Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fuel and Carburetor System Guide

Caricato da

Amirul Shahmin B. ZubirDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fuel and Carburetor System Guide

Caricato da

Amirul Shahmin B. ZubirCopyright:

Formati disponibili

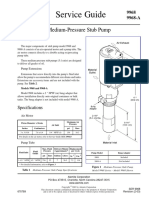

CONTENTS

FUEL SYSTEM FUEL COCK FUEL PUMP

CARBURETOR

.............................................................

6s 1 6- 2

.6- 3 .6_ 4 .6- 4 .6_ 6 6- 8 - 8 .6_ 9 - 9 .6_fO .6_11 .6_11 .6-Q .6-Q .6_13 .6_13 .6_14 .6_15 .6_17 .6_17 .6_18 ..6_18 .6_19

.................................................................

................................................................ .............................................................. CONSTRUCT/ON ................................

CARBURETOR

SPEC/F/CA T/ONS ..................................................... I.D. NO. LOCA T/ON ................................................... DIAPHRAGM SLOW AND PISTON OPERATION .....................6

SYSTEM

..................................................... SYSTEM...........................6

TRANSIENT MAIN

ENRICHMENT

SYSTEM

........................................................ .................................................. .....................................................

STARTER FLOAT

SYSTEM

SYSTEM

REMOVAL DISASSEMBL NEEDLE FLOAT

.............................................................. Y ........................................................ ................................... ...... .........................

VALVE INSPECTION HEIGHT ADJUSTMENT

REASSEMBLY BALANCING LUBRICATION

AND REMOUNTING CARBURETORS

... ......................... ......................... ......................... ......................... ......................... ........................ ...... .........................

.........

SYSTEM

.......................

O/L PRESSURE.

.............................

OlL FILTER .................................... OIL SUMP FILTER ........................ CHART

LUBRICATION

SYSTEM

6-1 FUEL AND

LUBRICATION

SYSTEM

FUEL SYSTEM

A vacuum operated fuel pump is used to supply fuel from the fuel tank to the carburetor. lower than the carburetor fuel bowl. In addition, conditions The pump is necessary as the fuel cock is mounted across rough terrain. the pump assures

an adequate supply of fuel to the engine under the steepest climbing

as well as while running

No. 2 carburetor

Fuel

Fuel pump

FUEL AND LUBRICATION

SYSTEM 6-2

FUEL COCK

A valve is provided With the valve ON at the top of the fuel cock (normal), lever and can switch over to OFF , ON and RES . the main passage opens. With the valve OFF , both holes close.

ON

position

RES

position

ON

WARNING: Gasoline is very explosive. Gaskets leakage. must Extreme care must be taken. with new ones to prevent fuel be replaced

INSPECTION AND CLEANING

If the fuel flow fuel strainer strainer with is dirty compressed with air. sediment power or rust, fuel will may result. not smoothly and loss in engine Clean the

6-3 FUEL AND

LUBRICATION

SYSTEM

FUEL PUMP

Vacuum vacuum pressure pulsations

is

from

the carburetor

intake

tract are used to operate

the pump diaphragm. the outlet

When to the

applied to the diaphragm,

fuel is drawn from the tank into the diaphragm chamber. As positive s back, pushing the fuel through

is applied,

the spring forces the diaphragm

carburetor. A series of check valves is used in the fuel flow route to allow the fuel to move in only one direction, through the pump body.

Fuel from

fuel

cock

Negat :ive

Fuel to carburetor

Positive

FUEL PUMP INSPECTION

In case of fuel leak at fuel pump or air leak into the fuel line, check the following * * Broken diaphragm of check valve replace the fuel pump assembly with a Loose screws on fuel pump * Malfunction items:

If any defect is found, new one.

FUEL

AND

LUBRICATION

SYSTEM

6-4

CARBURETOR

CARBURETOR CONSTRUCTION

No. 2 (FRO INT) CARBURETOR

( Syncronizing $ @ Throttle @ Throttle valve

cable

@ @ 8 spring @

Main jet Main Pilot jet holder jet plunger screw valve hose top cap valve spring

@ @ @ @

Jet needle Spacer E-ring Washer

stopper

plate

valve shaft return

@$ Starter Balance @$ Coasting

@$ Jet needle @$ Spring @ Piston @$ Needle

Needle

valve

0 @

Fuel hose Carburetor

valve jet

@$ Breather @ Seal ring @$ Piston

6-5 FUEL AND

LUBRICATION

SYSTEM

No.

1 (REAR)

CARBURETOR

@ Fuel hose @ Coasting @ @ @ 0 @ @ @ Drain Float Float Needle Filter Main jet valve stopper screw Needle valve @ Gasket pin valve screw

0 @ @ @ @ 0 $$

Pilot

jet screw valve stop screw valve valve plunger top cap shaft return spring

@ Breather @ Jet needle @ Spacer @ @ @ 0 @ E-ring Jet needle Washer Spring

hose stopper plate

Balance Throttle Throttle Throttle Pilot Starter

@I Throttle

screw

@$ Piston Needle

valve jet

@& Fartburetor

IS on valve spring

FUEL AND LUBRICATION SYSTEM 6-6

SPECIFICATIONS

CARBURETOR

ITEM Carburetor Bore SIX I.D. No. Idle r/min. Float height Main jet Main air jet Jet needle Needle jet Throttle Pilot jet By-pass Pilot outlet Valve seat Starter jet valve (M.J.) (M.A.J.) (J.N.1 (N.J.) (Th .V .) (P.J.) (8.P.) (P.0.) W.S.) (G.S.1 (P.S.)

I

CARBURETOR

SPECIFICATION E-02.04. 15,21,25,28,34 MIKUNI BDS36SS (No. 2) c t t in) 9.1 f 1 .O mm (0.36 f 0.04 in) #I20 t 5D49-3rd t c #40 0.8 mm x 3 PCS 1 .O mm t # 22.5 (PRE-SET) l-l/B turns back No.1 : (# 65). No.2: (I .2 mm) t 7 I Carburetor Bore size I.D. No.

SPECIFICATION ITEM type MIKUNI BS36SS (No. 1) 36 mm 45C20 1200 + 50 rlmin. E-33 MIKUNI BDS36SS (No. 2) t t t 9.1 + 1 .O mm (0.36 f 0.04 in) #/f?L?.i t

I

type

MIKUNI BS36SS (No. 1) 36 mm 45coo 1100f100r/min. 27.7fl.Omm I1 -09 20.04 # 132.5 1 .B mm 5FlOB-3rd

Idle rlmin. Float height Main jet Main air jet Jet needle Needle iet Throttle Pilot jet By-pass Pilot outlet Valve seat Starter jet valve (M.J.) (M.A.J.) (J.N.1 (N.J.) (Th.V.) (P.J.) (B.P.) (P.0.) (V.S.1 (G.S.) (P.S.) (P.A.J.)

27.7 * 1 .O mm (1.09 f 0.04 in) # 132.5 1.8 mm 5E73-1st

5D47-1

st

P-4 #115 #47.5 0.8 mm x 2PCS 0.8 mm 1.5 mm # 25 (PRE-SET) l-3/8 turns back No.1 : (# 70). No.2: (2.0 mm) 0.5 - 1 .O mm (0.02 - 0.04 in) 0.5 - 1 .O mm (0.02 - 0.04 in)

P-q

#125 #Y 0.8 mm x 2PCS 0.8 mm 1.5 -# 11,111

P-7 _

# 110 #YU 0.8 mm x 3PCS 1 n--11,111 I.

t

cl= L<

# 22.5 (PRE-SET) No. 1: (#65), No. 2: (1.2 mm) t

I

Pilot screw Pilot air jet Throttle

Pilot screw Pilot air jet Tlrr

I II,

(PRE-SE.1 r, I No. 1: (# 65). hln 7. , ,? mm) ,.. &. \L.U ~___( 0.5 - 1 .O mm (0.02 - 0.04 in) 0.5 - 1 .O mm (0.02 - 0.04 in)

1

(P.A.J.)

Throttle

cable play

cable play

Choke cable play t

L

Choke cable play

t

I

CARBURETOR

SPECIFICATION ITEM E-03 Carburetor Bore size I.D. No. Idle r/min. Float height Main jet Main air iet Jet needle Needle jet Throttle Pilot iet By-pass Pilot outlet Valve seat Starter iet valve (M.J.) (M.A.J.) (J.N.) (N.J.1 (Th .V .) 1P.J.) (B.P.) (P.0.) (V.S.1 (G.S.) 1200 type MIKUNI BS36SS (No. 36 mm 45ClO + 50 rlmin. in) MIKUNI BDSSBSS (No. 2) t t c 9.1 * 1 .O mm (0.36 * 0.04 in) # ir_ i ? t 5D47-1 p st

CARBURETOR

1)

27.7fl.Omm (1.09 * 0.04 # l3Z i

1.8 mm 5E72-1 st P-7 #I25 #Yi 0.8 mm x 2PCS 0.8 mm 1.5 mm #25

# 110 #YU 0.8 mm x 3 PCS 1.0 mm t #22.5

No. 2: (1.2 mm) Throttle cable play 0.5 - 1 .O mm (0.02 - 0.04 in) 0.5 - 1 .O mm (0.02 - 0.04 inl t t

Choke cable play

6-7 FUEL AND LUBRICATION

SYSTEM

CARBURETOR

SPECIFICATION ITEM Zarburetor Bore size I.D. No. Idle rlmin. Float height Main iet Main air jet Jet needle Needle jet Throttle PIlot jet Bypass Pilot outlet Valve seat Starter jet Pilot screw valve fM.J.1 (M.A.J.) (J.N.) (N.J.) (Th.V.) (P.J.) (B.P.1 (P.0.) (V.S.1 (G.S.) (P.S.) type MIKUNI BS36SS (No. 36 mm 4x40 1100f100r/min. 27.7fl.Omm (I .09 kO.04 in) E-01,16

CARBURETOR

I

Carburetor t t t

SPECIFICATION ITEM

I

U-woe

I

of E-22 MIKUNI BDS36SS (No. 2)

I)

MIKUNI fBDS36SS (No. 2)

type

MIKUNI BS36SS (No.

I)

9.1 + 1 .O mm (0.36 k 0.04 in) # 122.5 t 5D49-3rd t t #40 0.8 mm x 3PCS 1 .O mm t # 22.5 (PRESET) l-l /8 turns back Thrnttle Pilot jet Bypass I Pilot outlet Valve seat Starter jet valve

1 /

ni 135

1.8 mm 5Fl OS-3rd P-4 #I15 rry47.5 0.8 mm x 2PCS 0.8 mm 1.5 mm f 25 (PRESET) l-l /2 turns back

I I

fM.J.1 (M.A.J.) fJ.N.1 (N.J.) fTh.V.l fP.J.1 (B.P.) fP.0.) (V.S.) (G.S.) (P.S.) fP.A.J.1

k 122.5

t

5D49-3rd P-6

I

1 1 I

#I15

t

#40 0.8 mm x 3PCS I 1.0 mm t # 22.5 (PRESET) l-l/16 turns back) No. 1: (# 651, No. 2: (I .2 mm) t t I

j: 47.5

0.8 mm x 2PCS 0.8 mm 1.5 mm ti 25 (PRESET) 1 -l/8 turns back No. 1: (3-f 70). No. 2: (2.0 mm) 0.5 - 1 .O mm (0.02 - 0.04 in) 0.5 - 1 .O mm (0.02 - 0.04 in)

Pilot screw Pilot air jet Throttle

__::::_

CARBURETOR

ITEM 1 Carburetor Bore size I.D. No. 1 Idle rimin. tvpe +Sf=$$;N

cable play

Choke cable play

CARBURETOR

SPECIFICATION ITEM E-17 MIKUNI BS36SS (No. I) 36 mm 45070 1100 * 100 r/min. MIKUNI BDSBBSS (No. 2) t t t 9.1 i- 1 .O mm (0.36 f 0.04 in) # 122.5 t 5D49-3rd P-6 I + 1 I

MIKUNI BS36SS (No. I) 36 mm 45050

MIKUNI BDS36SS (No. 2) t t

Carburetor Bore size I.D. No. Idle rlmin. Float height Main jet Main air jet Jet needle

type

11100~100r/min.

27.7 f 1 .O mm (I .09 * 0.04 in) (M.J.) (M.A.J.) (J.N.) (N.J.) fTh.V.) (P.J.) (B.P.) fP.0.) (VS.) (G.S.) (P.S.) (P.A.J.)

I Needle iet I Throttle Pilot jet By pass Pilot outlet Valve seat Starter iet valve

(N.J.) fTh.V.) (P.J.) (B.P.) (P.0.) (VS.) 1G.S.)

/ 1

P-4 #I15 847.5 0.8 mm x 2PCS 0.8 mm

I I

+ t

#40 0.8 mm x 3PCS 1.0 mm t #22.5

Needle jet Throttle Pilot iet By-pass Pilot outlet Valve seat Starter iet valve

1 j / /

/

#I35 1.8 mm 5Fl08-3rd P-4 #I15

# 47.5

0.8 mm x 2PCS 0.8 mm 1.5 mm #25 (PRESET) l-3/8 turns back No. 1: (# 70), No. 2: (2.0 mm) 0.5 - 1 .O mm (0.02 - 0.04 in) 0.5 - 1 .O mm (0.02 - 0.04 in)

I /

# 40

0.8 mm x 3PCS 1 .O mm t # 22.5 (PRESET) l-114 turns back No. 1: (# 65). No. 2: (I .2 mm) t t

I 1

j 1

1.5 mm #25

Pilot screw Pilot air jet Throttle cable play 0.5 - 1 .O mm (0.02 - 0.04 in) 0.5 - 1 .O mm (0.02 - 0.04 in) Throttle

t t

cable play

Choke cable play

Choke cable play

FUEL

AND

LUBRICATION

SYSTEM

6-8

I.D. NO. LOCATION

Each carburetor has I.D. Number 0 stamped on the carburetor body according to its specifications.

DIAPHRAGM AND PISTON OPERATION

The carburetor matically orifice Rising is a variable-venturi valve type, whose venturi moves according pressure cross section into area is increased pressure or decreased autoon the down@ through an by the piston @ provided negative @ which valve 0. the spring from @ force, increasing. causing the piston Thus, air velocity optimum valve @ to rise to increase the in the venturi ratio of fuel/air passage is kept mixture. to the negative present chamber

stream side of the venturi

@I. Negative

is admitted

the diaphragm

in the piston

pressure

overcomes

said area and thus prevent relatively constant

the air velocity

for improved

fuel atomization

and for securing

Negative

pressure

6-9 FUEL AND LUBRICATION

SYSTEM

SLOW SYSTEM

This system from (#I pilot float and #2) supplies chamber 0. fuel during engine rich with operation jet 0 with throttle valve @ closed or slight air coming pilot 8. 0. passage to pilot The remainder opened. pilot screw 0. The fuel air jets A part by @ is metered by pilot where it mixes with in through

This mixture, is discharged

fuel, then goes up through pilot

of the mixture

into the main bore out of by-pass ports out into the main bore through outlet

is then metered

screw @ and sprayed

TRANSIENT ENRICHMENT SYSTEM

This transient generate normal proper enrichment joining system is a device which the throttle upper keeps fuel/air mixture suddenly inlet ratio during constant in order not to For _ unstable operation, fuel/air combustion ratio. when grip is returned part of carburetor valve is suddenly The valve constant @ which air passage. by varying the fuel/air mixture ratio by controlhigh speed driving.

of the air from

side to pilot with

air passage obtains pressure generatcloses an

mixture

But if the throttle to a diaphragm. condition

closed, a large negative interlocks

ed on cylinder This

side is applied

the diaphragm

air passage, thus, the pressure flows ing air flow in the pilot circuit.

out to the pilot

is system to keep the combustion

Pilot jet

@q

Fuel/Air s Fuel

mixture

FUEL AND

LUBRICATION

SYSTEM

6-10

MAIN SYSTEM

As throttle Consequently Meanwhile, 0, in which valve @ is opened, in float then engine speed rises, and this increases negative @ is metered through by main jet 0, main air jet between @to pressure in the venturi @. the piston the fuel fuel it mixes with into the venturi valve @ moves upward. chamber and the metered fuel enters needle jet 0, and is fuel the air admitted passes through @, in which form an emulsion. @ and jet needle by the engine. which the emulsified

The emulsified discharged Mixture must flow

the clearance in needle jet 0;

needle jet

it meets main air stream being drawn the clearance position. through ultimately on throttle

proportioning

is accomplished

in large or small, depending

Throttle valve (Q

..&$:~~~~~$& ::::,

.:$$$:.:.:.. . . . . . . .,....:,:.:

:.:,B

..../....:.. ,...,

,:::;::I :.

::?::

,..,

Fing

jet

.-..

--e---_

w-w--

-_ __-

-_ o-

-_ 0

Air Fuel/Air mixture

\

Main

int m

6-11

FUEL AND

LUBRICATION

SYSTEM

STARTER SYSTEM

Pulling Starter up the starter shaft jet @ 0, fuel is drawn into the starter circuit from the float chamber 0. meters this fuel, which then flows into starter rich in fuel content, reaches starter plunger through a passage pipe @ and mixes with the air coming from the float chamber @ . The mixture, @ The and mixes two extending proper mixture bore. again with the air coming of fuel starting with

from main bore. successive mixings mixture for air are such that when the @ into the main is produced

fuel/air

is sprayed out through starter outlet

FLOAT SYSTEM

Floats @ and needle valve @ are associated with the same 0 move up and down, the 0, floats @ are up and 0. As the fuel mechanism, so that, as the floats

needle valve @ too moves likewise. When fuel level is up in float chamber needle valve this condition, @ remains pushed up against valve seat. Under @ go down and needle valve @ unseats itself needle valve @ admits and shuts off fuel altera practically constant fuel level inside the

cr) ( \ /-fj carwretor

no fuel enters the float chamber

level falls, floats In this manner, nately float chamber 0.

to admit fuel into the chamber 0. to maintain

eedle 0

valve

lump

FUEL AND LUBRICATION

SYSTEM 6-12

REMOVAL 0 Refer to page

l

3-3. No. 1 and No. 2 carburetors attached along with the

Remove

the

synchronizing CAUTION:

cable 0

to the carburetors.

Be sure to identify No. 2 carburetor,

each removed parts as to its location, so that each will be restored

and

lay the parts out in groups designated as No. original location during assembly.

1 carburetor, to the

No. 2 (FRONT) @ : Syncronizing cable @ : Syncronizing cable adjuster @$ : Throttle cable (No. 2 carb.) @ : Throttle cable adjuster (No. 2 carb.) 0 : Throttle cable (No. 1 carb.) @ : Throttle cable adjuster (No. 1 carb.) 8 ; TrottIe stop screw crew 0 : Fuel hose

NOTE: Do not turn the throttle CAUTION: Do not turn the screw 0 Once removing a throttle the two carburetors. of the No. 2 carburetor. cable or the synchronizing cable or a carburetor body, it is necessary to balance cable adjusters @I , @ and the synchronizing cable adjuster @I .

DISASSEMBLY

l

Disassemble

the carburetors

as shown

in the illustrations

on pages 6-4 and 5.

6-13

FUEL

AND LUBRICATION

SYSTEM

Check following * Pilot jet * Main jet * Main air jet * Pilot air jet

items for any damage or clogging. * Diaphragm * Gasket * Throttle valve shaft oil seals * Pilot outlet and by-pass holes hole * Fuel hose * Coasting valve jet

* Needle jet air bleeding * Float

* Needle valve mesh and O-ring

* Starter

NEEDLE VALVE INSPECTION

If foreign flow. limits, sticks, worn with matter is caught will between the valve seat and the needle, the gasoline similar continue will occur. flowing and cause it to overthe permissible if the chamber. it together needle Clean with

If the seat and needle are worn trouble will the gasoline chamber as shown compressed not flow

beyond

Conversely, gasoline. replace

into the float

the float available

and float in the air.

parts with

If the needle is chamber

illustration,

seat. Clean

the fuel

passage of the mixing

FLOAT HEIGHT ADJUSTMENT

To check the float float just in contact with height, invert the carburetor body, with the arm kept free, measure the height @ while float arm is

needle valve by using calipers.

Float height

No. 1

27.7 f 1 .O mm (1.09 f 0.04 in) . 9.1 f 1.0 mm (0.36 f 0.04 in)

I

No. 2

REAR CARBURETOR

09900-20102

: Vernier

calipers

FRONT CARBURETOR

Bend the tongue value.

as necessary to bring the height

@ to this

FUEL AND

LUBRICATION

SYSTEM

6-14

REASSEMBLY AND REMOUNTING

Reassemble Pay attention

l

and remount

the carburetors points:

in the reverse order

of disassembly Align

and remounting. to the following @ of the needle jet with the pin @ and

the groove

replace it.

Place the tongue properly.

of diaphragm

to the carburetor

body

When holes.

installing

the

coasting

valve

to the

body,

align

the

Set each throttle meets the foremost

valve

in such a way that @I.

its top end

by-pass

6-15 FUEL AND LUBRICATION SYSTEM

BALANCING CARBURETORS

No. 2 (FRONT)

: Synchronizing cable : Synchronizing cable adjuster : Throttle cable (No. 2 carb.) : Throttle cable adjuster (No. 2 carb.) : Throttle cable (No. 1 carb.) : Throttle cable adjuster (No. 1 carb.) : Throttle stop screw : Screw : Fuel hose

No. 1 (REAR)

CAUTION: Once removing the synchronizing @ , 0 or carburetors, carburetors. IN CASE @: As the first step, calibrate follows: 09913-13121 09913-13140 : Carburetor : Adapter for warminspection @ balancer the carburetor balancer gauge, as OF CHANGING THE SYNCHRONIZING CABLE cable @ or throttle cables it is necessary to balance the two

Start up the engine and run it in idling condition ing up. Stop the warm-up screw @ with gasket. Connect engine. Remove the vacuum for No. 2 carburetor

and install the adapter

one of the four rubber hoses of the balancer gauge stop screw @I.

to this adapter, and start up the engine, and keep it running at idle speed by turning throttle NOTE: The idle speed is different and 7.) among the countries. (See pages 6-6

FUEL

AND LUBRICATION SYSTEM 6-16

Turn

the air screw

@ of the gauge so that the vacuum hose will bring the steel ball line 0. the steel ball Turn stays steady the adapter

act@ in

ing on the tube of that the tube to the center After center nect making the next sure

that

at the

line, disconnect

the hose from

and conhas

hose to the adapter.

air screw to bring

the other

steel ball to the center

line. Now the balancer

been calibrated. Remove Connect the vacuum inspection with balancer screw @ for No. 1 carburegasket. gauge hose to their respec-

tor and install tive adapters.

the adapter

each calibrated

Warm up the engine, Under two screw this condition, level at the center carburetors 0 and turn

and keep it running see if the two line, as they should, if not,

at idle speed. to signify loosen that the stop

steel balls stay equally the lock nut level line by

are in balance:

the synchronizing to bring

adjuster

@I and the throttle

the steel balls to the center at idle speed.

keeping the engine running

IN CASE OF CHANGING As the 1500

l l

THE THROTTLE the carburetor

CABLE balancer

@, 0: gauge at the

first

step, calibrate cable.

r/min,

as the same manners

of the case of changing

synchronizing Temporarily Equalize by turning nuts. NOTE:

remove the No. 1 carburetor. the throttle cables inner length the adjusters @I ,O after

at the connector loosening the lock

Be careful not to twist the throttle Throttle carburetor 6-6 and 7.)

cables 0,

0.

cable adjuster @ can not be turned when the No. 1 is installed to the engine. among the countries. (See pages

The idle speed is different

6-17 FUEL AND LUBRICATION

SYSTEM

Install which turning Under

the No. 1 carburetor is calibrated the throttle this condition, level

and set the carburetor

balancer by

at 1500 r/min. and keep it running grip. see if the two line, cable as they adjuster if not, steel balls stay equally to signify the two loosen the lock nut and @ to adjust the throttle level line. should, at 1500 r/min

Warm up the engine,

at the center carburetors turn valve setting NOTE: When equalizing

are in balance:

the throttle

to bring the steel balls to the center

the throttle

cables inner length,

make sure -

that each throttle cable have enough play. IN CASE OF CHANGING When changing synchronizing carburetor, forming THE CARBURETORS it is necessary to adjust IN CASE to remove the the THE cables. So once removing OF CHANGING

the carburetors, cable and throttle necessary and

it becomes

the cables by perOF CHANGING

above two

steps (i.e. IN CASE CABLE CABLE).

SYNCHRONIZING THE THROTTLE CAUTION :

In this case first adjust the synchronizing

cable.

LUBRICATION SYSTEM

OIL PRESSURE

Check the oil level in the inspection pressure in the following Install Install figure. Warm up the engine as follows: Summer Winter After 10 min. at 2000 r/min. 20 min. at 2000 r/min. warming up operation, increase below: the engine speed to and read the oil pressure gauge. manner: bolt. shown in the 0. Remove the oil pressure inspection the oil pressure adapter the oil pressure window and check the oil

gauge in the position

3000 r/min,

The oil pump pressure is specified OIL PRESSURE SPECIFICATION

Above 350 kPa (3.5 kg/cm*, Below 650 kPa (6.5 kg/cm*, Oil temp. at 60C (140 F)

50 psi) 92 psi) at 3000 r/min

FUEL AND LUBRICATION SYSTEM 6-16

CAUTION: The recommended low-40 motor oil. : Oil pressure gauge : Oil pressure gauge (meter) : Oil pressure gauge adapter engine oil is, API classification SE or SF,

0991574510 09915-77330 09915-74530

NOTE: Engine oil must be warmed up to 60 C 1140 F) when checking the oil pressure. If the oil pressure is lower or higher than the specifications, oil

several causes may be considered. * Low oil pressure is usually leakage from * High tion the result of clogged oil filter, of these items. caused by a engine oil which installais the oil passage way, is usually damaged oil seal, a defec-

tive oil pump or a combination oil pressure of the oil filter too heavy a weight,

a clogged oil passage, improper or a combination of these items.

OIL FILTER

Refer to page 2-8 for installation procedures.

OIL SUMP FILTER

At the same time wash the oil screen sump filter cap. Check to be sure that the strainer is free from any sign of rupture

and wash the strainer

clean periodically. procedures.

Refer to page 3-46 for installation

6-19

FUEL AND

LUBRICATION

SYSTEM

LUBRICATION

SYSTEM

CHART ) EXHAUST ROCKER ARM SHAFT i_-

Epy

INTAKE

Ii

J:

ROCKER ARM

1 CAMSHAFT 1. JOURNAL ) 1

CAMSHAFT

R. JOURNAL

;;;I$ 1

CLUTCH

1_I

1. CRANK JOURNAL f

R. CRANK JOURNAL t

MAIN GALLERY

GEAR AND BEARINGS

/ DRIVESHAFT

rOlL

PANZ

elf7

FUEL

AND

LUBRICATION

SYSTEM

6-20

Potrebbero piacerti anche

- FZR400 Service Manual Ch23 CorrectedDocumento76 pagineFZR400 Service Manual Ch23 CorrectedJoaquin PrietoNessuna valutazione finora

- Eaton: Medium Duty Piston PumpDocumento20 pagineEaton: Medium Duty Piston PumpFernando SabinoNessuna valutazione finora

- FZR400 Service Manual Ch23Documento76 pagineFZR400 Service Manual Ch23Hector Gomez Salazar100% (1)

- Part Catalog ScoopyDocumento54 paginePart Catalog Scoopymasbianto100% (1)

- Manual GA1 GA2 G3SS G3TR G4TRDocumento182 pagineManual GA1 GA2 G3SS G3TR G4TRKidKawie76% (17)

- 4D56Documento106 pagine4D56Nery Bardales Leon0% (1)

- MT-TITLEDocumento66 pagineMT-TITLERolfs Almonte DiazNessuna valutazione finora

- 11B 1.5L OverhaulDocumento51 pagine11B 1.5L OverhaultakedashindenNessuna valutazione finora

- Manual 12rDocumento198 pagineManual 12rnatalia jerez80% (5)

- Componentes Hidráulicos (SK210 Y SK330)Documento38 pagineComponentes Hidráulicos (SK210 Y SK330)alexis reyes100% (35)

- AlemiteDocumento10 pagineAlemiteGer DclNessuna valutazione finora

- T DynamoDocumento22 pagineT DynamoDian HidayatiNessuna valutazione finora

- FS120-FS200-FS300-FS350-FS400-FS450-FR350-FR450 Service ManualDocumento63 pagineFS120-FS200-FS300-FS350-FS400-FS450-FR350-FR450 Service Manualnik_nicholson_189% (18)

- Part Description Daihatsu 1Documento86 paginePart Description Daihatsu 1xxxvvvyyywww100% (3)

- 160.75-RP1 (210) - Yk (G)Documento92 pagine160.75-RP1 (210) - Yk (G)JayashtonNessuna valutazione finora

- RD Engine ManualDocumento23 pagineRD Engine Manualmotopi2271% (7)

- Turbocharger Maintenance StandardsDocumento17 pagineTurbocharger Maintenance StandardsanggieNessuna valutazione finora

- CH8 FuelSystem 05 Up TRX450R ER 8Documento26 pagineCH8 FuelSystem 05 Up TRX450R ER 8PD DiagnosticosNessuna valutazione finora

- Engine Mechanical PDFDocumento115 pagineEngine Mechanical PDFAndrey GladyshevNessuna valutazione finora

- IR Grease Pump Catalouge LM2250E-XX-B3-EnDocumento4 pagineIR Grease Pump Catalouge LM2250E-XX-B3-Enankit.jhawarNessuna valutazione finora

- Mitsubishi DelicaDocumento104 pagineMitsubishi DelicaGabriel BalcazarNessuna valutazione finora

- Yamaha XTZ750 Super Tenere Service ManualDocumento425 pagineYamaha XTZ750 Super Tenere Service ManualDhery Prieto Barrientos100% (2)

- Cummins Sec 7Documento28 pagineCummins Sec 7SpectrumRaijin0% (1)

- Honda Xr250r Service Manual Repair 1986-1995 Xr250Documento258 pagineHonda Xr250r Service Manual Repair 1986-1995 Xr250ronald.197893% (15)

- A46de A46dfDocumento227 pagineA46de A46dfddreidzer100% (1)

- Impreza Repair ManualDocumento656 pagineImpreza Repair Manualpsiefer100% (1)

- Data Sheet Tag 180-Pu-011eDocumento8 pagineData Sheet Tag 180-Pu-011eSarah PerezNessuna valutazione finora

- R32.engine - Manual Ca18i, Rb20e, Rb20de, Rb20det, Rb25de & Rb26dettDocumento580 pagineR32.engine - Manual Ca18i, Rb20e, Rb20de, Rb20det, Rb25de & Rb26dettNick Viccajee100% (1)

- Brother PT-9400 Parts ManualDocumento17 pagineBrother PT-9400 Parts ManualDuplessisNessuna valutazione finora

- 1LX100 SchematicDocumento4 pagine1LX100 Schematicab5951Nessuna valutazione finora

- D342 vehicular engine specifications guideDocumento47 pagineD342 vehicular engine specifications guideSertecmapQuetzaltenango100% (10)

- 0 17 018 PDFDocumento42 pagine0 17 018 PDFjoekid12Nessuna valutazione finora

- Homelite XL Super 2 Chainsaw Parts ManualDocumento12 pagineHomelite XL Super 2 Chainsaw Parts ManualGus McGrath100% (1)

- 3 Frame Piston Pump Models: SpecificationsDocumento4 pagine3 Frame Piston Pump Models: SpecificationsOl Em KarNessuna valutazione finora

- YZ250'1987Documento50 pagineYZ250'1987Nuno FerreiraNessuna valutazione finora

- H1000e K FJDocumento8 pagineH1000e K FJSyarif HidayatullahNessuna valutazione finora

- Unit 1. Overview 16112019Documento43 pagineUnit 1. Overview 16112019motores4297Nessuna valutazione finora

- Model E & Pe RegulatorsDocumento5 pagineModel E & Pe RegulatorsMiguel Angel NajeraNessuna valutazione finora

- Havoc 300 Engine Service ManualDocumento72 pagineHavoc 300 Engine Service ManualJohannes Du PlessisNessuna valutazione finora

- Roboshot Midjet MK4Documento312 pagineRoboshot Midjet MK4ctorres_505746100% (1)

- Service Manual 300050007500 PermconDocumento19 pagineService Manual 300050007500 PermconMiguel Angel Santos PintadoNessuna valutazione finora

- 4g93 Lancer EngineDocumento52 pagine4g93 Lancer Enginecsberny98% (45)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDa EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Combustion Engines: An Introduction to Their Design, Performance, and SelectionDa EverandCombustion Engines: An Introduction to Their Design, Performance, and SelectionNessuna valutazione finora

- Motorcycle, Solo (Harley-Davidson Model WLA)Da EverandMotorcycle, Solo (Harley-Davidson Model WLA)Nessuna valutazione finora

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsDa EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNessuna valutazione finora

- Helicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsDa EverandHelicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsValutazione: 5 su 5 stelle5/5 (1)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallDa EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallValutazione: 4 su 5 stelle4/5 (8)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeDa EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNessuna valutazione finora

- Green Process EngineeringDocumento49 pagineGreen Process EngineeringAmirul Shahmin B. ZubirNessuna valutazione finora

- SOLAR ENERGY InformationDocumento15 pagineSOLAR ENERGY InformationAmirul Shahmin B. ZubirNessuna valutazione finora

- Solar Energy CompleteDocumento6 pagineSolar Energy CompleteAmirul Shahmin B. ZubirNessuna valutazione finora

- Introduction to MetallographyDocumento19 pagineIntroduction to MetallographyAmirul Shahmin B. ZubirNessuna valutazione finora

- Cement Retainer 103387896 PDFDocumento1 paginaCement Retainer 103387896 PDFhitesh kumarNessuna valutazione finora

- 4-11 Fuel Control and Refuel ProcedureDocumento5 pagine4-11 Fuel Control and Refuel ProcedureOlubi FemiNessuna valutazione finora

- IP 15 Calculations in Support of IP15 The Area Classification Code For Petroleum Installations November 2001Documento63 pagineIP 15 Calculations in Support of IP15 The Area Classification Code For Petroleum Installations November 2001Yonatan Cristie100% (2)

- Astm Astm d2887 PDFDocumento20 pagineAstm Astm d2887 PDFharNessuna valutazione finora

- Bunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Documento1 paginaBunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Clarcy CrawfordNessuna valutazione finora

- Fuel RecommendationsDocumento7 pagineFuel RecommendationsLaiqNessuna valutazione finora

- Study and Testing of CI Engine by Rope Brake DynamometerDocumento21 pagineStudy and Testing of CI Engine by Rope Brake DynamometerGautam33% (3)

- Presentation On IOCL - PPT On SUMMER INTERNSHIP PROJECTDocumento15 paginePresentation On IOCL - PPT On SUMMER INTERNSHIP PROJECTMAHENDRA SHIVAJI DHENAK33% (3)

- Safe Use of Oxygen Fuel Gas EquipmentDocumento4 pagineSafe Use of Oxygen Fuel Gas Equipmentzam110Nessuna valutazione finora

- Difference Between Petrol and Diesel EngineDocumento6 pagineDifference Between Petrol and Diesel EngineWaiming Tan100% (2)

- Technical Data Technical Data: BX50 SeriesDocumento6 pagineTechnical Data Technical Data: BX50 SeriesadravidNessuna valutazione finora

- ASTM PruebasDocumento9 pagineASTM PruebasCarlos Olivares ZegarraNessuna valutazione finora

- Dictionary For LubricationDocumento64 pagineDictionary For LubricationChristine Sta RomanaNessuna valutazione finora

- DPF ManualDocumento16 pagineDPF Manualგიორგი კირჩხელი100% (1)

- Schenck Process Americas S.A.S / FCT Combustion Pty: Ficem Apcac Costa Rica 2012Documento22 pagineSchenck Process Americas S.A.S / FCT Combustion Pty: Ficem Apcac Costa Rica 2012Anonymous phm7cBGtNessuna valutazione finora

- Sheet 2Documento5 pagineSheet 2Bishoy EmileNessuna valutazione finora

- Chapter 11 Introduction To Organic Chemistry: HydrocarbonsDocumento14 pagineChapter 11 Introduction To Organic Chemistry: HydrocarbonsKatie-Nicole ChantalNessuna valutazione finora

- Enhanced Force Feed Lubrication System Upgrade GuideDocumento4 pagineEnhanced Force Feed Lubrication System Upgrade GuideIl Il Il IlNessuna valutazione finora

- WLPGA Annual Report 2016 PDFDocumento44 pagineWLPGA Annual Report 2016 PDFSanjai bhadouriaNessuna valutazione finora

- Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company Decant OilDocumento11 pagineSafety Data Sheet: 1. Identification of The Substance/Preparation and of The Company Decant OilZakyAlFatonyNessuna valutazione finora

- Service Manual: Chassis & Mast MC/FCDocumento30 pagineService Manual: Chassis & Mast MC/FCjulinugroho susantoNessuna valutazione finora

- 3A Total Feed of 200 MolDocumento2 pagine3A Total Feed of 200 Molgebre0% (1)

- Hydroprocessing Catalyst EvaluationDocumento15 pagineHydroprocessing Catalyst EvaluationKashifNessuna valutazione finora

- Mind Maps For Secondary Science Volume 1Documento1 paginaMind Maps For Secondary Science Volume 1ravichandran100% (1)

- Submitted in Partial Fulfilment For The Award of The Degree ofDocumento27 pagineSubmitted in Partial Fulfilment For The Award of The Degree ofJaymit PatelNessuna valutazione finora

- Autonext Study Material 1 (Engine) PDFDocumento23 pagineAutonext Study Material 1 (Engine) PDFAbhishek Jain100% (1)

- Green Engine PPT 2Documento23 pagineGreen Engine PPT 2asra tabassumNessuna valutazione finora

- API and ISO Gas-Lift Recommended Practices PDFDocumento47 pagineAPI and ISO Gas-Lift Recommended Practices PDFcarlosNessuna valutazione finora

- Servo Coat 120Documento1 paginaServo Coat 120BhaveshBalasNessuna valutazione finora

- Api 653Documento1 paginaApi 653Mahesh KumarNessuna valutazione finora