Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Interfacing A Servo To The Atmega16: 7 "#&0F99"007F +&9%G5 " 3.?& :30& H&0 F ". 0&I3 &) "& "& %J&

Caricato da

Gaurang 'TottaPhilic' GuptaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Interfacing A Servo To The Atmega16: 7 "#&0F99"007F +&9%G5 " 3.?& :30& H&0 F ". 0&I3 &) "& "& %J&

Caricato da

Gaurang 'TottaPhilic' GuptaCopyright:

Formati disponibili

Servo Laboratory Servo-1

San Jose State University Dept. oI Mechanical and Aerospace Engineering rev.3.3 02OCT2010

Interfacing a Servo to the ATmega16

Learning Objectives:

AIter successIully completing this lab, students will be able to:

x Desribe how a radio control (RC) servo works

x InterIace a RC servo to a microcontroller

x Use the ATmega16 to control the movement oI a servo

Components:

Qty. Item

1 ATmega16 microcontroller with STK 500 development board, serial port cable

1 Futaba FP-S148 servo or similar

Introduction:

In this lab you will explore the workings oI a radio control (RC) servo and how the ATmega16 can

be used to control one. An RC servo consists oI a dc motor, gear train, potentiometer, and some

control circuitry all mounted compactly in a case. RC servos are commonly used in radio-controlled

cars, airplanes, and boats to provide limited rotational motion to steer, move control surIaces, etc. RC

servos are attractive Ior educational use in mechatronics, because they are relatively inexpensive

(about $12-$20), they can put out about 42 oz/in oI torque, they can easily be modiIied to produce

continuous shaIt rotation at relatively slow speeds, and they can easily be controlled by a

microcontroller. Figure 1 shows that there are three wires, white, red, and black on the servo leading

Irom a 3-pin Iemale connector to the case. These carry the control signal, power, and ground return

respectively.

Black

Red

White or yellow

Figure 1. RC Servo. The RC servo uses three wires: white carries the control signal, red carries power (usually 4.8

V to 6 V), and black is ground.

Figure 2 shows how an RC servo is made to rotate. The control circuitry inside the servo must

receive a stream oI pulses whose widths may vary between about 1 to 2 ms. These pulses must occur

at intervals oI about 10 to 20 ms. A potentiometer coupled to the rotation oI the output shaIt produces

a voltage corresponding to the angle oI the shaIt. The control circuitry compares the 'average

voltage oI the control signal (i.e., by low pass Iiltering) with the voltage Irom the potentiometer, and

the shaIt rotates until the two voltages are the same.

Figure 2. RC Servo Operation. The RC servo needs to see a pulse-width modulated control signal in order to

position the output shaIt. Pulse-widths vary between approximately 1ms to 2 ms, and have a period between 10 ms

to 20 ms.

Servo Laboratory Servo-2

San Jose State University Dept. oI Mechanical and Aerospace Engineering rev.3.3 02OCT2010

Procedure:

In this lab, we are going to build a circuit to control the servo using the switches on the STK500.

1. As shown in Figure 3, connect the PORTA pins to the 10-pin header Ior the SWITCHES using a

10-pin ribbon cable jumper. Similarly, connect the PORTC pins to the 10-pin header Ior the

LEDs. (Figure A1 in the Appendix explains how the switches and LEDs on the STK500 are

wired internally.) Do not connect the servo yet!

2. Test your connections to the switches and LEDs by starting a new project in AVR Studio using

the servo_switch_control_test.c program Iound on the ME 106 website. Your program should

allow you to turn on the LEDs when the corresponding switch is pressed. Explain how the if-

else statement works and the significance of the ~ operator.

S

e

r

v

o

5V

white

STK500

PORTA

SWITCHES

PORTC

LEDs

PB3

red

black

Figure 3. Servo control circuit. PORTA pins are jumpered to the SWITCHES, and PORTC pins are jumpered to

the LEDs on the STK500. The 5V source to power the servo can come Irom a VTG pin oI one oI the headers on the

STK500.

3. AIter you have proven that the switches and LEDs have been wired correctly, add the servo.

Connect the servo`s white wire to the STK500 board at pin PB3. The red and black wires should

be connected to power and ground, and thus can be hooked up to a VTG and GND on the

STK500 board. Now connect the oscilloscope to the white wire going to the servo. Don`t Iorget

to connect the oscilloscope`s ground clip to a GND pin on the STK500. Also, we will be using

RS232 communication Ior the next part oI the lab, so connect a jumper Irom RS232 SPARE to

pins PD0 and PD1.

4. Create a new project in AVR Studio, copy mainservo.c, uart.c, and uart.h Irom the ME 106

website into your project Iolder, and add these Iiles to AVR Studio as you have done in previous

labs. You are going to need to print out Iloating point values, so Iollow the instructions in the

comments in uart.h to add the necessary inIormation in your linker options. See Figure 4 below.

Click on the Custom Options button on the leIt hand side oI the window, click |Linker Options|

in the list and paste this line in the text Iield. Don`t Iorget to press the Add button!

Servo Laboratory Servo-3

San Jose State University Dept. oI Mechanical and Aerospace Engineering rev.3.3 02OCT2010

Figure 4. AVR Studio compilation options. In order to add Iloating point support to printI, paste the linker

options listed in uart.h into the text box as shown, and click Add`.

5. BeIore we continue, let`s take a look at a couple oI sections oI the demo program to try and get a

better idea oI what`s going on. In the RC Filter lab, we used a timer to generate various tones to

mimic a simple piano. We did this by setting up Timer1 (a 16-bit timer) so that we could vary the

period while keeping the duty cycle constant at 50. In this lab we will use Timer0 (an 8-bit

timer) to vary the duty cycle while keeping the period constant.

The timers that are included on the AVR line oI microcontrollers are really multi-purpose devices

that are capable oI acting as counters that can count a number oI external pulses, timers that can

trigger a soItware interrupt aIter a certain period oI time, as well as devices that generate square

waves oI varying duty cycles and periods. For this lab we will use a timer to generate a PWM

signal in a conIiguration known as Phase Correct PWM. Phase Correct PWM works by

incrementing a counter, which is attached to a reIerence clock signal until the counter reaches a

maximum value (255 Ior Timer0). When this maximum value is reached, the counter starts

counting back down to zero, and the process repeats. At every increment oI the counter, the timer

compares the value oI the counter to a value stored in an Output Compare Register, iI these values

are the same it toggles an output pin on the microcontroller, that is, it changes its value Irom high

(5V) to low (GND) or vice-versa.

Let`s take a look at the init() Iunction in the demo program:

void init()

{

//Initialize Timer0

TCCR0 = _BV(WGM00) | _BV(COM01) | _BV(CS02);

//Enable output

DDRB |= _BV(PB3);

}

Servo Laboratory Servo-4

San Jose State University Dept. oI Mechanical and Aerospace Engineering rev.3.3 02OCT2010

Just like the ports and all other components oI the ATmega16, the timers are controlled by

registers. The registers that we need to deal with Ior Timer0 are: TCCR0 (Timer Counter Control

Register 0) which conIigures the timer, and OCR0 (Output Compare Register 0), which holds the

compare value.

We set the WGM00 bit in TCCR0, which sets the timer to Phase Correct PWM, the COM01 bit

to enable the output oI the PWM on pin PB3, and the CS02 bit to select the CPU clock/256 as the

clock source Ior the timer. All oI these registers and bits are discussed in greater detail in the

ATmega16 datasheet.

The last thing to we need to do is conIigure the port containing the pin which will output the

PWM signal. This is done by setting the appropriate bit in the DDRB register. Note that the

datasheet reIers to the PWM output pin as OC0, not as PB3. Since almost all the pins have

additional Iunctionality associated with them besides standard IO, we can see which pins are

associated with that Iunctionality by looking at the 'pinout on page two oI the ATmega16

datasheet, also shown below in Figure 6.

Figure 5. ATmega16 pinout. The pinout not only shows which pins are associated with which ports, but also

what other Iunctionality that they may provide. For example, we can see that the output compare pin Ior

Counter/Timer0 (OC0) is on PB3, that the UART/RS232 communication (RXD and TXD) are on pins PD0 and

PD1, and that the Analog to Digital Conversion (ADCx) pins are all on PORTA. Figure from page 2 of the

ATmega16 Datasheet, 2008 Atmel Corporation.

Next, we`ll look at part oI the UART character received interrupt where we actually set the

Output Compare Register:

if ((input == 'a') && (OCR0 != 255))

{

OCR0++; //Increment timer0's Output Compare Register

printf("Period: %f/%f\tOCR0: %u/255\r\n", T*OCR0/255, T, OCR0);

}

As mentioned in the comments, you don`t have to worry too much about how the ISR works, just

that it gets called whenever the microcontroller receives a character Irom the UART. Here, we

check iI the incoming character is the letter a`, and we make sure that the OCR0 register is not at

Servo Laboratory Servo-5

San Jose State University Dept. oI Mechanical and Aerospace Engineering rev.3.3 02OCT2010

its maximum value. II this is the case, we increment the value oI the output compare register,

which increases the duty cycle.

The overall period is determined by the size oI our counter and the clock signal that we`re using.

Since the ATmega16 has a deIault clock speed oI 8MHz, and we`re using a prescale value oI

256, the actual clock speed that the timer is using is:

which gives us a period oI 32s. When operating in Phase Correct PWM, one complete cycle

consists oI the counter counting all the way to 255 and back to zero, so one period oI our output

PWM signal is:

which is within our required range oI 10ms 20ms as required by the servo.

To set the duty cycle oI our PWM signal, all we have to do is set the value oI the OCR0 register,

which will correspond to the length oI the duty cycle. II OCR0 is equal to 0, we will have a 0

duty cycle. II OCR0 register is 255, we will have a 100 duty cycle.

Figure 7 below shows how OCR0 is used to control the duty cycle. When OCR0 is selected to be

50, the duty cycle will be 50/255*100 19.6. When the Irequency is suIIiciently high,

controlling the duty cycle oI a PWM wave could actually be used in digital to analog conversion

(i.e. DC motor speed control)

Figure 6. How OCR0 Controls Duty Cycle. The Iigure demonstrates how the OCR0 value is used

to control the duty cycle Ior Phase Correct PWM. The OC0 pin is initially at 5V, and once the

counter reaches the OCR0 value, the OC0 pin is set to low. OC0 is pulled high when the counter

reaches the OCR0 value again.

|Go to the Atmel website and Iind the datasheet Ior the ATmega16. (Download the Iull datasheet,

not the summary.) Find the section Ior TimeRCounter 0, and look over it. What bits of the

TCCR0 register would need to be set if we wanted a clock prescale of 1024? What would

the period of the output signal be? Hint: All oI the bits that control the clock prescale are

named CS0x.|

6. Now build your project and program the microcontroller. Check the Iuses to ensure that your

microcontroller`s clock is actually set to 8MHz. Now connect the serial cable to the RS232 Spare

port and start HyperTerminal, and reset the STK500.

Servo Laboratory Servo-6

San Jose State University Dept. oI Mechanical and Aerospace Engineering rev.3.3 02OCT2010

7. Press the a` key on your keyboard a couple oI times. You should see the servo move and be able

to observe the PWM signal on your oscilloscope. Add the 'Period and 'Duty Cycle

measurements to your oscilloscope`s display. Continue to increase the duty cycle by pressing the

a` key. Note that the period displayed on the oscilloscope may not exactly match the theoretical

value oI 16.364 ms. The ATmega16`s internal oscillator is not that precise, and any projects that

require exact timing should use an external oscillator or external crystal. This discrepancy should

have no eIIect on our servo`s perIormance though.

8. Continue to press the a` and z` keys on the keyboard. Find the values oI OCR0 that correspond

to the servo at the Iull leIt, Iull right, and center positions. The servos in lab only have 180 oI

travel so be sure that your servo is not actively trying to drive its selI against one oI the stops

(maintain the OCR0 value within the range oI 3-38). (You should be able to tell when this is

happening by a noticeable twitch oI the servo and hum oI the motor. Leaving the servo in this

state will only decrease its liIe.) Include these values, the theoretical on time of the duty

cycle as displayed on HyperTerminal, and the actual on time of the duty cycle in your lab

report.

4. Now create a new project and copy in the mainyourservo.c Iile Irom the ME 106 website. Use

this template to write a program that makes the servo move all the way to the leIt when SW0 is

pressed, all the way to the right when SW1 is pressed, and centered when no switches are

pressed. Additionally, the corresponding LED should light up when the button is pressed. Be

sure to include this code with your lab report. As always, your code should be properly

formatted and indented to improve clarity and reduce the time you spend debugging.

Notes:

It is relatively easy to modiIy a servo so that it can rotate continuously. An excellent step-by-step

guide Ior doing so can be Iound at: http://www.seattlerobotics.org/guide/servohack.html

II you use the Futaba FP-S148, it is especially easy. You don`t even need to replace the

potentiometer as noted in the link above. You can manually position the pot shaIt to its center

position.

Once you`ve hacked the servo, you then have a low-cost, relatively powerIul variable speed dc motor

drive system that is great Ior any term projects or any other applications that needs a decent amount

oI accuracy.

Using a servo can be a low-cost and eIIicient approach Ior giving mobility to your robot. Tower

Hobbies (http://www.towerhobbies.com/) has the best prices around Ior Futaba servos (3 Ior $39.47).

Servo Laboratory Servo-7

San Jose State University Dept. oI Mechanical and Aerospace Engineering rev.3.3 02OCT2010

Appendix A STK500 LED and Switch Implementation

Figure A1. Schematics for the switches and LEDs on the STK500 interface board. Output pins on the

ATmega16 can sink enough current to turn on the LEDs, and thus can be connected directly to the LED`s header on

the STK500. Likewise, the SWITCHES header pins can be connected directly to the pins oI an input port on the

ATmega16. Note that when a switch is pressed on the STK500 board, it connects the corresponding SWn pin to

ground. Otherwise the SWn pin is held high by the 10k: pullup resistor. Also note that a LOW signal on the LEDn

pin will cause the LED to turn on.

Potrebbero piacerti anche

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Pic PWMDocumento9 paginePic PWMAditya Gannamaraju100% (1)

- Projects With Microcontrollers And PICCDa EverandProjects With Microcontrollers And PICCValutazione: 5 su 5 stelle5/5 (1)

- Timer Programing of Atmega32Documento8 pagineTimer Programing of Atmega32Stephanie Flores100% (1)

- Sine Wave Generation and Implementation Using DsPIC33FJDocumento27 pagineSine Wave Generation and Implementation Using DsPIC33FJpaaraib100% (1)

- RTS Noise Impact in CMOS Image Sensors Readout CircuitDocumento5 pagineRTS Noise Impact in CMOS Image Sensors Readout CircuiturpublicNessuna valutazione finora

- IR TachometerDocumento10 pagineIR TachometerMohammed Abdulrahman MossaNessuna valutazione finora

- Experiment 6: Motor Speed Control: ErratumDocumento5 pagineExperiment 6: Motor Speed Control: ErratumBambang PrasetyoNessuna valutazione finora

- 16-B PWM U O - C T Relevant Devices: IT Sing AN N HIP ImerDocumento12 pagine16-B PWM U O - C T Relevant Devices: IT Sing AN N HIP ImerLauderi MartinsNessuna valutazione finora

- ProjectDocumento25 pagineProject9897856218Nessuna valutazione finora

- CPR E 381x/382x Lab11aDocumento10 pagineCPR E 381x/382x Lab11aHelenNessuna valutazione finora

- Interfacing Programs For 8085Documento37 pagineInterfacing Programs For 8085archankumarturagaNessuna valutazione finora

- M4 Micro OneNoteDocumento6 pagineM4 Micro OneNoteAryan RaiNessuna valutazione finora

- Tty To Rs232Documento8 pagineTty To Rs232sandeepverma8257100% (2)

- DC Motor Speed ControlDocumento5 pagineDC Motor Speed ControlAnita WulansariNessuna valutazione finora

- PWM ControlDocumento28 paginePWM ControlAgus Lesmana100% (2)

- 10 PWMDocumento6 pagine10 PWMMikroc Thupati SrinivsNessuna valutazione finora

- PWM Signal Generators: Testing Status: Mixed. Some Untested, Some SPICE SimulatedDocumento15 paginePWM Signal Generators: Testing Status: Mixed. Some Untested, Some SPICE SimulatedSivareddy MudiyalaNessuna valutazione finora

- Basics of InvertersDocumento12 pagineBasics of InvertersTatenda BizureNessuna valutazione finora

- PWM Signal GeneratorsDocumento3 paginePWM Signal GeneratorsjalalhNessuna valutazione finora

- ECE 5570 - Lab 8: Brushless DC Motor Control With 6-Step CommutationDocumento6 pagineECE 5570 - Lab 8: Brushless DC Motor Control With 6-Step CommutationAnimesh GhoshNessuna valutazione finora

- Project Underdamped SystemDocumento6 pagineProject Underdamped SystemPablo HenriqueNessuna valutazione finora

- CISE 204 Digital System Design Lab Manual PDFDocumento44 pagineCISE 204 Digital System Design Lab Manual PDFEng-Mohammed KayedNessuna valutazione finora

- Sensors and Sensing Lab 1: Arduino Motor Control and ROSDocumento7 pagineSensors and Sensing Lab 1: Arduino Motor Control and ROSFebri Rizky PratamaNessuna valutazione finora

- The 555 Timer Circuit IIDocumento15 pagineThe 555 Timer Circuit IIDeshitha Chamikara WickramarathnaNessuna valutazione finora

- Siren Project With Pic MicrocontrollerDocumento12 pagineSiren Project With Pic MicrocontrollerMatthew Hunter100% (1)

- PLC AutomationDocumento13 paginePLC AutomationVamsi KumarNessuna valutazione finora

- Raewwwwwwwwwwwwwwwwwwwwwwwww: RUNG - A Section of The PLC Ladder Program That Terminates in An OutputDocumento6 pagineRaewwwwwwwwwwwwwwwwwwwwwwwww: RUNG - A Section of The PLC Ladder Program That Terminates in An Outputpatil_555Nessuna valutazione finora

- Hobby Servo Motor Control Via PIC Pulse Width Modulation: Nathan Markey April 4, 2003Documento7 pagineHobby Servo Motor Control Via PIC Pulse Width Modulation: Nathan Markey April 4, 2003Luciana Gutierrez Salazar100% (1)

- Objective:: Lab TasksDocumento9 pagineObjective:: Lab TasksAsit44 gleNessuna valutazione finora

- Traffic Light Control System ProjectDocumento12 pagineTraffic Light Control System ProjectVinay ReddyNessuna valutazione finora

- Setup and Use The AVR® TimersDocumento16 pagineSetup and Use The AVR® Timersmike_helplineNessuna valutazione finora

- Motor Tachometer Speed Calculation Using Hardware Timer Capture FeatureDocumento3 pagineMotor Tachometer Speed Calculation Using Hardware Timer Capture Featureaani13Nessuna valutazione finora

- 99 000 RPM Contact Less Digital TachometerDocumento11 pagine99 000 RPM Contact Less Digital TachometerHemanth Kumar K SNessuna valutazione finora

- Microcontroller Tutorial Ii Timers: What Is A Timer?Documento13 pagineMicrocontroller Tutorial Ii Timers: What Is A Timer?Ting Chee SiongNessuna valutazione finora

- Openloop Motor ModelingDocumento16 pagineOpenloop Motor ModelingUmair RazaNessuna valutazione finora

- ATMPWMDocumento6 pagineATMPWMOkiPetrus Hutauruk LumbanBaringinNessuna valutazione finora

- 4 - 1 Arduino Basic Functions - 1Documento7 pagine4 - 1 Arduino Basic Functions - 1ankita81123singhNessuna valutazione finora

- BER MeterDocumento8 pagineBER Metersakti prasad nandaNessuna valutazione finora

- Automatic College Bell REPORTDocumento34 pagineAutomatic College Bell REPORTNagraj Tondchore50% (2)

- Transient AnalysisDocumento46 pagineTransient AnalysisArryshah DahmiaNessuna valutazione finora

- PWM, A Software Solution For The PIC16CXXX: MethodsDocumento14 paginePWM, A Software Solution For The PIC16CXXX: Methodsjavixl1Nessuna valutazione finora

- University of Essex: School of Computer Science andDocumento18 pagineUniversity of Essex: School of Computer Science andVlad SimizeanuNessuna valutazione finora

- Newbie's Guide To AVR Timers: Dean CameraDocumento27 pagineNewbie's Guide To AVR Timers: Dean CameracoraztoNessuna valutazione finora

- Microchip-Introduction To Capacitive SensingDocumento10 pagineMicrochip-Introduction To Capacitive Sensinghoe3852Nessuna valutazione finora

- Ee446 Embedded Systems Lab #01: InstructionsDocumento4 pagineEe446 Embedded Systems Lab #01: InstructionsMuhammad ShafeeqNessuna valutazione finora

- Session 4Documento2 pagineSession 4Manoj GudiNessuna valutazione finora

- Using PWM With Code WarriorDocumento14 pagineUsing PWM With Code WarriorGowrishankar Gupta100% (1)

- Modul 3. Timer & CounterDocumento6 pagineModul 3. Timer & CounterYohana Crisma LimbongNessuna valutazione finora

- Modul 3. Timer & Counter 1. TujuanDocumento6 pagineModul 3. Timer & Counter 1. TujuanYohana Crisma LimbongNessuna valutazione finora

- Ac Voltage Controller Using Thyristor Project Report by SandeepDocumento29 pagineAc Voltage Controller Using Thyristor Project Report by SandeepSANDEEP DHANDA100% (1)

- Texas A&M VCO Lab: CMOS LC Oscillator Analysis & SimulationDocumento8 pagineTexas A&M VCO Lab: CMOS LC Oscillator Analysis & SimulationRekha YadavNessuna valutazione finora

- An Freq MeasurementDocumento14 pagineAn Freq MeasurementfarcasiunNessuna valutazione finora

- Microcontrollers LabDocumento19 pagineMicrocontrollers LabAMARNATHNAIDU77Nessuna valutazione finora

- PWM With Microcontroller 8051 For SCR or Triac Power ControlDocumento8 paginePWM With Microcontroller 8051 For SCR or Triac Power ControlSyedMahinNessuna valutazione finora

- EXP6Documento10 pagineEXP6fatih_ealNessuna valutazione finora

- 1 41552 PDFDocumento16 pagine1 41552 PDFGaurang 'TottaPhilic' GuptaNessuna valutazione finora

- Real Turbojet Engine Cycle AnalysisDocumento1 paginaReal Turbojet Engine Cycle AnalysisGaurang 'TottaPhilic' GuptaNessuna valutazione finora

- Turbojet With After BurnerDocumento1 paginaTurbojet With After BurnerGaurang 'TottaPhilic' GuptaNessuna valutazione finora

- Basic Concepts of ChemistryDocumento25 pagineBasic Concepts of ChemistrySanchit JainNessuna valutazione finora

- TurbofanDocumento2 pagineTurbofanGaurang 'TottaPhilic' GuptaNessuna valutazione finora

- Matching A Propeller To A MotorDocumento5 pagineMatching A Propeller To A MotorGaurang 'TottaPhilic' GuptaNessuna valutazione finora

- Aerodynamics For Students - BladeDocumento6 pagineAerodynamics For Students - BladeGaurang 'TottaPhilic' GuptaNessuna valutazione finora

- Fundamentals of Small Unmanned Aircraft Flight-BartonDocumento18 pagineFundamentals of Small Unmanned Aircraft Flight-BartonGaurang 'TottaPhilic' Gupta100% (1)

- Attitude Estimation With Accelerometers and Gyros Using Fuzzy Tuned Kalman FilterDocumento6 pagineAttitude Estimation With Accelerometers and Gyros Using Fuzzy Tuned Kalman FilterĐinh Hữu KiênNessuna valutazione finora

- Flight Power Relations: Lab 1 Lecture NotesDocumento4 pagineFlight Power Relations: Lab 1 Lecture NotesGaurang 'TottaPhilic' GuptaNessuna valutazione finora

- Kuhn - Working Charts For The Determination of The Lift Distribution Between Biplane Wings - NACADocumento15 pagineKuhn - Working Charts For The Determination of The Lift Distribution Between Biplane Wings - NACAfedeoseayoNessuna valutazione finora

- Preview of "Microsoft Word - IITB - Abstract - Docx"Documento14 paginePreview of "Microsoft Word - IITB - Abstract - Docx"Gaurang 'TottaPhilic' GuptaNessuna valutazione finora

- Economic Analysis of Aircraft DesignDocumento21 pagineEconomic Analysis of Aircraft DesignGaurang 'TottaPhilic' GuptaNessuna valutazione finora

- AeroDocumento6 pagineAeroGaurang 'TottaPhilic' GuptaNessuna valutazione finora

- Major Project - Grid Solving RobotDocumento84 pagineMajor Project - Grid Solving RobotAshish Bharade57% (7)

- Twist Distribution For Swept WingDocumento13 pagineTwist Distribution For Swept WingGaurang 'TottaPhilic' GuptaNessuna valutazione finora

- Concept of Lift and DragDocumento7 pagineConcept of Lift and DraglarasmoyoNessuna valutazione finora

- IEEMA June 2020 - Generator 95% Stator Earth Fault and Its CalculationDocumento5 pagineIEEMA June 2020 - Generator 95% Stator Earth Fault and Its CalculationVishal Kumar LaddhaNessuna valutazione finora

- Objective: Parkavi RDocumento3 pagineObjective: Parkavi Rparkavi02Nessuna valutazione finora

- 3 BR 2565 JFDocumento36 pagine3 BR 2565 JFMindSet MarcosNessuna valutazione finora

- Seventy Years of Getting Transistorized 2017Documento5 pagineSeventy Years of Getting Transistorized 2017RajatNessuna valutazione finora

- 20 KW Water-Cooled Prototype of A Buck-Boost Bidirectional DC-DC Converter Topology For Electrical Vehicle Motor DrivesDocumento6 pagine20 KW Water-Cooled Prototype of A Buck-Boost Bidirectional DC-DC Converter Topology For Electrical Vehicle Motor DrivesEnes UğurNessuna valutazione finora

- 8th Sem ProjectDocumento29 pagine8th Sem ProjectRashmi B ReddyNessuna valutazione finora

- TDR900 QuickStartGuide PDFDocumento2 pagineTDR900 QuickStartGuide PDFmiamor$44Nessuna valutazione finora

- AVR-051 User Manual: Monicon International Co., LTD AVR-051Documento10 pagineAVR-051 User Manual: Monicon International Co., LTD AVR-051GONZALONessuna valutazione finora

- Color Television/ Video Cassette Recorder: Service ManualDocumento61 pagineColor Television/ Video Cassette Recorder: Service Manualomaderas1Nessuna valutazione finora

- MC33385 - Atm36bDocumento11 pagineMC33385 - Atm36btason07Nessuna valutazione finora

- Serial Communication: User's Manual QJ71C24N, QJ71C24N-R2 QJ71C24N-R4 QJ71C24, QJ71C24-R2Documento24 pagineSerial Communication: User's Manual QJ71C24N, QJ71C24N-R2 QJ71C24N-R4 QJ71C24, QJ71C24-R2Ing Capriel CaprielNessuna valutazione finora

- Power Quality Monitoring For Electrical Power Systems: Sentron Pac4200Documento4 paginePower Quality Monitoring For Electrical Power Systems: Sentron Pac4200Omar Alfredo Del Castillo QuispeNessuna valutazione finora

- DMR-EX89 Service ManualDocumento96 pagineDMR-EX89 Service ManualEmjay111100% (1)

- 2.1.1.5 Lab The World Runs On Circuits (ACT1FINAL)Documento3 pagine2.1.1.5 Lab The World Runs On Circuits (ACT1FINAL)Rhoda ObiasNessuna valutazione finora

- 04 Telephone DiagnosticsDocumento19 pagine04 Telephone DiagnosticsSalisburNessuna valutazione finora

- Monitoring of Electrical System Using Internet of Things With Smart Current Electric SensorsDocumento8 pagineMonitoring of Electrical System Using Internet of Things With Smart Current Electric SensorsMarcela VelasteguíNessuna valutazione finora

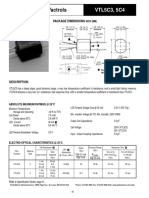

- Low Cost Axial Vactrols: VTL5C3, 5C4Documento2 pagineLow Cost Axial Vactrols: VTL5C3, 5C4sillyNessuna valutazione finora

- Corporate TimelineDocumento28 pagineCorporate TimelineMikael VelschowNessuna valutazione finora

- Jntu Kak 2 2 Ece Emtl Set 3Documento6 pagineJntu Kak 2 2 Ece Emtl Set 3himeshemraanNessuna valutazione finora

- Introduction to PIC Microcontrollers Architecture and Instruction SetDocumento41 pagineIntroduction to PIC Microcontrollers Architecture and Instruction SethulavanyaNessuna valutazione finora

- AXP288Documento3 pagineAXP288Jungkook JeonNessuna valutazione finora

- Honeywell S7830 SpecDocumento16 pagineHoneywell S7830 SpecAndres ParedesNessuna valutazione finora

- COA Unit 1 Lecture 4Documento35 pagineCOA Unit 1 Lecture 4Pratibha SNessuna valutazione finora

- How Does Radio Waves Works in Radio BroadcastingDocumento2 pagineHow Does Radio Waves Works in Radio BroadcastingFahmi DimacalingNessuna valutazione finora

- 8086 Microprocessor ArchitectureDocumento3 pagine8086 Microprocessor ArchitecturePavan KumarNessuna valutazione finora

- Flexi Released Configurations v4.3Documento76 pagineFlexi Released Configurations v4.3GabrieleNessuna valutazione finora

- PDF - 2956 - DIV08L1A-2419 v1.1Documento3 paginePDF - 2956 - DIV08L1A-2419 v1.1aboediartoNessuna valutazione finora

- AC9 User GuideDocumento124 pagineAC9 User GuideDaniel IsailaNessuna valutazione finora

- Ch08-Image CompressionDocumento38 pagineCh08-Image Compressionbaigsalman251Nessuna valutazione finora