Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Orion Double Adjustment

Caricato da

EmnDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Orion Double Adjustment

Caricato da

EmnCopyright:

Formati disponibili

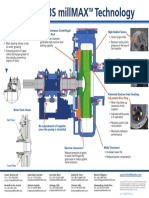

The Orion series of

Heavy & mining duty horizontal slurry pumps with double adjustment

Metso Minerals (Sweden) AB Norrngsgatan 2, SE-733 38 Sala, Sweden, Phone: +46 224 374 00, Fax: +46 224 169 69 Metso Minerals Industries Inc. 621 South Sierra Madre, Suite #100, Colorado Springs, CO 80903, USA, Phone: +1 719 471 3443, Fax: +1 719 471 4469 Metso Minerals Industries Inc. P.O. Box 96, Birmingham, AL 35201, USA, Phone: +1 205 599 6600, Fax: +1 205 599 6623 Metso Minerals (South Africa) (Pty) Ltd. Private Bag X2006, Isando, Johannesburg,1600, South Africa, Phone: +27 11 397 5090, Fax: +27 11 397 5826 Metso Minerals (Australia) Ltd. Level 2, 1110 Hay Street, West Perth, WA 6005, Australia, Phone: +61 8 9420 5555, Fax: +61 8 9320 2500 Metso Minerals (India) Pvt Ltd 1th floor, DLF Building No. 10, Tower A, DLF Cyber City, Phase - III, Gurgaon - 122 002, India, Phone: +91 124 235 1541, Fax: +91 124 235 1601 Metso Per S.A. Calle 5 Nro. 144, Urb. Industrial Vulcano, Ate, Lima 03, Peru, Phone: +51 1 313 4366, Fax: +51 1 349 0913 Metso Minerals (Chile) S.A. Av. Los Conquistadores 2758, - Piso 3, Providencia, Santiago, Chile, Phone: +56 2 370 2000, Fax: +56 2 370 2039 Metso Brasil Indstria e Comrcio Ltda. Av. Independncia, 2500 den, 18087-101 Sorocaba-SP - Brazil, Phone: +55 15 2102 1300

www.metso.com E-mail: minerals.info@metso.com Pumps information at www.metso.com/pumps

Metso Corporation, Fabianinkatu 9 A, P.O. Box 1220, FI-00101 Helsinki, Finland, tel. +358 20 484 100, fax +358 20 484 101, www.metso.com

Subject to alteration without prior notice Brochure No. 1846-10 -10-MBL/Sala-English 2010 Metso Minerals Printed in Sweden

Total impeller wear clearance adjustment

Closing both back and front impeller running clearences permits optimum continuous performance of the pump. All adjustments can be made on installed pumps without disassembly.

Centrifugal seal arrangement

The expeller generates a high head and works in conjunction with expelling back vanes of the impeller to provide a highly effective seal against positive inlet heads without gland leakage. Performence improves with wear clearance adjustment at the back of the impeller. Abrasion resistant materials ensure wear life equivalent to the pump. Four rings of grease-lubricating packing, seal the pump while stationary.

Even wear design

Back pull-out design

Designed for ease of maintenace.

Taper roller bearings

Case and impeller are matched for minimum hydraulic turbulence for longer and more equally distributed impeller and case wear life.

Impeller design

Heavy duty grease lubricated bearings in a sealed cartridge designed for maximum bearing life. Double bearing arrange-ments available.

Partial mixed flow main vanes reduce hydraulic shock losses at the suction eye. Large diameters and strategic mass distribution permit high head and high performance at slow speeds without the sacrifice of efficiency.

Seals

ANSI / Metric flanges as required

Double sealed with V-ring protected lip seal to ensure reliable operation.

Suction and discharge flanges are split on all HM and MM pumps for optional flange configurations, ease of pipe connection and alignment. Rubber lined pumps have slotted flanges to allow most metric or ANSI flanges.

Heavy duty shaft

Wear resistant castings

Designed for tough services. High power transmission design with reduced impeller overhang for minimum shaft deflection and a maximum pump life.

Strict metallurgical control and casting integrity with extra metal at known areas of severe wear.

Front and back expeller vanes

Standard materials of construction*

Metal Standard Rubber Standard Casing HighChrome Case liners Natural rubber Impeller HighChrome Impeller Natural rubber Back liner HighChrome Backliner Natural rubber Expeller HighChrome Expeller HighChrome Expeller ring HighChrome Expeller ring Natural rubber Shaft sleeve HighChrome Shaft sleeve HighChrome Shaft Carbon steel Shaft Carbon steel Seals Nitrile Seals Nitrile

Double adjustment feature permits the use of narrow expelling vanes greatly reducing internal recirculation with minimal energy consumption.

Wet ends

Hard metal and rubber lined wet ends available.

*Consult factory for available options

Potrebbero piacerti anche

- 10-400FLSmidthKrebs SlurryMAX Brochure EmailDocumento8 pagine10-400FLSmidthKrebs SlurryMAX Brochure EmailpacodmxNessuna valutazione finora

- Euroflo Centrifugal Product Flyers 2009Documento11 pagineEuroflo Centrifugal Product Flyers 2009Zhang ZhaoyangNessuna valutazione finora

- Warman Technical CatalogueDocumento1 paginaWarman Technical CatalogueMamiherintsoa Issaia RanaivoarimananaNessuna valutazione finora

- Bombas FlowserveDocumento36 pagineBombas FlowserveJuan José RoncalNessuna valutazione finora

- Durco M3 ANSI Ps-10-13-E1Documento36 pagineDurco M3 ANSI Ps-10-13-E1Alfred Lam100% (1)

- 1345 John CraneDocumento2 pagine1345 John CraneseptixNessuna valutazione finora

- 005056B6021E1ED4AEFF0B99E4B424D3Documento8 pagine005056B6021E1ED4AEFF0B99E4B424D3Cristhian Niño MartinezNessuna valutazione finora

- GX Catalogue2013Documento32 pagineGX Catalogue2013Leobardo DiazNessuna valutazione finora

- Krebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsDocumento4 pagineKrebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsPhaniNessuna valutazione finora

- Ensival Moret GeneralDocumento2 pagineEnsival Moret GeneralPatricia J ÁngelesNessuna valutazione finora

- Industrial Processes PDFDocumento58 pagineIndustrial Processes PDFJOSEPH REFUERZONessuna valutazione finora

- 905 Series Liquid Ring Vacuum Pumps & CompressorsDocumento4 pagine905 Series Liquid Ring Vacuum Pumps & CompressorscarlosNessuna valutazione finora

- Slurrymax Camur Pompasi 3 PDFDocumento8 pagineSlurrymax Camur Pompasi 3 PDFTecnologia Fabricación MetalmecanicaNessuna valutazione finora

- Slurry High Pressure PumpDocumento15 pagineSlurry High Pressure PumpOhmar Jamon LuzanoNessuna valutazione finora

- Products Pumps Mission-2500Documento3 pagineProducts Pumps Mission-2500backieuphong1696Nessuna valutazione finora

- CPT Pump For The Petroleum Industry According To ASME B73.1: Sulzer PumpsDocumento12 pagineCPT Pump For The Petroleum Industry According To ASME B73.1: Sulzer PumpsAhmed HassanNessuna valutazione finora

- GouldsDocumento11 pagineGouldsKaren Isabel Ambiado Rivas100% (1)

- Pumps For Heat Transfer TechnologyDocumento12 paginePumps For Heat Transfer TechnologybmsengineeringNessuna valutazione finora

- Salomix SLG GearDrive E00506 PDFDocumento4 pagineSalomix SLG GearDrive E00506 PDFgilbertogatoNessuna valutazione finora

- Z22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USDocumento2 pagineZ22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USediNessuna valutazione finora

- Hoja Tecnica - Sello Mecanico - Marca FlowserveDocumento4 pagineHoja Tecnica - Sello Mecanico - Marca FlowserveJonathan Villagra100% (1)

- A7 PumpDocumento14 pagineA7 PumpIr Go JarNessuna valutazione finora

- Ej PDFDocumento20 pagineEj PDFduongpnNessuna valutazione finora

- WPG 151AH31: 14 MM 14 MMDocumento24 pagineWPG 151AH31: 14 MM 14 MMMamiherintsoa Issaia RanaivoarimananaNessuna valutazione finora

- 00 Mill MAXSlurry Pump July 2016 CutawayDocumento1 pagina00 Mill MAXSlurry Pump July 2016 CutawayPatricio Acuña100% (1)

- 3604 SMN-JWR PDFDocumento7 pagine3604 SMN-JWR PDFsaharaNessuna valutazione finora

- Manual de BombasDocumento41 pagineManual de BombasGabriel BecerraNessuna valutazione finora

- Flowserve ISC2 PP RepairDocumento12 pagineFlowserve ISC2 PP RepairedekovacsNessuna valutazione finora

- EthanolDocumento8 pagineEthanolapi-3699282Nessuna valutazione finora

- QL Series: Vertical, Double-Suction Twin-Volute Turbine PumpsDocumento8 pagineQL Series: Vertical, Double-Suction Twin-Volute Turbine PumpstangouzeNessuna valutazione finora

- 2020 Style 688 Split SealtekDocumento8 pagine2020 Style 688 Split SealtekdiamsamNessuna valutazione finora

- BR MiningDocumento12 pagineBR MiningSteven TremolNessuna valutazione finora

- HPH BrochureDocumento12 pagineHPH BrochureCristhian Vilca SilvestreNessuna valutazione finora

- Horizontal & SuHorizontal & Sump Pumpmp PumpsDocumento105 pagineHorizontal & SuHorizontal & Sump Pumpmp PumpsAnonymous dHLFEZuhBa50% (2)

- Ensival CatalogDocumento38 pagineEnsival CatalogabsahkahNessuna valutazione finora

- User Instructions: Installation Operation MaintenanceDocumento55 pagineUser Instructions: Installation Operation MaintenanceSantos Rudas SaucedoNessuna valutazione finora

- 811 Brochure GrisgoldDocumento20 pagine811 Brochure GrisgoldEmerson RuizNessuna valutazione finora

- Catalogo EagleBurgmann API 682 3ra Edición (58 E) PDFDocumento30 pagineCatalogo EagleBurgmann API 682 3ra Edición (58 E) PDFRobert VillavicencioNessuna valutazione finora

- Ahlstar End-Suction Single-Stage Centrifugal Pumps: Flow EquipmentDocumento28 pagineAhlstar End-Suction Single-Stage Centrifugal Pumps: Flow EquipmentARYAN_FATHONI_AMRINessuna valutazione finora

- WPG 20L21: 13 MM 13 MMDocumento1 paginaWPG 20L21: 13 MM 13 MMMamiherintsoa Issaia RanaivoarimananaNessuna valutazione finora

- Características Técnicas Bombas Mark IIIDocumento60 pagineCaracterísticas Técnicas Bombas Mark IIIBORISINHO2975Nessuna valutazione finora

- Catalogo de Bombas de Caudal VariableDocumento29 pagineCatalogo de Bombas de Caudal VariableRaul Rivera100% (1)

- B.5 MillMAX 3x2-14x12 IOM (July 2015)Documento67 pagineB.5 MillMAX 3x2-14x12 IOM (July 2015)Alief FadilNessuna valutazione finora

- 254 SMO-Outu KumpuDocumento8 pagine254 SMO-Outu KumpujoseritoNessuna valutazione finora

- KREBS slurryMAX Pump BrochureDocumento12 pagineKREBS slurryMAX Pump Brochuredavidgaro12Nessuna valutazione finora

- Manejo de Catalogo Reductores Montados Sobre Eje DODGEDocumento56 pagineManejo de Catalogo Reductores Montados Sobre Eje DODGEPedro Julio PérezNessuna valutazione finora

- Ensival Moret PumpsDocumento5 pagineEnsival Moret PumpsBenicio Joaquín Ferrero Brebes0% (1)

- Safematic Seal Support - ENGDocumento8 pagineSafematic Seal Support - ENGManojkumar ThilagamNessuna valutazione finora

- Sulzer EPD MD 150 360 SkidDocumento4 pagineSulzer EPD MD 150 360 SkidAdolfo CanceloNessuna valutazione finora

- Hevvy Hns Brocuhre enDocumento11 pagineHevvy Hns Brocuhre enJacobo MartínezNessuna valutazione finora

- Guia Seleccion de Bombas RUHRPUMPENDocumento28 pagineGuia Seleccion de Bombas RUHRPUMPENYadir Bojaca100% (1)

- Weir Split Case BrochureDocumento4 pagineWeir Split Case Brochure'Muhammad Saiful Rahman HmmwNessuna valutazione finora

- Dimension - A Series 31-100 To 33-125Documento1 paginaDimension - A Series 31-100 To 33-125Energy Technology100% (1)

- Malmedi 50HZ 14-09-04Documento538 pagineMalmedi 50HZ 14-09-04rhusseinpos4765Nessuna valutazione finora

- Slurry Pumps Ar1 PDFDocumento40 pagineSlurry Pumps Ar1 PDFsanjayagrawal70-1Nessuna valutazione finora

- Watson Marlow Bredal SPX PumpsDocumento12 pagineWatson Marlow Bredal SPX PumpsCesar Armando Hernandez ViteNessuna valutazione finora

- Scanpump PN25 BK NKDocumento2 pagineScanpump PN25 BK NKRafael SouzaNessuna valutazione finora

- Series T10 Knurled Thumb Nuts: Optional "Face" KnurlsDocumento2 pagineSeries T10 Knurled Thumb Nuts: Optional "Face" KnurlsbmsaliNessuna valutazione finora

- SWOP Capabilities WEBDocumento8 pagineSWOP Capabilities WEBKarthik AnandanNessuna valutazione finora

- High-Performance GM LS-Series Cylinder Head GuideDa EverandHigh-Performance GM LS-Series Cylinder Head GuideValutazione: 4.5 su 5 stelle4.5/5 (2)

- ARI-Strainer: Strainer - Screen and Supporting Basket Made of Stainless SteelDocumento6 pagineARI-Strainer: Strainer - Screen and Supporting Basket Made of Stainless SteelEmnNessuna valutazione finora

- Cam and GrooveDocumento4 pagineCam and GrooveEmnNessuna valutazione finora

- Chapter 1 - Manual & Mechanical Control Techniques: A. Weed PullingDocumento7 pagineChapter 1 - Manual & Mechanical Control Techniques: A. Weed PullingEmnNessuna valutazione finora

- Wilco Bulk Plant DSDocumento4 pagineWilco Bulk Plant DSEmnNessuna valutazione finora

- 8.criteria For The Optimum Design of Drive & Brake Units in Belt ConveyorsDocumento15 pagine8.criteria For The Optimum Design of Drive & Brake Units in Belt ConveyorsEmnNessuna valutazione finora

- Add Maths F4 Topical Test 3 (E)Documento3 pagineAdd Maths F4 Topical Test 3 (E)HANIFAH50% (2)

- Raw Meal Grinding Aids: Improving BurnabilityDocumento3 pagineRaw Meal Grinding Aids: Improving BurnabilityfaheemqcNessuna valutazione finora

- Gerador #LotofácilDocumento10 pagineGerador #LotofácilEmanuel BezerraNessuna valutazione finora

- BARAKA Modelling ProposalDocumento9 pagineBARAKA Modelling Proposalmurali.5482Nessuna valutazione finora

- Business Statistics I: Hypothesis TestingDocumento58 pagineBusiness Statistics I: Hypothesis TestingJamesNessuna valutazione finora

- Laptop Repair Part 2 OCRDocumento336 pagineLaptop Repair Part 2 OCRAlvaro Amaya PérezNessuna valutazione finora

- Model Rocketry Safety CodeDocumento2 pagineModel Rocketry Safety CodeAviation/Space History LibraryNessuna valutazione finora

- Public Servants and Government ServantsDocumento10 paginePublic Servants and Government Servantsalexandra angelinaNessuna valutazione finora

- Basiccharge Ev Ftu Superfast Data Sheet 028413Documento2 pagineBasiccharge Ev Ftu Superfast Data Sheet 028413Cojoc Constantin-CosminNessuna valutazione finora

- Have A One Track Mind: Lorna WingDocumento4 pagineHave A One Track Mind: Lorna WingsophilauNessuna valutazione finora

- MANUALrev Fviewing 1Documento12 pagineMANUALrev Fviewing 1saleossNessuna valutazione finora

- Is - 2026-4Documento27 pagineIs - 2026-4jm.mankavil6230Nessuna valutazione finora

- Linux Lab-1Documento32 pagineLinux Lab-1Naveen KumarNessuna valutazione finora

- TAPCON® 240: Voltage Regulator For Regulating TransformersDocumento6 pagineTAPCON® 240: Voltage Regulator For Regulating TransformerscastrojpNessuna valutazione finora

- Resume Bhairo SINGHwish PhotoDocumento2 pagineResume Bhairo SINGHwish PhotoHR BitozzzNessuna valutazione finora

- E-Rpms Portfolio (Design 3) - Depedclick-1Documento42 pagineE-Rpms Portfolio (Design 3) - Depedclick-1angeliNessuna valutazione finora

- Physiological, Anthropometric, and Motor Characteristics of Elite Chinese Youth Athletes From Six Different SportsDocumento12 paginePhysiological, Anthropometric, and Motor Characteristics of Elite Chinese Youth Athletes From Six Different SportsRafida I CNessuna valutazione finora

- ATS Monitoring Device InstructionsDocumento25 pagineATS Monitoring Device InstructionsVinhNessuna valutazione finora

- Assignment 2Documento3 pagineAssignment 2Hannah Van GeeresteinNessuna valutazione finora

- Battista Mondin, Saint Thomas Aquinas' Philosophy. in The Commentary To The Sentences (Inglés) PDFDocumento134 pagineBattista Mondin, Saint Thomas Aquinas' Philosophy. in The Commentary To The Sentences (Inglés) PDFFray Daniel Sisa NiñoNessuna valutazione finora

- Revo Uninstaller Pro HelpDocumento61 pagineRevo Uninstaller Pro HelpGuy Sinclaire OmbeNessuna valutazione finora

- Asynchronous ActivityDocumento1 paginaAsynchronous ActivityJoanna Mae MendozaNessuna valutazione finora

- The Impact of Updating Health Benefits Plans On Health Technologies Usage and Expenditures The Case of ColombiaDocumento24 pagineThe Impact of Updating Health Benefits Plans On Health Technologies Usage and Expenditures The Case of ColombiaTeana Zapata JaramilloNessuna valutazione finora

- LGIT CatalogueDocumento11 pagineLGIT CatalogueArjun SharmaNessuna valutazione finora

- Python Cheat SheetDocumento11 paginePython Cheat SheetWasswa OpioNessuna valutazione finora

- Radical Pedagogies in Architectural Education - Architectural ReviewDocumento11 pagineRadical Pedagogies in Architectural Education - Architectural ReviewGabriella VillaçaNessuna valutazione finora

- Unit-V 191eec303t LicDocumento80 pagineUnit-V 191eec303t LicPonkarthika BNessuna valutazione finora

- Quiz 1 Distribusi Plus JawabanDocumento6 pagineQuiz 1 Distribusi Plus JawabandimasfupNessuna valutazione finora

- LAtihan Ujian Inggris MinatDocumento13 pagineLAtihan Ujian Inggris MinatDfzh HhNessuna valutazione finora

- SPHE8281DDocumento35 pagineSPHE8281Ddiego-tNessuna valutazione finora