Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Domestic Gas Planning and Sizing

Caricato da

Boab DingwallDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Domestic Gas Planning and Sizing

Caricato da

Boab DingwallCopyright:

Formati disponibili

DOMESTIC GAS PIPEWORK

PART 1 - PIPE SIZING

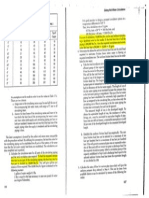

opper's strength, neat unobtrusive appearance, fire and corrosion resistance make it an ideal material for gas installation pipes. Determining tube sizes BS 6891 is the industry standard for mains gas piping installations. It states that in a domestic natural gas installation the pressure drop along the pipeline at periods of maximum demand should be no more than 1mbar.The reason for this is that, if under-sized pipes are installed, the pressure at the burner could become so low that incomplete combustion occurs, which is dangerous as carbon monoxide will be produced! So, when planning a gas installation it is important to ensure that the tube diameters chosen are able to supply the volume of gas required by the appliances without excessive pressure loss. Manufacturers installation instructions will only give guidance on the appropriate diameter of tube to be used to supply their own gas appliance.Where more than one appliance is to be installed, it is necessary to determine suitable tube diameters for the installation that can satisfy the maximum demand without excessive pressure loss. Figure 1 shows a typical domestic natural gas piping installation; it supplies a gas fire with a heat input of 7kW and a cooker with a heat input of 16kW. The main existing piping run (1-2) is installed with 22mm tube. A boiler (with piping shown dashed) with a heat input of 35kW is to be added to the installation. Assessing the existing meter capacity Before extending an existing installation to add another appliance it is necessary to consider the existing meter capacity. In the UK the standard domestic

gas meter has a maximum volume flowrate of 6m3 of gas per hour (Q max on the meter data plate), which equates to a maximum of 64.1kW of appliance heat input. This figure should not be exceeded, otherwise the meter will be overloaded and the pressure drop will be too great. So, to check for spare capacity on an installation, first examine the data plates of the existing appliances to find their heat input in kW. Then total these and subtract the total from 64 to determine any spare capacity for the extra appliance. In Figure 1 the existing heat inputs are 7 + 16 = 23kW, and 64 23 = 41kW of spare capacity, which is more than is required for the new boiler with a heat input of 35kW. Note: if there is insufficient capacity for the extra appliance, the gas supplier should be contacted before commencing work to extend the installation. Table 1 gives details of maximum lengths of copper tube for various flowrates for natural gas. We can use it to select suitable tube diameters for the installation.

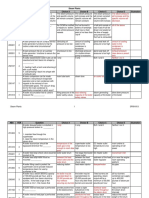

Note: Flow rates are for lowpressure supplies with 1mbar differential pressure between ends of pipe for gas of relative density 0.6 Determining the gas flow rate for an appliance To determine the gas-rate for an appliance divide the appliance heat input in kW by the calorific value (CV) of the gas being burnt. In the case of natural gas this is 38.5MJ/m3. For example, for a 10kW appliance the flow rate will be: 10 38.5 = 0.26litres/second. This figure can then be multiplied by 3.6 to convert the flow rate from l/s to m3/hour = 0.26 x 3.6 = 0.936m3/hour. Table 2 - illustrates how the tube sizes needed to supply the appliances shown in Figure 1 can be found. First, each numbered pipe run is identified on the drawing and then listed in column 1 of the table. Next, the total gas flow in kW through each pipe run is found. This is determined by totalling the number of kW each pipe run supplies; this is then noted in column 2. For example, pipe run 1-2 has to serve all appliances and so will need to pass 7 + 16 + 35 = 58kW. Pipe run 2-4 serves the cooker and boiler, so it will need to pass 16 + 35 = 51kW. These figures can then be converted

Table 1 Approximate flow of gas (m3/hour) in straight horizontal copper tube Tube size Length of pipe run (m) (mm) 3 6 9 10 x 0.6 12 x 0.6 15 x 0.7 22 x 0.9 28 x 0.9 0.84 1.52 2.9 8.7 18 0.56 1.01 1.9 5.8 12 0.51 0.84 1.5 4.6 9.4 12 0.36 0.82 1.3 3.9 8 15 0.31 0.67 1.1 3.6 7.2 20 0.22 0.51 0.95 2.8 6 25 0.17 0.39 0.92 2.6 5.4 30 0.14 0.33 0.88 2.3 4.8

Flow rates are for low-pressure supplies with 1mbar differential pressure between ends of pipe for gas of relative density 0.6. Add 0.3m for each 90 bend and 0.5m for each elbow or tee fitted to the actual length of the tube to obtain the total effective length.

27

into m3/hour by dividing each in turn by 38.5 and then multiplying by 3.6 and these results are noted in column 3. The measured length of each pipe run is then listed in column 5. Next an allowance has to be made for the pipe fittings. Allow 0.3m for each 90 bend and 0.5m for each elbow or tee that creates a change of direction and note the total fitting length for each pipe run in column 6.The figures in each row of column 5 and 6 can then be added to give an effective length for each pipe run, which is then noted in column 7. By referring to the sizing table (Table 1) we can now select a provisional tube size (or check an existing tube size) and note this in column 4. To use the table, first look down the column of the table that shows a length of pipe equal to or above the effective

length of the pipe run in question until the flow rate required is reached; look to the right to see if longer lengths of pipe will give the required flow rate. If they do then use the longest possible length in column 8, then read off the tube diameter from the left-most column. In the case of the 22mm existing pipe run 1-2 with an effective length of 5.5m we look down the 6m column until we reach the figure 5.8m3/hour. Column 8 is then used to note the maximum length of tube that can supply the flow rate required; in this case 6m. Column 9 is used to record the actual pressure drop along the pipe run; the actual pressure drop is found by dividing the figure in column 7 by the figure in column 8.Then the progressive pressure drop can be found; this is done by totalling the pressure drops for each pipe run supplying an appliance. Table 2 Tabulation form - gas pipe sizing

In this example we are concerned to check whether the existing pipe runs 1-2 and 2-4 are adequate to serve the new boiler: from the table we can see that the progressive pressure drop along pipe runs 1-2 and 2-4 when supplying the new boiler will be 0.92 + 0.67 = 1.58mbar. This is well over the maximum allowed so a larger tube size (say 28mm) will have to be selected and noted in column 4 and the figures reworked to determine whether this is satisfactory. If the boiler is supplied by 28mm tube for pipe runs 1-2, 2-4 and 22mm tube for pipe run 4-6, the reworked progressive pressure drops are 0.18 + 0.13 + 0.17 = 0.48mbar, which shows that these tube sizes will be adequate to supply the new boiler. Brian Curry: March 2008

Pipe length Col 1 1-2 2-4 4-6

Power (kW) Col 2 58.00 51.00 35.00

Flow rate Assumed Effective {col 2 x 3.6} Measured Extra for diameter {from length cv length (m) fittings (m) Table 1} (mm) {5 + 6} (m) 3/hour) (m Col 3 Col 4 Col 5 Col 6 Col 7 5.42 4.77 3.27 22.00 22.00 22.00 4.00 4.00 2.00 1.50 0.00 0.50 5.50 4.00 2.50

Maximum length {from Table 1} (m) Col 8 6.00 6.00 15.00

Actual pressure drop {78} (mbar) Col 9 0.92 0.67 0.17

Progressive pressure drop (mbar) Col 10 0.92 1.58 1.75

Re-work pipe runs 1 - 2 and 2 - 4 with 28mm tube size due to pressure drop being greater than permitted 1-2 2-3 2-4 4-5 4-6 58.00 7.00 51.00 16.00 35.00 5.42 0.65 4.77 1.50 3.27 28.00 12.00 28.00 15.00 22.00 4.00 3.00 4.00 2.50 2.00 1.50 1.00 0.00 1.00 0.50 5.50 4.00 4.00 3.50 2.50 25.00 15.00 25.00 9.00 15.00 0.22 0.27 0.16 0.39 0.17 0.22 0.49 0.38 0.77 0.55

New boiler 35kW

Gas meter

2m

Existing 22mm piping

4m 4m

16kW cooker

4

2.5m

2

Figure 1

3m

7kW gas fire

3

28

Potrebbero piacerti anche

- Physical Security Audit Checklist PDFDocumento3 paginePhysical Security Audit Checklist PDFHendrawan StbNessuna valutazione finora

- IEC60947 3 Approved PDFDocumento3 pagineIEC60947 3 Approved PDFosmpotNessuna valutazione finora

- Gaspipe SizingDocumento15 pagineGaspipe SizingmaxxhaloNessuna valutazione finora

- LPG (Gas) Pipe Sizing Notes: Properties Natural Gas Liquid Petroleum Gas (LPG) PropaneDocumento4 pagineLPG (Gas) Pipe Sizing Notes: Properties Natural Gas Liquid Petroleum Gas (LPG) PropaneSarah DeanNessuna valutazione finora

- Brief Design of LPG PipeworkDocumento22 pagineBrief Design of LPG Pipeworkkhabbab hussainNessuna valutazione finora

- Design of A FireTube Steam BoilerDocumento41 pagineDesign of A FireTube Steam BoilervuhyperbinhduongNessuna valutazione finora

- HANDBOOK Blanket Gas Regulators PDFDocumento8 pagineHANDBOOK Blanket Gas Regulators PDFfrankz89Nessuna valutazione finora

- 750-326 Blowdown Separator 11 2015Documento10 pagine750-326 Blowdown Separator 11 2015osamaNessuna valutazione finora

- Chapter 4 - Gas Piping Installations PDFDocumento14 pagineChapter 4 - Gas Piping Installations PDFGeorge_Wabag_2014Nessuna valutazione finora

- Stanton Premier BoilerDocumento28 pagineStanton Premier Boilermyousif63Nessuna valutazione finora

- Tank BlankettingDocumento6 pagineTank BlankettingBaskar KannaiahNessuna valutazione finora

- Install and Maintain Oasis RC Coal Effect Gas FireDocumento29 pagineInstall and Maintain Oasis RC Coal Effect Gas Firewally_watkins4061Nessuna valutazione finora

- Engineering Design Guide For Storage TanksDocumento107 pagineEngineering Design Guide For Storage Tankssonng.engNessuna valutazione finora

- Ratio Pressure Reducing ValvesDocumento4 pagineRatio Pressure Reducing Valveskanem1Nessuna valutazione finora

- Section 5 - LPG266 - 154562Documento11 pagineSection 5 - LPG266 - 154562handoyo_eko20017573Nessuna valutazione finora

- A Project Work: Study of Carbon Emission in Transportation ProblemDocumento37 pagineA Project Work: Study of Carbon Emission in Transportation ProblemGaurav BajpaiNessuna valutazione finora

- Venta: Two-Way Pressure Balanced Valve PN 16 (232 Psi)Documento5 pagineVenta: Two-Way Pressure Balanced Valve PN 16 (232 Psi)DedeKurniawanNessuna valutazione finora

- Gas Cylinder Safety RulesDocumento24 pagineGas Cylinder Safety RulesAnuj SinhaNessuna valutazione finora

- Jesco Ejector PresiuniDocumento2 pagineJesco Ejector PresiuniNicolae Ciprian AnghelNessuna valutazione finora

- Sizing Forced Draft Fans For Fired HeatersDocumento5 pagineSizing Forced Draft Fans For Fired Heatersdlalameen4471Nessuna valutazione finora

- Benzene - It'S Characteristics and Safety in Handling, Storing & TransportationDocumento6 pagineBenzene - It'S Characteristics and Safety in Handling, Storing & TransportationEhab SaadNessuna valutazione finora

- Heat Exchanger Lectures CompleteDocumento72 pagineHeat Exchanger Lectures CompletehananNessuna valutazione finora

- ECO4Documento9 pagineECO4محمد عباس نصارNessuna valutazione finora

- Thermal Conversion ProcessesDocumento24 pagineThermal Conversion ProcessesAl JawadNessuna valutazione finora

- Typical Desuperheater Installations: Block 15Documento10 pagineTypical Desuperheater Installations: Block 15Omprakash_janaNessuna valutazione finora

- Industrial BoilersDocumento22 pagineIndustrial BoilersAbdul Razzaq MughalNessuna valutazione finora

- Steam Plant FundamentalsDocumento228 pagineSteam Plant FundamentalsMark Allen San Antonio100% (1)

- Selection and Sizing of Pressure Relief ValvesDocumento21 pagineSelection and Sizing of Pressure Relief ValvesjoesuhreNessuna valutazione finora

- Distillation Column DesignDocumento9 pagineDistillation Column DesignAgeyo Omondi Kaila100% (1)

- Minor Project Report On: "LPG Detector"Documento28 pagineMinor Project Report On: "LPG Detector"Gaurav SharmaNessuna valutazione finora

- STORAGE TANK Design and RulesDocumento3 pagineSTORAGE TANK Design and RulesSusan MishraNessuna valutazione finora

- Delivering Excellence in Combustion and Process Heating SystemsDocumento11 pagineDelivering Excellence in Combustion and Process Heating SystemssajjadyasinNessuna valutazione finora

- Boiler: Heat Sources Materials Energy Boiler EfficiencyDocumento10 pagineBoiler: Heat Sources Materials Energy Boiler EfficiencyrpercorNessuna valutazione finora

- Vortex Pilot Gas Heater Over Temperature ProtectionDocumento17 pagineVortex Pilot Gas Heater Over Temperature ProtectionDon BettonNessuna valutazione finora

- University of Lahore, Islamabad Campus: Nozzle Thermpdynamics-Ii Engr. Babar AshfaqDocumento65 pagineUniversity of Lahore, Islamabad Campus: Nozzle Thermpdynamics-Ii Engr. Babar AshfaqGhaffar KhanNessuna valutazione finora

- NG Engineering by Engr DR CIC AnyadiegwuDocumento31 pagineNG Engineering by Engr DR CIC Anyadiegwudavidchinedu008Nessuna valutazione finora

- Benzene ReductionDocumento11 pagineBenzene ReductionzahasherhNessuna valutazione finora

- HRSGDocumento24 pagineHRSGsathishsggsNessuna valutazione finora

- Recovering Heat When Generating PowerDocumento8 pagineRecovering Heat When Generating Poweraliscribd46Nessuna valutazione finora

- O2 SafetyDocumento3 pagineO2 Safetyrajpatil0007Nessuna valutazione finora

- EN TankHeating DG H56887 - tcm432 26444 PDFDocumento30 pagineEN TankHeating DG H56887 - tcm432 26444 PDFyassine633Nessuna valutazione finora

- ATM Storage TankDocumento10 pagineATM Storage TanksameerpecNessuna valutazione finora

- Vacuum Distillation ColumnsDocumento2 pagineVacuum Distillation Columnsmehfuzansari1100% (1)

- LPG Induction Course NewDocumento28 pagineLPG Induction Course NewMha RizNessuna valutazione finora

- Oil To Chemicals-April2018Documento4 pagineOil To Chemicals-April2018Sanjay RajoraNessuna valutazione finora

- Boilers Basic Components (Att. VIII)Documento28 pagineBoilers Basic Components (Att. VIII)Vijay RajNessuna valutazione finora

- Base StocksDocumento42 pagineBase StocksLuis Carlos Garcia Umaña100% (1)

- Section 22.1 Working Plans: Automatic Sprinkler Systems Handbook 2010Documento13 pagineSection 22.1 Working Plans: Automatic Sprinkler Systems Handbook 2010ahmad adnanNessuna valutazione finora

- Cooling Tower 434Documento15 pagineCooling Tower 434arslan MaqboolNessuna valutazione finora

- Hot High Pressure SeparatorDocumento2 pagineHot High Pressure SeparatorKhai NguyenNessuna valutazione finora

- Blowdown of LPG PipelinesDocumento10 pagineBlowdown of LPG PipelinesBehnam HosseinzadehNessuna valutazione finora

- SRU UnitDocumento33 pagineSRU UnitCenk Yağız ÖzçelikNessuna valutazione finora

- Problem PipingDocumento79 pagineProblem PipingSiddhi MhatreNessuna valutazione finora

- FW Visbreaker HeatersDocumento5 pagineFW Visbreaker HeatersZita MoreiraNessuna valutazione finora

- Gas Installation PDFDocumento31 pagineGas Installation PDFNelson VargasNessuna valutazione finora

- Domestic Gas PipingDocumento2 pagineDomestic Gas Pipingvalentinlupascu33Nessuna valutazione finora

- Perhitungan Pipa Gas CustomerDocumento13 paginePerhitungan Pipa Gas CustomerFah RoziNessuna valutazione finora

- Insight into Solving Steam Distribution IssuesDocumento9 pagineInsight into Solving Steam Distribution IssuesKyriakos MichalakiNessuna valutazione finora

- Gas Pipe SizingDocumento17 pagineGas Pipe Sizingcentaury2013100% (2)

- Pipe Sizing for Optimal Steam FlowDocumento6 paginePipe Sizing for Optimal Steam Flowferdie14Nessuna valutazione finora

- Sizing Hot Water Circulation SystemsDocumento1 paginaSizing Hot Water Circulation Systemsimtiyaz94Nessuna valutazione finora

- Gas Reticulation Project Group 8Documento13 pagineGas Reticulation Project Group 8Mohd Hafiz50% (2)

- Physical Science Summative Exam. First QuarterDocumento5 paginePhysical Science Summative Exam. First QuarterIsagani WagisNessuna valutazione finora

- Oxyprobe PDFDocumento16 pagineOxyprobe PDFSrinivasa RNessuna valutazione finora

- Save and share GZCL training spreadsheets onlineDocumento263 pagineSave and share GZCL training spreadsheets onlinejohn wick100% (1)

- 2016 Ruptured Pseudoaneurysm of The Middle Meningeal ArteryDocumento5 pagine2016 Ruptured Pseudoaneurysm of The Middle Meningeal ArteryJulio Cesar Velasco CastroNessuna valutazione finora

- Being ProfessionalDocumento3 pagineBeing ProfessionalPutra SyahrezaNessuna valutazione finora

- ZV Class Links @Medliferesuscitation-CopyDocumento31 pagineZV Class Links @Medliferesuscitation-CopyDebajyoti DasNessuna valutazione finora

- Smartphone Technician Cum App Tester: Trade PracticalDocumento218 pagineSmartphone Technician Cum App Tester: Trade PracticalF ZaidiNessuna valutazione finora

- 1154ec108nanoelectronics PDFDocumento3 pagine1154ec108nanoelectronics PDFLordwin CecilNessuna valutazione finora

- Texture Crystallisation and Freezing Point DepressionDocumento18 pagineTexture Crystallisation and Freezing Point DepressionJán PeterNessuna valutazione finora

- Galapagos Penguins: Shelter, Niche and NeedsDocumento8 pagineGalapagos Penguins: Shelter, Niche and Needsjim munkNessuna valutazione finora

- Review of Literature Review of LiteratureDocumento31 pagineReview of Literature Review of LiteratureeswariNessuna valutazione finora

- Rainwater Harvesting: Dr. Muhammad Anwar Baig Iese, Scee NUST H-12, IslamabadDocumento30 pagineRainwater Harvesting: Dr. Muhammad Anwar Baig Iese, Scee NUST H-12, IslamabadTalha Bin UmeedNessuna valutazione finora

- Discover the flavors of Southwestern Luzon and Bicol RegionDocumento5 pagineDiscover the flavors of Southwestern Luzon and Bicol RegionGraceCayabyabNiduazaNessuna valutazione finora

- JDP Rainbox Attenuation CratesDocumento6 pagineJDP Rainbox Attenuation CratesBerat DalyabrakNessuna valutazione finora

- Drug Study Pre OpDocumento6 pagineDrug Study Pre OpgiaNessuna valutazione finora

- Extraction and Isolation of Saponins PDFDocumento2 pagineExtraction and Isolation of Saponins PDFMikeNessuna valutazione finora

- Paket 4Documento6 paginePaket 4Lovis ShalahuddinNessuna valutazione finora

- TLC Analysis of Siling Labuyo Extract ComponentsDocumento3 pagineTLC Analysis of Siling Labuyo Extract ComponentsJan Eric Balete0% (1)

- Tata Bluescope Steel Limited, Jamshedpur.: Liquefied Petroleum Gas Material Safety Data SheetDocumento6 pagineTata Bluescope Steel Limited, Jamshedpur.: Liquefied Petroleum Gas Material Safety Data Sheetsujit5584Nessuna valutazione finora

- Carte Tehnica Partea IDocumento22 pagineCarte Tehnica Partea IadrianNessuna valutazione finora

- Comparison of Infrastructure in Punjab and Andhra PradeshDocumento7 pagineComparison of Infrastructure in Punjab and Andhra PradeshDivyam GXNessuna valutazione finora

- Corn Genetics and Chi Square AnalysisDocumento2 pagineCorn Genetics and Chi Square AnalysisBonifacius Budi NugrohoNessuna valutazione finora

- BSN-2D 1st Semester ScheduleDocumento2 pagineBSN-2D 1st Semester ScheduleReyjan ApolonioNessuna valutazione finora

- Akron Grad School Statement of Purpose PDFDocumento2 pagineAkron Grad School Statement of Purpose PDFapi-406039291Nessuna valutazione finora

- Eugenics in The United StatesDocumento14 pagineEugenics in The United StatesSnark Jacobs100% (1)

- SPR MAN 4 14 ET Operating ManualDocumento24 pagineSPR MAN 4 14 ET Operating ManualJason WeeksNessuna valutazione finora

- Atlas Tool Specs SummaryDocumento3 pagineAtlas Tool Specs SummaryWaleed Barakat MariaNessuna valutazione finora

- Penicillin G Benzathine-Drug StudyDocumento2 paginePenicillin G Benzathine-Drug StudyDaisy Palisoc67% (3)