Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PPAP

Caricato da

Prasad K NagarajaiahDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PPAP

Caricato da

Prasad K NagarajaiahCopyright:

Formati disponibili

Appendix A

The 18 PPAP Documents

All production part approval process (PPAP) submissions include a part submission warrant (PSW), which tells the customer basic information about the submission package. The Automotive Industry Action Group (AIAG) denes the content of the PPAP as:1 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. Part submission warrant (PSW) Design records/drawings Engineering change documents Design failure mode and effects analysis (DFMEA) Process ow diagram Process failure mode and effects analysis (PFMEA) Dimensional results Material/performance test results Initial process study Measurement system assessment (MSA) studies Qualied laboratory documentation Prelaunch control plan Process control plan Appearance approval report Bulk material checklist Product sample Master sample Checking aids Customer specic requirements

The PPAP process and documentation attempts to provide evidence that the supplier understands all of the customers requirements, and that the development work and the process work are capable of consistently achieving those requirements under production rate stresses. Any change

253

2009 by Taylor & Francis Group, LLC

254

Project Management of Complex and Embedded Systems

Design Records Engineering Change Documentation Customer Engineering Approval Engineering Design FMEA Appearance Approval Report Master Sample Material Performance, Test Results Evaluation Qualied Laboratory Documentation Lab Scope Lab Qualifying Documentation

PPAP

Process Flow Diagrams Process FMEA Initial Process Study Production MSA Studies Sample Product Checking Aids Dimensional Results Bulk Material Requirements Checklist Process Control Plan Quality Part Submission Warrant Records of Compliance w/Customer-Specic Requirements

Figure A.1

PPAP structure.

to the product or processes must be with the customers knowledge and consent. These changes will typically require a resubmission of the PPAP documents (see Figure A.1). Depending on the nature of the change, the resubmission could be from warrant only to all PPAP activities including product samples, complete rework of the documentation, and review of the supplying organizations manufacturing facility.

Chapter Notes

1

Automotive Industry Action Group, Production Part Approval Process (PPAP), (Southeld, MI, AIAG 2006) p18.

2009 by Taylor & Francis Group, LLC

Potrebbero piacerti anche

- LV07 KDocumento11 pagineLV07 KSalman Shah83% (6)

- APQP ChecklistDocumento18 pagineAPQP ChecklistmichaelbarkovicNessuna valutazione finora

- Ppap Level III RequirementsDocumento1 paginaPpap Level III Requirementsapi-383246575% (4)

- Ppap ChecklistDocumento2 paginePpap ChecklistTrushant Nakum75% (4)

- Core Tools Forms V5dDocumento119 pagineCore Tools Forms V5dIng. Alberto AguilarNessuna valutazione finora

- Manual - APQP 20121017 PDFDocumento135 pagineManual - APQP 20121017 PDFBerk NoyanNessuna valutazione finora

- AIAG PPAP Cover SheetDocumento1 paginaAIAG PPAP Cover SheetSCHOPENHAUERNessuna valutazione finora

- Advance Product Quality Planning - MatrixDocumento6 pagineAdvance Product Quality Planning - Matrixomm100% (1)

- 040 X52-62-72 UNIC-flex V1Documento63 pagine040 X52-62-72 UNIC-flex V1Антон Сорока100% (2)

- Production Part Approval Process PPAPDocumento4 pagineProduction Part Approval Process PPAPtintucinNessuna valutazione finora

- Production Part Approval ProcessDocumento6 pagineProduction Part Approval ProcessleonardoNessuna valutazione finora

- PPAP Process-Guide ExampleDocumento5 paginePPAP Process-Guide ExampleN.B.P0% (1)

- APQP ENG SiemensDocumento12 pagineAPQP ENG SiemensVikash KumarNessuna valutazione finora

- Supplier APQP Training SupplementDocumento78 pagineSupplier APQP Training SupplementjcperezNessuna valutazione finora

- 1 ApqpDocumento30 pagine1 ApqpVIPIN YADAVNessuna valutazione finora

- Apqp PlanDocumento3 pagineApqp Plananon-448387100% (1)

- Sr. No. Requirements: Ppap Check ListDocumento3 pagineSr. No. Requirements: Ppap Check Listkamlesh kuchekarNessuna valutazione finora

- APQP Sample FormatDocumento32 pagineAPQP Sample FormatManigandan RNessuna valutazione finora

- NPD Procedure PDFDocumento5 pagineNPD Procedure PDFRohit AttriNessuna valutazione finora

- Ppap-Template 4th EditionDocumento23 paginePpap-Template 4th EditionAshutosh SinghNessuna valutazione finora

- D10414410a Fmea MachiningDocumento13 pagineD10414410a Fmea MachiningSuraj RawatNessuna valutazione finora

- Apqp (Fac)Documento1 paginaApqp (Fac)Fernando MejíaNessuna valutazione finora

- AIAG & VDA PFMEA FormatDocumento1 paginaAIAG & VDA PFMEA Formatmahesh KhatalNessuna valutazione finora

- P13-Process For APQPDocumento6 pagineP13-Process For APQPBangali Singh100% (1)

- Giriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeDocumento9 pagineGiriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeMohit KaushikNessuna valutazione finora

- Vda63 Audit Report EnglishDocumento8 pagineVda63 Audit Report Englishjhmagagnin100% (1)

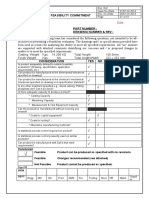

- 02-Team Feasibility CommittmentDocumento1 pagina02-Team Feasibility CommittmentVinod SaleNessuna valutazione finora

- MSIL Audit Cheklist 16Documento22 pagineMSIL Audit Cheklist 16Pravin Balasaheb GunjalNessuna valutazione finora

- PS - APQP Check ListDocumento17 paginePS - APQP Check ListalexrferreiraNessuna valutazione finora

- Apqp FormsDocumento67 pagineApqp FormsNeumar NeumannNessuna valutazione finora

- PPAP 101 - What You Need To KnowDocumento9 paginePPAP 101 - What You Need To KnowQGFNessuna valutazione finora

- Layout Inspection Report XH5DR June 20 2012Documento17 pagineLayout Inspection Report XH5DR June 20 2012nathiven100% (1)

- Supplier-QUAL TM 0027-01 PPAP PackageDocumento192 pagineSupplier-QUAL TM 0027-01 PPAP Packagesurya bhawan100% (1)

- APQP FormsDocumento23 pagineAPQP FormsJOECOOL670% (1)

- SPC 001 PDFDocumento240 pagineSPC 001 PDFSalah BennourNessuna valutazione finora

- Apqp Ppap TrainingDocumento2 pagineApqp Ppap TrainingAnkur DhirNessuna valutazione finora

- Control Plan FormatDocumento1 paginaControl Plan FormatMagesh WaranNessuna valutazione finora

- Apqp Status LogDocumento1 paginaApqp Status Logsathyabalaraman67% (3)

- Evidences To Be Maintained As Per APQP For PMDocumento3 pagineEvidences To Be Maintained As Per APQP For PMSachin RamdurgNessuna valutazione finora

- Procedure - Special CharacteristicsDocumento13 pagineProcedure - Special Characteristicsalexandru.ghiniaNessuna valutazione finora

- NcManagement Ra - Ha 50253631 Adinath Forging P LTD 50253631 - IATF16 26.jun.2021 27.jun.2021Documento8 pagineNcManagement Ra - Ha 50253631 Adinath Forging P LTD 50253631 - IATF16 26.jun.2021 27.jun.2021Abhishek DahiyaNessuna valutazione finora

- APQP-PPAP - Workbook ExampleDocumento37 pagineAPQP-PPAP - Workbook ExampleVIBHOR50% (2)

- Apqp Stages AIAG-1Documento49 pagineApqp Stages AIAG-1Jose Antonio Santoyo RayaNessuna valutazione finora

- .013-00-Checking AidsDocumento3 pagine.013-00-Checking Aidsdaniel_sasikumarNessuna valutazione finora

- 18 Point Ppap Plan Approval-WaiverDocumento4 pagine18 Point Ppap Plan Approval-WaiverBrenda GillNessuna valutazione finora

- PPAP ChecklistDocumento4 paginePPAP ChecklistHirbod HirmandNessuna valutazione finora

- Apqp 23 Elements What Is APQP 23 Elements?: 1. Customer OrderDocumento7 pagineApqp 23 Elements What Is APQP 23 Elements?: 1. Customer OrderAdrian Alcorta100% (1)

- APQPDocumento3 pagineAPQPsam1hi5Nessuna valutazione finora

- PPAP Process Checklist / Sign Off Sheet InstructionsDocumento7 paginePPAP Process Checklist / Sign Off Sheet InstructionsSantosh TiwariNessuna valutazione finora

- IATF Audit Observation 21.06.2021-23.06.2021Documento6 pagineIATF Audit Observation 21.06.2021-23.06.2021Karan Malhi100% (1)

- MsaDocumento7 pagineMsaGobi PSNessuna valutazione finora

- Process SheetDocumento8 pagineProcess SheetSuraj RawatNessuna valutazione finora

- Production Part Approval ProcessDocumento5 pagineProduction Part Approval Processapi-3701058Nessuna valutazione finora

- Ppap Guidelines For Submission: Supplier Production Part Approval ProcessDocumento33 paginePpap Guidelines For Submission: Supplier Production Part Approval ProcessAndy PriceNessuna valutazione finora

- APQP FormDocumento103 pagineAPQP FormJERFSON AUGUSTONessuna valutazione finora

- Work Instruction For Operator (English)Documento1 paginaWork Instruction For Operator (English)PRAMODNessuna valutazione finora

- Excel Tool Prozessaudit VDA 6.3 2010 enDocumento29 pagineExcel Tool Prozessaudit VDA 6.3 2010 enHokuto No KenNessuna valutazione finora

- APQP TrainingDocumento22 pagineAPQP TrainingSandeep Malik100% (1)

- PFMEA AIAG VDA Heading Hints PDFDocumento1 paginaPFMEA AIAG VDA Heading Hints PDFRamdas PaithankarNessuna valutazione finora

- Production Part Approval Process A Complete Guide - 2019 EditionDa EverandProduction Part Approval Process A Complete Guide - 2019 EditionNessuna valutazione finora

- 2ND Quarter MTB - Mle Lesson Plan December 2, 2022Documento4 pagine2ND Quarter MTB - Mle Lesson Plan December 2, 2022sherry ann corderoNessuna valutazione finora

- AWS Cloud Architect: Nanodegree Program SyllabusDocumento14 pagineAWS Cloud Architect: Nanodegree Program Syllabustausif shaikhNessuna valutazione finora

- Grade 4 Social Sciences-Geography Term 2 Lesson PlansDocumento9 pagineGrade 4 Social Sciences-Geography Term 2 Lesson Plansgobedimalapile02Nessuna valutazione finora

- Gb590 Report - SpangaroDocumento137 pagineGb590 Report - Spangarotome44Nessuna valutazione finora

- Xpert R410a Onoff Ar Na 230613Documento62 pagineXpert R410a Onoff Ar Na 230613Wilson Segovia CarrascoNessuna valutazione finora

- SPHE8281DDocumento35 pagineSPHE8281Ddiego-tNessuna valutazione finora

- Symbol ListDocumento4 pagineSymbol ListMa JunNessuna valutazione finora

- 5 Dysfunctions of A TeamDocumento5 pagine5 Dysfunctions of A TeamSreejit Menon100% (2)

- Carlo Pescio: A Physics of SoftwareDocumento11 pagineCarlo Pescio: A Physics of SoftwareCarlo PescioNessuna valutazione finora

- Iso SpinDocumento5 pagineIso SpinjhgsgsNessuna valutazione finora

- Dynamic Modelling of Gas TurbinesDocumento8 pagineDynamic Modelling of Gas TurbinesdannyNessuna valutazione finora

- FrenchDocumento2 pagineFrenchRashid BumarwaNessuna valutazione finora

- A Comparative Study of Indian and Western Music FormsDocumento6 pagineA Comparative Study of Indian and Western Music FormsSophieNessuna valutazione finora

- ABB High Speed Directional Relays PDFDocumento28 pagineABB High Speed Directional Relays PDFking_electricalNessuna valutazione finora

- Updated Eva ResumeDocumento1 paginaUpdated Eva Resumeapi-534826411Nessuna valutazione finora

- 6-Boundary and Initial ConditionsDocumento8 pagine6-Boundary and Initial ConditionsqazwsxNessuna valutazione finora

- Lesson Outline: Introduction To LeadershipDocumento2 pagineLesson Outline: Introduction To LeadershipAmritpal SinghNessuna valutazione finora

- Phillip Hudson: (813) - 334-3337 PSH5017@psu - EduDocumento1 paginaPhillip Hudson: (813) - 334-3337 PSH5017@psu - Edupsh5017Nessuna valutazione finora

- Dwnload Full Business Research Methods 9th Edition Zikmund Solutions Manual PDFDocumento35 pagineDwnload Full Business Research Methods 9th Edition Zikmund Solutions Manual PDFerichuel33a100% (14)

- 2014 04 14 Veterinary Instrumentation Presented The Simon Award 2014 For Outstanding Contribution in The Field of Veterinary Surgery To Michael Guilliard MA, VetMB, CertSAO, FRCVSDocumento2 pagine2014 04 14 Veterinary Instrumentation Presented The Simon Award 2014 For Outstanding Contribution in The Field of Veterinary Surgery To Michael Guilliard MA, VetMB, CertSAO, FRCVSHenry ScheinNessuna valutazione finora

- Analysis of The Flow Induced by Air-Bubble SystemsDocumento16 pagineAnalysis of The Flow Induced by Air-Bubble SystemsStephany CamacaroNessuna valutazione finora

- GasLink - Development of GLIADocumento24 pagineGasLink - Development of GLIAOribuyaku DamiNessuna valutazione finora

- 12 Chemistry Chapter 1 Assignment 2Documento2 pagine12 Chemistry Chapter 1 Assignment 2Mohd UvaisNessuna valutazione finora

- Thomson Catalog CompressedDocumento210 pagineThomson Catalog CompressedCharlesNessuna valutazione finora

- ATS Monitoring Device InstructionsDocumento25 pagineATS Monitoring Device InstructionsVinhNessuna valutazione finora

- CDI1Documento40 pagineCDI1Leonino Angelica Aiko S.Nessuna valutazione finora

- RESEARCH FORM and STYLEDocumento8 pagineRESEARCH FORM and STYLEKristian Karl Bautista Kiw-isNessuna valutazione finora