Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

400W Rms Hexfet Mosfet Symmetrical Amplifier

Caricato da

albedo367Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

400W Rms Hexfet Mosfet Symmetrical Amplifier

Caricato da

albedo367Copyright:

Formati disponibili

Construction notes for the symmetrical 400 watt amplifier

Introduction The symmetrical amplifier is an update of one of my designs, which appeared in the Australian electronics magazine Silicon Chip in June 1994. The main changes made in this design was the addition of a clipping detector circuit and bias circuit modifications for the use of International Rectifier HEXFET MOSFETs. Later modifications where made to the error amp and VAS stages which improved the overall sound of the amplifier. Tools you will need to complete the construction of this module A good temperature controlled soldering Iron Resin core 40/60 solder A mini drill or a drill press, which can handle drill, bit sizes down to 0.6mm A small flat blade screwdriver and 1 point Philips screwdriver. An electric hand drill Pre-cut and drilled Aluminium right angle bracket, 196mm long, 3mm to 5mm thick. To mount the Mosfets onto. The Error Amp Stage The first stage is what I call an asymmetrical input error amplifier. It has the ability to accept an unbalanced I/P source only. Now I will explain how each device in this stage works together. Q2, Q3, R35- R36, form the main differential error amplifier, which then has its collectors connected to a cascode load. Q4, Q5, R4 and ZD2 form the cascode stage, which provides a constant 14.4 volts on the collectors of Q4, Q5. Q1, R8, R7, ZD1 and C1 form a constant current source, which supplies 1.5milliamps to the first differential stage. These modules form the first stage of the amplifier and basically set up how the whole amplifier is biased from front to back. The Voltage Amplification Stage This next stage provides most of the voltage amplification that the next stage needs to drive the o/p stage to full power. Q6, Q7, Q8, Q9, R15, R14, R12, R13, C3, C7, C8 form the second differential voltage amplification stage. Q7 and Q9 form what is known as a current mirror load for the second differential stage and basically force this stage to share the current supplied from R15, which is about 8milliamps. The remaining components, namely the caps provide local frequency compensation for this stage. The Bias Stage As the name suggests Q10, R34, 37, 38, C12form the Bias stage. Its main purpose is to provide the MOSFET Gates with a stable and compensated supply voltage. The Output Stage or Current Amplification Stage Once again as the name suggests this stage converts the voltage developed in the VAS and provides all the amperes needed to drive 8 or 4 Ohm loads. 2-Ohm loads are not possible unless more o/p devices are added. Power supply requirements for the 400 Amplifier

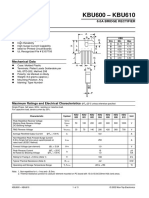

The power supply components for this amplifier are as follows and are expressed for Two Channels. 1 x Toroidal Transformer with a Core rating of 625VA. Primary windings are made to suit your local mains supply. Eg: for Australia One single primary winding with a 240VAC rating. For USA, 110VAC, 115VAC and I believe there is a 220-Volt AC mains supply in some areas of the United States. For the UK it would be 220 VAC to 240 VAC. The secondary windings are as follows. 2 x 50 volts AC at full load. One 400 Volt 35 Ampere, bridge rectifier. 2 x 4.7K 5 Watt ceramic resistors Minimum filter capacitor requirements would be 2 x 10,000uf 100 volt electrolytic. Ideal capacity would be 40,000uf per voltage rail. A suggested power supply schematic is shown below with the schematic of The amplifier.

Revised Schematic (C)Copyright 1994-99 Anthony.E.Holton LAST REV.01/06/1998

D

+70 VOLTS D1 1N4004 R15 120 R32 100 Ohm F1 5 AMP

D

C8 100uf

R3 2k2

R4 10k

R5 2k2

C5 100uF 100v

Q4 BC546 RCA1 C2 2.2UF R2 1K R1 15k C6 1.0nF Q2 BC546 ZD2 15v

Q5 BC546 Q3 BC546 C7 10pf

Q6 MJE350

Q8 MJE350 C4 10pF Q11 2SK1530 R17 470 R19 470 Q13 2SK1530 R21 470 Q15 2SK1530 R23 470 Q17 2SK1530

R36 100 Ohm

R35 100 Ohm

R14 10k

C3 100nf R38 4k7 P1 5k Q10 BD139

ZD3 1N4737

R25 0.22 Ohm

R27 0.22 Ohm

R29 0.22 Ohm

R31 0.22 Ohm

C12 .47

R6 18K

C

ZD4 1N4737

R24 0.22 Ohm

R26 0.22 Ohm

R28 0.22 Ohm

R30 0.22 Ohm

C

C11 18pf

R37 1k

R34 82 ohm

R7 10k C1 100uf ZD1 15v

Q1 MJE340

Q7 MJE340

Q9 MJE340

R16 470 Q12 2SJ201

R18 470 Q14 2SJ201

R20 470 Q16 2SJ201

R22 470 Q18 2SJ201

R8 10K

R12 100

R13 100

D2 1N4004 R33 100 Ohm

F2 5 AMP C10 100uF 100v -70 VOLTS

C9 100uf

C13 330uF C14 470nf MKT

R10 470

R11 15k

R9 10 Ohm

R41 1k

R42 1m

C16 100nf C15 10nf R44 330k

R43 100k

Q20 BC556

Q19 BC546 R45 5k6 R40 82k

LD1

Suggested Power Supply

T1 SW1a Active 240VAC/115VAC SW1b Neutral E1 10,000uf 100V E3 10,000uf 100V A Chassis Ground BR1 600V/35 AMP

+70 Volts

625VA 2x50 VAC secondary wi ndi ngs

E2 10,000uf 100v

E4 10,000uf 100V

-70 Volts

Title Size A2 Date: File: 1 2 3 4 5 6 7 23-Feb-2001 E:\SCH\MOSAMP8.S01 Sheet of Drawn By: 8 Number Revision

How to match MOSFETs

When using this type of MOSFET in the AV800 amplifier is strongly recommended that the output stage devices be matched. As it has been found that if this is not done then there is no guarantee that they will share the current under load. The Source resistors provide only a bit of local feedback and dont in any way force the devices to current share. The best method I have found to work very well utilises just a 150 Ohm 1 watt resistor and a +15 volt DC power supply. If you look at the schematic below it shows how to connect and measure the N-channel devices and the P-channel devices. With the devices connected, as shown measure across R1 with a multimeter set to DC volts and measurement of between 3.8 volts and 4.2 volts will be shown. Simply match the device in-groups to a tolerance of +-100mv. Please note that you only have to match the n-channel to the n-channel devices and the pchannel to the p-channel devices, not the N-channel devices to the P-channel devices.

+15 VOLTSVCC DRAIN

C

GND Q2 P-channel MOSFET

C

M1 DC VOLTMETER

R1 150 Ohm 1 watt DRAIN GATE Q1 N-channel MOSFET SOURCE M1 DC VOLTMETER

GATE SOURCE R1 150 Ohm 1 watt

GND

VCC

+15 VOLTS

A Title Size B Date: File: 1 2 3 4 5 6-Feb-2001 C:\WINNT\..\FET_MATCH.Sch Sheet of Drawn By: 6 Number Revision

Assembling the Printed Circuit Board

One of the first things to do is to look at the PCB and see if all of the holes on the board are of the correct size for the components you wish to insert. The holes that have been drilled into the PCB should be OK. However it does pay to check before you start. If you find that some of the holes are not big enough then you will need to drill them out to the correct size. The standard holes sizes used for most electronic components are as follows. watt watt resistors = 0.7mm to 0.8mm 1watt resistors = 1.0mm watt to 1-watt zener and normal power diodes = 0.8mm Small signal transistors such as BC546 of the TO-92 pack = 0.6mm Medium signal transistors such as MJE340 of the TO-126 pack = 1.0mm Power Output devices such as the IRFP240 require a hole size of 2.5mm Start constructing the PCB by inserting any wire links, which are shown on the component overlays the wire links are made from spare component leads such as from 5-watt ceramic resistors or watt resistor leads. Once the links have been taken care of the insertion of all the resistors is next, followed by the capacitors and then the small signal semiconductors. You will need to cross-reference the parts list with the white screen component overlay on the PCB to see where to insert the required component. Be careful to always insert the polarised components in the right way as shown on the screen-printed overlay. Failure to do this will most likely result in the module not functioning properly or damaging one or more of the components in the module. The output stage transistors and Q10, which is the BD139 device, are to be left till last. Pre-flight test OK at this stage I am assuming you have populated all of the PCB except Q10 and the main output stage devices IRFP240s and IRFP9240s For the time been temporarily insert and solder Q10 into its position located in the middle of the PCB. Pre-flight test continued It is important to test the function of the amplifier at this point in time so as to make sure it is working properly. This is achieved by soldering a 10-Ohm watt resistor across ZD3, On the screen-printed side of the PCB. What this does is to connect the feedback resistor R11 to the output of the buffer stage. In doing so it bypasses the output stage and turns it into a very low powered amplifier, which can be tested without damaging the expensive output stage. Assuming you have connected the resistor from o/p to the buffer stage. It is now time too connect the +-70 volt supply to it and power it up. Be sure to have 4k7 Ohm 5-watt bleeder resistors across the power supply capacitors. Now assuming that there was no smoke, with a multimeter on volts. Measure the following voltage drops across these resistors locations marked in blue and if they match to within +10% then you can be sure that the amplifier is OK. When you have done the checks, be sure to power down and remove the 10 Ohm resistor. R3~1.6 volts R5~1.6 volts R15~1.0 volts R12~500mv R13~500mv Offset voltage at R11 should be close to 0 volts, but can be as high as 100mv.

Now we have come to the soldering in of the output devices. It is assumed at this point that you have all ready matched the output stage devices as outlined in the accompanying document on How to match output devices. If this is already done then you can proceed by getting the PCB and the pre-drilled alloy bracket. Now first get the N-channel devices and a pair of long nose pliers and bend the pins at right angles. The same needs to be done for the p-channel devices. Once this is done get 8 x TO3-P insulation washers and 8 x M3 x 25mm bolts and nuts and mount the devices onto the alloy bracket and thereby clamping the alloy bracket to the main PCB. After completely mounting and insulating the N and the P channel devices. Solder the devices in on the copper side of the PCB. Now its time to get the 0.22 Ohm 5 watt resistors and bend the pins at rights on each device and using a pair of side cutters, trim the leads back so about 10mm to 12mm of lead is protruding from the body of each resistor. Then solder each resistor on the copper side of the PCB. After completing this task the module for the most part is completed. The only other thing you will need to decide is wether to use PCB stakes to solder the external wiring too or solder the cable directly into the PCB pads. Now there is one device that requires some special attention. This is Q10 and this device is the Vbe multiplier or bias compensation device, which needs to be mounted off board on top of Q11 in the output stage. Q10 will need flying leads soldered from the Base, Collector and Emitter pins of the BD139 to the appropriately marked pads on the PCB shown as Q10. Now having completed the power module and tested the Error, VAS and Buffer stages and you are confident that it is working OK. Its time to bolt it down to a suitable heat sink. Remember that all of the o/p devices must be insulated with either silicon rubber washers or mica washers and heat sink compound. The type, size and shape of heat sink are left up to you and the local availability of heat sinks. But be sure to have a heat sink rated at 0.5 degrees/watt or better.

Completing the Module

So we have come to the point where we need to do a full test on the amplifier module. There are a few checks that need to be done first. The Drain pins on all the o/p devices need to be checked for S/C to the heat sink. The power supply wiring has been checked for correct polarity to the PCB. The Multi-turn pot P1 has been turned back to 0 Ohms, so that a measurement of approximately 4.7k is measured across the Base and Collect pins of Q10 BD139. When wiring up the power supply, be sure to have 8 amp fuses inserted on each of the supply lines. Connect a multimeter on DC volt range to the o/p of the amplifier. Ok now that you are happy that the module is setup correctly apply power via a VARIAC if you have access to one, otherwise just power the amplifier up. Looking at the voltmeter you should get from 1mv to 50mv offset voltage. If this is not the case then power the amplifier down and check your work. Assuming all is well then power the amplifier down and find a small flat blade screwdriver so you can be ready to adjust P1 for the biasing of the o/p stage. But first connect the voltmeter across one of the o/p stage Source resistors using Alligator leads. Now reapply power to the amplifier and slowly adjust P1 while watching the voltmeter, for a reading of 18mv. This sets the bias current in the output stage to just under 100ma per device Now check across the rest of the Source resistors and find the one, which has the highest reading, and adjust P1 till 18mv is read. Now connect a load and signal source to the amplifier and with a CRO if you have access to one observe that the waveform is clean and free from noise and distortion. If you dont have a CRO and Signal generator, connect a pre-amp and loudspeaker and have a good listen. The sound should be very clean and dynamic. Congratulations, the amplifier is complete. Best Regards Anthony Eric Holton 8th February 2001 www.aussieamplifiers.com

Testing the module

Specifications for the symmetrical 400 watt amplifier Power rating of 200 Watts RMS into 8 Ohms Per Channel 400 Watts RMS into 4 Ohms Per Channel. Total Harmonic Distortion is typically 0.005%, Signal to Noise Ratio of 122dB unweighted (20Hz to 20Khz) A-weighted -126dB, Damping Factor Greater than 200 at 8 Ohms. 1.2 volts RMS for full power O/P

Part Used PartType

Designators

-----------------------------------------------------------------------

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

4 1 8 1 1 2 2 2 1 1 4 4 2 1 2 1 1 1 3 1 1 1 2 2 2 2 2 1 1 2 1 1 2 2 1 1 2 3 1 1 1 9 1 1 1 5 1 1 3 2 .47 0.22 Ohm 1.0nF 1K 1N4004 1N4737 1k 1m 2.2UF 2SJ201 2SK1530 2k2 4k7 5 AMP 5k 5k6 6k8 10,000uf 100V 10,000uf 100v 10K 10 Ohm 10k 10nf 10pF 15k 15v 18K 18pf 47 Ohm 82k 82 ohm 100 100 Ohm 100k 100nf 100uF 100v 100uf 120 330k 330uF 470

LD1 RCA1 SW1a SW1b C12 R24 R25 R26 C6 R2 D1 D2 ZD3 ZD4 R37 R41 R42 C2 Q12 Q14 Q16 Q11 Q13 Q15 R3 R5 R38 F1 F2 P1 R45 R14 E1 E3 E4 E2 R8 R9 R4 R7 C3 C15 C4 C7 R1 R11 ZD1 ZD2 R6 C11 R35 R36 R40 R34 R12 R13 R32 R33 R43 C16 C5 C10 C1 C8 C9 R15 R44 C13 R10 R16 R17 R27 R28 R29 R30 R31

Q18 Q17

R18 R19 R20 R21 R22 R23

470nf MKT C14 600V/35 AMP BR1 625VA 2x50 VAC secondary windings T1 BC546 Q2 Q3 Q4 Q5 Q19 BC556 Q20 BD139 Q10 MJE340 Q1 Q7 Q9 MJE350 Q6 Q8

Part Cross Reference Report For : C:\WINNT\Profiles\aholton\Desktop\My Documents\MOSAMP8_BOM.XRF 2-Mar-2001 11:45:59

Designator Component Library Reference Sheet ----------------------------------------------------------------BR1 C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12 C13 C14 C15 C16 D1 D2 E1 E2 E3 E4 F1 F2 LD1 P1 Q1 Q2 Q3 Q4 Q5 Q6 Q7 Q8 Q9 Q10 Q11 Q12 Q13 Q14 Q15 Q16 Q17 Q18 Q19 Q20 R1 R2 R3 R4 R5 R6 R7 R8 600V/35 AMP 100uf 2.2UF 10nf 10pF 100uF 100v 1.0nF 10pf 100uf 100uf 100uF 100v 18pf .47 330uF 470nf MKT 10nf 100nf 1N4004 1N4004 10,000uf 100V 10,000uf 100v 10,000uf 100V 10,000uf 100V 5 AMP 5 AMP 5k MJE340 BC546 BC546 BC546 BC546 MJE350 MJE340 MJE350 MJE340 BD139 2SK1530 2SJ201 2SK1530 2SJ201 2SK1530 2SJ201 2SK1530 2SJ201 BC546 BC556 15k 1K 2k2 10k 2k2 18K 10k 10K E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01

R9 R10 R11 R12 R13 R14 R15 R16 R17 R18 R19 R20 R21 R22 R23 R24 R25 R26 R27 R28 R29 R30 R31 R32 R33 R34 R35 R36 R37 R38 R40 R41 R42 R43 R44 R45 RCA1 SW1a SW1b T1 ZD1 ZD2 ZD3 ZD4

10 Ohm 470 15k 100 100 10k 120 470 470 470 470 470 470 470 470 0.22 Ohm 0.22 Ohm 0.22 Ohm 0.22 Ohm 0.22 Ohm 0.22 Ohm 0.22 Ohm 0.22 Ohm 100 Ohm 100 Ohm 82 ohm 100 Ohm 100 Ohm 1k 4k7 82k 1k 1m 100k 330k 5k6

625VA 2x50 VAC sec 15v 15v 1N4737 1N4737

E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01 E:\SCH\MOSAMP8.S01

Potrebbero piacerti anche

- Antenna Analyzer vk5jst Version 1 Instructions PDFDocumento10 pagineAntenna Analyzer vk5jst Version 1 Instructions PDFPisu Miau Pisu MiauNessuna valutazione finora

- 25839-Designing Offline Ac DC Switching Power Supplies Brick by Brick PDFDocumento9 pagine25839-Designing Offline Ac DC Switching Power Supplies Brick by Brick PDFAshwin KonaleNessuna valutazione finora

- SC 2007-12 DecDocumento116 pagineSC 2007-12 DecJimy HendrixNessuna valutazione finora

- 4495 Tech of Sound Repro Amplifiers PDFDocumento268 pagine4495 Tech of Sound Repro Amplifiers PDFimrefodorNessuna valutazione finora

- How To Wind Your Own Audio TransformerDocumento8 pagineHow To Wind Your Own Audio TransformerOscar Pacheco100% (1)

- Expandable Graphic EqualiserDocumento6 pagineExpandable Graphic EqualiserCarlos TigseNessuna valutazione finora

- LEAK Stereo 30Documento6 pagineLEAK Stereo 30BunyippyNessuna valutazione finora

- Amplifier PDFDocumento46 pagineAmplifier PDFvladareanucatalindanNessuna valutazione finora

- KLIPSCH Computer Speaker Service ManualDocumento21 pagineKLIPSCH Computer Speaker Service ManualEric CreechNessuna valutazione finora

- Design of 4 Watt Power AmplifierDocumento3 pagineDesign of 4 Watt Power AmplifierTapas Sarkar100% (1)

- AmplifikatoretDocumento124 pagineAmplifikatoretXha RuliNessuna valutazione finora

- Tram 2 PreampDocumento30 pagineTram 2 Preampdecky999100% (1)

- High Current DC Regulated Power Supply Circuit With LM317Documento5 pagineHigh Current DC Regulated Power Supply Circuit With LM317jonatanNessuna valutazione finora

- Inductance of A ToroidDocumento2 pagineInductance of A ToroidgeraltNessuna valutazione finora

- AC Current Monitor by LM358Documento14 pagineAC Current Monitor by LM358wlen2012Nessuna valutazione finora

- Headphone Stereo Amplifier Elektor PDFDocumento3 pagineHeadphone Stereo Amplifier Elektor PDFJailson RodriguesNessuna valutazione finora

- Ga 399 MaDocumento9 pagineGa 399 MaEnos Marcos BastosNessuna valutazione finora

- Analisis de Circuito Big MuffDocumento10 pagineAnalisis de Circuito Big MuffNacho ConsolaniNessuna valutazione finora

- Dac 2Documento15 pagineDac 2Hutanu GabrielNessuna valutazione finora

- Signal InjectorDocumento7 pagineSignal Injectornoor3250Nessuna valutazione finora

- A Simple Regen Radio For BeginnersDocumento4 pagineA Simple Regen Radio For BeginnersEsequiel YakueczikNessuna valutazione finora

- Power SupplyDocumento22 paginePower Supplyandree w100% (1)

- Elektor (Nonlinear - Ir) 1976-04 - TextDocumento54 pagineElektor (Nonlinear - Ir) 1976-04 - TextQuincheNessuna valutazione finora

- Electronique - Audio - Microphone Valve PreampDocumento7 pagineElectronique - Audio - Microphone Valve PreampkoukihamedNessuna valutazione finora

- Preamp and Tone Control Circuit With TDA1524ADocumento4 paginePreamp and Tone Control Circuit With TDA1524A_download_only_Nessuna valutazione finora

- Cca & More RmafDocumento19 pagineCca & More RmafJCMNessuna valutazione finora

- DAC Final TestDocumento21 pagineDAC Final TestKemboya LuigiNessuna valutazione finora

- LM386 Audio Amplifier Circuits With PCBDocumento20 pagineLM386 Audio Amplifier Circuits With PCBMuhammad YousafNessuna valutazione finora

- SAMS Transistor Specifications Manual 4th 1970Documento196 pagineSAMS Transistor Specifications Manual 4th 1970Raul Hernan Sojos ChiribogaNessuna valutazione finora

- Transformerless Power SupplyDocumento3 pagineTransformerless Power Supply27051977Nessuna valutazione finora

- Electronics Circuits Designer's Casebook, Volume 14-ADocumento159 pagineElectronics Circuits Designer's Casebook, Volume 14-AViktor Mathias BucherNessuna valutazione finora

- Jason Strohmaier DIY CD PlayerDocumento14 pagineJason Strohmaier DIY CD PlayerclannadNessuna valutazione finora

- 45-860MHz Radio Receiver Based On UV916-tunerDocumento7 pagine45-860MHz Radio Receiver Based On UV916-tunerSutharsan Kumar KrishnamoorthyNessuna valutazione finora

- Speaker Crossover LabDocumento51 pagineSpeaker Crossover LabRoland HendriksNessuna valutazione finora

- 500 Watt DCDocumento9 pagine500 Watt DCTariq AliNessuna valutazione finora

- An Audio Amplifier SystemsDocumento0 pagineAn Audio Amplifier SystemsHoan LeNessuna valutazione finora

- KORG MONOLOGUE Service ManualDocumento16 pagineKORG MONOLOGUE Service ManualSomeone SomewhereNessuna valutazione finora

- A Simple Audio AmplifierDocumento3 pagineA Simple Audio AmplifierFayyaz Ahmad AttariNessuna valutazione finora

- Audio Note Feed Forward Shunt RegulatorDocumento6 pagineAudio Note Feed Forward Shunt RegulatorMario CaneverNessuna valutazione finora

- Totem-Pole Output StageDocumento18 pagineTotem-Pole Output StageSlanky BirOe PulauNessuna valutazione finora

- How To Wind Your Own Audio TransformersDocumento6 pagineHow To Wind Your Own Audio TransformersSougata DasNessuna valutazione finora

- Scanspeak Full V10Documento22 pagineScanspeak Full V10Dan ClaiborneNessuna valutazione finora

- NiceDocumento503 pagineNiceAnggy Pramanta Putra100% (2)

- ESR Tester 096kDocumento41 pagineESR Tester 096kFabrício AngieneNessuna valutazione finora

- Class D Amplifiers - Interactive SimulationsDocumento5 pagineClass D Amplifiers - Interactive SimulationsCristi BondNessuna valutazione finora

- Poor Man 1GHzDocumento3 paginePoor Man 1GHzmuddogNessuna valutazione finora

- Constant Current SourceDocumento5 pagineConstant Current SourceAnonymous TPVfFif6TONessuna valutazione finora

- Grounding 2Documento15 pagineGrounding 2Abdul AzimNessuna valutazione finora

- RC 1976 02Documento68 pagineRC 1976 02Jan Pran100% (2)

- Class-D Power AmplifierDocumento30 pagineClass-D Power AmplifierSidney O. EbotNessuna valutazione finora

- EMI SourcesDocumento17 pagineEMI SourcesedwinNessuna valutazione finora

- AcroSound Ultralinear Output Transformers (Amplifier Schematics) (1954)Documento16 pagineAcroSound Ultralinear Output Transformers (Amplifier Schematics) (1954)jimmy67musicNessuna valutazione finora

- Practical Transistor CircuitsDocumento11 paginePractical Transistor CircuitsFilip Angelovski100% (1)

- AV1000 + Assembly + ManualDocumento22 pagineAV1000 + Assembly + ManualAnonymous V1NW1Cm3w4100% (3)

- 1.5v Battery ChargerDocumento25 pagine1.5v Battery ChargerJOHN BRICCO A. MATACSILNessuna valutazione finora

- Photograph High Voltage Power Supply Shown With Optional 24 VAC TransformerDocumento8 paginePhotograph High Voltage Power Supply Shown With Optional 24 VAC TransformerdughirNessuna valutazione finora

- PWMcircuit 08Documento10 paginePWMcircuit 08kcarringNessuna valutazione finora

- 2 Guide SSHV2Documento3 pagine2 Guide SSHV2Calsonic CMGNessuna valutazione finora

- Exercise On Analog Circuits: PHYS 331: Junior Physics Laboratory IDocumento6 pagineExercise On Analog Circuits: PHYS 331: Junior Physics Laboratory Iviso167Nessuna valutazione finora

- RAN3308: Flexi RFM 3T6R 2100Documento2 pagineRAN3308: Flexi RFM 3T6R 2100Reza BordbarNessuna valutazione finora

- Digital vs. Analog - Tait Radio AcademyDocumento3 pagineDigital vs. Analog - Tait Radio AcademySukhirthan SenthilkumarNessuna valutazione finora

- MPXV7007Documento11 pagineMPXV7007Phi MacNessuna valutazione finora

- Load Flow and Short-Circuit Analysis in A Romanian 11020 KV Retrofitted Substationmicu2016Documento6 pagineLoad Flow and Short-Circuit Analysis in A Romanian 11020 KV Retrofitted Substationmicu2016Tahsin AhmedNessuna valutazione finora

- fs9001 PDFDocumento16 paginefs9001 PDFforoNessuna valutazione finora

- 15EC35 - Electronic Instrumentation - Module 4Documento33 pagine15EC35 - Electronic Instrumentation - Module 4Anish AnniNessuna valutazione finora

- The Wien Bridge OscillatorDocumento8 pagineThe Wien Bridge OscillatorSamuel ArthurNessuna valutazione finora

- LEM Itz - 5000-sbDocumento14 pagineLEM Itz - 5000-sbnaveenNessuna valutazione finora

- Fan Wall Technology Versus Centrifugal FansDocumento3 pagineFan Wall Technology Versus Centrifugal FansWilliam Greco100% (1)

- (NOT Gate) DM7404 PDFDocumento5 pagine(NOT Gate) DM7404 PDFSai KumarNessuna valutazione finora

- F Frame Snubber Resistor Replacement For 1336 PLUS, PLUS II, Force, Impact and Regen DrivesDocumento6 pagineF Frame Snubber Resistor Replacement For 1336 PLUS, PLUS II, Force, Impact and Regen DrivesAnonymous GbfoQcCNessuna valutazione finora

- Brochure SRT 4672 - enDocumento2 pagineBrochure SRT 4672 - enbejanNessuna valutazione finora

- 4 Main Types of Distribution Feeder Systems To Recognize - EEPDocumento11 pagine4 Main Types of Distribution Feeder Systems To Recognize - EEPFernando CastroNessuna valutazione finora

- EEL Product BriefDocumento4 pagineEEL Product BriefHaroon ShaikhNessuna valutazione finora

- Abstraction: How Electronics Devices Begin?Documento11 pagineAbstraction: How Electronics Devices Begin?Shane Patrick PanilagNessuna valutazione finora

- Computer Logic Design Lab 213371Documento24 pagineComputer Logic Design Lab 213371Habib Ur rehmanNessuna valutazione finora

- Marvelous Mungin: Work ExperienceDocumento3 pagineMarvelous Mungin: Work ExperienceEhab IbrahimNessuna valutazione finora

- ELEC3300 10-Memory InterfaceDocumento35 pagineELEC3300 10-Memory InterfaceKwun Hok ChongNessuna valutazione finora

- Digital Control System PDFDocumento0 pagineDigital Control System PDFwww.bhawesh.com.np100% (1)

- Dfc2053 Computer System ArchitectureDocumento54 pagineDfc2053 Computer System ArchitectureHasif AimanNessuna valutazione finora

- Reverse Bias - Silicon Diode: Controls InstructionDocumento1 paginaReverse Bias - Silicon Diode: Controls InstructionDev AabhroyNessuna valutazione finora

- PTP QB 8200 Tsunami QB 8200 G Datasheet USDocumento2 paginePTP QB 8200 Tsunami QB 8200 G Datasheet USPengRyanNessuna valutazione finora

- Line Protection UnitDocumento6 pagineLine Protection Unitsumitverma1990Nessuna valutazione finora

- BAB 3: PearuhDocumento14 pagineBAB 3: PearuhhafizeijaNessuna valutazione finora

- Site Survey For Solar PVDocumento4 pagineSite Survey For Solar PVLavancha Renewables100% (1)

- KBU608Documento4 pagineKBU608José AdelinoNessuna valutazione finora

- GPG Findings 028-Control Optimization System 1535393590Documento4 pagineGPG Findings 028-Control Optimization System 1535393590angga.snc29Nessuna valutazione finora

- Solar Data Logger ManualDocumento4 pagineSolar Data Logger ManualMihirNessuna valutazione finora

- Electrical Tech & Specs ADocumento78 pagineElectrical Tech & Specs AAbdillah FadhilNessuna valutazione finora

- Audio Control ACP 3110Documento1 paginaAudio Control ACP 3110Himanshu HaldarNessuna valutazione finora