Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

LM2500 Performance

Caricato da

Li Fang HuangDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

LM2500 Performance

Caricato da

Li Fang HuangCopyright:

Formati disponibili

ISO performance based on natural gas with water injection to 25 ppmvd NOx.

Power Output (kWe) Heat Rate LHV (Btu/kWe-Hr) Exhaust Flow (lbs/sec) Exhaust Temperature (0F) Emissions (ppmvd)

Gas-DLE Gas or Liquid-Water Gas-Steam

LM2000 18,000 9,900 134 927 NOx/CO

25/25 25/75, 42/68 25/74

LM2500 22,000 9,465 149 990 NOx/CO

25/25 25/30

LM2500+ 30,500 8,850 191 960 NOx/CO

25/25 25/138

25/50, 42/30 25/60, 42/60

LM2500

Technology

Gas Turbine

Power Turbine Speed (rpm) No. of Compressor Stages No. of Turbine Stages

3,600 16 6

3,600 16 6

3,600 17 6 or 2

Service

GE Aero Energy is the worlds largest aeroderivative service provider, with a global network of field service offices and fully equipped depots. A wide range of products and services are offered for the LM2500+, LM2500, and LM2000 Industrial, Cogeneration, and Oil & Gas operators, including: Level IV depot repair and overhaul capability in Houston, Texas; Rheden, The Netherlands, and Agotnes, Norway Conversions, Modifications and Upgrades (CM&U) designed to enhance the efficiency, power output and reliability of the LM2500, such as Exhaust Flow Enhancer, Wet/Dry Low Emissions (DLE) Upgrades; Inlet Conditioning, Fuel Conversions, Remote Monitoring and Diagnostics, among many others Spare or Lease Engine Options Engine Exchange Programs Rotable Hot Section and Module Exchange Programs Wide Variety of Contractual or Long-Term Service Agreements This comprehensive product offering, combined with GE Aero Energys commitment to reduced depot and outage turn times, results in substantial life cycle cost savings for the plant owner/operator.

Derived from the CF6 family of aircraft engines used on wide body jet liners, the LM2500 family is a hot-end drive, two-shaft gas generator with free power turbine. Thermal efficiencies are from 34% to 40%. Baseload Power Capabilities of 18 - 32 MW ISO Unsurpassed Reliability Exceeding 99% Three Models with a High Degree of Parts Commonality

Experience

Maintaining a high degree of commonality with its flight-tested forerunners, the LM2500 family continues to build its reputation as the most reliable industrial gas turbine generator in its class. 40 Million Operating Hours More than 2,000 units End-users: Mechanical Drive and Power Generation for Industrial Plants, Pipelines, Platforms and Marine Ships Configurations: Simple-cycle, Cogeneration and Combined-Cycle

Innovation

GE Aero Energy offers three models in the LM2500 family of products: LM2500+ Providing More Than 30 MW ISO Power Generation, Marine and Mechanical Drive Applications Available in a 6-stage or 2-stage Power Turbine Configuration LM2500 Produces in Excess of 22 MW ISO Operates at 3000 or 3600 rpm Without a Gearbox Optional Steam Injection (STIG) for Power Enhancement LM2000 Capable of 18 MW ISO Extended Maintenance Intervals

LM2500 60Hz Output and Heat Rate

25,000 23,000 OUTPUT (kW) 21,000 9,600 19,000 17,000 15,000 0 20 40 60 AMBIENT ( F)

0

9,900 9,800 9,700 HEAT RATE (Btu /kW)

9,500 9,400 9,300 120

80

100

0 ft, 60% RH, 4/6 in H20 inlet/exhaust loss on natural gas with water injection to 25ppmvd NOx water inj.

LENGTH

686 x

WIDTH

149 x

HEIGHT

295

STANDARD 60HZ LM2500 GENERATOR PACKAGE Gas Turbine

16 Stage Axial Compressor > 1st 6 Stages are VIGV > Horizontal Split Casing > 20:1 Compression Ratio > 103 lb/s Nominal Inlet Mass Flow Annular Combustor

OPTIONAL EQUIPMENT AND SERVICES

Generator Options > TEWAC > Voltages: 12.47kV > Enclosure > Fault Protection Fuel System > Liquid Water Injection or DLE > Dual Water Injection or DLE > Gas Water or Steam Injection or DLE > Filters Control System > 10 minute start > Black start > Continuous Emission Monitoring > Remote Display > Control House > Motor Control center Lube Oil System > Air to Oil Coolers > First Fill Lubricants Winterization Remote Monitoring and Diagnostics Pulse Air Filter Inlet Conditioning > Evaporative Cooling > Chilling > Heating

> 30 Nozzles Gas Fuel, Water Injection for NOx Control 6 Stage Power Turbine

Generator

Continuous Duty 13.8kV, 0.85 PF 2 pole, 3 Phase Brushless Exciter WPII Weather Protected Voltage Regulator/Neutral Side Protection CTs NEMA Class F Insulation & B Temperature Rise

Package

24V and 125V DC Batteries 90dBA Near Field Design Barrier Inlet Air Filters Electro-hydraulic Start System Class I Div 2 Group D Class Electrical System Digital Control System with a Human Machine Interface (HMI) Turbine and Generator Lube Oil System with Simplex Shell

and Tube Coolers Turbine Factory Tested On/Off-line Water Wash 1 Year Parts/Service Warranty Package Familiarization Training Electronically Transmitted Drawings Startup Technical Assistance

Potrebbero piacerti anche

- SXE10 ECU PinoutDocumento13 pagineSXE10 ECU PinoutLeiden O'Sullivan100% (2)

- Form-093-Dump Truck Safety ChecklistDocumento2 pagineForm-093-Dump Truck Safety Checklistshamroz khan100% (2)

- Torque Converter Voith Torque ConverterDocumento22 pagineTorque Converter Voith Torque ConverterDewayne MaddenNessuna valutazione finora

- Ge Ms5001pDocumento14 pagineGe Ms5001pMohamed Hamed100% (1)

- Handbook For Sap PP in S/4HANADocumento477 pagineHandbook For Sap PP in S/4HANArahmani83% (6)

- Ge Lm6000 Training 2Documento161 pagineGe Lm6000 Training 2sasa hhNessuna valutazione finora

- G3516 (975 Ekw 1218 kVA)Documento7 pagineG3516 (975 Ekw 1218 kVA)Antwon CharlesNessuna valutazione finora

- GEH-6126 Vol IDocumento128 pagineGEH-6126 Vol IPremkumar Vasudevan100% (2)

- Gas TurbineDocumento93 pagineGas TurbineShubhankit Porwal100% (2)

- Gas Turb Optimum Operation Lm2500Documento109 pagineGas Turb Optimum Operation Lm2500Samir Benabdallah100% (1)

- 11-Presentation MitchCohen PDFDocumento32 pagine11-Presentation MitchCohen PDFbigsteve9088Nessuna valutazione finora

- Ger 3658d Speedtronic Mark V Gas Turbine Control System PDFDocumento19 pagineGer 3658d Speedtronic Mark V Gas Turbine Control System PDFyos100% (1)

- GE Gas Turbine Extendor Combustion SystemDocumento2 pagineGE Gas Turbine Extendor Combustion SystemRaden Mas100% (1)

- Specsheet 3516 1825 kVA PrimeDocumento6 pagineSpecsheet 3516 1825 kVA PrimeYusman EkaNessuna valutazione finora

- Siemens Gas Turbine Product Range Comparison 0-130 MW: For Siemens Internal Use OnlyDocumento2 pagineSiemens Gas Turbine Product Range Comparison 0-130 MW: For Siemens Internal Use Onlythunder0% (1)

- 9FB Maintenance Considerations SumDocumento10 pagine9FB Maintenance Considerations Sumgalinalbertas100% (1)

- SBLM2500 IND 174rev1Documento7 pagineSBLM2500 IND 174rev1Daniil SerovNessuna valutazione finora

- lm2500 LubesupplyDocumento3 paginelm2500 LubesupplyDenis Jimenez100% (2)

- Gek105162 Operating InstructionDocumento72 pagineGek105162 Operating InstructionMiguel Francisco Goytia100% (1)

- Lm2500 IntroDocumento4 pagineLm2500 IntroDenis JimenezNessuna valutazione finora

- LM TM2500 Upgrade Solutions PDFDocumento2 pagineLM TM2500 Upgrade Solutions PDFLibyanManNessuna valutazione finora

- LM2500+ Shutdown SequencesDocumento6 pagineLM2500+ Shutdown Sequencesrenzobermudez89Nessuna valutazione finora

- Aerosila NPP JSC: Gas Turbine Power PlantsDocumento30 pagineAerosila NPP JSC: Gas Turbine Power PlantsSatish Babu Garikapati100% (2)

- Lm2500 DescripDocumento2 pagineLm2500 DescripDenis Jimenez100% (1)

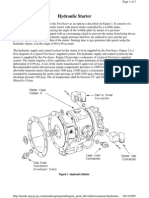

- Figure 1. Hydraulic StarterDocumento3 pagineFigure 1. Hydraulic StarterDenis JimenezNessuna valutazione finora

- LM6000Documento22 pagineLM6000Hernan Delgado50% (2)

- Lm2500 InstrumentationDocumento4 pagineLm2500 InstrumentationDenis JimenezNessuna valutazione finora

- GT Gas Fuel and Air FlowDocumento38 pagineGT Gas Fuel and Air FlowhinaNessuna valutazione finora

- APA DOC No. 2014 PDFDocumento67 pagineAPA DOC No. 2014 PDFThanapaet RittirutNessuna valutazione finora

- Ge LM6000 Training 1Documento74 pagineGe LM6000 Training 1sasa hh100% (1)

- Gas Turbine ControlDocumento8 pagineGas Turbine ControlDAHRAOUI Mohamed Riad100% (1)

- Pages From GEK105059Documento29 paginePages From GEK105059phoenix609Nessuna valutazione finora

- IGV Operational Principle - 1Documento5 pagineIGV Operational Principle - 1ramkrishnaNessuna valutazione finora

- PDFDocumento124 paginePDFEmanuel Conde100% (1)

- MS Fa 6593Documento668 pagineMS Fa 6593Jeya PrakashNessuna valutazione finora

- 01 Tab01 130916060639 Phpapp02 PDFDocumento36 pagine01 Tab01 130916060639 Phpapp02 PDFajo zinzoNessuna valutazione finora

- Variable Inlet Guide Vane System: GE Power SystemsDocumento4 pagineVariable Inlet Guide Vane System: GE Power Systemsanggita gigih wahyu iriawan100% (1)

- Dry Low Nox 2.0+ System Operation: Ge Power SystemsDocumento10 pagineDry Low Nox 2.0+ System Operation: Ge Power SystemsFernando Piaggio100% (1)

- Action Technological PlanDocumento22 pagineAction Technological PlanMarvin AbaoNessuna valutazione finora

- CatalogoPGT25 PDFDocumento4 pagineCatalogoPGT25 PDFshihabjamaan100% (4)

- Combined Cycle Fundamentals PDFDocumento110 pagineCombined Cycle Fundamentals PDFShamimAhammedNessuna valutazione finora

- GearboxDocumento16 pagineGearboxMehul zareNessuna valutazione finora

- LM 2500Documento12 pagineLM 2500pramodtryNessuna valutazione finora

- 2012 WTUI Conference LM2500 Breakout Session March 18-21, 2012Documento100 pagine2012 WTUI Conference LM2500 Breakout Session March 18-21, 2012ferrerick100% (3)

- GT Mtc. PracticesDocumento59 pagineGT Mtc. PracticesAbhishek Prakash SrivastavaNessuna valutazione finora

- Gas Turbine ControlDocumento9 pagineGas Turbine ControlHBNBILNessuna valutazione finora

- lIQUID FUEL SYSTEM PDFDocumento23 paginelIQUID FUEL SYSTEM PDFJJNessuna valutazione finora

- LM6000-InD-239 - Improved LPT Coupling NutDocumento9 pagineLM6000-InD-239 - Improved LPT Coupling NutIqbal UsmaniNessuna valutazione finora

- GT Operation (Nanjin)Documento146 pagineGT Operation (Nanjin)Ady FardyNessuna valutazione finora

- 04 - Dry Low NOxDocumento15 pagine04 - Dry Low NOxdenmas90Nessuna valutazione finora

- ISO IEC 17025 2017 Transition TemplateDocumento8 pagineISO IEC 17025 2017 Transition TemplateaasNessuna valutazione finora

- 7SL87 PDFDocumento6 pagine7SL87 PDFGanesh Duraisamy0% (1)

- Gas Turbine Range OverviewDocumento2 pagineGas Turbine Range Overviewyourikats6161Nessuna valutazione finora

- Gek97310 File0001Documento2 pagineGek97310 File0001Mendez Francisco33% (3)

- Gas Turbine Engines Characteristics and Performance Combustion ChamberDocumento2 pagineGas Turbine Engines Characteristics and Performance Combustion ChamberNicolas Guatibonza LNessuna valutazione finora

- Wabash Gas TurbinesDocumento16 pagineWabash Gas TurbinesMadhan Kumar100% (1)

- General Electric Power Business Unit: Strategic Analysis Tools and Techniques - Coursework 2Documento13 pagineGeneral Electric Power Business Unit: Strategic Analysis Tools and Techniques - Coursework 2Ibilola IbisankaleNessuna valutazione finora

- Device NomenclatureDocumento6 pagineDevice Nomenclaturecbra2020Nessuna valutazione finora

- GFA - GT Exhaust Spread ProblemDocumento5 pagineGFA - GT Exhaust Spread Problemأمير معروف100% (1)

- LM 2500 PlusDocumento2 pagineLM 2500 Plusalexandr_popov_2Nessuna valutazione finora

- g3520c Natural Gas For 1950Documento6 pagineg3520c Natural Gas For 1950Shahzad AliNessuna valutazione finora

- 3512 1275 kVA Prime Low BSFC - EMCP4 - EU PDFDocumento6 pagine3512 1275 kVA Prime Low BSFC - EMCP4 - EU PDFAashish MoyalNessuna valutazione finora

- Cat C175-16 - Jul 2010Documento6 pagineCat C175-16 - Jul 2010Lei YinNessuna valutazione finora

- 3516B TaDocumento6 pagine3516B TaGeovanny Chasi PesantezNessuna valutazione finora

- C9300ekwStandbyTier3 EMCP4Documento6 pagineC9300ekwStandbyTier3 EMCP4CAR6Nessuna valutazione finora

- 500 KVA PrimeC15 Lean I6 - EUDocumento6 pagine500 KVA PrimeC15 Lean I6 - EUanon_46672526Nessuna valutazione finora

- IMSLP309433 PMLP01893 Op.33 Etudes Tableaux 3. GraveDocumento3 pagineIMSLP309433 PMLP01893 Op.33 Etudes Tableaux 3. GraveLi Fang HuangNessuna valutazione finora

- Ginastera Argentina DancesDocumento14 pagineGinastera Argentina DancesLi Fang Huang100% (5)

- IMSLP06173-Ravel - Sonatine Piano PDFDocumento14 pagineIMSLP06173-Ravel - Sonatine Piano PDFLi Fang HuangNessuna valutazione finora

- Brahms - Rhapsody in B Minor Op 79 PT 1Documento9 pagineBrahms - Rhapsody in B Minor Op 79 PT 1Carlos FranciscoNessuna valutazione finora

- Wobbe IndexDocumento2 pagineWobbe IndexLi Fang HuangNessuna valutazione finora

- Shell Case StudyDocumento9 pagineShell Case StudyAnslem MirandaNessuna valutazione finora

- Next Generation Network Addressing SolutionsDocumento318 pagineNext Generation Network Addressing SolutionspvsairamNessuna valutazione finora

- STRG6653 PDFDocumento8 pagineSTRG6653 PDFAman MobilesNessuna valutazione finora

- Iso 19114Documento70 pagineIso 19114Ximena Garcia ReyesNessuna valutazione finora

- E500 Series: E F C PDocumento44 pagineE500 Series: E F C Pnghienhugo100% (1)

- Function CatalogueDocumento591 pagineFunction CatalogueAshish PatwardhanNessuna valutazione finora

- Documentatie Flowserve Norbro 3 3 Actionare Electrica Norbro Serie 75 Sialco Reprezentanta Flowserve RomaniaDocumento16 pagineDocumentatie Flowserve Norbro 3 3 Actionare Electrica Norbro Serie 75 Sialco Reprezentanta Flowserve RomaniaВладислав ВиршинитNessuna valutazione finora

- V RF DirectoryDocumento103 pagineV RF Directoryjd_tan_29Nessuna valutazione finora

- C Dual RS232 Install LegacyDocumento20 pagineC Dual RS232 Install LegacyfmanriquezarceNessuna valutazione finora

- Interview With DR Lawrence MaysDocumento6 pagineInterview With DR Lawrence Maysapi-332371318Nessuna valutazione finora

- Implementing DR Demings Quality PhilosophyDocumento45 pagineImplementing DR Demings Quality PhilosophyDavid del CampoNessuna valutazione finora

- AcquView EliteDocumento10 pagineAcquView EliteMd AlauddinNessuna valutazione finora

- Ergonomics Research Papers PDFDocumento2 pagineErgonomics Research Papers PDFChris0% (1)

- FAQ AWS AcademyDocumento3 pagineFAQ AWS AcademyMohamed Chiheb BEN CHAABANENessuna valutazione finora

- Plasma 2012AH Controller ManualDocumento54 paginePlasma 2012AH Controller ManualMarco Andres Cisneros Vargas100% (1)

- Blockchain Stackfor First Party DMPV 1Documento88 pagineBlockchain Stackfor First Party DMPV 1suhasNessuna valutazione finora

- Chap 12 Biotechnology and Its ApplicationsDocumento3 pagineChap 12 Biotechnology and Its ApplicationsRajarshiNessuna valutazione finora

- MEO Class 4 Examination - Subjects, Syllabus, Courses, Eligibility EtcDocumento10 pagineMEO Class 4 Examination - Subjects, Syllabus, Courses, Eligibility EtcRavi Viknesh67% (3)

- Labsheet#2 - Erd (Amirafatiha Kct15005)Documento4 pagineLabsheet#2 - Erd (Amirafatiha Kct15005)Amira EiraNessuna valutazione finora

- Ec-1 Unit 3Documento24 pagineEc-1 Unit 3Mohammed OvaizNessuna valutazione finora

- Nord G1012Documento114 pagineNord G1012Fabinho GarciaNessuna valutazione finora

- CFS VehicleHistoryReportDocumento8 pagineCFS VehicleHistoryReportJAVINessuna valutazione finora

- Actron Digital Multimeter cp7676 Manual de UsuarioDocumento72 pagineActron Digital Multimeter cp7676 Manual de UsuarioManuel OrtizNessuna valutazione finora

- Land Line Tariff Plans: ALTTC, GhaziabadDocumento66 pagineLand Line Tariff Plans: ALTTC, GhaziabadRajesh KumarNessuna valutazione finora