Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Indexable Insert Ion System

Caricato da

docstungestemetTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Indexable Insert Ion System

Caricato da

docstungestemetCopyright:

Formati disponibili

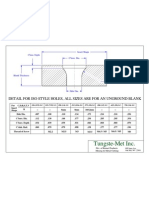

Tungste-Met, Inc.

Designation system for Indexable Inserts commonly used for turning tools

Fourth position First position Shape A Parallelogram 85 B Parallelogram 82 C Diamond 80 D Diamond 55 E Diamond 75 H Hexagon 120 K Parallelogram 55 L Rectangle 90 M Diamond 86 0 Octagon 135 P Pentagon 108 R Round S Square 90 T Triangle 60 V Diamond 35 W Trigon 80 Third position Tolerance class1) B A 0.0002 B 0.0002 C 0.0005 D 0.0005 E 0.001 F 0.0002 G 0.001 H 0.0005 J 0.0002 K 0.0005 L 0.001 M 0.003-0.0082) N 0.003-0.0082) U 0.005-0.0152) A 0.001 0.001 0.001 0.001 0.001 0.0005 0.001 0.0005 0.002-0.006 0.002-0.006 0.002-0.006 0.002-0.006 0.002-0.006 0.003-0.010 T 0.001 0.005 0.001 0.005 0.001 0.001 0.005 0.001 0.001 0.001 0.001 0.005 0.001 0.005

A With hole B With hole and one countersink (70 90) C With hole and two countersinks (70 90) F Without hole with chip grooves on two rake faces G With hole and chip grooves on two rake faces H With hole, one countersink (70 90) and chip groove on one rake face J With hole, two countersinks (70 90) and chip grooves on two rake faces M With hole and chip groove on one rake face N Without hole O With hole and two countersinks (40 60) R Without hole with chip groove on one rake face T With hole, one countersink (40 60) and chip groove on rake face U With hole, two countersinks (40 60) and chip grooves on two rake faces W With hole and one countersink (40 60)

Fifth position Size (I.C.) Regular polygons and diamonds Number of eighths of an inch in the inscribed circle as follows: Example: 5/32 inch I.C. = 1.2 3/16 inch I.C. = 1.5 7/32 inch I.C. = 1.8 1/4 inch I.C. = 2 5/16 inch I.C. = 2.5 3/8 inch I.C. = 3 1/2 inch I.C. = 4 5/8 inch I.C. = 5 3/4 inch I.C. = 6 1 inch I.C. = 8 1 1/4 inch I.C. = 10 Rectangles and parallelograms Use two digits to size: First digit: Number of eighths of an inch in width Second digit: Number of fourths of an inch in length

Type

Second position Clearance A 3 B 5 C 7 D 15 E 20 F 25 G 30 N 0 P 11

EXAMPLE:

Sixth position Thickness Regular polygons, diamonds, rectangles and parallelograms. Number of sixteenths of an inch in thickness as follows: Example: 3/32 inch 1.5 1/8 inch 2 5/32 inch 2.5 3/16 inch 3 7/32 inch 3.5 1/4 inch 4 5/16 inch 5 3/8 inch 6 7/16 inch 7 1/2 inch 8

Seventh position Cutting-point configuration 0 0.004-inch radius 0.5 0.008-inch radius 1 1/64-inch radius 2 1/32-inch radius 3 3/64-inch radius 4 1/16-inch radius 5 5/64-inch radius 6 3/32-inch radius 7 7/64-inch radius 8 1/8-inch radius

Eighth position3) Edge and surface preparations

A Light Honed (0.0005 to 0.0025 inch) B Medium Honed (0.003 to 0.0045 inch) C Heavy Honed (0.005 to 0.007 inch) J Polished to 4-microinch AA (Rake face only) T Chamfered Manufacturer's standard

Ninth position3) Hand R Right LLeft N Neutral

Tenth position Manufacturer's option Shall only by used if desired by the manufacturer.

(Negative land Rake face only)

Tolerances given are plus and minus from nominal. The tolerance depends on the size and shape of the insert. 3) Shall only be used when required.

1) 2)

Potrebbero piacerti anche

- Raymond Queneau - Exercises in StyleDocumento27 pagineRaymond Queneau - Exercises in StyleFelicita Anahi CalfatNessuna valutazione finora

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionDa EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNessuna valutazione finora

- Blood. Honor. Steel.: RAW Your Blade AND Join THE Fight FOR OkuganDocumento15 pagineBlood. Honor. Steel.: RAW Your Blade AND Join THE Fight FOR OkuganNokowire TVNessuna valutazione finora

- Workshop Manual - Daihatsu 3 Cyl 993cc EFIDocumento182 pagineWorkshop Manual - Daihatsu 3 Cyl 993cc EFIrhozel201082% (11)

- Drmg189 PDFDocumento124 pagineDrmg189 PDFcos2inNessuna valutazione finora

- Hyundai Service Manual SonataNF Engine Mechanical System 2007Documento99 pagineHyundai Service Manual SonataNF Engine Mechanical System 2007cavp7675% (4)

- Making A Spur GearDocumento9 pagineMaking A Spur GearHaraprasad DolaiNessuna valutazione finora

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Independent Study Packet Preschool Week 2Documento35 pagineIndependent Study Packet Preschool Week 2Jeszel Marie NengskieNessuna valutazione finora

- Voith Hirth Couplings PDFDocumento10 pagineVoith Hirth Couplings PDFsgupta_615796Nessuna valutazione finora

- SsDocumento5 pagineSsOluap Nosaj100% (1)

- Xii - Bio Exp - 10 & 11 by DDKDocumento4 pagineXii - Bio Exp - 10 & 11 by DDKYaishnave R75% (8)

- Strategic Plan For NetflixDocumento16 pagineStrategic Plan For NetflixShehzadi Mahum (F-Name :Sohail Ahmed)Nessuna valutazione finora

- Drilling Reaming & TappingDocumento17 pagineDrilling Reaming & TappingLeo HsiehNessuna valutazione finora

- Denise Duffield Thomas Lucky Bitch BookDocumento92 pagineDenise Duffield Thomas Lucky Bitch BookAlex Plingu100% (17)

- Tube Bending SeminarDocumento48 pagineTube Bending Seminarhopkhtn100% (1)

- Sandvik Metal Cutting Technology Training HandbookDocumento364 pagineSandvik Metal Cutting Technology Training HandbookITL200_U95% (21)

- Machining Worksheet DJJ30082Documento11 pagineMachining Worksheet DJJ30082zairil izuwan0% (1)

- Margeau Chapeau: A New Perspective on Classic Knit HatsDa EverandMargeau Chapeau: A New Perspective on Classic Knit HatsValutazione: 3.5 su 5 stelle3.5/5 (6)

- G1975 - Instruction ManualDocumento36 pagineG1975 - Instruction ManualLeon GalindoNessuna valutazione finora

- CNC InsertDocumento3 pagineCNC InsertAsif AliNessuna valutazione finora

- Basic of CNC InsertsDocumento50 pagineBasic of CNC InsertspandajayNessuna valutazione finora

- Insert Designation ChartDocumento10 pagineInsert Designation ChartEmba MadrasNessuna valutazione finora

- Sumitomo 1Documento1 paginaSumitomo 1Julio Luis Guzman MarañonNessuna valutazione finora

- Stellogram Insert Part 2Documento6 pagineStellogram Insert Part 2hnam1Nessuna valutazione finora

- Insert Inch DesignationDocumento6 pagineInsert Inch DesignationAvinash KunchurkarNessuna valutazione finora

- How To Calculate The Quantity of Steel in Column (BBS)Documento27 pagineHow To Calculate The Quantity of Steel in Column (BBS)mamuka kassaNessuna valutazione finora

- Actuador NeumaticoDocumento12 pagineActuador NeumaticoJose Alfredo Rojas UribeNessuna valutazione finora

- Q1/What Is The Density of Each Al, C.S, Ti, Ni, ST - ST, MG?Documento3 pagineQ1/What Is The Density of Each Al, C.S, Ti, Ni, ST - ST, MG?اوس محمد رؤوف لؤيNessuna valutazione finora

- Design AidsDocumento28 pagineDesign Aidsresurrection786Nessuna valutazione finora

- SPVSDocumento4 pagineSPVSshyhuNessuna valutazione finora

- General Turning Insert Nomenclature For CNC DummiesDocumento4 pagineGeneral Turning Insert Nomenclature For CNC DummiesSumitNessuna valutazione finora

- Dynamic Bar Brochure InchDocumento12 pagineDynamic Bar Brochure InchJonathan PlataNessuna valutazione finora

- Circular MeasuresDocumento11 pagineCircular MeasuresHayati Aini AhmadNessuna valutazione finora

- Mech311 Midterm 2009, 2011 and 2012Documento9 pagineMech311 Midterm 2009, 2011 and 2012Parvinder SinghNessuna valutazione finora

- Nippon Steels ShapesDocumento6 pagineNippon Steels ShapesP.S.J.SarmaNessuna valutazione finora

- Insert PhisicsDocumento17 pagineInsert PhisicsHimanshu MishraNessuna valutazione finora

- EC20A RK203: 20mm Size Metal Shaft TypeDocumento4 pagineEC20A RK203: 20mm Size Metal Shaft TypeshyhuNessuna valutazione finora

- Trigonometry Notes: Chapter 1: The Trigonometric FunctionsDocumento13 pagineTrigonometry Notes: Chapter 1: The Trigonometric FunctionsBreanna JonesNessuna valutazione finora

- CalculationDocumento120 pagineCalculationRakeshSinhaRayNessuna valutazione finora

- 1 Full Rotation 360 2 (Degrees) (Radians)Documento3 pagine1 Full Rotation 360 2 (Degrees) (Radians)api-168512039Nessuna valutazione finora

- Torsion Test MOM Lab 2Documento12 pagineTorsion Test MOM Lab 2TejkumarigurungNessuna valutazione finora

- Ch-4 LatheDocumento99 pagineCh-4 LatheMANJEET KUMARNessuna valutazione finora

- Round Holes Staggered PDFDocumento3 pagineRound Holes Staggered PDFAleksandar StanisavljevicNessuna valutazione finora

- Plaquitas IscarDocumento178 paginePlaquitas Iscarvpizarro_23Nessuna valutazione finora

- Lecture 6 Measurement of Angles and DirectionDocumento72 pagineLecture 6 Measurement of Angles and DirectionAli SandsNessuna valutazione finora

- Endo InstDocumento111 pagineEndo InstNeha GulatiNessuna valutazione finora

- Hardness & Workpiece - Comparison TablelDocumento18 pagineHardness & Workpiece - Comparison TablelJadmiko Ldnr ThokNessuna valutazione finora

- Ms 2 XBDocumento3 pagineMs 2 XBTungstenCarbideNessuna valutazione finora

- Objectives:: KAEA1147 Engineering SurveyingDocumento13 pagineObjectives:: KAEA1147 Engineering SurveyingPouyan SaraNessuna valutazione finora

- 1.3 - Curve Setting by Theodolite Total StationDocumento20 pagine1.3 - Curve Setting by Theodolite Total Stationanon_265583577Nessuna valutazione finora

- N XD 3 2 1 XD XD XD: TurningDocumento3 pagineN XD 3 2 1 XD XD XD: TurningAlejandro Alvarez AlvaradoNessuna valutazione finora

- Insert Designation ChartDocumento7 pagineInsert Designation ChartShobhith.DevadigaNessuna valutazione finora

- Stringing ChartDocumento4 pagineStringing ChartHikmat B. Ayer - हिक्मत ब. ऐरNessuna valutazione finora

- Engg Metrology (C-4)Documento11 pagineEngg Metrology (C-4)Mohammed AseerNessuna valutazione finora

- Vc3Mb: Ball Nose End Mill, Medium Cut Length, 3 FL UteDocumento1 paginaVc3Mb: Ball Nose End Mill, Medium Cut Length, 3 FL UteTungstenCarbideNessuna valutazione finora

- Din 6799 - Freios CavaleirosDocumento3 pagineDin 6799 - Freios CavaleirostimanelNessuna valutazione finora

- Making of A Cone:-: ProcedureDocumento5 pagineMaking of A Cone:-: Procedurebrpnaidu2157Nessuna valutazione finora

- Assignment For SurveyingDocumento4 pagineAssignment For SurveyingSakshi GuptaNessuna valutazione finora

- Taper and Angular MeasureDocumento29 pagineTaper and Angular Measurelaxmikanta sahuNessuna valutazione finora

- Mueller Equivalent Lengths PDFDocumento1 paginaMueller Equivalent Lengths PDFkuchaitanyaNessuna valutazione finora

- Dimensiones l150gDocumento6 pagineDimensiones l150gCesar BarajasNessuna valutazione finora

- Disston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderDa EverandDisston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderNessuna valutazione finora

- Thread ChasersDocumento12 pagineThread ChasersdocstungestemetNessuna valutazione finora

- SquareDocumento43 pagineSquaredocstungestemetNessuna valutazione finora

- Saw Tip IsoDocumento2 pagineSaw Tip IsodocstungestemetNessuna valutazione finora

- Tungste-Met, Inc.: Material Safety Data SheetDocumento3 pagineTungste-Met, Inc.: Material Safety Data SheetdocstungestemetNessuna valutazione finora

- Oil RelatedDocumento1 paginaOil RelateddocstungestemetNessuna valutazione finora

- Metric Screws For ISO HolesDocumento2 pagineMetric Screws For ISO HolesdocstungestemetNessuna valutazione finora

- ISO Hole Details For BlanksDocumento1 paginaISO Hole Details For BlanksdocstungestemetNessuna valutazione finora

- Coal - Coal MiningDocumento20 pagineCoal - Coal MiningdocstungestemetNessuna valutazione finora

- Flat Head Socket Cap ScrewsDocumento1 paginaFlat Head Socket Cap ScrewsdocstungestemetNessuna valutazione finora

- YA3 TRM ListeningDocumento15 pagineYA3 TRM Listeningema_mirela88Nessuna valutazione finora

- Audi A3 8PDocumento6 pagineAudi A3 8PBruno PorcelliNessuna valutazione finora

- Paket A: Kabupaten GunungkidulDocumento20 paginePaket A: Kabupaten GunungkidulTrianita Syanata MadjidNessuna valutazione finora

- Delivering Happiness NEWDocumento5 pagineDelivering Happiness NEWRJ GutierrezNessuna valutazione finora

- Eeebees Royal Cakes WWW - Royalcakes.in: by C. PrakashDocumento19 pagineEeebees Royal Cakes WWW - Royalcakes.in: by C. PrakashsanaskumarNessuna valutazione finora

- Food Is MedicineDocumento7 pagineFood Is MedicineCHETSUN100% (1)

- PRELIM EXAM SCC Art Appreciation Leo21Documento5 paginePRELIM EXAM SCC Art Appreciation Leo21Leo Patrick CabrigasNessuna valutazione finora

- Smpte 292M: InfrastructuresDocumento17 pagineSmpte 292M: InfrastructuresMuhammad Hassan KhanNessuna valutazione finora

- Basf ProteinsDocumento1 paginaBasf ProteinsJade LaceyNessuna valutazione finora

- CLM-WP ReadMe - 3 - To CustomizeDocumento4 pagineCLM-WP ReadMe - 3 - To CustomizeGrudge MindlessNessuna valutazione finora

- Who Gets To Cry?Documento8 pagineWho Gets To Cry?Cassius DeDragonNessuna valutazione finora

- Gb9/Db: Phase 2: Jazz Guitar With JaneDocumento2 pagineGb9/Db: Phase 2: Jazz Guitar With JaneAeewonge1211Nessuna valutazione finora

- Plamenac KeyboardMusic14th 1951Documento27 paginePlamenac KeyboardMusic14th 1951Thijs ReeNessuna valutazione finora

- Food Drink Desserts Wordearch Wordsearches 69890Documento3 pagineFood Drink Desserts Wordearch Wordsearches 69890AbiiLuuNessuna valutazione finora

- Skid Pack: Monoblock-FilterDocumento55 pagineSkid Pack: Monoblock-FilterAsuncion Gomez-Cambronero LoroNessuna valutazione finora

- PanelDocumento1 paginaPanelsr cNessuna valutazione finora

- Module 1 - Computer Fundamentals PPTDocumento54 pagineModule 1 - Computer Fundamentals PPT77丨S A W ً100% (1)

- 94-0437-4-A Guidance Rugged Prism A4 2pp - V4-High ResDocumento2 pagine94-0437-4-A Guidance Rugged Prism A4 2pp - V4-High ResketanNessuna valutazione finora

- SEL Compass OptionsDocumento13 pagineSEL Compass Optionsgeorge_cpp2Nessuna valutazione finora

- Healthy Pregnancy Meals:: LAMB Doula and Birthing CenterDocumento16 pagineHealthy Pregnancy Meals:: LAMB Doula and Birthing Centerapi-44273750Nessuna valutazione finora

- 2 Elizabethan DramaDocumento11 pagine2 Elizabethan DramaChristel EsquenaziNessuna valutazione finora

- Interpretationoftablewithrrl (May25,2023) (10pm)Documento21 pagineInterpretationoftablewithrrl (May25,2023) (10pm)Laurence Niña X. OrtizNessuna valutazione finora