Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Engineering Graphics2

Caricato da

ILAYAPERUMAL KDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Engineering Graphics2

Caricato da

ILAYAPERUMAL KCopyright:

Formati disponibili

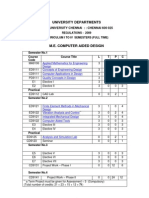

185101

ENGINEERING GRAPHICS 5

2 3 0

AIM To develop graphic skills in students. OBJECTIVES To develop in students graphic skill for communication of concepts, ideas and design of engineering products and expose them to existing national standards related to technical drawings. Concepts and conventions (Not for Examination) 1 Importance of graphics in engineering applications Use of drafting instruments BIS conventions and specifications Size, layout and folding of drawing sheets Lettering and dimensioning. UNIT I PLANE CURVES AND FREE HAND SKETCHING 15

Curves used in engineering practices: Conics Construction of ellipse, Construction of Parabola Construction of hyperbola by eccentricity method Construction of cycloid Construction of involutes of squad and circle Drawing of tangents and normal to the above curves. Free hand sketching: Representation of Three Dimensional objects General principles of orthographic projection Need for importance of multiple views and their placement First angle projection layout views Developing visualization skills through free hand sketching of multiple views from pictorial views of objects. UNIT II PROJECTION OF POINTS, LINES AND PLANE SURFACES 14 Projection of points located in the first quadrant Projection of straight lines located in the first quadrant Determination of true lengths and true inclinations Projection of polygonal surface and circular lamina inclined to both reference planes. UNIT III PROJECTION OF SOLIDS 15 Projection of simple solids like prisms, pyramids, cylinder and cone when the axis is inclined to one reference plane by change of position method. UNIT IV SECTION OF SOLIDS AND DEVELOPMENT OF SURFACES 15 Sectioning of above solids in simple vertical position by cutting planes inclined to one reference plane and perpendicular to the other Obtaining true shape of section. Development of lateral surfaces of simple and truncated solids Prisms, pyramids, cylinders and cones Development of lateral surfaces of solids with cylindrical cutouts, perpendicular to the axis. UNIT V ISOMETRIC AND PERSPECTIVE PROJECTIONS 15

Principles of isometric projection isometric scale isometric projections of simple solids truncated prisms, pyramids, truncated cylinders and cones. Perspective projection of prisms, pyramids and cylinders by visual ray method. TOTAL: 75 PERIODS

TEXT BOOKS REFERENC N.D. Bhatt, Engineering Drawing Charotar Publishing House, ES 46 Edition, (2003).

1. th

1. K. V. Natrajan, A text book of Engineering Graphics, Dhanalakshmi Publishers, Chennai (2006). 2. M.S. Kumar, Engineering Graphics, D.D. Publications, (2007). 3. K. Venugopal & V. Prabhu Raja, Engineering Graphics, New Age International (P) Limited (2008). 4. M.B. Shah and B.C. Rana, Engineering Drawing, Pearson Education (2005). 5. K. R. Gopalakrishnana, Engineering Drawing (Vol.I&II), Subhas Publications (1998). 6. Dhananjay A.Jolhe, Engineering Drawing with an introduction to AutoCAD Tata McGraw Hill Publishing Company Limited (2008). 7. Basant Agarwal and Agarwal C.M., Engineering Drawing, Tata McGraw Hill Publishing Company Limited, New Delhi, (2008). Publication of Bureau of Indian Standards: 1. IS 10711 2001: Technical products Documentation Size and lay out of drawing sheets. 2. IS 9609 (Parts 0 & 1) 2001: Technical products Documentation Lettering. 3. IS 10714 (Part 20) 2001 & SP 46 2003: Lines for technical drawings. 4. IS 11669 1986 & SP 46 2003: Dimensioning of Technical Drawings. 5. IS 15021 (Parts 1 to 4) 2001: Technical drawings Projection Methods. Special points applicable to University Examinations on Engineering Graphics: 1. There will be five questions, each of either or type covering all units of the syllabus. 2. All questions will carry equal marks of 20 each making a total of 100. 3. The answer paper shall consist of drawing sheets of A3 size only. The students will be permitted to use appropriate scale to fit solution within A3 size. 4. Whenever the total number of candidates in a college exceeds 150, the University Examination in that college will be conducted in two sessions (FN and AN on the same day) for 50 percent of student (approx) at a time.

185152

ENGINEERING PRACTICES LABORATORY

0 0 3 2

OBJECTIVES To provide exposure to the students with hands on experience on various basic engineering practices in Civil, Mechanical, Electrical and Electronics Engineering.

GROUP A (CIVIL & MECHANICAL)

I Buildings: (a) Study of plumbing and carpentry components of residential and industrial buildings. Safety aspects. Plumbing Works: (a) Study of pipeline joints, its location and functions: valves, taps, couplings, unions, reducers, elbows in household fittings. (b) Study of pipe connections requirements for pumps and turbines. (c) Preparation of plumbing line sketches for water supply and sewage works. (d) Hands-on-exercise: Basic pipe connections Mixed pipe material connection Pipe connections with different joining components. (e) Demonstration of plumbing requirements of high-rise buildings. Carpentry using Power Tools only: (a) Study of the joints in roofs, doors, windows and furniture. (b) Hands-on-exercise: Wood work, joints by sawing, planing and cutting. II MECHANICAL ENGINEERING PRACTICE 13 CIVIL ENGINEERING PRACTICE 9

Welding: (a) Preparation of arc welding of butt joints, lap joints and tee joints. (b) Gas welding practice Basic Machining: (a) Simple Turning and Taper turning (b) Drilling Practice Sheet Metal Work: (a) Forming & Bending: (b) Model making Trays, funnels, etc. (c) Different type of joints.

Machine assembly practice: (a) Study of centrifugal pump (b) Study of air conditioner Demonstration on: (a) Smithy operations, upsetting, swaging, setting down and bending. Example Exercise Production of hexagonal headed bolt. (b) Foundry operations like mould preparation for gear and step cone pulley. (c) Fitting Exercises Preparation of square fitting and vee fitting models.

GROUP B (ELECT RICAL & ELECTRONICS)

III 1. 2. 3. 4. ELECTRICAL ENGINEERING PRACTICE 10

Residential house wiring using switches, fuse, indicator, lamp and energy meter. Fluorescent lamp wiring. Stair case wiring Measurement of electrical quantities voltage, current, power & power factor in RLC circuit. 5. Measurement of energy using single phase energy meter. 6. Measurement of resistance to earth of an electrical equipment. IV ELECTRONICS ENGINEERING PRACTICE 13

1. Study of Electronic components and equipments Resistor, colour coding measurement of AC signal parameter (peak-peak, rms period, frequency) using CR. 2. Study of logic gates AND, OR, EOR and NOT. 3. Generation of Clock Signal. 4. Soldering practice Components Devices and Circuits Using general purpose PCB. 5. Measurement of ripple factor of HWR and FWR.

TOTAL : 45 PERIODS REFERENCES:

1. K.Jeyachandran, S.Natarajan & S, Balasubramanian, A Primer on Engineering

Practices Laboratory, Anuradha Publications, (2007). 2. T. Jeyapoovan, M.Saravanapandian & S.Pranitha, Engineering Practices Lab Manual, Vikas Publishing House Pvt.Ltd, (2006). 3. H.S. Bawa, Workshop Practice, Tata McGraw Hill Publishing Company Limited, (2007). 4. A. Rajendra Prasad & P.M.M.S. Sarma, Workshop Practice, Sree Sai Publication, (2002). 5. P.Kannaiah & K.L.Narayana, Manual on Workshop Practice, Scitech Publications, (1999).

SEMESTER EXAMINATION PATTERN The Laboratory examination is to be conducted for Group A & Group B, allotting 90 minutes for each group, with a break of 15 minutes. Both the examinations are to be taken together in sequence, either in the FN session or in the AN session. The maximum marks for Group A and Group B lab examinations will be 50 each, totaling 100 for the Lab course. The candidates shall answer either I or II under Group A and either III or IV under Group B, based on lots.

Engineering Practices Laboratory List of equipment and components (For a Batch of 30 Students) CIVIL 1. Assorted components for plumbing consisting of metallic pipes, plastic pipes, flexible pipes, couplings, unions, elbows, plugs and other fittings. 15 Sets. 2. Carpentry vice (fitted to work bench) 15 Nos. 3. Standard woodworking tools 15 Sets. 4. Models of industrial trusses, door joints, furniture joints 5 each 5. Power Tools: (a) Rotary Hammer 2 Nos (b) Demolition Hammer 2 Nos (c) Circular Saw 2 Nos (d) Planer 2 Nos (e) Hand Drilling Machine 2 Nos (f) Jigsaw 2 Nos MECHANICAL 1. Arc welding transformer with cables and holders 2. Welding booth with exhaust facility 3. Welding accessories like welding shield, chipping hammer, wire brush, etc. 4. Oxygen and acetylene gas cylinders, blow pipe and other welding outfit. 5. Centre lathe 6. Hearth furnace, anvil and smithy tools 7. Moulding table, foundry tools 8. Power Tool: Angle Grinder 9. Study-purpose items: centrifugal pump, air-conditioner ELECTRICAL 1. 2. 3. 4. 5. Assorted electrical components for house wiring 15 Sets Electrical measuring instruments 10 Sets Study purpose items: Iron box, fan and regulator, emergency lamp 1 each Megger (250V/500V) 1 No. Power Tools: (a) Range Finder 2 Nos (b) Digital Live-wire detector 2 Nos 5 Nos. 5 Nos. 5 Sets. 2 Nos. 2 Nos. 2 Sets. 2 Sets. 2 Nos One each.

ELECTRONICS 1. 2. 3. 4. 5. Soldering guns Assorted electronic components for making circuits Small PCBs Multimeters Study purpose items: Telephone, FM radio, low-voltage power supply 10 50 10 10 Nos. Nos. Nos. Nos.

Potrebbero piacerti anche

- D904 - D906 - D914 - D916 - D924 - D926 - 8718458 - 04092008 - v02 - enDocumento218 pagineD904 - D906 - D914 - D916 - D924 - D926 - 8718458 - 04092008 - v02 - enАлексей89% (18)

- Jeep TJ Torque SpecsDocumento4 pagineJeep TJ Torque SpecsmaulotaurNessuna valutazione finora

- Engine Interface ModuleDocumento3 pagineEngine Interface ModuleLuciano Pereira0% (2)

- CAEDPDocumento2 pagineCAEDPDurgaprasad DhanivireddyNessuna valutazione finora

- E-Catalog 2021 Jan JMI Dan KimDocumento52 pagineE-Catalog 2021 Jan JMI Dan KimbobNessuna valutazione finora

- DEH-X500BT DEH-S4150BT: CD Rds Receiver Receptor de CD Con Rds CD Player Com RdsDocumento53 pagineDEH-X500BT DEH-S4150BT: CD Rds Receiver Receptor de CD Con Rds CD Player Com RdsLUIS MANUEL RINCON100% (1)

- GE2115 Computer Practice Laboratory - I L T P C 0 0 3 2 List of Exercises A) Word Processing 15Documento5 pagineGE2115 Computer Practice Laboratory - I L T P C 0 0 3 2 List of Exercises A) Word Processing 15Kingsly UshaNessuna valutazione finora

- Design of Transmission SystemsDocumento3 pagineDesign of Transmission Systemsgowrisankar32Nessuna valutazione finora

- CIV ManualDocumento40 pagineCIV ManualVishnuNessuna valutazione finora

- Ge6152 Engineering GraphicsDocumento2 pagineGe6152 Engineering Graphicskb210538Nessuna valutazione finora

- Ge6152 Engineering Graphics L T P C 2 0 3 4Documento3 pagineGe6152 Engineering Graphics L T P C 2 0 3 4balajimeieNessuna valutazione finora

- Engineering Graphics and Design LAB SyllabusDocumento2 pagineEngineering Graphics and Design LAB Syllabusharsh dubeyNessuna valutazione finora

- Ge1101 - Engineering Practices Laboratory L T P C 0 0 3 2Documento3 pagineGe1101 - Engineering Practices Laboratory L T P C 0 0 3 2eswar110582Nessuna valutazione finora

- ME1001, ME1004, ME1005 - Basic Mech+Graphics+Workshop Pract.Documento6 pagineME1001, ME1004, ME1005 - Basic Mech+Graphics+Workshop Pract.Mayank AgarwalNessuna valutazione finora

- MC512 Mechanical Drawing IIDocumento2 pagineMC512 Mechanical Drawing IIEduardo RNessuna valutazione finora

- B.tech (Hons) Mechanical Course OutlineDocumento16 pagineB.tech (Hons) Mechanical Course OutlineTableegi TehreekNessuna valutazione finora

- Engineering GraphicsDocumento110 pagineEngineering GraphicsAkarshan upadhyayNessuna valutazione finora

- GE8261 EP Lab ManualDocumento82 pagineGE8261 EP Lab Manualsirajudeen I100% (1)

- Engineering Graphics-18EGDL25 Notes 2020-21Documento169 pagineEngineering Graphics-18EGDL25 Notes 2020-21PanduNessuna valutazione finora

- Drafting PracticeDocumento3 pagineDrafting PracticeprincipalsptNessuna valutazione finora

- MEM201 601 Fall AY0809 - RCDocumento6 pagineMEM201 601 Fall AY0809 - RCMahir MahmoodNessuna valutazione finora

- Jain Un Syllabus 4th SemDocumento13 pagineJain Un Syllabus 4th SemAnshul LallNessuna valutazione finora

- Computer Aided Engineering Drawing SyllabusDocumento4 pagineComputer Aided Engineering Drawing SyllabusAkhil DeshpandeNessuna valutazione finora

- Eg PDFDocumento109 pagineEg PDFfahamith ahamedNessuna valutazione finora

- EMG 1102 Engineering Drawing COURSE CONTENT (2023)Documento4 pagineEMG 1102 Engineering Drawing COURSE CONTENT (2023)osebe.bisonga23Nessuna valutazione finora

- Nptel: Engineering Drawing - Web CourseDocumento4 pagineNptel: Engineering Drawing - Web Courseankit kumarNessuna valutazione finora

- IMEED NMU SyllabusDocumento3 pagineIMEED NMU Syllabusnavneet patilNessuna valutazione finora

- Engeering Graphic 1st YearDocumento64 pagineEngeering Graphic 1st YearRajpurohit Samundra0% (1)

- Structural EngineeringDocumento31 pagineStructural EngineeringLarry SmithNessuna valutazione finora

- Engineering Graphics IDocumento10 pagineEngineering Graphics IHarish RamNessuna valutazione finora

- 11 Engineering Graphics 2015 16Documento3 pagine11 Engineering Graphics 2015 16Prabhu Charan TejaNessuna valutazione finora

- Basic Engineering DrawingDocumento8 pagineBasic Engineering DrawingHardik ParmarNessuna valutazione finora

- M.E. Engineering DesignDocumento47 pagineM.E. Engineering DesignSms RajaNessuna valutazione finora

- Btech 2Documento17 pagineBtech 2Divyesh SindhiNessuna valutazione finora

- 6th Sem BArchDocumento10 pagine6th Sem BArchKomal MehtaNessuna valutazione finora

- Zero LectureDocumento23 pagineZero Lecturetemobam569Nessuna valutazione finora

- M.E. Computer Aided Design SyllabusDocumento50 pagineM.E. Computer Aided Design SyllabusJoswa CaxtonNessuna valutazione finora

- ME CAD SyllabusDocumento50 pagineME CAD Syllabussubha_aeroNessuna valutazione finora

- Syllabus - B.E. Mechanical - 2009 RegulationDocumento161 pagineSyllabus - B.E. Mechanical - 2009 RegulationshivakumarNessuna valutazione finora

- Epl Lab Manual Sxcce PDFDocumento110 pagineEpl Lab Manual Sxcce PDFBijumonNessuna valutazione finora

- S1 Civil - & - Mechanical - WorkshopDocumento5 pagineS1 Civil - & - Mechanical - WorkshopMathew JohnNessuna valutazione finora

- Eson Plan 2016 Small SizeDocumento2 pagineEson Plan 2016 Small SizevsanthanamNessuna valutazione finora

- Laboratory Manual: Department of Mechanical EngineeringDocumento9 pagineLaboratory Manual: Department of Mechanical Engineeringrajamanickam sNessuna valutazione finora

- Engineering Graphics & Design Gtu SyllDocumento3 pagineEngineering Graphics & Design Gtu SyllAPOLLO Sem 4 I.T.Nessuna valutazione finora

- Engineering Drawing SylabousDocumento11 pagineEngineering Drawing SylabousysonuNessuna valutazione finora

- Lab Manual EGLDocumento100 pagineLab Manual EGLKartik SharmaNessuna valutazione finora

- BGS Institute of Technology B.G.Nagar-571448: Course Objectives & OutcomesDocumento23 pagineBGS Institute of Technology B.G.Nagar-571448: Course Objectives & OutcomeshemarajuNessuna valutazione finora

- Engineering Graphics I PDFDocumento10 pagineEngineering Graphics I PDFRahul JaiswalNessuna valutazione finora

- ED 240 Syllabus-Njovu-El-2Documento3 pagineED 240 Syllabus-Njovu-El-2Anthony MubangaNessuna valutazione finora

- GE8152 Engineering Graphics SYLLABUSDocumento2 pagineGE8152 Engineering Graphics SYLLABUSnarayanamoortyNessuna valutazione finora

- Syllabus - BE Mech II Wef 2012-13 PDFDocumento28 pagineSyllabus - BE Mech II Wef 2012-13 PDFPavan KishoreNessuna valutazione finora

- Engineering Drawing: Course OverviewDocumento2 pagineEngineering Drawing: Course OverviewmuthuNessuna valutazione finora

- Elements of Mechanical Engineering Syllabus For 1st Sem B.TechDocumento6 pagineElements of Mechanical Engineering Syllabus For 1st Sem B.TechDebarshi BaruahNessuna valutazione finora

- Engineering Graphics: N.P.R. College of Engineering & TechnologyDocumento109 pagineEngineering Graphics: N.P.R. College of Engineering & Technologynabemdu100% (1)

- Devi Ahilya Vishwavidyalaya, Indore: Scheme For B.E. All Semester Examination Effective From July 2006Documento88 pagineDevi Ahilya Vishwavidyalaya, Indore: Scheme For B.E. All Semester Examination Effective From July 2006Rahul SakareyNessuna valutazione finora

- Structural Engineering PDFDocumento22 pagineStructural Engineering PDFrajaktraja_779727735Nessuna valutazione finora

- Engineering Design SyllabusDocumento49 pagineEngineering Design SyllabusanandandmeenaNessuna valutazione finora

- Annamalai Eg LPDocumento7 pagineAnnamalai Eg LPAnonymous QmCUGe0MpNessuna valutazione finora

- A Manual of Elementary Geometrical Drawing Involving Three Dimensions: In Five Divisions, Div. I. Elementary Projections Div. II. Details of Constructions in Masonry Wood, and Metal Div. III. Rudimentary Exercises in Shades and Shadows Div. IV. Isometrical Drawing Div. V. Elementary Structural DrawingDa EverandA Manual of Elementary Geometrical Drawing Involving Three Dimensions: In Five Divisions, Div. I. Elementary Projections Div. II. Details of Constructions in Masonry Wood, and Metal Div. III. Rudimentary Exercises in Shades and Shadows Div. IV. Isometrical Drawing Div. V. Elementary Structural DrawingValutazione: 5 su 5 stelle5/5 (1)

- Structural Drafting - A Practical Presentation of Drafting and Detailed Methods used in Drawing up Specifications for Structural Steel WorkDa EverandStructural Drafting - A Practical Presentation of Drafting and Detailed Methods used in Drawing up Specifications for Structural Steel WorkValutazione: 3 su 5 stelle3/5 (1)

- Notes on Mechanical Drawing - Prepared for the Use of Students in Mechanical, Electrical and Chemical EngineeringDa EverandNotes on Mechanical Drawing - Prepared for the Use of Students in Mechanical, Electrical and Chemical EngineeringNessuna valutazione finora

- Private Car Policy WordingDocumento9 paginePrivate Car Policy WordingILAYAPERUMAL KNessuna valutazione finora

- ManualDocumento4 pagineManualILAYAPERUMAL KNessuna valutazione finora

- QB114462Documento8 pagineQB114462ILAYAPERUMAL KNessuna valutazione finora

- ExercisesDocumento1 paginaExercisesILAYAPERUMAL KNessuna valutazione finora

- 2-Critical Speed of ShaftDocumento5 pagine2-Critical Speed of ShaftRidani Faulika Amma100% (3)

- ME6503 Design of Machine Elements Question BankDocumento9 pagineME6503 Design of Machine Elements Question BankILAYAPERUMAL KNessuna valutazione finora

- Madeeasy List NitDocumento1 paginaMadeeasy List NitILAYAPERUMAL KNessuna valutazione finora

- 5th SemesterDocumento8 pagine5th SemesterILAYAPERUMAL KNessuna valutazione finora

- Merit Vol II Issue IV - April 2015 (LO)Documento13 pagineMerit Vol II Issue IV - April 2015 (LO)ILAYAPERUMAL KNessuna valutazione finora

- 2016 Digital Trends Survey ResultsDocumento47 pagine2016 Digital Trends Survey ResultsILAYAPERUMAL KNessuna valutazione finora

- Lecture (1) Properties of Fluids: LecturerDocumento28 pagineLecture (1) Properties of Fluids: LecturerILAYAPERUMAL KNessuna valutazione finora

- Publication 10 5968 1369Documento2 paginePublication 10 5968 1369ILAYAPERUMAL KNessuna valutazione finora

- Fluid Mechanics and MachineryNovDec2014R2013Documento3 pagineFluid Mechanics and MachineryNovDec2014R2013ILAYAPERUMAL KNessuna valutazione finora

- Fluid Mechanics and Machinery (Nov, Dec2012)Documento3 pagineFluid Mechanics and Machinery (Nov, Dec2012)Vijaya Prabhu KumarasamyNessuna valutazione finora

- GATE 2017 Exam Pattern: Section No. No. of Questions Marks Per Total MarksDocumento1 paginaGATE 2017 Exam Pattern: Section No. No. of Questions Marks Per Total MarksILAYAPERUMAL KNessuna valutazione finora

- Madeeasy List IitDocumento1 paginaMadeeasy List IitILAYAPERUMAL KNessuna valutazione finora

- Gate Cut Off MarksDocumento1 paginaGate Cut Off MarksVikas SurarapuNessuna valutazione finora

- GKP List PsuDocumento2 pagineGKP List PsuILAYAPERUMAL KNessuna valutazione finora

- Me6401 Kinematics of Machinery L T P CDocumento2 pagineMe6401 Kinematics of Machinery L T P CThiru Moorthy100% (1)

- Chapter 3 Torsion: P D T P DDocumento25 pagineChapter 3 Torsion: P D T P DAjoy Kumar PandeyNessuna valutazione finora

- GKP All About GateDocumento7 pagineGKP All About GateILAYAPERUMAL KNessuna valutazione finora

- Kinematics of MachineryDocumento8 pagineKinematics of MachineryILAYAPERUMAL KNessuna valutazione finora

- DME Question BankDocumento4 pagineDME Question BankILAYAPERUMAL KNessuna valutazione finora

- Finite (Mayjune2013)Documento4 pagineFinite (Mayjune2013)ILAYAPERUMAL KNessuna valutazione finora

- ME 6603 Finite Element Analysis - Assignment 2Documento2 pagineME 6603 Finite Element Analysis - Assignment 2ILAYAPERUMAL KNessuna valutazione finora

- Pearson Gate 2016 Detailed Analysis MeDocumento4 paginePearson Gate 2016 Detailed Analysis MeILAYAPERUMAL KNessuna valutazione finora

- Intelligent Vision Based Mobile Robot For Pipe Line Inspection and CleaningDocumento5 pagineIntelligent Vision Based Mobile Robot For Pipe Line Inspection and CleaningILAYAPERUMAL KNessuna valutazione finora

- About The Institution Organizing Committee Chief Patrons: Chairman, Rajalakshmi InstitutionsDocumento2 pagineAbout The Institution Organizing Committee Chief Patrons: Chairman, Rajalakshmi InstitutionsILAYAPERUMAL KNessuna valutazione finora

- Academic Performance of Affiliated Colleges 042014Documento19 pagineAcademic Performance of Affiliated Colleges 042014ILAYAPERUMAL KNessuna valutazione finora

- Data Iep Goals and Objectives ExampleDocumento4 pagineData Iep Goals and Objectives Exampleapi-455438287100% (2)

- Brochure Delegation Training For LeadersDocumento6 pagineBrochure Delegation Training For LeadersSupport ALProgramsNessuna valutazione finora

- CERADocumento10 pagineCERAKeren Margarette AlcantaraNessuna valutazione finora

- Task 4 - Illustrating Psychoanalytic CriticismDocumento9 pagineTask 4 - Illustrating Psychoanalytic CriticismTroJaf OfficialNessuna valutazione finora

- Recovering The Snorra Edda On Playing Gods, Loki, and The Importance of HistoryDocumento17 pagineRecovering The Snorra Edda On Playing Gods, Loki, and The Importance of HistoryM SNessuna valutazione finora

- 实用多元统计分析Documento611 pagine实用多元统计分析foo-hoat LimNessuna valutazione finora

- Daftar PustakaDocumento1 paginaDaftar PustakaUlul Azmi Rumalutur NeinaNessuna valutazione finora

- Binary To DecimalDocumento8 pagineBinary To DecimalEmmanuel JoshuaNessuna valutazione finora

- Helena HelsenDocumento2 pagineHelena HelsenragastrmaNessuna valutazione finora

- TSM 101 Course Outline (2022)Documento2 pagineTSM 101 Course Outline (2022)ChryseanjNessuna valutazione finora

- The Future of Comparative Literary StudiesDocumento14 pagineThe Future of Comparative Literary StudiesNabeesath ArifaNessuna valutazione finora

- Kibera Mirror JULYDocumento8 pagineKibera Mirror JULYvincent achuka maisibaNessuna valutazione finora

- CH 6 Answers (All) PDFDocumento29 pagineCH 6 Answers (All) PDFAhmed SideegNessuna valutazione finora

- Negotiation SimulationDocumento11 pagineNegotiation SimulationJade Arbee BarbosaNessuna valutazione finora

- Text Ranslation and TradicitonDocumento283 pagineText Ranslation and TradicitonSCAF55100% (4)

- TLE CapsLet G10Documento5 pagineTLE CapsLet G10Larnie De Ocampo PanalNessuna valutazione finora

- McMurdo FastFind 220 PLB DatasheetDocumento4 pagineMcMurdo FastFind 220 PLB DatasheetGiorgos PapadopoulosNessuna valutazione finora

- Lab 4 SimulationDocumento8 pagineLab 4 SimulationaziziNessuna valutazione finora

- Obat Keras N0vember 2021Documento137 pagineObat Keras N0vember 2021antonNessuna valutazione finora

- Tle10 Cookery DLL Q1-Week1 Sy2022-2023Documento4 pagineTle10 Cookery DLL Q1-Week1 Sy2022-2023Edmar S AguilarNessuna valutazione finora

- Project Report - Performance Anaylysis of Mutual Funds in IndiaDocumento52 pagineProject Report - Performance Anaylysis of Mutual Funds in Indiapankaj100% (1)

- SFC PresentationDocumento51 pagineSFC PresentationjmtriggerzNessuna valutazione finora

- Digestive System Lesson PlanDocumento5 pagineDigestive System Lesson PlanSachi Summers100% (2)

- Annex 1: Homeroom Guidance Monitoring Tool (School Level) Homeroom Guidance Monitoring ToolDocumento2 pagineAnnex 1: Homeroom Guidance Monitoring Tool (School Level) Homeroom Guidance Monitoring ToolMariel Gregore0% (1)

- TM GUIDE (Basic Competencies)Documento19 pagineTM GUIDE (Basic Competencies)Emelito T. ColentumNessuna valutazione finora