Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Dhen Automation

Caricato da

Paul Allen LegarteDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Dhen Automation

Caricato da

Paul Allen LegarteCopyright:

Formati disponibili

SCADA SCADA (supervisory control and data acquisition) generally refers to industrial control systems: computer systems that

monitor and control industrial, infrastructure, or facility-based processes, as described below: Industrial processes include those of manufacturing, production, power generation, fabrication, and refining, and may run in continuous, batch, repetitive, or discrete modes. Infrastructure processes may be public or private, and include water treatment and distribution, wastewater collection and treatment, oil and gas pipelines, electrical power transmission and distribution, Wind farms, civil defense siren systems, and large communication systems. Facility processes occur both in public facilities and private ones, including buildings, airports, ships, and space stations. They monitor and control HVAC, access, and energy consumption.

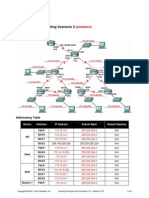

SCADA architecture First generation: "Monolithic" In the first generation, computing was done by mainframe computers. Networks did not exist at the time SCADA was developed. Thus SCADA systems were independent systems with no connectivity to other systems. Wide Area Networks were later designed by RTU vendors to communicate with the RTU. The communication protocols used were often proprietary at that time. The first-generation SCADA system was redundant since a back-up mainframe system was connected at the bus level and was used in the event of failure of the primary mainframe system. Second generation: "Distributed" The processing was distributed across multiple stations which were connected through a LAN and they shared information in real time. Each station was responsible for a particular task thus making the size and cost of each station less than the one used in First Generation. The network protocols used were still mostly proprietary, which led to significant security problems for any SCADA system that received attention from a hacker. Since the protocols were proprietary, very few people beyond the developers and hackers knew enough to determine how secure a SCADA installation was. Since both parties had vested interests in keeping security issues quiet, the security of a SCADA installation was often badly overestimated, if it was considered at all. Third generation: "Networked" These are the current generation SCADA systems which use open system architecture rather than a vendor-controlled proprietary environment. The SCADA system utilizes open standards and protocols, thus distributing functionality across a WAN rather than a LAN. It is easier to connect third party peripheral devices like printers, disk drives, and tape drives due to the use of open architecture. WAN protocols such as Internet Protocol (IP) are used for communication between the master station and communications equipment. Due to the usage of standard protocols and the fact that many networked SCADA systems are accessible from the internet; the systems are potentially vulnerable to remote cyber-attacks. On the other hand, the usage of standard protocols and security techniques means that standard security improvements are applicable to the SCADA systems, assuming they receive timely maintenance and updates. MMI (Man- Machine Interface) It stands for "Man-Machine Interface" and, as you may gather from the name, is the hardware and/or software which allows the operator, engineer, etc. to control and monitor the machine function, as opposed to the hardware and/or software that contains the logic by which machine operation is controlled. MMI means "Man-Machine Interface." MMI's are used to provide control and status for

automated systems. For example, this could be the screen that a machine operator uses to start a machine cycle, or set the number of cycles the system needs to run, or see the reason why the system stopped, and so on. These used to be boards made up of pilot lights, pushbuttons, and selector switches, and you still see these on many older systems. However, the cost of all those individual pilot lights, pushbuttons, & the cost to wire them back to a controller is usually more expensive than most solid-state type MMI's today. Plus, the MMI screens take up less space and can be changed relatively easily compared to push button stations, especially when adding more lights & buttons to a system. By the way, each pilot light & push button needs to be wired up to it's own I/O point (and sometimes to more than one I/O point) on a controller, which usually increases the amount of controller I/O modules required for your system, which increases the system cost.

DIRECT DIGITAL CONTROL Direct digital control (DDC) is the automated control of a condition or process by a digital device (computer). A very early example of a DDC system meeting the above requirements was completed by the Australian business Midac in 1981-1982 using R-Tec Australian designed hardware. The system installed at theUniversity of Melbourne used a serial communications network, connecting campus buildings back to a control room "front end" system in the basement of the Old Geology building. Each remote or Satellite Intelligence Unit (SIU) ran 2 Z80 microprocessors whilst the front end ran 11 in a Parallel Processing configuration with paged common memory. The z80 microprocessors shared the load by passing tasks to each other via the common memory and the communications network. This was possibly the first successful implementation of a distributed processing direct digital control system. SAFETY INSTRUMENTED SYSTEM A Safety Instrumented System (SIS) is a form of process control usually implemented in industrial processes, such as those of a factory or an oil refinery. The SIS performs specified functions to achieve or maintain a safe state of the process when unacceptable or dangerous process conditions are detected. Safety instrumented systems are separate and independent from regular control systems but are composed of similar elements, including sensors, logic solvers, actuators and support systems. The specified functions, or safety instrumented functions (SIF) are implemented as part of an overall risk reduction strategy which is intended to reduce the likelihood of identified hazardous events involving a catastrophic release. The safe state is a state of the process operation where the hazardous event cannot occur. The safe state should be achieved within one-half of the process safety time. Most SIF are focused on preventing catastrophic incidents. The correct operation of an SIS requires a series of equipment to function properly. It must have sensors capable of detecting abnormal operating conditions, such as high flow, low level, or incorrect valve positioning. A logic solver is required to receive the sensor input signal(s), make appropriate decisions based on the nature of the signal(s), and change its outputs according to user-defined logic. The logic solver may use electrical, electronic or programmable electronic equipment, such as relays, trip amplifiers, or programmable logic controllers. Next, the change of the logic solver output(s) results in the final element(s) taking action on the process (e.g. closing a valve) to bring it to a safe state. Support systems, such as power, instrument air, and communications, are generally required for SIS operation. The support systems should be designed to provide the required integrity and reliability. International standard IEC 61511 was published in 2003 to provide guidance to end-users on the application of Safety Instrumented Systems in the process industries. This standard is based on IEC 61508, a generic standard for design, construction, and operation of electrical/electronic/programmable electronic systems. Other industry sectors may also have standards that are based on IEC 61508, such as IEC 62061(machinery systems), IEC 62425 (for railway signaling systems), IEC 61513 (for nuclear systems), and ISO 26262 (for road vehicles, currently a draft international standard).

DISTRIBUTED CONTROL SYSTEM A distributed control system (DCS) refers to a control system usually of a manufacturing system, process or any kind of dynamic system, in which the controller elements are not central in location (like the brain) but are distributed throughout the system with each component sub-system controlled by one or more controllers. The entire system of controllers is connected by networks for communication and monitoring. DCS is a very broad term used in a variety of industries, to monitor and control distributed equipment. Electrical power grids and electrical generation plants Environmental control systems Traffic signals radio signals Water management systems Oil refining plants Metallurgical Process Plants Chemical plants Pharmaceutical manufacturing Sensor networks Dry cargo and bulk oil carrier ships

Applications Distributed Control Systems (DCSs) are dedicated systems used to control manufacturing processes that are continuous or batch-oriented, such as oil refining, petrochemicals, central station power generation, fertilizers, pharmaceuticals, food & beverage manufacturing, cement production, steelmaking, and papermaking. DCSs are connected to sensors and actuators and use setpoint control to control the flow of material through the plant. The most common example is a setpoint control loop consisting of a pressure sensor, controller, and control valve. Pressure or flow measurements are transmitted to the controller, usually through the aid of a signal conditioning Input/Output (I/O) device. When the measured variable reaches a certain point, the controller instructs a valve or actuation device to open or close until the fluidic flow process reaches the desired setpoint. Large oil refineries have many thousands of I/O points and employ very large DCSs. Processes are not limited to fluidic flow through pipes, however, and can also include things like paper machines and their associated quality controls (see Quality Control System QCS), variable speed drives and motor control centers, cement kilns, mining operations, ore processing facilities, and many others. A typical DCS consists of functionally and/or geographically distributed digital controllers capable of executing from 1 to 256 or more regulatory control loops in one control box. The input/output devices (I/O) can be integral with the controller or located remotely via a field network. Todays controllers have extensive computational capabilities and, in addition to proportional, integral, and derivative (PID) control, can generally perform logic and sequential control. Modern DCSs support also neural networks and fuzzy application. DCSs may employ one or several workstations and can be configured at the workstation or by an off-line personal computer. Local communication is handled by a control network with transmission over twisted pair, coaxial, or fiber optic cable. A server and/or applications processor may be included in the system for extra computational, data collection, and reporting capability.

Example PLC and DCS Projects: Installed the iFIX SCADA system at a large municipal filtration plant. The application had a about 2500 tags and several hundred screens. Existing Allen-Bradley PLC 5/40's were used for controls. Historical data was stored in MS SQL Server on a dedicated Historian PC and reports were generated in Excel. Implemented operating controls for 2 freeze drying lines using Taylor Pro-Worx Plus Software, Modicon 984-130 Processor and Fix DMACS. Designed and implemented a plant control system for operation of the Heat Exchange Facility, part of a Lake Source Cooling Project. The control system is capable of being controlled remotely from Cornell Universitys Central Heating Plant using a PC based NT operating platform running Intellution FIX V7.0 Full SCADA server with additional SQL/ODBC option installed. Remote communications was accomplished over an Ethernet backbone via user assigned TCP/IP addressing network scheme. Controls were implemented using a Quantum PLC processor, programmed with Concept IEC 1131-3, which offers Ladder Logic, Function Block, Sequential Function Chart, Structured Text, and Instruction List type programs. Designed and implemented system using three Modicon Quantum PLCs, and Five Wonderware workstations to control two Dual Fuel Furnaces with multiple burner controls as well as associated equipment including baghouse, automatic spark arresting system, automatic hood dampers, stack caps and 300 HP ID fan. Recommended system components and replaced SCADA system for a network with 11 nodes and remote redundant SCADA capability communicating with 26 remote substations. Allen Bradley PLCs are used as the I/O nodes and Intellution FIX DMACS is the HMI software. Recommended system components and replaced complete SCADA system for a large water authority. Routinely perform ongoing upgrades and support for the Windows NT based SCADA system, which utilizes multiple Intellution SCADA nodes. It also includes remote SCADA capability through the water authority WAN. The system employs radios and a leased digital network to communicate with over 25 remote substations and associated tanks. Substation control is achieved using Allen-Bradley PLC's. The SCADA system includes data archiving for system analysis, alarming, reporting, and event and alarm-based emails and paging. Provided installation of new instrumentation and controls to allow for the remote operation of two (2) industrial water-pumping sites. In each of the locations, the pumps were locally controlled by Allen Bradley PLCs, and then connected back to a central Provox DCS control room via 900MHz and 2Ghz radio links.

WESTMEAD INTERNATIONAL SCHOOL College of Engineering & Architecture Alangilan, Batangas City

In Partial Fulfillment of the Subject Requirement In Industrial Automation (ME Elec 4)

Submitted by: Geraldine A. Gupit BSME 511

Submitted to: Engr. Januh Pante Instructor

August 2, 2011

Potrebbero piacerti anche

- Networked Control System: Fundamentals and ApplicationsDa EverandNetworked Control System: Fundamentals and ApplicationsNessuna valutazione finora

- SCADADocumento12 pagineSCADAStephen Rey CaldeaNessuna valutazione finora

- SCADADocumento12 pagineSCADAStephen Rey CaldeaNessuna valutazione finora

- Preboard Exam in Ee 2Documento14 paginePreboard Exam in Ee 2Christian Benedict SolomonNessuna valutazione finora

- BY: Sayed Qaisar Shah Bs Telecom, Ccna, Cwna REG# A1DE-109004 DATE: 01-08-12Documento44 pagineBY: Sayed Qaisar Shah Bs Telecom, Ccna, Cwna REG# A1DE-109004 DATE: 01-08-12Muntaha Daudpota100% (1)

- Scada PDFDocumento7 pagineScada PDFTakudzwa MpofuNessuna valutazione finora

- SCADA - WikipediaDocumento66 pagineSCADA - WikipediaMazen Al-mahbashiNessuna valutazione finora

- Dcs Vs ScadaDocumento44 pagineDcs Vs ScadaSAYED QAISAR SHAH100% (1)

- Supervisory Control and Data Acquisition (SCADA)Documento16 pagineSupervisory Control and Data Acquisition (SCADA)محمد العراقيNessuna valutazione finora

- ScadaDocumento13 pagineScadamdayyub50% (6)

- Common System ComponentsDocumento24 pagineCommon System ComponentsPrabhat SharmaNessuna valutazione finora

- SCADA - Wikipedia, The Free EncyclopediaDocumento9 pagineSCADA - Wikipedia, The Free EncyclopediaDayanand Gowda KrNessuna valutazione finora

- Systems Concepts: SCADA Is TheDocumento5 pagineSystems Concepts: SCADA Is TheAfrNessuna valutazione finora

- Systems Concepts: SCADA Is TheDocumento5 pagineSystems Concepts: SCADA Is TheAfrNessuna valutazione finora

- Systems Concepts: SCADA Is TheDocumento5 pagineSystems Concepts: SCADA Is ThePHPNessuna valutazione finora

- SCADADocumento5 pagineSCADAapi-3765150100% (1)

- Systems Concepts: SCADA Is TheDocumento5 pagineSystems Concepts: SCADA Is TheAfrNessuna valutazione finora

- Distributed Control SystemDocumento6 pagineDistributed Control SystemmshahidshaukatNessuna valutazione finora

- PLC and Automation: Topic: Supervisory Control and Data AcquisitionDocumento16 paginePLC and Automation: Topic: Supervisory Control and Data AcquisitionKamalesh nNessuna valutazione finora

- Industrial Control SystemDocumento31 pagineIndustrial Control Systempraveen100% (1)

- Scad ADocumento8 pagineScad AYasir KhanNessuna valutazione finora

- SCADA Seminar ReportDocumento27 pagineSCADA Seminar ReportRakesh Hs67% (3)

- Scada: From Wikipedia, The Free EncyclopediaDocumento10 pagineScada: From Wikipedia, The Free EncyclopediaextremedownloadingsNessuna valutazione finora

- Scada: Common System ComponentsDocumento9 pagineScada: Common System Componentsperumal1312Nessuna valutazione finora

- Introduction To PLCDocumento59 pagineIntroduction To PLCAbdisa BegnaNessuna valutazione finora

- Distributed Control SystemDocumento31 pagineDistributed Control SystemAbdullah BarkaNessuna valutazione finora

- Introduction To AutomationDocumento20 pagineIntroduction To AutomationGourav Solanki100% (1)

- Scada: Systems ConceptsDocumento6 pagineScada: Systems ConceptsCalNessuna valutazione finora

- 1 What Does Scada MeanDocumento8 pagine1 What Does Scada MeanmwbmughalNessuna valutazione finora

- Distributed Control System: IndustryDocumento6 pagineDistributed Control System: Industryshakeel212Nessuna valutazione finora

- SCADADocumento11 pagineSCADApaluru sandeepNessuna valutazione finora

- Scada in Power Distribution SystemsDocumento10 pagineScada in Power Distribution SystemsMike AjayiNessuna valutazione finora

- EditDocumento64 pagineEditHagenimana ErnestNessuna valutazione finora

- The SCADA System For PipelinesDocumento12 pagineThe SCADA System For PipelinesCarlos ReNessuna valutazione finora

- Lecture 2 - Student VersionDocumento46 pagineLecture 2 - Student VersionMYLENE BUENONessuna valutazione finora

- Instrumentation and Control EngineeringDocumento2 pagineInstrumentation and Control EngineeringIan JadeNessuna valutazione finora

- Scada Seminar ReportDocumento20 pagineScada Seminar ReportPrakash Kumar76% (17)

- IasalumnoDocumento36 pagineIasalumnoFernando Leyva VegaNessuna valutazione finora

- Chapter - 6 - Scada IntroductionDocumento5 pagineChapter - 6 - Scada IntroductionMathavaraja JeyaramanNessuna valutazione finora

- Scada Hack SandhuDocumento6 pagineScada Hack SandhuSatinder Singh SandhuNessuna valutazione finora

- Securing SCADA InfrastractureDocumento13 pagineSecuring SCADA InfrastractureMiko QuijanoNessuna valutazione finora

- Industrial Control SystemDocumento7 pagineIndustrial Control SystemAbdullah ZubairNessuna valutazione finora

- DCS. Distributed Control System-1Documento43 pagineDCS. Distributed Control System-1Aditia C PurnomoNessuna valutazione finora

- Scada Fully 222Documento13 pagineScada Fully 222pedalcastroNessuna valutazione finora

- What Is SCADADocumento4 pagineWhat Is SCADASumit LunaychNessuna valutazione finora

- SCADA PaperDocumento15 pagineSCADA Paperprashantbgpatel1Nessuna valutazione finora

- Distributed Control SystemDocumento6 pagineDistributed Control Systemsimonliu_68Nessuna valutazione finora

- Control System: Types of Industrial Control SystemsDocumento19 pagineControl System: Types of Industrial Control SystemsAdnan Nawaz100% (2)

- SCADA - WikipediaDocumento62 pagineSCADA - WikipediaSudip MondalNessuna valutazione finora

- Scada in Power Distribution Systems SeminarDocumento2 pagineScada in Power Distribution Systems Seminarsumitsinha89100% (1)

- Research Paper On ScadaDocumento7 pagineResearch Paper On ScadamkmanojdevilNessuna valutazione finora

- Application of SCADA in PSDocumento5 pagineApplication of SCADA in PSTeju NookalaNessuna valutazione finora

- Scada IntroductionDocumento5 pagineScada IntroductionmuhammadmusakhanNessuna valutazione finora

- Scada Report of Seminar by Electronis and Electrical DepartmentDocumento22 pagineScada Report of Seminar by Electronis and Electrical DepartmentatharNessuna valutazione finora

- Vinamra TiwariDocumento16 pagineVinamra TiwariVinamra TiwariNessuna valutazione finora

- SCADA - WikipediaDocumento19 pagineSCADA - WikipediaPriscilla Felicia HarmanusNessuna valutazione finora

- Sarang R. Deshmukh Je T.P.S. Paras K53, KTC KoradiDocumento34 pagineSarang R. Deshmukh Je T.P.S. Paras K53, KTC KoradiVikrant OkeNessuna valutazione finora

- SCADADocumento2 pagineSCADASaad AhmedNessuna valutazione finora

- Paper On Scada (Supervisory Control and Data Acquisition)Documento14 paginePaper On Scada (Supervisory Control and Data Acquisition)Rama KarthikNessuna valutazione finora

- Iaa Unit 04Documento19 pagineIaa Unit 04SurajNessuna valutazione finora

- 6 3 AnswersDocumento4 pagine6 3 Answersshiwaisanxian100% (1)

- Biogas Technology: Construction, Utilization and Operation ManualDocumento52 pagineBiogas Technology: Construction, Utilization and Operation ManualDwi Cahyo NugrohoNessuna valutazione finora

- Project 3 FinalDocumento15 pagineProject 3 Finalapi-285419046Nessuna valutazione finora

- Metrolla Steels Industrial Visit ReportDocumento39 pagineMetrolla Steels Industrial Visit ReportSanjay R Nair100% (1)

- SLAManualDocumento187 pagineSLAManualfarhadhassan100% (1)

- This Worksheet Is Due by The Deadline Posted On Blackboard. This Is An Individual SubmissionDocumento2 pagineThis Worksheet Is Due by The Deadline Posted On Blackboard. This Is An Individual SubmissionAhsan AliNessuna valutazione finora

- Fundamentals of Rock MechanicsDocumento4 pagineFundamentals of Rock Mechanicsmaomao_vt890% (1)

- 24 - Article - $mbps Vs $MHZ Why Is This ImportantDocumento2 pagine24 - Article - $mbps Vs $MHZ Why Is This ImportantShiraz SiddiqNessuna valutazione finora

- Brock NarrowCorr (Sept 08)Documento44 pagineBrock NarrowCorr (Sept 08)betojulioNessuna valutazione finora

- ACI 232.1 Use of Pozzolans in ConcreteDocumento24 pagineACI 232.1 Use of Pozzolans in ConcreteSree Nivas100% (1)

- Benq mp510 Level1Documento212 pagineBenq mp510 Level1Juan Duarte Lopez100% (1)

- Mathcad - 01 - Sump TankDocumento10 pagineMathcad - 01 - Sump Tankisrar khan0% (1)

- Btree Practice ProbsDocumento2 pagineBtree Practice ProbsAbyssman ManNessuna valutazione finora

- Uahel NoticeDocumento2 pagineUahel NoticeChiranjivi ChudharyNessuna valutazione finora

- Kroo Subsonic WingDocumento8 pagineKroo Subsonic WingRod ManserNessuna valutazione finora

- SCELDocumento46 pagineSCELzacklawsNessuna valutazione finora

- Test PDFDocumento6 pagineTest PDFDr. L. Bhanuprakash Reddy100% (1)

- EMC PartDocumento67 pagineEMC PartFelix DiazNessuna valutazione finora

- DST FingerprintDocumento10 pagineDST FingerprintAli DMNessuna valutazione finora

- Size Matters: (Type The Document Subtitle)Documento16 pagineSize Matters: (Type The Document Subtitle)SamarthGoelNessuna valutazione finora

- Simplex Spray Systems OverviewDocumento3 pagineSimplex Spray Systems OverviewHuda LestraNessuna valutazione finora

- Empaque Espirometalicos PDFDocumento50 pagineEmpaque Espirometalicos PDFgregorioNessuna valutazione finora

- Tutorial Sheet 7Documento2 pagineTutorial Sheet 7Muhammad NidzwanNessuna valutazione finora

- FTB - Fire Alarm Boq Take Off - 10-08-2022Documento4 pagineFTB - Fire Alarm Boq Take Off - 10-08-2022Thai ChheanghourtNessuna valutazione finora

- Fizik F4 P2 (2016)Documento19 pagineFizik F4 P2 (2016)AHMAD FAISALNessuna valutazione finora

- O&M TransformerDocumento47 pagineO&M TransformerAshish PatelNessuna valutazione finora

- SS-7 May Refer To:: RFC 2719 RFC 2719Documento15 pagineSS-7 May Refer To:: RFC 2719 RFC 2719William GentryNessuna valutazione finora

- Assignment 1 Low Temperature and SuperconductivityDocumento3 pagineAssignment 1 Low Temperature and SuperconductivityNadhrah MuradNessuna valutazione finora

- Memristor Modeling in MATLAB®&SimulinkDocumento6 pagineMemristor Modeling in MATLAB®&Simulinkjoseamh69062247Nessuna valutazione finora

- Omfb MTC 11.12.23Documento2 pagineOmfb MTC 11.12.23obviousplatinum2Nessuna valutazione finora