Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

What Mechanical Engineers Do - Design, Develop, Influence Products <40

Caricato da

Pranav WaghDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

What Mechanical Engineers Do - Design, Develop, Influence Products <40

Caricato da

Pranav WaghCopyright:

Formati disponibili

What is Mechanical Engineering?

Mechanical engineers design and develop everything you think of as a machine - from supersonic fighter jets to bicycles to toasters. And they influence the design of other products as well - shoes, light bulbs and even doors. Many mechanical engineers specialize in areas such as manufacturing, robotics, automotive/transportation and air conditioning. Others cross over into other disciplines, working on everything from artificial organs to the expanding field of nanotechnology. And some use their mechanical engineering degree as preparation for the practice of medicine and law. The mechanical engineer may design a component, a machine, a system or a process. Mechanical engineers will analyze their design using the principles of motion, energy, and force to insure the product functions safely, efficiently, reliably, and can be manufactured at a competitive cost. Mechanical engineers work in the automotive, aerospace, chemical, computer, communication, paper, and power generation industries. Mechanical engineers will be found in virtually any manufacturing industry. Increasingly, mechanical engineers are needed in the environmental and bio-medical fields. Indeed virtually every product or service in modern life has probably been touched in some way by a mechanical engineer. In the ME-EM department these activities are reflected in the way we organize our teaching and research efforts. Faculty are organized in the following technical areas:

Design and Dynamic Systems Area --This area emphasizes modeling and contr dynamic processes in engineering systems. Current research activity is in engin acoustics and noise control, NVH, vibrations and modal analysis, system model and identification, control systems, system dynamics, computer simulation of material-forming processes, off-line programming of robots, automobile crashworthiness, computer-aided strain analysis, software sensor development, optimal control of automated manufacturing, application of artificial intelligenc interactive design software, environmentally conscious design, and design of or devices for gait rehabilitation.

Energy Thermo-Fluids Area --Emphasizes thermodynamics, heat transfer, and f mechanics. Current research activity is in combustion processes, internal combu engines, transmissions, heat and mass transfer, fluid mechanics, computational f dynamics, and emissions and air quality control.

Manufacturing/Industrial Area--Current research activity is in metal cutting, me forming (with specific thrusts in sheet metal deformation), grinding, tribologica aspects of forming and machining, computer-aided design of dies for forming m and polymers, robotics and automation, metrology, data-dependent system anal industrial engineering, and environmentally conscious manufacturing. The manufacturing systems engineering program emphasizes the integration of desig materials, computers, and manufacturing with an exposure to business and engineering administration, and is particularly suitable for those who have a bac degree in mechanical, electrical, metallurgical, or chemical engineering.

Solid Mechanics Area--Emphasizes topics in mechanics and materials science. Current research activity is in mechanics of materials with microstructure, experimental mechanics, plasticity, wave propagation and dynamic fracture, biomechanics, micromechanics, ceramics, crashworthiness, polymer matrix composites, and computational mechanics.

(back to top)

What do Mechanical Engineers do?

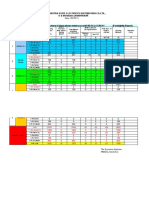

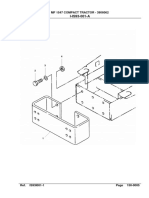

Up-Sized Tractor Variant Prototype: Elmers Crane & Dozer was formed in 1956. They currently have 15 locations in Michigans Lower Peninsula. They

This Senior Design Team won 2nd place in the Undergrad Research Expo. They developed an automatically Indexing Insert Toolholder design

have built 20 current Du-More tractor models. The current Du-More has a 1.5 yard bucket and 115 HP engine. Our team is designing a larger, more powerful and more capable tractor for Elmers Crane and Dozer, based on the current Du-More model. The new machine will incorporate existing components while preserving the functions of the existing model.

project that focused on the design, prototyping, and testing of a toolholder for turning operations. The key feature that separates this toolholder from others on the market is its ability to automatically rotate an indexable insert from a dull to fresh edge via an electrically actuated mechanism. Doing so saves significant machining downtime associated with the current method of manually indexing an insert. The projected savings in time allow the end user to reduce the costs related to machining parts, especially if the components being turned are made from hard materials that wear the insert rapidly.

Mechanical Engineers study:

Statics: How are forces transmitted to and throughout a structure? Dynamics: What are the velocities,accelerations and resulting forces for a system in motion? Kinematics: How does a mechanism behave as it moves through its range of motion? Strength of Materials: Is the component strong enough to support the loads? Is it stiff enough? Materials Science: Which material has the optimum properties? Thermodynamics : How does energy get converted to useful power? What are the losses? Fluid Mechanics: What is the pressure drop due to the fluid flow? What are the aerodynamic drag forces? Heat Transfer: How do you calculate heat transfer rates from temperature data? How do you predict the temperature distributions? Manufacturing: What manufacturing processes do you select? Machine Design: How do you synthesize all of the above? Electrical Circuits: How do you integrate electronic controls into your design? Laboratory Methods: How do you make and interpret both thermal and mechanical measurements? Vibrations: How do you predict and control vibrations? Engineering Economics: How do you estimate manufacturing costs?

Mechanical Engineers can take the following career paths:

Industry (the most common) Graduate School Entrepreneur/Business Owner Research Labs

Military Government Preparation for other Professions (law, medicine, teaching, etc.)

Mechanical Engineers are engaged in the following activities:

Conceptual design Analysis Presentations and report writing Multidisciplinary teamwork Concurrent engineering Benchmarking the competition Project management Prototyping Testing Measurements Data Interpretation Developmental design Research Work with suppliers Sales Consulting Customer service

Skills that help Mechanical Engineers to be successful in their careers:

Problem solving (The essence of engineering!) Creativity Hands-on understanding Networking Leadership/conflict resolution Knowledge management

Mechanical Engineering careers can have the following stages:

Early years - technical work most important Middle years - project management and product expert knowledge (still technical) become more important. Senior years - corporate, market, and global understanding become important.

Communication and team skills remain important throughout.

Potrebbero piacerti anche

- Mechanical Engineering ProfessionDocumento6 pagineMechanical Engineering ProfessionKent Lloyd CeloNessuna valutazione finora

- What Is Mechanical EngineeringDocumento5 pagineWhat Is Mechanical EngineeringShanna Sophia PelicanoNessuna valutazione finora

- IME - Module 1 - NotesDocumento26 pagineIME - Module 1 - NotesSudheer KiniNessuna valutazione finora

- Mechanical EngineeringDocumento21 pagineMechanical EngineeringsachinrajkvNessuna valutazione finora

- WEEK 7 Introduction To Mechanical EngineeringDocumento42 pagineWEEK 7 Introduction To Mechanical EngineeringRahim AssaniNessuna valutazione finora

- S Are Involved in Almost Every Aspect of Designing Cars and Trucks, FromDocumento8 pagineS Are Involved in Almost Every Aspect of Designing Cars and Trucks, FromNaveen GoyalNessuna valutazione finora

- MECHANICAL ENGINEERING CAREERDocumento9 pagineMECHANICAL ENGINEERING CAREERandreNessuna valutazione finora

- What Is Mechanical Engineering? (40 characters)Mechanical Engineering: An OverviewDocumento74 pagineWhat Is Mechanical Engineering? (40 characters)Mechanical Engineering: An OverviewilmanNessuna valutazione finora

- Mechanical Engineering Professional SkillDocumento27 pagineMechanical Engineering Professional SkillBiniam DegeNessuna valutazione finora

- Imo State Polytechnic Umuagwo P.M.B 1472 Owerri, Imo StateDocumento4 pagineImo State Polytechnic Umuagwo P.M.B 1472 Owerri, Imo StateUgoStanNessuna valutazione finora

- BTech Degrees in Top Engineering FieldsDocumento10 pagineBTech Degrees in Top Engineering FieldsAravind JayarajNessuna valutazione finora

- Exam ME01Documento2 pagineExam ME01Nica Mariz Dela CruzNessuna valutazione finora

- A Hybrid of Mechanical and Electrical Engineering, Commonly Intended To Examine The Design of Automation SystemsDocumento5 pagineA Hybrid of Mechanical and Electrical Engineering, Commonly Intended To Examine The Design of Automation SystemsMahmoud HosnyNessuna valutazione finora

- What Is MechatronicsDocumento11 pagineWhat Is MechatronicsKEVIN SNessuna valutazione finora

- 1.3 Specialized Sub-Disciplines in Mechanical Engineering - Production, Automobile, Energy EngineeringDocumento37 pagine1.3 Specialized Sub-Disciplines in Mechanical Engineering - Production, Automobile, Energy EngineeringMr. K.S. Raghul Asst Prof MECHNessuna valutazione finora

- Central Philippine University College of Engineering Mechanical Engineering DepartmentDocumento5 pagineCentral Philippine University College of Engineering Mechanical Engineering DepartmentKent Lloyd CeloNessuna valutazione finora

- Mechanical Engineering Overview: The FieldDocumento21 pagineMechanical Engineering Overview: The FieldKain KapanNessuna valutazione finora

- Mapa MentalDocumento6 pagineMapa Mentalreygnzlz157Nessuna valutazione finora

- Mechanical Engineering - The Diverse Field of Designing MotionDocumento8 pagineMechanical Engineering - The Diverse Field of Designing MotionLimitless AyodejiNessuna valutazione finora

- Bcme FinalDocumento94 pagineBcme FinalyagneshyallapuNessuna valutazione finora

- Mechanical Engineering Uq ThesisDocumento5 pagineMechanical Engineering Uq Thesisheatheredwardsmobile100% (2)

- Engineering Branches - A Concise OverviewDocumento4 pagineEngineering Branches - A Concise OverviewJustin K KurianNessuna valutazione finora

- Unit-5 MechatronicsDocumento34 pagineUnit-5 Mechatronicsrudrav3210Nessuna valutazione finora

- 21EME15 Module 1 Part 1 Introduction To Mechanical EngineeringDocumento6 pagine21EME15 Module 1 Part 1 Introduction To Mechanical EngineeringApurv PegwarNessuna valutazione finora

- Mechanical Engineering Basics CourseDocumento23 pagineMechanical Engineering Basics CourseMANOJKUMAR MNessuna valutazione finora

- What is Mechanical EngineeringDocumento3 pagineWhat is Mechanical EngineeringLiliane AlameddineNessuna valutazione finora

- Mechatronics Careers: Overview, Demand, Jobs, Salaries, and Top UniversitiesDocumento10 pagineMechatronics Careers: Overview, Demand, Jobs, Salaries, and Top Universities2DONessuna valutazione finora

- Chemical Engineers Use Their Analytical Skills and Aptitude For Chemistry When Working With Ground-Breaking Technologies To Enhance People's LivesDocumento15 pagineChemical Engineers Use Their Analytical Skills and Aptitude For Chemistry When Working With Ground-Breaking Technologies To Enhance People's LivesAbelNessuna valutazione finora

- What Is Mechanical Engineering?Documento3 pagineWhat Is Mechanical Engineering?KramnedOdnipacNessuna valutazione finora

- Navigating The Dynamics of Mechanical EngineeringDocumento1 paginaNavigating The Dynamics of Mechanical EngineeringumvhzfccnbnupcbjduNessuna valutazione finora

- What is Mechatronics EngineeringDocumento3 pagineWhat is Mechatronics EngineeringROGELIO STEBAN MORENO MARINNessuna valutazione finora

- Mechanical EngineeringDocumento3 pagineMechanical EngineeringdopinderNessuna valutazione finora

- What Jobs Can You Do With A Mechanical Engineering Degree?Documento4 pagineWhat Jobs Can You Do With A Mechanical Engineering Degree?Shelomi GerdanNessuna valutazione finora

- Guidelines For Mechatronics EngineeringDocumento10 pagineGuidelines For Mechatronics EngineeringPyae HtooNessuna valutazione finora

- Fmem - Unit VDocumento57 pagineFmem - Unit VBodhi SealNessuna valutazione finora

- What Is Mechanical EngineeringDocumento3 pagineWhat Is Mechanical EngineeringMuhamad Eko FebriansyahNessuna valutazione finora

- Control Systems and Automatic ControlDocumento1 paginaControl Systems and Automatic ControlSofija MilenkovicNessuna valutazione finora

- Mechanical EngineeringDocumento2 pagineMechanical EngineeringMUHAMMAD SYAFIQ SYAZWAN BIN ZAKARIA STUDENTNessuna valutazione finora

- Working As A Mechanical EngineerDocumento13 pagineWorking As A Mechanical EngineerNikita PawarNessuna valutazione finora

- Fa17 Bme 057Documento8 pagineFa17 Bme 057tayyub qayyumNessuna valutazione finora

- Guide to Mechanical Engineering MajorsDocumento7 pagineGuide to Mechanical Engineering MajorsAngelica HernandezNessuna valutazione finora

- Handbook of ESP For EngineeringDocumento77 pagineHandbook of ESP For EngineeringElfira DyahNessuna valutazione finora

- Engineering OrientationDocumento5 pagineEngineering OrientationRafael C RamirezNessuna valutazione finora

- Nars Characterization of Mechanical Design and Production EngineeringDocumento8 pagineNars Characterization of Mechanical Design and Production EngineeringDr_M_SolimanNessuna valutazione finora

- Why I Should Chose Mechanical EngineeringDocumento2 pagineWhy I Should Chose Mechanical EngineeringR S PappuNessuna valutazione finora

- Introduction Ot Mechanical Engineering, Role and Emerging TrendsDocumento11 pagineIntroduction Ot Mechanical Engineering, Role and Emerging TrendskasateeshNessuna valutazione finora

- What Is Mechanical EngineeringDocumento2 pagineWhat Is Mechanical EngineeringRavindra_1202Nessuna valutazione finora

- Mechanical Engineering Is A Discipline Of: There Are Two Ways We Can Produce Electricity From The SunDocumento2 pagineMechanical Engineering Is A Discipline Of: There Are Two Ways We Can Produce Electricity From The SunfahnaNessuna valutazione finora

- MechatronicsDocumento44 pagineMechatronicsTboiNessuna valutazione finora

- ME Laws MODULE 1Documento10 pagineME Laws MODULE 1Niaz KilamNessuna valutazione finora

- Mechatronics DisciplineDocumento3 pagineMechatronics Disciplineoearnest02Nessuna valutazione finora

- MECHANICAL ENGINEERING CAREERSDocumento7 pagineMECHANICAL ENGINEERING CAREERSandreNessuna valutazione finora

- Untitled DocumentDocumento6 pagineUntitled Documentapi-479942386Nessuna valutazione finora

- MechatronicsDocumento4 pagineMechatronicsbeckymwila18Nessuna valutazione finora

- What Is Mechanical Engineering? Careers and FieldsDocumento2 pagineWhat Is Mechanical Engineering? Careers and Fieldskate trishaNessuna valutazione finora

- ME 6702 Introduction to MechatronicsDocumento37 pagineME 6702 Introduction to MechatronicsSubbu SuniNessuna valutazione finora

- Basics of MechDocumento31 pagineBasics of MechAgateNessuna valutazione finora

- An Introduction to ADMS: The Operation, Command and Control of Electricity Distribution NetworksDa EverandAn Introduction to ADMS: The Operation, Command and Control of Electricity Distribution NetworksNessuna valutazione finora

- Embedded Mechatronic Systems, Volume 1: Analysis of Failures, Predictive ReliabilityDa EverandEmbedded Mechatronic Systems, Volume 1: Analysis of Failures, Predictive ReliabilityNessuna valutazione finora

- Engineering Applications: A Project Resource BookDa EverandEngineering Applications: A Project Resource BookValutazione: 2.5 su 5 stelle2.5/5 (1)

- Fault Database - Flat TVDocumento3 pagineFault Database - Flat TVZu AhmadNessuna valutazione finora

- What Is A Project in Project ManagementDocumento3 pagineWhat Is A Project in Project ManagementSamuel AntobamNessuna valutazione finora

- Clear IM Inventory DifferencesDocumento11 pagineClear IM Inventory DifferencesnguyencaohuygmailNessuna valutazione finora

- Generador de Vapor Cu360Documento36 pagineGenerador de Vapor Cu360Jonatan medran ochoaNessuna valutazione finora

- Digital Vision Installation PDFDocumento2 pagineDigital Vision Installation PDFnikola5nikolicNessuna valutazione finora

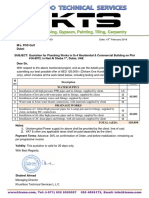

- KTS Quotation Meidan Building Plumbing Works PDFDocumento1 paginaKTS Quotation Meidan Building Plumbing Works PDFShakeel Ahmad100% (1)

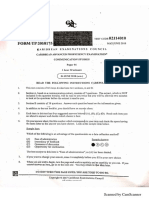

- 2018 PAPER 1 Communication Studies PDFDocumento14 pagine2018 PAPER 1 Communication Studies PDFKimNessuna valutazione finora

- Ladybug5 DatasheetDocumento2 pagineLadybug5 DatasheetEloy Ricardo Franco FigueiraNessuna valutazione finora

- Online Ticket Reservation SystemDocumento100 pagineOnline Ticket Reservation SystemPiya SharmaNessuna valutazione finora

- Exam 1 With SolutionsDocumento11 pagineExam 1 With SolutionsSsebass PozzoNessuna valutazione finora

- EXCEL Formula DictionaryDocumento1 paginaEXCEL Formula Dictionarysprk4uNessuna valutazione finora

- SuperStr 14Documento1 paginaSuperStr 14Poshan DhunganaNessuna valutazione finora

- CADAM 2000 - Model ParametersDocumento3 pagineCADAM 2000 - Model ParametersAqua MaNessuna valutazione finora

- Engineering Technical Report of The v12 Engine and Related Assignments at Tipco IncDocumento36 pagineEngineering Technical Report of The v12 Engine and Related Assignments at Tipco Incapi-244817040Nessuna valutazione finora

- Barangay Profile: (BP DCF No. 1 S. 2022)Documento4 pagineBarangay Profile: (BP DCF No. 1 S. 2022)AiMae BaobaoenNessuna valutazione finora

- 4 Thermodynoamics ExercisesDocumento25 pagine4 Thermodynoamics ExercisesGoran MaliNessuna valutazione finora

- Bs1030 BrochureDocumento2 pagineBs1030 BrochuremgvuleNessuna valutazione finora

- Class B BiosolidsDocumento9 pagineClass B BiosolidsGissmoNessuna valutazione finora

- CSEC Spanish January P2 2024-1Documento24 pagineCSEC Spanish January P2 2024-1Sajiv JadoonananNessuna valutazione finora

- 30x173 - TPDS-T - MK317 Mod0 - NAVSEA - 2011Documento16 pagine30x173 - TPDS-T - MK317 Mod0 - NAVSEA - 2011Anonymous jIzz7woS6Nessuna valutazione finora

- True/False: List of Attempted Questions and AnswersDocumento15 pagineTrue/False: List of Attempted Questions and AnswersDeepak Kumar VermaNessuna valutazione finora

- Stresses, Loads, and Factors of Safety in Structural ElementsDocumento6 pagineStresses, Loads, and Factors of Safety in Structural ElementsMark Louies Mago VillarosaNessuna valutazione finora

- OSN 6800 Electronic DocumentDocumento159 pagineOSN 6800 Electronic DocumentRashid Mahmood SajidNessuna valutazione finora

- MTA Reorganization Letter and BriefDocumento9 pagineMTA Reorganization Letter and BriefGersh KuntzmanNessuna valutazione finora

- 3530 Nellikuppam Clarifier SpecDocumento62 pagine3530 Nellikuppam Clarifier Specgopalakrishnannrm1202100% (1)

- What is a Gear Motor? - An In-Depth GuideDocumento15 pagineWhat is a Gear Motor? - An In-Depth GuidePuneet KumarNessuna valutazione finora

- Syabas Water ApplicationDocumento7 pagineSyabas Water ApplicationKen Chia0% (1)

- Strategic Human Resource Development I SlidesDocumento26 pagineStrategic Human Resource Development I SlidesAbhiman Behera50% (2)

- Maharashtra State Electricity Distribution Co - LTD., O & M Division, NANDURBARDocumento3 pagineMaharashtra State Electricity Distribution Co - LTD., O & M Division, NANDURBARPuru BornareNessuna valutazione finora

- MF1547Front Linkage - Seat PDFDocumento18 pagineMF1547Front Linkage - Seat PDFAhmad Ali NursahidinNessuna valutazione finora