Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Patente Lintec

Caricato da

diego.peinado8856Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Patente Lintec

Caricato da

diego.peinado8856Copyright:

Formati disponibili

ABSTRACT

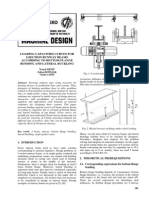

The screen has a feed device (37) at one front end of the drum rotating around its longitudinal axis, and an outlet (30) for conditioned material at the other. The second front end lies in a circular area with ring filter sections of differing mesh widths, 5,10,20,30 mm, surrounding the drum. There are silos (38) underneath the drum to receive filter material of different particle size. At the second end of the drum, there is a stationary collection area (30), in which either grainy material from above (33) or conditioned material (39) from inside the drum passes. At the bottom of the collection area (30), there is an opening, which can be shut by a flap (31), linked to another silo (36). Beside the collection area, the drum is shaped as a radially wider space (34) with shovels (32) to lift and transport the grainy material to the ring filter sections.

DESCRIPTION

The invention relates to a drum to condition or grading of granular material, particularly for road construction, with an input device on a first front end of about their lying longitudinal axis of the rotating drum and an output of conditioned goods at the second front end into an annular space, the formed by the drum concentrically surrounding ring sieve sections with different, from the second to the first end face increasing mesh sizes, and with the underside of the drum arranged in silos to hold screenings of different particle size. Such a drum is known (DE-OS 41 21 585) and serves to condition the one hand, granular material, for example by a torch applied to the granular material, and sort on the other hand, the individual parts of the granular material according to their size. However, the road is also granular material that was already installed and should be used together with new material again. This was already using material consists essentially of granular material that is coated on the surface with asphalt and bitumen, and therefore the drum of the type mentioned above are not used to classify too good with this kind of sticky surface in terms of size. But this just recycling or reprocessing of this asphalt is an important way of sparing use of nature and the environment. The invention is based on the task of designing a drum of the type mentioned, are that asphalt mixes and the like, classified and processed for further use in combination with other substances. This is achieved by the characterizing part of claim mentioned features. The drum according to the invention is suitable for two modes, one for the normal operation so far of conditioning and classification of granular material, the other for the collection of pre-built granular material for further processing. In the second operating state, the crushed asphalt outside the flash range, but given the side burner into the drum and passes from there into a special silo. The crushed asphalt is not reached on the screens, so that there can be no bonding and no wear. There is also the possibility of granules in the drum and the outer wall of the primary rock fabrics to mix and heat gently. Water vapor and any bitumen fumes can pass through the burner flame and be disposed of through a filter system. At higher amounts of asphalt, an indirectly-heated drums is used in parallel, which works with the hot exhaust gas from the main drum. This can take up to 50% material will be added and still achieve low emissions. The invention will be described with reference to the drawing, for example. The single FIGURE of the drawing shows a diagrammatic side view of a drum according to the invention. The drum shown in the figure is supplied via a conveyor belt 37 from the right-hand end. The material travels in a substantially horizontal direction to the other end of the drum, where a burner is installed th 35 Thereafter, the conditioned material from entering the ring sieve areas which have been schematically indicated by 5, 10, 20 and 30 mm. Underneath is the silos are 38 screens, filled in the classified material is, which can then be removed downwardly. At the burner end of the drum 34 is equipped with an extension, which are located on the inner circumference 34 of the extension blades 32 which are arranged diagonally, and ensure that the material found there, moved back to the ring sieve sections. At the burner end of the drum is constructed with a collecting section 30, which leads to its lower end by a flap 31 operable to another silo 36th In the position shown, the flap 31 in the open position, so that material that has accumulated in region 30, can enter the silo 36th If one of these in days of operation

from outside one of 33 reclaimed asphalt granules, so it collects in the lower part of the collecting th section 30 and enters the silo 36

CLAIMS

Drum to condition or grading of granular material, particularly for road construction, with an input device(37) at a first end face of oneself to their lying longitudinal axis of the rotating drum and an output (30) of conditioned goods at the second front end into an annular space, the through the drum concentrically surrounding ring sieve sections with different, from the second to the first end face of increasing mesh sizes, is formed, and at the bottom of the drum arranged in silos (38) for supporting screening material of different particle size, wherein the second front end of the drum, a stationary collection area (30) is formed, passes into the either granular material mainly from above (33) or wellconditioned (39) from the interior of the drum, the collecting area (30) below, a (31) over a flap closable opening exhibits, which is an additional silo (36) connected, and that the collecting area (30) adjacent to the drum in a radially expanded space (34) with blades (32) for lifting and transporting of granular material (39) to the ring sieve sections is formed.

Potrebbero piacerti anche

- Book PDFDocumento244 pagineBook PDFAdam VargasNessuna valutazione finora

- ConnectorToolingGuide 01Documento176 pagineConnectorToolingGuide 01diego.peinado8856100% (1)

- Aerodynamic and Structural DesignDocumento147 pagineAerodynamic and Structural Designvjayasankaran12100% (1)

- Aph001 Application Note Dw1000 Hardware Design GuideDocumento41 pagineAph001 Application Note Dw1000 Hardware Design Guidediego.peinado8856Nessuna valutazione finora

- 1.4006 en PDFDocumento2 pagine1.4006 en PDFdiego.peinado8856Nessuna valutazione finora

- CATIA Fry BasketDocumento135 pagineCATIA Fry BasketPuix Ozil TherPanzerNessuna valutazione finora

- 27 1 43 RawDocumento6 pagine27 1 43 Rawdiego.peinado8856Nessuna valutazione finora

- Configuration Drone MotorDocumento20 pagineConfiguration Drone Motordiego.peinado8856Nessuna valutazione finora

- 122FERDocumento6 pagine122FERceshesolNessuna valutazione finora

- Box and Pan Brakes: Operating Instructions and Parts ManualDocumento12 pagineBox and Pan Brakes: Operating Instructions and Parts Manualdiego.peinado8856Nessuna valutazione finora

- Grain Drying in Asia Part 4 86776 PDFDocumento41 pagineGrain Drying in Asia Part 4 86776 PDFdiego.peinado8856Nessuna valutazione finora

- Kloss Abq 2011 FinalDocumento50 pagineKloss Abq 2011 Finaldiego.peinado8856Nessuna valutazione finora

- Box and Pan Brakes: Operating Instructions and Parts ManualDocumento12 pagineBox and Pan Brakes: Operating Instructions and Parts Manualdiego.peinado8856Nessuna valutazione finora

- Nema Abcde Torque Curves PDFDocumento2 pagineNema Abcde Torque Curves PDFvtadlimbekarNessuna valutazione finora

- 181-186 For Web PDFDocumento6 pagine181-186 For Web PDFdiego.peinado8856100% (1)

- Design of Rolling Bearing Mountings in Motors and MachineryDocumento34 pagineDesign of Rolling Bearing Mountings in Motors and MachineryankitsarvaiyaNessuna valutazione finora

- URW-094 Product SheetDocumento1 paginaURW-094 Product Sheetdiego.peinado8856Nessuna valutazione finora

- AirlineGuideToPMA PDFDocumento48 pagineAirlineGuideToPMA PDFdiego.peinado8856Nessuna valutazione finora

- An Open Source CFD-DEM Perspective: Christoph GONIVA, Christoph KLOSS, Alice Hager and Stefan PIRKERDocumento10 pagineAn Open Source CFD-DEM Perspective: Christoph GONIVA, Christoph KLOSS, Alice Hager and Stefan PIRKERdiego.peinado8856Nessuna valutazione finora

- 01 Propellers&WindTurbines 4A1629Documento48 pagine01 Propellers&WindTurbines 4A1629Martina RichardNessuna valutazione finora

- Tesis Secaderos RotatoriosDocumento284 pagineTesis Secaderos Rotatoriosdiego.peinado8856Nessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Plastic and Environmental PollutionDocumento13 paginePlastic and Environmental PollutionAli KhalidNessuna valutazione finora

- All Makes Filters Cross Reference GuidesDocumento5 pagineAll Makes Filters Cross Reference GuidesJafet Israel RojasNessuna valutazione finora

- Aniline Point & Diesel IndexDocumento1 paginaAniline Point & Diesel IndexSerena Serena0% (1)

- PET Resin Production and UsesDocumento13 paginePET Resin Production and UsesA MahmoodNessuna valutazione finora

- Quality Assurance Plan For Casting PartsDocumento14 pagineQuality Assurance Plan For Casting Partsanand bandekarNessuna valutazione finora

- Electrochemistry Cell Potentials and Half-ReactionsDocumento40 pagineElectrochemistry Cell Potentials and Half-ReactionsJithesh Parambath0% (1)

- Song Chuan - 201191911194279049-1203708Documento7 pagineSong Chuan - 201191911194279049-1203708Braian Cabañas Visca BarçaNessuna valutazione finora

- Cavitation and Pump NPSHRDocumento39 pagineCavitation and Pump NPSHRRicardo BarrosNessuna valutazione finora

- Void Content of Reinforced Plastics: Standard Test Methods ForDocumento3 pagineVoid Content of Reinforced Plastics: Standard Test Methods ForStéfany Vier SteffenNessuna valutazione finora

- Gas Chromatography Troubleshooting GuideDocumento12 pagineGas Chromatography Troubleshooting GuideAbhishek Banerjee100% (1)

- Aphrin 500 MG Capsule BPR 1Documento12 pagineAphrin 500 MG Capsule BPR 1ShagorShagor100% (1)

- 02 01 05 Formaldehyde Contributions Us Canada EconomyDocumento11 pagine02 01 05 Formaldehyde Contributions Us Canada EconomySurjendu MaityNessuna valutazione finora

- Experimental Mechanics Laboratory ManualDocumento76 pagineExperimental Mechanics Laboratory Manualprabhaakar100% (1)

- Underground Cables - 010954Documento23 pagineUnderground Cables - 010954lawrence momanyiNessuna valutazione finora

- 7.1 Cement MFG - R1617.1Documento22 pagine7.1 Cement MFG - R1617.1arsenic_94Nessuna valutazione finora

- Concrete Mix Design: Grade M45Documento4 pagineConcrete Mix Design: Grade M45vidudalaraviNessuna valutazione finora

- ASHRAE Recommend 2 PDFDocumento6 pagineASHRAE Recommend 2 PDFAhmed LabibNessuna valutazione finora

- Stone Cladding Fixings Technical StandardsDocumento6 pagineStone Cladding Fixings Technical StandardsvtalexNessuna valutazione finora

- Finite Element Analysis of The Stability of Tunnel Surrounding Rock With Weak Rock LayerDocumento6 pagineFinite Element Analysis of The Stability of Tunnel Surrounding Rock With Weak Rock LayerVahid ShariatyNessuna valutazione finora

- Effectivity of Cellophanes As Alternative of Commercialized FloorwaxDocumento14 pagineEffectivity of Cellophanes As Alternative of Commercialized FloorwaxFranzes Mar Eria100% (1)

- 2710 100 Series - Screw Side-Action GripsDocumento4 pagine2710 100 Series - Screw Side-Action GripsLitarmjNessuna valutazione finora

- MSDS PVCDocumento9 pagineMSDS PVCDharu AbdulNessuna valutazione finora

- F-2200 Flow Meter Manual - 12-08Documento22 pagineF-2200 Flow Meter Manual - 12-08Luis DerasNessuna valutazione finora

- Milling Concept MILL 450 enDocumento6 pagineMilling Concept MILL 450 enHeineken Ya PraneetpongrungNessuna valutazione finora

- Why Using MCCB Instead of FusesDocumento4 pagineWhy Using MCCB Instead of Fuses123peniscolaNessuna valutazione finora

- The Fortessa Collection 2010Documento36 pagineThe Fortessa Collection 2010monu6006Nessuna valutazione finora

- Sno Pro Diagnostic Troubleshooting Guide 72 520 1Documento72 pagineSno Pro Diagnostic Troubleshooting Guide 72 520 1papamatt100% (1)

- Boiler ProblemsDocumento59 pagineBoiler ProblemsDharmendra BurraNessuna valutazione finora

- Webasto Heater Remote Control: Here Is The Climate Control Unit J255 That Is Going To Be ModifiedDocumento8 pagineWebasto Heater Remote Control: Here Is The Climate Control Unit J255 That Is Going To Be ModifiedAlexanderNessuna valutazione finora

- REPORT OF EOT CRANE EXAMINATIONDocumento2 pagineREPORT OF EOT CRANE EXAMINATIONRavikant PandeyNessuna valutazione finora