Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sample Splice For Plate Girder Design

Caricato da

Chandan SinghDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sample Splice For Plate Girder Design

Caricato da

Chandan SinghCopyright:

Formati disponibili

SHEET NO.

PROJECT: SUBJECT:

OF

Project Subject

JOB NO. MADE BY: CHKD BY:

Job # Name Name

DATE: DATE:

Date Date

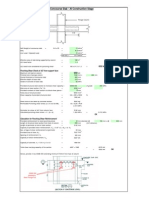

Steel Girder Field Splice Design

(AASHTO 1996 Criteria)

English or Metric = Service Load/Load Factror Design = Composite ? = Steel Splice Yield Strength (Fy) = Steel Ultimate Strength (Fumin) = Allowable Fatigue Stress Range =

Metric LFD No

(Metric/English) (LFD/SL) (Yes/No)

Input Values Shown In Shaded Cells

FS Calculation Sheet 1 of 7

WARNING - Design Insufficient

50 MPa 65 MPa

(AASHTO Table 10.2A)

16.0 MPa

(As Per AASHTO Table 10.3.1A / # of Cyclers and Category)

Service Live Load at Splice (Fatigue)

Max. Positive Moment = Max. Negative Moment = Live Load Range = 2422.00 kN-m -2061.00 kN-m 4483.00 kN-m

Factored Loads at Splice

Shear = Moment = 220.00 kN-m 5340.00 kN-m = =

Overload

(Dividing by 1.3)

169.23 kN-m 4107.69 kN-m

(D.L. + 5/3 L.L.)

Steel Girder Section I

Top Flange = Web = Bottom Flange = Base 24.000 0.625 0 625 28.000 Thickness 2.500 mm 78.000 78 000 mm 2.500 mm

Steel Girder Section II

Top Flange = Web = Bottom Flange = Base 28.000 0.625 0 625 28.000 Thickness 2.500 mm 78.000 78 000 mm 2.500 mm

3.96 5.00 Controlling Steel Section = Section I

(Smaller Section to Control - AASHTO 10.18.1)

Bolt Specifications

Bolt Diameter = Slip Critical PhiFs = Shear PhiF = Bolt Area = PhiR = 0.875 mm 21 MPa 35 MPa 0.601 mm^2 0.02 kN

(Refer to AASHTO Table 10.57A) (Refer to AASHTO 10.56.1.3 and AASHTO Table 10.56A)

Hole Larger Than Bolt By =

(Bolt Capacity - Single Shear Plane)

0.125 mm

Net Section Properties at Splice

Assumed Rows of Bolts on Flange= % Area Reduced by Bolt Holes = 4

(Using Smaller Section) Flanges Shall Be Reduced If Bolts Holes Reduce The Flanges By More Than 15% (AASHTO 10.18.1)

(Update When Design Complete)

16.67 % - 15% =

1.67 % Reduction of Flanges

(AASHTO 10.18)

Material

Top Flange Web Bot. Flange Deck Reinf.

Area (mm^2)

d (mm)

Ad (mm^3)

Ad^2 (mm^4)

Io (mm^4)

24716.3 -

I (mm^4)

95583.7 24716.3 111514.3 0.0 231814.2 231814 2 mm^4 -887.1 mm^4 230927.1 mm^4

59.00 40.250 48.75 68.83 -40.250 0.00 0.000 176.58 176 58 mm^2 -2.24 mm

2374.8 95583.7 -2770.5 111514.3 0.0 0.0 -395.79 mm^3 395 79

d comp. section =

Reduced Inertia Due to New Centroid = IComposite = d Bot of Steel = S Bot of Steel = 39.26 mm 5882.20 mm^3

d Top of Steel = S Top of Steel =

43.74 mm 5279.37 mm^3

Design Moments and Shears

Criteria 1: M Net = 75% M Net = Criteria 2: M Avg = 0.26 kN-m 0.20 kN-m 2670.13 kN-m

(AASHTO 10.18.1 - Splice Strength > Avg. Required Strength and Member Strength (AASHTO 10.18.1 - Splice Strength > 75% Girder Strength)

Design Moment = Design Shear =

2670.13 kN-m 110.01 kN

(Actual Shear Multiplied by Moment Increase)

14219875-Field-Splice-Design

SHEET NO. PROJECT: SUBJECT:

OF

Project Subject

JOB NO. MADE BY: CHKD BY:

Job # Name Name

DATE: DATE:

Date Date

Web Splice Geometry

Diagram Dimensions = millimeters "C" Bolt Spaces @ "D" "F" (Typ.) "G" (Typ.) 3.00 Web Splice Plate Thickness = 0.500 mm (Assumed Both The Same)

(AASHTO 10.18.2.1 Requires Min. of Two Bolt Columns) FS Calculation Sheet 2 of 7

"E"

A= B= Top Flange C= D= E= F= G=

16 Spaces 4.25 mm 2 Space(s) 4.00 mm 2.00 mm 2.00 mm 2.00 mm

Bolt Pattern Typical Both Sides

"A" Bolt Spaces @ "B"

72.00

78.00

# Bolts in Column 17 Bottom Flange Total # Web Bolts 102

24.00

Elevation Web Splice

I Web = 24961.2 mm^4 mm 4

( (Io + Ad2)

Web Moments for Design Loads

M V= MW= 0.66 kN-m 288.62 kN-m 289.28 kN-m

(AASHTO 10.18.2.1)

Eccentricity =

6 mm

(Moment Produced From Shear) (Web Portion of Moment)

Hole Area (Cross Sectional) = Percentage of Holes in Web = 8.61 % of Plate Reduction = Sum d2 = Sum Ad2 = 3684.75 mm^2 5375.40 mm^4 23.61 % - 15% =

0.5 mm^2 8.61 %

(AASHTO 10.18.1)

36.47 % of Hole Reduction (Ability Loss)

Material

2-Splice Plates 2- (Qty. Holes)

Area (mm^2)

72.00 -6.20

d (mm)

-2.241 -2.241

Ad^2 (mm^4)

361.7 -31.1

Io (mm^4)

31104.0 -5375.4

I (mm^4)

31465.7 -5406.5 26059.2 mm^4

d Top of Splice = S Top of Splice =

38.24 mm 681.44 mm^3

d Bot of Splice = S Bot of Slice =

33.76 mm 771.93 mm^3

Maximum Bending Stress f b= 424509.81 MPa Maximum Shear Stress f v= 1527.85 MPa

<

50 MPa

WARNING - Design Insufficient

<

27.5 MPa

( ssu ed (Assumed Fv = 0 55 y AASHTO 10.48.8) 0.55Fy S O 0 8 8)

WARNING - Design Insufficient

14219875-Field-Splice-Design

SHEET NO. PROJECT: SUBJECT:

OF

Project Subject

JOB NO. MADE BY: CHKD BY:

Job # Name Name

DATE: DATE:

Date Date

Web Bending Stress Range for Service Loads

(Fatigue Check With Service Loads) FS Calculation Sheet 3 of 7

MW= f b=

484.57 kN-m 588917.73 MPa

(SL Moment Range) (SL Bending Stress Range)

f b=

588917.73 MPa

<

16.0 MPa

(As Per AASHTO Table 10.3.1A # of Cyclers and Category)

WARNING - Design Insufficient

Web Bolts and Web/Splice Plate Bearing Capacity

Bolts: Slip Critical Bolt Cap. (PhiRs) = Bolt Shear Capacity = Splice Plates: (Capacity) PhiR Equals Less of = Lc = 0.09 kN/Bolt 0.10 kN/Bolt Lc = 0.05 kN/Bolt 0.06 kN/Bolt

(AASHTO 10.56.1.3)

0.03 kN/Bolt 0.04 kN/Bolt 1.50 mm

(AASHTO 10.57.3.1 - Two Slip Planes) (Double Shear) (Minimum of Vertical/Horizontal Clear Hole Distance or Edge Distance)

(Considers Both Web Plates)

Girder Web: (Capacity) PhiR Equals Less of =

1.50 mm

(Minimum of Vertical/Horizontal Clear Hole Distance or Edge Distance)

Summary:

Slip Critical Bolt Capacity = and Bolt Shear Capacity Contolling =

0.03 kN/Bolt 0.04 kN/Bolt

(Controlling Bolt Shear/Plate Capacity)

(To Be Checked Against Overload) (To Be Checked Against Design Loads)

Web Bolt Group Geometry

Polar Moment of Inertia of Bolt Group = Distance From Centroid to Outermost Bolt = 22908.7 mm^2 36.46 mm

Web Moments for Bolts

Eccentricity = Slip Critical Check (Overload Forces): M V= MW= 1.02 kN-m 444.00 kN-m 445.02 kN-m P s= P m= P v= P h= P Total = 708.67 kN/Bolt < 0.03 kN/Bolt

(Slip Critical Capacity)

6 mm

3.32 kN 708.29 kN 77.70 kN 704.02 kN

(Load Due to Shear) (Load On Outermost Bolt Due to Moment) (Vertical Component of Load) (Horizontal Component of Load)

WARNING - Design Insufficient

Bolt Shear and Bearing Check (Design Forces): M V= MW= 0.66 kN-m 288.62 kN-m 289.28 kN-m 289 28 kN m P s= P m= P v= P h= P Total = 460.66 kN/Bolt < 0.04 kN/Bolt

(Controlling Bolt Shear/Plate Capacity)

2.16 kN 460.41 kN 50.51 50 51 kN 457.63 kN

(Load Due to Shear) (Load On Outermost Bolt Due to Moment) (Vertical Component of Load) (Horizontal Component of Load)

WARNING - Design Insufficient

14219875-Field-Splice-Design

SHEET NO. PROJECT: SUBJECT:

OF

Project Subject

JOB NO. MADE BY: CHKD BY:

Job # Name Name

DATE: DATE:

Date Date

Flange-Splice Design Top Splice PlatesF b Top = P Top = 491313.51 MPa 29478.81 kN

(Average Stress in Top Flange) (Total Top Flange Force) (1.0 Fy) (1.0 Fu) FS Calculation Sheet 4 of 7

Gross Area Required Top Splice = Net Area Required Top Splice =

589576.21 mm^2 453520.16 mm^2

Diagram Dimensions = millimeters All Dimensions Typical 0.00 54.00

Bolt Hole Diameter =

1.000

mm

"I"

"C" Bolt Spaces @ "D" 24.00 "H" 2.188 28.00

"E" 9.50

"F"

"G" "A" Bolt Spaces @ "B"

(AASHTO 10.18.2.1 Requires Min. of Two Bolt Rows)

Top Flange Plan

Outer Splice Plate Thickness = Inner Splice Plates Thickness = A= B= C= D= Total # of Bolt Columns = Total # of Bolt Rows = # of Bolts in Top Flange Splice = Area Plates Top Splice = Area Bolts Top Splice = Gross Area Provided Top Splice = Net Area Provided Top Splice =

(1.0 (1 0 Fy) (1.0 Fu)

1.500 mm 0.750 mm 6 Spaces 3.75 mm 1 Space(s) 4.50 mm 14 4 56 50.25 mm^2 9 mm^2 48.788 mm^2 41.250 mm^2 > >

E= F= G= H= I=

24.00 2.50 2.00 2.50 2.50

mm mm mm mm mm

(Includes Reduction of Percentage Greater Than 15%)

48.79 mm 2 48 79 mm^2 41.25 mm^2

589576.21 mm 2 589576 21 mm^2 453520.16 mm^2

WARNING - Design Insufficient WARNING - Design Insufficient

14219875-Field-Splice-Design

SHEET NO. PROJECT: SUBJECT:

OF

Project Subject

JOB NO. MADE BY: CHKD BY:

Job # Name Name

DATE: DATE:

Date Date

Bottom Splice PlatesF b Bottom = P Bottom = 439480 70 MP 439480.70 MPa 30763.65 kN

(Average Stress in Bottom Flange) (Total Bottom Flange Force) (1.0 Fy) (1.0 Fu) FS Calculation Sheet 5 of 7

Gross Area Required Bottom Splice = Net Area Required Bottom Splice =

615272.99 mm^2 473286.91 mm^2

Diagram Dimensions = millimeters All Dimensions Typical 0.00 41.00

Bolt Hole Diameter =

1.000

"I"

"C" Bolt Spaces @ "D" 28.00 "H" 2.688 28.00

"E" 11.00

"F"

"G" "A" Bolt Spaces @ "B"

(AASHTO 10.18.2.1 Requires Min. of Two Bolt Rows)

Bottom Flange Plan

Outer Splice Plate Thickness = Inner Splice Plates Thickness = A= B= C= D= Total # of Bolt Columns = Total # of Bolt Rows = # of Bolts in Bottom Flange Splice = Area Plates Bottom Splice = Area Bolts Bottom Splice = Gross Area Provided Bottom Splice = Net Area Provided Bottom Splice =

(1.0 Fy) (1.0 Fu)

1.500 mm 0.750 mm 4 Spaces 4.00 mm 2 Space(s) 3.50 mm 10 6 60 58.5 mm^2 13.5 mm^2 53.775 mm^2 45.000 mm^2 > >

E= F= G= H= I=

28.00 2.50 2.00 2.00 2.00

mm mm mm mm mm

(Includes Reduction of Percentage Greater Than 15%)

53.78 mm^2 45.00 mm^2 mm 2

615272.99 mm^2 473286.91 mm^2 mm 2

WARNING - Design Insufficient WARNING - Design Insufficient

Splice Plate ChecksService Load Moment Range = Top Flange f ST = Bottom Flange f ST = Top Flange Splice f ST = Bottom Flange Splice f ST = 4483.00 kN-m 824887.49 MPa 737863.15 MPa 968524.61 MPa 868197.95 MPa < <

(Average Stress in Top/Bottom Flange)

16.0 MPa 16.0 MPa

WARNING - Design Insufficient WARNING - Design Insufficient

(Average Corresponding Stress in Top/Bottom Flange Splice Plates)

14219875-Field-Splice-Design

SHEET NO. PROJECT: SUBJECT:

OF

Project Subject

JOB NO. MADE BY: CHKD BY:

Job # Name Name

DATE: DATE:

Date Date

Flange Bolts and Flange/Splice Plate Bearing Capacity

(AASHTO 10.56.1.3) FS Calculation Sheet 6 of 7

Top FlangeBolts: Slip Critical Bolt Cap. (PhiRs) = Bolt Shear Capacity = Splice Plates: (Capacity) PhiR Equals Less of = Lc = 0.13 kN/Bolt 0.15 kN/Bolt Lc = 0.29 kN/Bolt 0.26 kN/Bolt 0.03 kN/Bolt 0.03 kN/Bolt 1.50 mm

(AASHTO 10.57.3.1 - Two Slip Planes) (Double Shear With UnEqual Area Plate Ratio Considered) (Minimum of Vertical/Horizontal Clear Hole Distance or Edge Distance) (Both Inner and Outer Plates are Considered. Assume Both Plates to Take Equal Loading - Slightly Conservative))

Girder Flange: (Capacity) PhiR Equals Less of =

2.00 mm

(Minimum of Vertical/Horizontal Clear Hole Distance or Edge Distance)

Summary:

Slip Critical Bolt Capacity = and Bolt Shear Capacity Contolling =

0.03 kN/Bolt 0.03 kN/Bolt

( (Controlling Bolt Shear/Plate Capacity) g p y)

(To Be Checked Against Overload) (To Be Checked Against Design Loads)

Slip Critical Check (Overload Forces): F b= P Top = Bolts Required = 755829.58 MPa 45349.77 kN 1795642.4 Bolts or

Bolt Shear and Bearing Check (Design Forces): F b= P Top = Bolts Required = 491313.51 MPa 29478.81 kN 1018669.3 Bolts WARNING - Design Insufficient

(Average Stress in Top Flange) (Top Flange Force)

Controlling # of Bolts Required =

1795642.4 Bolts

<

28 Bolts Used

Bottom FlangeBolts: Slip Critical Bolt Cap. (PhiRs) = Bolt Shear Capacity = Splice Plates: (Capacity) PhiR Equals Less of = Lc = 0.13 kN/Bolt 0.15 kN/Bolt Lc = 0.29 kN/Bolt 0.26 kN/Bolt 0.03 kN/Bolt 0.03 kN/Bolt 1.50 m

(AASHTO 10.57.3.1 - Two Slip Planes) (Double Shear With UnEqual Area Plate Ratio Considered) (Minimum of Vertical/Horizontal Clear Hole Distance or Edge Distance) (Both Inner and Outer Plates are Considered. Assume Both Plates to Take Equal Loading - Slightly Conservative))

Girder Flange: (Capacity) PhiR Equals Less of =

2.00 mm

(Minimum of Vertical/Horizontal Clear Hole Distance or Edge Distance)

Summary: S

Slip C iti l Bolt Capacity = Sli Critical B lt C it and Bolt Shear Capacity Contolling =

0.03 kN/Bolt 0 03 kN/B lt 0.03 kN/Bolt

(Controlling Bolt Shear/Plate Capacity)

(To B Ch k d Against Overload) (T Be Checked A i t O l d) (To Be Checked Against Design Loads)

Slip Critical Check (Overload Forces): F b= P Top = Bolts Required = 676090.74 MPa 47326.35 kN 1873905.8 Bolts or

Bolt Shear and Bearing Check (Design Forces): F b= P Top = Bolts Required = 439480.70 MPa 30763.65 kN 1071927.1 Bolts WARNING - Design Insufficient

(Average Stress in Bottom Flange) (Bottom Flange Force)

Controlling # of Bolts Required =

1873905.8 Bolts

<

30 Bolts Used

14219875-Field-Splice-Design

SHEET NO. PROJECT: SUBJECT:

OF

Project Subject

JOB NO. MADE BY: CHKD BY:

Job # Name Name

DATE: DATE:

Date Date

FS Calculation Sheet 7 of 7

Field Splice Summary

Web Splice-

2 Plates Includes

Top Flange Splice-

72.00 mm High x 102 Bolts with a

24.00 mm Wide x 0.875 mm Bolt Diameter

0.50 mm Thick

Outer Plate 2 - Inner Plates Includes

Bottom Flange Splice-

54.00 mm Long x 54.00 mm Long x 56 Bolts with a

24.00 mm Wide x 9.50 mm Wide x 0.875 mm Bolt Diameter

1.500 mm Thick 0.750 mm Thick

Outer Plate 2 - Inner Plates Includes

41.00 mm Long x 41.00 mm Long x 60 Bolts with a WARNING - Design Insufficient

28.00 mm Wide x 11.00 mm Wide x 0.875 mm Bolt Diameter

1.500 mm Thick 0.750 mm Thick

Load Factor Design

14219875-Field-Splice-Design

Potrebbero piacerti anche

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDa EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNessuna valutazione finora

- Bracing ConnectionDocumento15 pagineBracing ConnectionrajedmaglinteNessuna valutazione finora

- RCCe11 Element DesignDocumento8 pagineRCCe11 Element DesignZayyan RomjonNessuna valutazione finora

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionDa EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNessuna valutazione finora

- STAAD - Pro Advanced Analysis ModuleDocumento2 pagineSTAAD - Pro Advanced Analysis Modulexio maraNessuna valutazione finora

- ACI Beam LedgeDocumento7 pagineACI Beam LedgeMahmoud ShakerNessuna valutazione finora

- EQ06 - Shear Wall and B.E. DesignDocumento124 pagineEQ06 - Shear Wall and B.E. DesignrahuljainNessuna valutazione finora

- Effective LengthDocumento17 pagineEffective LengthJob NantawatNessuna valutazione finora

- Anchor Bolt DesignDocumento1 paginaAnchor Bolt DesignpawanNessuna valutazione finora

- Advanced Steel Structure Design, Construction For Oil and Gas and Petrochemical IndustryDocumento5 pagineAdvanced Steel Structure Design, Construction For Oil and Gas and Petrochemical IndustryMUTHUKKUMARAMNessuna valutazione finora

- Description: Welded Lifting LugDocumento2 pagineDescription: Welded Lifting LugHomer SilvaNessuna valutazione finora

- Column Beam Seismic ConnectionDocumento8 pagineColumn Beam Seismic ConnectionPrakash Singh RawalNessuna valutazione finora

- Wind Load CalculationsDocumento1 paginaWind Load Calculationsfrog15Nessuna valutazione finora

- Splice 03Documento15 pagineSplice 03LexNessuna valutazione finora

- Here: Mat Foundation Design Spreadsheet PDFDocumento2 pagineHere: Mat Foundation Design Spreadsheet PDFbiniamNessuna valutazione finora

- RAM Connection Input With CommentsDocumento6 pagineRAM Connection Input With CommentsAhmed Saeed OokaNessuna valutazione finora

- Analysis and Design of Vertical Post-Tensioned Precast Shear WallDocumento5 pagineAnalysis and Design of Vertical Post-Tensioned Precast Shear WallEditor IJRITCC0% (1)

- Bolted Splice DesignDocumento8 pagineBolted Splice DesignAnonymous sfkedkymNessuna valutazione finora

- Assignment On Structural Design Lab - 2 Submitted by PRADYUT ANAND/ MT/CE/10016/19Documento15 pagineAssignment On Structural Design Lab - 2 Submitted by PRADYUT ANAND/ MT/CE/10016/19Pradyut AnandNessuna valutazione finora

- Analysis of Railway Bridge Steel Sections With Different Type of Trusses For 32.5 Tonne Axle LoadingDocumento10 pagineAnalysis of Railway Bridge Steel Sections With Different Type of Trusses For 32.5 Tonne Axle LoadingIJRASETPublicationsNessuna valutazione finora

- IS800 - 2007 - Tube - Detailed Calculation PDFDocumento4 pagineIS800 - 2007 - Tube - Detailed Calculation PDFLandon MitchellNessuna valutazione finora

- Check For Requirement of Boundary ElementDocumento9 pagineCheck For Requirement of Boundary ElementJai ThakkarNessuna valutazione finora

- Portal Frame Practice ProblemsDocumento10 paginePortal Frame Practice ProblemsBoyzz ChinNessuna valutazione finora

- Structural ExampleDocumento32 pagineStructural ExampleHarry Ccayascca FloresNessuna valutazione finora

- Design of Monolithic Corbels and Brackets According To Aci 318 - 99Documento1 paginaDesign of Monolithic Corbels and Brackets According To Aci 318 - 99Sulaiman Mohsin AbdulAzizNessuna valutazione finora

- Beam Ledge DesignDocumento2 pagineBeam Ledge Designauatipu100% (1)

- Beam End Connection Using Clip Angles Per AISC 9th Edition (ASD)Documento36 pagineBeam End Connection Using Clip Angles Per AISC 9th Edition (ASD)cengizNessuna valutazione finora

- Cap PlateDocumento18 pagineCap PlateVinoth KumarNessuna valutazione finora

- Using Spreadsheets For Steel DesignDocumento4 pagineUsing Spreadsheets For Steel DesignAmro Ahmad AliNessuna valutazione finora

- Appendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)Documento10 pagineAppendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)sundarNessuna valutazione finora

- Brace DesignDocumento457 pagineBrace DesignRyan Goh Chuang HongNessuna valutazione finora

- Anchor Bolt Design Sprea..Documento153 pagineAnchor Bolt Design Sprea..hatot100% (1)

- Design of RCC Footing As Per ACI 318 95 EdDocumento2 pagineDesign of RCC Footing As Per ACI 318 95 EdMaad Ahmed Al-MaroofNessuna valutazione finora

- SAP2000 Section PropertiesDocumento3 pagineSAP2000 Section PropertiesCon Can100% (1)

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionDocumento6 pagineConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionVenu GopalNessuna valutazione finora

- Double Angle ConnectionDocumento8 pagineDouble Angle ConnectionrunkirNessuna valutazione finora

- Cellar Box Design: Bending Moment LocationsDocumento1 paginaCellar Box Design: Bending Moment LocationsSudathipTangwongchaiNessuna valutazione finora

- Truss DesignDocumento16 pagineTruss DesignRabindraUpretiNessuna valutazione finora

- Roof TrussDocumento4 pagineRoof TrussShamie Dela Cruz CaldeaNessuna valutazione finora

- Sample Shear ConnectionDocumento1 paginaSample Shear ConnectionmaheshbandhamNessuna valutazione finora

- AISC 13th Slip Critical Bolt Capacity ASDDocumento1 paginaAISC 13th Slip Critical Bolt Capacity ASDdantevariasNessuna valutazione finora

- Beam - Section Classification Is 800-2007Documento6 pagineBeam - Section Classification Is 800-2007ranjitNessuna valutazione finora

- Anchorage To ConcreteDocumento10 pagineAnchorage To ConcretemakakkNessuna valutazione finora

- Hollow Sections ConnectionsDocumento4 pagineHollow Sections Connectionsאחמד סלאח כאמלNessuna valutazione finora

- 12-7 Column Web Moment ConnectionDocumento1 pagina12-7 Column Web Moment ConnectionsuperpiojooNessuna valutazione finora

- Steel Joint Design (Fin Plate)Documento8 pagineSteel Joint Design (Fin Plate)Wazini D. IzaniNessuna valutazione finora

- Beam Column ConnectionDocumento2 pagineBeam Column ConnectionHAZIRACFS SURATNessuna valutazione finora

- Column Base Plate Design PDFDocumento2 pagineColumn Base Plate Design PDFDrewNessuna valutazione finora

- Corbel BS8110Documento3 pagineCorbel BS8110Nugraha BintangNessuna valutazione finora

- Pile Cap Theory - BentleyDocumento4 paginePile Cap Theory - BentleyParameswaran GanesanNessuna valutazione finora

- Connection DesignDocumento33 pagineConnection DesignSri KalyanNessuna valutazione finora

- AISC Tension MemberDocumento3 pagineAISC Tension Membermodulor3dNessuna valutazione finora

- Project: 34M Stadium Mast - Philips India Limited Description: D-28/SM/TLL Pile Cap Design For CompressionDocumento4 pagineProject: 34M Stadium Mast - Philips India Limited Description: D-28/SM/TLL Pile Cap Design For CompressionEr Ravi VishwakarmaNessuna valutazione finora

- Estimating Deadloads On Timber CanopiesDocumento1 paginaEstimating Deadloads On Timber CanopiesConrad HarrisonNessuna valutazione finora

- Rafter To Column Top Connection Design Given DataDocumento10 pagineRafter To Column Top Connection Design Given DataSafi Zabihullah SafiNessuna valutazione finora

- End Plate DesignDocumento4 pagineEnd Plate DesignAgnon Fung100% (4)

- Punching Shear Check For SlabDocumento2 paginePunching Shear Check For SlabArnab Sur50% (2)

- Rafter Splice DesignDocumento2 pagineRafter Splice DesignkalpanaadhiNessuna valutazione finora

- Aashto Shear and TorsionDocumento4 pagineAashto Shear and Torsion3cesNessuna valutazione finora

- Mono Strand JacksDocumento2 pagineMono Strand JacksChandan SinghNessuna valutazione finora

- Bridge Launching Equipment 1 1Documento49 pagineBridge Launching Equipment 1 1Chandan Singh100% (1)

- Dubai LRT Viaduct Span by Span Erection MethodDocumento10 pagineDubai LRT Viaduct Span by Span Erection MethodShaukatQadeerNessuna valutazione finora

- High Tensile Bolts TechnicalDocumento6 pagineHigh Tensile Bolts Technicalventhan_kalaiNessuna valutazione finora

- FREYSSINET Prestress ManualDocumento53 pagineFREYSSINET Prestress Manualras_deep100% (2)

- FREYSSINET Prestress ManualDocumento53 pagineFREYSSINET Prestress Manualras_deep100% (2)

- Unit 4 PCDocumento28 pagineUnit 4 PCChandan Singh100% (1)

- Insdag Jan 06Documento7 pagineInsdag Jan 06hazi007Nessuna valutazione finora

- Front Support BracketDocumento1 paginaFront Support BracketChandan SinghNessuna valutazione finora

- Understanding - Unbrako Fasteners (Technical Brochure)Documento48 pagineUnderstanding - Unbrako Fasteners (Technical Brochure)pavan_jssatebNessuna valutazione finora

- 5 Plastic AnalysisDocumento14 pagine5 Plastic AnalysisParveen RidhalNessuna valutazione finora

- HSFG Manual Railway BridgeDocumento11 pagineHSFG Manual Railway BridgeChandan SinghNessuna valutazione finora

- Effect of Preload On Natural Frequency of Bolted Joint Under Impact LoadingDocumento4 pagineEffect of Preload On Natural Frequency of Bolted Joint Under Impact LoadingInternational Journal of Innovative Science and Research Technology100% (1)

- Hardie Best PracticesDocumento28 pagineHardie Best PracticesJon DavisNessuna valutazione finora

- Grundfos CR 1 8 A FGJ A E HQQE 96537544 DatasheetDocumento13 pagineGrundfos CR 1 8 A FGJ A E HQQE 96537544 DatasheetLeduța DomnescuNessuna valutazione finora

- Washing Machine: User ManualDocumento64 pagineWashing Machine: User ManualAndrea DiggitaloNessuna valutazione finora

- Technical Data Sheet For The HSL 3 Heavy Duty Anchor Technical Information ASSET DOC 2331111Documento15 pagineTechnical Data Sheet For The HSL 3 Heavy Duty Anchor Technical Information ASSET DOC 2331111Nelson Eduardo Zárate SalazarNessuna valutazione finora

- GBC MP2500ix Parts ManualDocumento32 pagineGBC MP2500ix Parts ManualToddNessuna valutazione finora

- SECTION 2.00: Cylinder Head RemovalDocumento5 pagineSECTION 2.00: Cylinder Head RemovalLUISA FERNANDA TORRES MANOSALVANessuna valutazione finora

- Mass-10 14 1 - May-2016Documento14 pagineMass-10 14 1 - May-2016ianfldNessuna valutazione finora

- Ffu 0000024 01 PDFDocumento23 pagineFfu 0000024 01 PDFRodolfo Alberto Muñoz CarcamoNessuna valutazione finora

- Manual Maintenance Interval Schedule Caterpillar 320d R L Hydraulic ExcavatorsDocumento59 pagineManual Maintenance Interval Schedule Caterpillar 320d R L Hydraulic ExcavatorsDhany Siregar100% (2)

- 9.6 Inner Floor InstallationDocumento17 pagine9.6 Inner Floor InstallationVishwasen KhotNessuna valutazione finora

- Design For Steel Circular Columns (R1)Documento8 pagineDesign For Steel Circular Columns (R1)rahul1433Nessuna valutazione finora

- HSFG BoltsDocumento4 pagineHSFG BoltspajipitarNessuna valutazione finora

- Design of Machine Elements - Ii: Course Code:13ME1126 L TPC 4 1 0 3Documento3 pagineDesign of Machine Elements - Ii: Course Code:13ME1126 L TPC 4 1 0 3Krypton 2000Nessuna valutazione finora

- Apollo Top Entry Ball Valves Installation, Operation, & Maintenance ManualDocumento9 pagineApollo Top Entry Ball Valves Installation, Operation, & Maintenance ManualErcan YilmazNessuna valutazione finora

- Calg CDDocumento92 pagineCalg CDMilutinMMNessuna valutazione finora

- M400-60 (Check Valves) PDFDocumento8 pagineM400-60 (Check Valves) PDFLazzarus Az GunawanNessuna valutazione finora

- 0185-0001-E 5V6 IG Linear Motors P01Documento46 pagine0185-0001-E 5V6 IG Linear Motors P01michael KetselaNessuna valutazione finora

- External FixatorsDocumento49 pagineExternal FixatorsdvenumohanNessuna valutazione finora

- GB090 2614 250 CS DB 0001 - 0 - Design Basis For Steel StructureDocumento25 pagineGB090 2614 250 CS DB 0001 - 0 - Design Basis For Steel StructuretanujaayerNessuna valutazione finora

- MQC Screw ThreadsDocumento22 pagineMQC Screw ThreadsNayemNessuna valutazione finora

- TOM Print NotesDocumento82 pagineTOM Print NotesOm TandelNessuna valutazione finora

- Mini Project-Assignment 2 - Wheel Stud-MaterialsDocumento5 pagineMini Project-Assignment 2 - Wheel Stud-MaterialsKhaled AlhawariNessuna valutazione finora

- Sttype ABDocumento1 paginaSttype ABSean YangNessuna valutazione finora

- 309-8e SKR PDFDocumento56 pagine309-8e SKR PDFabs0001100% (1)

- Beam Jacketing MSDocumento10 pagineBeam Jacketing MSdraganugNessuna valutazione finora

- Steel ConstructionDocumento70 pagineSteel Constructionfabhinaya100% (11)

- Clestae3 Chair PDFDocumento28 pagineClestae3 Chair PDFmohan kNessuna valutazione finora

- Manual de Roscas EstandaresDocumento136 pagineManual de Roscas EstandaresDavid AgNessuna valutazione finora

- LG Axle Workshop Manual 201408 2Documento88 pagineLG Axle Workshop Manual 201408 2Fredy Velazquez100% (1)