Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Enhancement of Electrical Properties On Zno: Al Thin Film Due To Hydrogen Annealing and Sio Coating in Damp-Heat Environment

Caricato da

hazbi2011Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Enhancement of Electrical Properties On Zno: Al Thin Film Due To Hydrogen Annealing and Sio Coating in Damp-Heat Environment

Caricato da

hazbi2011Copyright:

Formati disponibili

TRANSACTIONS ON ELECTRICAL AND ELECTRONIC MATERIALS VOL. 10, NO.

2, APRIL 25, 2009

Enhancement of Electrical Properties on ZnO: Al Thin Film due to Hydrogen Annealing and SiO2 Coating in Damp-heat Environment

Hao Chen, Yun-Hwan Jeong, and Choon-Bae Park*

School of Electrical, Electronic and Information Engineering, Wonkwang University, WRISS, 344-2 Shinyong-dong, Iksan-si, Chonbuk 570-749, Republic of Korea (Received February 18 2009, Accepted April 22 2009) The electrical stability of ZnO: Al thin films deposited on glass substrate by the RF magnetron sputtering method have been modified by a hydrogen annealing treatment and SiO2 protection layer. AZO thin films were deposited at room temperature and different RF powers of 50, 100, 150, and 200 W to optimize the AZO film growth condition. The lowest value of resistivity of 9.4410-4 cm was obtained at 2 mtorr, room temperature, and a power level of 150 W. Then, the AZO thin films were annealed at 250-400 C for 1 h in hydrogen ambient. The minimum resistivity obtained was 8.3210-4 cm as-annealed at 300 C. The electrical properties were enhanced by the hydrogen annealing treatment. After a 72 h damp-heat treatment in harsh conditions of a water steam at 110 C for four representative samples, a degradation of electrical properties was observed. The sample of hydrogen-annealed AZO thin films with SiO2 protection layer showed a slight degradation ratio (17 %) of electrical properties and a preferable transmittance of 90 %. The electrical stability of AZO thin films had been modified by hydrogen annealing treatment and SiO2 protection layer. Keywords: Hydrogen annealing, SiO2 protection layer, Electrical stability, Damp-heat environment

1. INTRODUCTION1

Transparent conductive oxide (TCO) films such as indium tin oxide (ITO) and zinc oxide (ZnO), heavily doped with n-type dopants, have been extensively applied to thin film solar cells as front electrodes because of their high transmittance and good electrical properties. In particular, Al-doped ZnO (AZO) films are regarded as good substitutes for ITO films. AZO thin films show high transparency in the visible wavelength range, high electrical conductivity, high thermal stability, and low cost comparable to those of ITO thin films[1,2]. Magnetron-sputtered AZO thin films are used in front contact windows for silicon and Cu (In, Ga) Se2 (CIGS)-based thin film solar cells[3]. Good long-term stability of solar cells in harsh outdoor conditions is necessary to realize successful commercialization. However, the electrical properties of AZO thin films are degraded when films are exposed to air ambient[1], which restricts the use of AZO films for solar cells. Researchers have done some work on improving the ability to resist the degradation of film conductivity and transmission during the preparation of AZO thin films[3]. It was reported that thermally-treated AZO thin films in hydrogen ambient could improve electrical conductivity[1] as well as increase stability in air exposure[4]. It is known that SiO2 thin films find wide application for anti-reflective coatings, such as protective layers, and have been applied in various ways to improve the aging of photovoltaic devices as encapsulated coatings[5,6]. However, few works have been reported on the stability of the AZO thin films with SiO2 film coating as a protective layer. In this paper, the electrical properties of AZO thin films with a SiO2 protective layer are investigated, which may be helpful in improving the aging of encapsulated-modules for long-term stability of solar cells in harsh outdoor conditions.

*Author to whom corresponding should be addressed: electronic mail: cbpark@wonkwang.ac.kr

1229-7607/2009/10(2)/1/4(WWW.TRANSEEM.ORG) 58

We used a damp-heat environment as a module of harsh outdoor conditions to test the electrical stability of AZO thin films with or without hydrogen annealing treatment and a SiO2 protective layer. We found that a hydrogen annealing treatment enhanced the electrical characteristics of AZO thin films, and the SiO2 protection layer apparently water from penetrating into the AZO thin films, thereby resisting the degradation of film conductivity. Thus, the electrical stability of AZO thin films can be improved.

2. EXPERIMENTS

The AZO thin films and SiO2 protection layer were deposited by RF magnetron sputtering with a base pressure of 810-6 Torr at room temperature. AZO thin films were deposited on Corning 1737 glass substrates with a ZnO: Al2O3 (2 wt%) ceramic target. The substrates were sequentially ultrasonically cleaned in acetone, alcohol, and de-ionized water, and dried with nitrogen gas. During the sputtering, the working pressure was maintained at 2 mtorr with Ar ambient, and the RF power was controlled in the range of 50-200 W. The pre-sputtering and deposition times were 10 min and 60 min, respectively. The SiO2 protective layer was deposited on the AZO thin films using a glass target. RF power and deposition time was 50 W and 2 hrs, respectively. Other conditions were the same as for the AZO thin films. Annealing treatments were carried out in ambient atmospheric hydrogen for 1 hr at a temperature of 250-400 C. The details of deposition and annealing conditions of the AZO thin films are listed in Table 1, and the details of deposition conditions for the SiO2 protection layer are listed in Table 2. The electrical properties were evaluated by Hall measurement. Cross-section morphologies were observed by scanning electron microscopy (SEM). Four representative samples were selected for the electrical stability test: A: as-deposited AZO thin films; B: hydrogen-annealed AZO

2009 KIEEME

Trans. Electr. Electron. Mater. 10(2) 58 (2009): H. Chen et al. Table 1. Conditions of AZO thin film deposition on glass substrate by RF magnetron sputtering and annealing. Parameters Detailed conditions substrate target base pressure working pressure growth temperature ambient gas RF power pre-sputtering time deposition time Coring glass 1737 ZnO: Al2O3 (2 wt %) 810-6 Torr 2 mTorr RT Ar 50, 100, 150, 200 W 10 min 1 hr H2 10 Torr 250, 300, 350, 400 C 1 hr

59

Figure 1 shows the deposition RF power. The deposition rate was found to be directly proportional to the deposition RF powers from 50 W to 200 W. An increase in deposition rate with RF power results from more target atoms being ejected from the source when RF power is increased[7-9]. The thin film resistivity decreased from 19.510-4 to 9.4410-4 cm as the RF power increased from 50 to 150 W, and thereafter the resistivity increased slightly at 200 W. Figure 2 illustrates the carrier concentration and Hall mobility of AZO films as a function of RF power. Both carrier concentration and Hall mobility increased as the RF power was increased up to 150 W. Thereafter, they decreased at a power of 200 W. This characteristic can be understood from the fact that the probability of trapped Al or Zn increased with the increase in RF power[10]. The lowest resistivity of 9.4410-4 cm was achieved when the AZO thin films were deposited with RF power of 150 W.

annealing

Table 2. Conditions of SiO2 protection layer deposition on AZO thin film by RF magnetron sputtering. Parameters Detailed Conditions substrate target base pressure working pressure growth temperature ambient gas RF power pre-sputtering time deposition time AZO thin films on the glass Glass 810-6 Torr 2 mTorr RT Ar 50 W 10 min 2 hrs Fig. 1. Deposition rate and resistivity of AZO thin films as a function of RF power.

thin films; C: as-deposited AZO thin films with SiO2 protection layer; and D: hydrogen-annealed AZO thin films with SiO2 protection layer. All of these samples were exposed in the damp-heat environment at a temperature of 100 C in a water steam for 72 h, and the resistance values of the samples were recorded once every 24 h to analyze the evolution of the electrical characteristics. The optical transmittance of the damp-heat treated samples were measured in the range of 300-1100 nm by a spectrophotometer.

Fig. 2. Carrier concentration and Hall mobility of AZO thin films as a function of RF power.

3. RESULTS AND DISCUSSION

First, we investigated the influence of deposition power on the electrical properties of as-deposited AZO thin films.

The deposited AZO films were thermally treated in ambient hydrogen. Changes in the electrical characteristics of the hydrogen-annealed AZO films were investigated as a function of annealing temperature, as shown in Fig. 3.

60

Trans. Electr. Electron. Mater. 10(2) 58 (2009): H. Chen et al.

Fig. 3. Resistivity, carrier concentration, and Hall mobility of AZO thin films as a function of the hydrogen annealing temperature.

Hydrogen annealing treatment improved the electrical characteristics of the AZO films, and the resistivity of the film annealed at 300 C was as low as 8.3210-4 cm. The resistivity is inversely proportional to carrier concentration n and mobility [11]:

1 ne

increase of all films varies in the range of 17 %-72 %. Sample D (hydrogen-annealed AZO thin films with SiO2 protection layer) showed the smallest increase of resistance, while sample A (as-deposited AZO thin films) was affected the most by the damp-heat environment. The degradation of electrical properties can be explained as follows: in the damp-heat environment, oxygen and water molecules penetrate into the films via defect paths[9]. So, the width and height of grain boundary barriers are increased. The water existing in a grain boundary could strengthen the effect of grain boundary scattering and led to enhanced capture of free carriers, thus decreasing the carrier concentration and the mobility[3]. Comparing samples A and B, hydrogen annealing treatment improved the electrical stability of the AZO thin films. Hydrogen annealed AZO thin films with a SiO2 protection layer higher electrical stability than thin films with only an SiO2 protection layer, as shown by samples C and D. This indicates that the hydrogen annealing process resulted in desorption of weakly adsorbed oxygen species on the grain boundaries[1]. Moreover, the advantage of the SiO2 protection layer which the electrical stability of AZO thin films has apparently been shown by samples C and D apparently. Thus, the SiO2 protection layer effectively prevented the oxygen and water molecules from penetrating into the AZO thin films.

The carrier concentration decreased and the mobility increased sequentially as the annealing temperature from 250 to 300 C, but the degree of mobility increased to a greater than the carrier concentration decreased, which lead to the resistivity decreasing accordingly. Hence, the faster increase in mobility resulted in a major contribution to electrical conductivity. Due to the polycrystalline nature of the film, we assumed that as-deposited films have an excess of oxygen chemisorbed at grain boundaries and other defects; for example, at oxygen vacancies and metal interstitials[3], which reduce the mobility of the AZO films [3]. Moreover, the chemisorbed oxygen forms depletion regions; i. e., the barrier near the grain boundary surfaces, which causes a decrease in the mobility of the AZO films [1]. Desorption of oxygen from the boundaries should occur while the films are annealing in the hydrogen atmosphere; therefore, the mobility of electrons increases. At the same time, some oxygen diffuses to oxygen vacancies in the films, which reduced the carrier concentration. When the annealing temperature is larger than 300 C, we can see the reverse trend in the electron mobility and the carrier concentration. The SiO2 protection layer was deposited on the AZO thin films to promote the electrical stability of AZO film. Figure 4 shows a cross-section FE-SEM image of the SiO2 protection layer that deposited on the AZO thin film. This SiO2 protection layer presented a compact microstructure. We note that the compact structure of SiO2 can prevent degradation of AZO thin film from water vapor in air, which is helpful in enhancing the electrical stability of AZO thin films. The results of the electrical stability test confirmed this point of view. Figure 5 shows the resistance increase ratio of four representative samples (A, B, C, and D) as a function of the exposed time in the damp-heat environment. The samples were exposed in the damp-heat environment after 72 h; it can be seen that the resistance

Fig. 4. Cross-sectional FE-SEM image of SiO2 protection layer deposited on AZO thin film.

Fig. 5. Ratio of resistance increase for four representative films (A: samples as-deposited AZO thin films; B: hydrogen-annealed AZO thin films; C: as-deposited AZO thin films with SiO2 protection layer; and D: hydrogen-annealed AZO thin films with SiO2 protection layer) as a function of damp-heat environment exposure time.

Trans. Electr. Electron. Mater. 10(2) 58 (2009): H. Chen et al.

61

100

80

60

A B C D

40

20

0 400 600 800 1000 1200

Wavelength (nm)

Fig. 6. Transmittance for four AZO films. (A: samples as-deposited AZO thin films, B: hydrogen-annealed AZO thin films, C: as-deposited AZO thin films with SiO2 protection layer, D: hydrogen-annealed AZO thin films with SiO2 protection layer)

sputtered SiO2 protection layer on AZO thin films exhibited compact structure, which was an advantage in retarding corrosion from the external environment. After 72 h damp-heat treatment in harsh conditions in a water steam at 110 C for four representative samples, degradation of electrical properties was observed. The average optical transmittance for all the samples was above 85 % in wavelength region of 400-1100 nm, which is suitable to the silicon solar cell. The sample of hydrogen-annealed AZO thin film with SiO2 protection layer showed a preferable transmittance of 90 % and the faintish degradation ratio (17 %) of electrical properties, which was much better than other films. The electrical stability of AZO thin films had been modified by hydrogen annealing treatment and SiO2 protection layer, implying that the hydrogen annealed AZO thin film with SiO2 protection layer is applicable to the silicon solar cell without any reduction of optical transmittance.

Transmittance (%)

ACKNOWLEDGMENTS

The transmittance of the samples (A, B, C and D) for 72 h of damp-heat treatment was measured at room temperature and the spectra are shown in Fig. 6. The average optical transmittance was above 85 % in the wavelength range of 400-1100 nm for all samples, which is suitable to silicon solar cells. The sample D (hydrogenannealed AZO thin films with SiO2 protection layer) showed a preferable transmittance of 90 %. It suggests that SiO2 protection layer also improves the transmission of AZO films. Moreover, the transmittance edge shifts to shorter wavelength (~312 nm) for the hydrogen annealed AZO thin films (sample B and D) compared with the sample A. This phenomenon is due to the Burstein-Moss effect that the optical band gap is widened with increasing donor concentration due to the filling of conduction band by increase of electron carriers.

This work was supported by the Small and Medium Business Administration (SMBA) of South Korea through the Enterprise Attached Research Institute.

REFERENCES

[1] B.-Y. Oh, M.-C. Jeong, and J.-M. Myoung, Appl. Surf. Sci. 253, 7157 (2007). [2] E.-M. Jin, E.-C. Shin, T.-W. Kim, and C.-B. Park, J. of KIEEME(in Korean) 20, 357 (2007). [3] W. Lina, R. Maa, J. Xueb, and B. Kanga, Sol. Energy Mater. Sol. Cells. 91, 1902 (2007). [4] S. H. Lee, T. S. Lee, K. S. Lee, B. Cheong, Y. D. Kim, and W. M. Kim, J. Phys. D: Appl. Phys. 41, 095303 (2008). [5] C. GuillenU, A. Morales, and J. Herrero, Surf. Coat. Technol. 132, 31 (2000). [6] C. Ballifa, J. Dickerb, D. Borcherta, and T. Hofmannc, Sol. Energy Mater. Sol. Cells. 82, 331 (2004). [7] D. Song, Appl. Surf. Sci. 254, 4171 (2008). [8] D.-J. Kwak, M.-W. Park, and Y.-M. Sung, Vacuum 83, 113 (2008). [9] Y.-H. Jeong, H.-J. Jin, and C.-B. Park, J. of KIEEME(in Korean) 21, 863 (2008). [10] W. J. Jeong, S. K. Kim, and G. C. Park, Thin Solid Films 506-507, 180 (2006). [11] W. Liu, G. Du, Y. Sun, Y. Xu, T. Yang, X. Wang, Y. Chang, and F. Qiu, Thin Solid Films 515, 3057 (2007.)

4. CONCLUSION

Electrical properties were enhanced due to the removal of the absorbed oxygen species at the grain boundaries by the hydrogen annealing process. Resistivity decreased from 9.4410-4 cm to 8.3210 -4 cm after annealing in a hydrogen atmosphere for 1 h at 300 C. An RF magnetron-

Potrebbero piacerti anche

- TF100-9D - Refrigerant Hose With Att FittingsDocumento28 pagineTF100-9D - Refrigerant Hose With Att FittingsJai BhandariNessuna valutazione finora

- Applications of Linear Algebra in Computer ScienceDocumento8 pagineApplications of Linear Algebra in Computer ScienceSameed Ahmed Rafi100% (2)

- Astron: MFL Testing Procedure For Tank FloorDocumento16 pagineAstron: MFL Testing Procedure For Tank FloorleonciomavarezNessuna valutazione finora

- Solubility PDFDocumento36 pagineSolubility PDFAshwin Narayan100% (1)

- Shape and Volume: A Presentation On AcousticsDocumento35 pagineShape and Volume: A Presentation On AcousticsSiddharth BhandariNessuna valutazione finora

- NPTEL CC Assignment4Documento4 pagineNPTEL CC Assignment4Paul Stark100% (1)

- CN101A Timer ManualDocumento2 pagineCN101A Timer ManualMauricioVilalvaJr.0% (1)

- Microwave Studies of Thermally Oxidized Vacuum Evaporated Bismuth Thin Films On AluminaDocumento7 pagineMicrowave Studies of Thermally Oxidized Vacuum Evaporated Bismuth Thin Films On AluminaSofa KingNessuna valutazione finora

- بحث 6Documento3 pagineبحث 6wisam44Nessuna valutazione finora

- Preparation and Electrochromic Properties of Rfsputtered Molybdenum Oxide FilmsDocumento6 paginePreparation and Electrochromic Properties of Rfsputtered Molybdenum Oxide FilmsHusam Abduldaem MohammedNessuna valutazione finora

- Thin Solid Films: Yong-June Choi, Kyung-Mun Kang, Hong-Sub Lee, Hyung-Ho ParkDocumento7 pagineThin Solid Films: Yong-June Choi, Kyung-Mun Kang, Hong-Sub Lee, Hyung-Ho ParkBhabani Sankar SwainNessuna valutazione finora

- MPM144 13 SakharovDocumento6 pagineMPM144 13 SakharovВадим АрыковNessuna valutazione finora

- 1 s2.0 S0040609015003363 MainDocumento4 pagine1 s2.0 S0040609015003363 MainBhabani Sankar SwainNessuna valutazione finora

- Influence of Substrate Temperature On Structural, Electrical and Optical Properties of Zno:Al Thin FilmsDocumento11 pagineInfluence of Substrate Temperature On Structural, Electrical and Optical Properties of Zno:Al Thin FilmsMuhammad Sahlan RidwanNessuna valutazione finora

- Common Deposition Techniques: Electron-BeamDocumento4 pagineCommon Deposition Techniques: Electron-BeamjorgeNessuna valutazione finora

- Cao2010Documento9 pagineCao2010Riston SinagaNessuna valutazione finora

- Electrical and Optical Properties of Al-Doped Zno Thin Films by Sol-Gel ProcessDocumento6 pagineElectrical and Optical Properties of Al-Doped Zno Thin Films by Sol-Gel ProcessMurtaza SieamNessuna valutazione finora

- Proceedings of SpieDocumento9 pagineProceedings of SpieYoungNessuna valutazione finora

- I-V Characteristic of Cdo/Ps HeterojunctionDocumento6 pagineI-V Characteristic of Cdo/Ps HeterojunctionInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Optics Communications: C. Guillén, J. HerreroDocumento5 pagineOptics Communications: C. Guillén, J. HerreroTran Phuong LinhNessuna valutazione finora

- Dependence of The Electrical and Optical Properties On The Bias Voltage For Zno:Al Films Deposited by R.F. Magnetron SputteringDocumento5 pagineDependence of The Electrical and Optical Properties On The Bias Voltage For Zno:Al Films Deposited by R.F. Magnetron SputteringGeetha Sokkian RammanoharNessuna valutazione finora

- 24 Characteristicsof SN O2 FThin Films Depositedby Ultrasonic Spray Pyrolysis Effectof Water Contentin Solutionand Substrate TemperatureDocumento7 pagine24 Characteristicsof SN O2 FThin Films Depositedby Ultrasonic Spray Pyrolysis Effectof Water Contentin Solutionand Substrate TemperatureMariane AzevedoNessuna valutazione finora

- Synthesis and Analysis of Low-K Material For Intermetal Dielectric Applications in VLSIDocumento5 pagineSynthesis and Analysis of Low-K Material For Intermetal Dielectric Applications in VLSIjbhavananNessuna valutazione finora

- ITO Thin Films For Low-Resistance Gas SensorsDocumento16 pagineITO Thin Films For Low-Resistance Gas SensorsMarisela SantosNessuna valutazione finora

- Growth of Passive Films On Valve Metals and Their AlloysDocumento9 pagineGrowth of Passive Films On Valve Metals and Their AlloysDjedili AmelNessuna valutazione finora

- Journal Pre-Proof: Thin Solid FilmsDocumento31 pagineJournal Pre-Proof: Thin Solid FilmsSahin CoskunNessuna valutazione finora

- High Quality Crystalline Zno Buffer Layers On Sapphire (001) by Pulsed Laser Deposition For Iii-V NitridesDocumento3 pagineHigh Quality Crystalline Zno Buffer Layers On Sapphire (001) by Pulsed Laser Deposition For Iii-V NitridesEidelsayedNessuna valutazione finora

- δ-Bi2O3 thin films prepared by reactive sputtering - Fabrication and characterizationDocumento6 pagineδ-Bi2O3 thin films prepared by reactive sputtering - Fabrication and characterizationrafael pimentelNessuna valutazione finora

- JApplPhys 93 3837 PDFDocumento7 pagineJApplPhys 93 3837 PDFEidelsayedNessuna valutazione finora

- Electrical and Optical Properties of Electron Beam Evaporated ITO Thin FilmsDocumento4 pagineElectrical and Optical Properties of Electron Beam Evaporated ITO Thin FilmsAhmet KılıçNessuna valutazione finora

- IOSR JournalsDocumento6 pagineIOSR JournalsInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- JApplPhys 85 2595 PDFDocumento8 pagineJApplPhys 85 2595 PDFEidelsayedNessuna valutazione finora

- Comparative Studies of Al-Doped Zno and Ga-Doped Zno Transparent Conducting Oxide Thin FilmsDocumento6 pagineComparative Studies of Al-Doped Zno and Ga-Doped Zno Transparent Conducting Oxide Thin FilmsMurtaza SieamNessuna valutazione finora

- Characterization of PVD Aluminum Nitride For Heat Spreading in RF IC'sDocumento4 pagineCharacterization of PVD Aluminum Nitride For Heat Spreading in RF IC'srahil7860Nessuna valutazione finora

- Electrical Properties of Li-Doped NiO FilmsDocumento6 pagineElectrical Properties of Li-Doped NiO FilmsWL JangNessuna valutazione finora

- Tsung-Cheng Chen 2018Documento7 pagineTsung-Cheng Chen 2018thoriqulhaqNessuna valutazione finora

- Dry Etching of Al O Thin Films in O /BCL /ar Inductively Coupled PlasmaDocumento4 pagineDry Etching of Al O Thin Films in O /BCL /ar Inductively Coupled PlasmaStephen MyersNessuna valutazione finora

- Diketonates Aluminum Films On Solar Cells: Effect of ParametersDocumento6 pagineDiketonates Aluminum Films On Solar Cells: Effect of ParametersСергей ХрипкоNessuna valutazione finora

- The Electromagnetic Shielding e Ectiveness of Indium Tin Oxide ®lmsDocumento3 pagineThe Electromagnetic Shielding e Ectiveness of Indium Tin Oxide ®lmsreza mirzakhaniNessuna valutazione finora

- Chemical Bath DepositionDocumento6 pagineChemical Bath DepositionJune AlapaNessuna valutazione finora

- Enhanced Performance of a-IGZO Thin-Film Transistors by Forming AZO/IGZO Heterojunction Source/drain ContactsDocumento6 pagineEnhanced Performance of a-IGZO Thin-Film Transistors by Forming AZO/IGZO Heterojunction Source/drain ContactsRajesh AgarwalNessuna valutazione finora

- Studies On The Properties PDFDocumento3 pagineStudies On The Properties PDFZeen MajidNessuna valutazione finora

- Effects of Nano Pigments On The Corrosion Resistance of Alkyd CoatingDocumento8 pagineEffects of Nano Pigments On The Corrosion Resistance of Alkyd Coatingdvega1981Nessuna valutazione finora

- Comparison of Electrical Properties of NiCr Thin Film Deposited On Different SubstratesDocumento9 pagineComparison of Electrical Properties of NiCr Thin Film Deposited On Different SubstratesQilin XiaNessuna valutazione finora

- Solid-State Electronics: Fahd Al-Juaid, Amar Merazga, Ateyyah Al-Baradi, Fouad Abdel-WahabDocumento6 pagineSolid-State Electronics: Fahd Al-Juaid, Amar Merazga, Ateyyah Al-Baradi, Fouad Abdel-WahabIntenNessuna valutazione finora

- Effect of Post Annealing in Oxygen Ambient On Characteristics of IGZO TFTDocumento5 pagineEffect of Post Annealing in Oxygen Ambient On Characteristics of IGZO TFTjasyongNessuna valutazione finora

- Study Some Structural and Optical Properties of Copper Nano FilmDocumento6 pagineStudy Some Structural and Optical Properties of Copper Nano FilmInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Flexible Cu (In, Ga) Se On Al Foils and The Effects of Al During Chemical Bath DepositionDocumento5 pagineFlexible Cu (In, Ga) Se On Al Foils and The Effects of Al During Chemical Bath DepositionketamencoNessuna valutazione finora

- 2012aluminum-Doped Zinc Oxide Formed by Atomic Layer Deposition For Use As Anodes in Organic Light Emitting DiodesDocumento7 pagine2012aluminum-Doped Zinc Oxide Formed by Atomic Layer Deposition For Use As Anodes in Organic Light Emitting DiodesKanchanee NIYOMNessuna valutazione finora

- 2022wang JAC FabricationandcharacterizationofsputteredMgandFco DopedZnOfilmsdifferentsubtemperaturesolarcell P CompressedDocumento11 pagine2022wang JAC FabricationandcharacterizationofsputteredMgandFco DopedZnOfilmsdifferentsubtemperaturesolarcell P CompressedBeyza Nur AKBOLATNessuna valutazione finora

- Highly Compact Tio2 Layer For Efficient Hole-Blocking in Perovskite Solar CellsDocumento5 pagineHighly Compact Tio2 Layer For Efficient Hole-Blocking in Perovskite Solar CellsNyau NyauNessuna valutazione finora

- Wo3 NanorodsDocumento6 pagineWo3 NanorodsinfinitopNessuna valutazione finora

- And Effect Fillers: Ltd. High 1155 Komaki, JapanDocumento8 pagineAnd Effect Fillers: Ltd. High 1155 Komaki, JapanRosi DavidNessuna valutazione finora

- Preparation of Plasma-Polymerized SiOx-like Thin Films From A MixtureDocumento6 paginePreparation of Plasma-Polymerized SiOx-like Thin Films From A MixturekgvtgNessuna valutazione finora

- The Effect of Substrate Temperature On Filtered Vacuum Arc Deposited Zinc Oxide and Tin Oxide Thin FilmsDocumento9 pagineThe Effect of Substrate Temperature On Filtered Vacuum Arc Deposited Zinc Oxide and Tin Oxide Thin FilmsAlev KızılbulutNessuna valutazione finora

- Ultrathin Hfalo Ferroelectrics Enhancing Electron Transport and Perovskite Solar Cell PerformanceDocumento11 pagineUltrathin Hfalo Ferroelectrics Enhancing Electron Transport and Perovskite Solar Cell Performancewhdrhks7907Nessuna valutazione finora

- Msa20111000007 87029177Documento5 pagineMsa20111000007 87029177Mario Misael Machado LòpezNessuna valutazione finora

- Al-Zno Paper JoamDocumento7 pagineAl-Zno Paper JoamYasir KhanNessuna valutazione finora

- Ontheelectricalandopticalpropertiesof CD SfilmsthermallydepositedDocumento4 pagineOntheelectricalandopticalpropertiesof CD SfilmsthermallydepositedExtrusion TutorialsNessuna valutazione finora

- 754 FullDocumento1 pagina754 FullGetachew YirgaNessuna valutazione finora

- Electric Contacts For ZnODocumento5 pagineElectric Contacts For ZnOjmcorreahNessuna valutazione finora

- Electrochemical Impedance Study On Galvanized Steel Corrosion Under Cyclic Wet-Dry Conditions - in Uence of Time of WetnessDocumento13 pagineElectrochemical Impedance Study On Galvanized Steel Corrosion Under Cyclic Wet-Dry Conditions - in Uence of Time of WetnessVanessa Rios NolayaNessuna valutazione finora

- 2 s2.0 85030846253Documento7 pagine2 s2.0 85030846253ARSALAN AHMADNessuna valutazione finora

- J Ijhydene 2004 01 009Documento9 pagineJ Ijhydene 2004 01 009AKASH PRAVIN JOSE JNessuna valutazione finora

- Aida 2Documento4 pagineAida 2anil sonawaneNessuna valutazione finora

- Fluorine Doped-Tin Oxide Prepared Using Spray Method For Dye Sensitized Solar Cell ApplicationDocumento4 pagineFluorine Doped-Tin Oxide Prepared Using Spray Method For Dye Sensitized Solar Cell ApplicationBlue StarNessuna valutazione finora

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)Da EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)Nessuna valutazione finora

- 3.003 Principles of Engineering Practice: One Month Review Solar CellsDocumento20 pagine3.003 Principles of Engineering Practice: One Month Review Solar Cellshazbi2011Nessuna valutazione finora

- Thin Film Growth StepsDocumento45 pagineThin Film Growth Stepshazbi2011Nessuna valutazione finora

- Vacuum Basics PDFDocumento49 pagineVacuum Basics PDFhazbi2011Nessuna valutazione finora

- Vacuum BasicsDocumento49 pagineVacuum Basicshazbi2011Nessuna valutazione finora

- Fpls 12 764103Documento10 pagineFpls 12 764103Pawan MishraNessuna valutazione finora

- New ScriptDocumento2 pagineNew ScriptDeveloper 4Nessuna valutazione finora

- Chapter Test 2nd Quarter.Documento5 pagineChapter Test 2nd Quarter.Roziel MontalbanNessuna valutazione finora

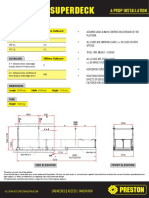

- SuperDeck All ModelsDocumento12 pagineSuperDeck All Modelsarthur chungNessuna valutazione finora

- 11Documento47 pagine11Felipe Retamal100% (1)

- Eaton Xeffect Industrial Switchgear Range Catalog Ca003002en en UsDocumento379 pagineEaton Xeffect Industrial Switchgear Range Catalog Ca003002en en UsMAURIZIO MARININessuna valutazione finora

- EC303Documento19 pagineEC303api-3853441Nessuna valutazione finora

- Partial Differential Equations (Pdes)Documento5 paginePartial Differential Equations (Pdes)uploadingpersonNessuna valutazione finora

- Simultaneous Equations - Word ProblemsDocumento27 pagineSimultaneous Equations - Word ProblemsSandy Wong0% (1)

- About Planets - Vaishali's ProjectDocumento3 pagineAbout Planets - Vaishali's ProjectRaj KumarNessuna valutazione finora

- Case StudyDocumento6 pagineCase Studyzaid bin shafiNessuna valutazione finora

- Carbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEDocumento53 pagineCarbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEsaintEmNessuna valutazione finora

- BXE Experiment No.3Documento8 pagineBXE Experiment No.3DsgawaliNessuna valutazione finora

- IT6602 SA Coaching Class QuestionsDocumento3 pagineIT6602 SA Coaching Class QuestionsvinothNessuna valutazione finora

- Open Mapping Theorem (Functional Analysis)Documento3 pagineOpen Mapping Theorem (Functional Analysis)Silambu SilambarasanNessuna valutazione finora

- Datasheets A S50ib enDocumento2 pagineDatasheets A S50ib envantuan17792Nessuna valutazione finora

- Sistema de Refrigeração de Óleo, EspecificaçõesDocumento2 pagineSistema de Refrigeração de Óleo, EspecificaçõesAlexandreNessuna valutazione finora

- UntitledDocumento33 pagineUntitledapi-235198167Nessuna valutazione finora

- PM BCE DCS Crash WebDocumento4 paginePM BCE DCS Crash WebAna Paola VazquezNessuna valutazione finora

- BS DanielDocumento6 pagineBS Danielsandy30694Nessuna valutazione finora

- FluidsDocumento10 pagineFluidslara alghamdiNessuna valutazione finora

- Sap Query Procedure (Sqvi)Documento8 pagineSap Query Procedure (Sqvi)nona_rose218Nessuna valutazione finora

- National Programming Skills Report - Engineers 2017 - Report BriefDocumento20 pagineNational Programming Skills Report - Engineers 2017 - Report BriefNewsBharati100% (2)