Submersible Hayward MotorsKasinathan MuniandiNessuna valutazione finora

- SKF Induction HeaterDocumento2 pagineSKF Induction HeaterAdrian CantaragiuNessuna valutazione finora

- Master in Hydraulic Engineering Final DefenesDocumento26 pagineMaster in Hydraulic Engineering Final DefenesPheng XiongNessuna valutazione finora

- Principles of Engineering Thermodynamics Si Edition 1st Edition Reisel Solutions ManualDocumento36 paginePrinciples of Engineering Thermodynamics Si Edition 1st Edition Reisel Solutions Manualmohicans.meute.jhwyt100% (23)

- LNG 20150116Documento11 pagineLNG 20150116Rajeshkumar ElangoNessuna valutazione finora

- Mechanical OperationsDocumento46 pagineMechanical OperationsAditya MoreNessuna valutazione finora

- Ansaldo Thomassen - Gas Turbine Remanufacturing (2014)Documento4 pagineAnsaldo Thomassen - Gas Turbine Remanufacturing (2014)guerrez100% (1)

- 1.1.1.4 Lab - Ohms LawDocumento2 pagine1.1.1.4 Lab - Ohms LawSilvia De LéonNessuna valutazione finora

- Handout 3 Types of DC GeneratorsDocumento11 pagineHandout 3 Types of DC GeneratorsAdriel JohnNessuna valutazione finora