Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Design of Aluminum Structure 1

Caricato da

Ray CoelloDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Design of Aluminum Structure 1

Caricato da

Ray CoelloCopyright:

Formati disponibili

Design of Aluminum Structure

Design method in General Design of Tensile member Design of Compression member

General:

Aluminum is used in many architectural components of buildings such as window frame, handrail, awning, canopy, catwalk, and platforms, etc. It is relatively light weigh and low strength comparing to structural steel. But, it is easy to be fabricated and has good rust resistance.

Design specification:

Aluminum Design Manual, 2010 edition.

Common aluminum Shapes:

Similar to structural steel, aluminum has shapes from extrusions (angle, channel, W shape, etc), Sheet & plate, Rod & bar, Tube & pipe, etc. See Aluminum design manual Part V for section properties.

Material designation:

Aluminum material is defined by its alloy and temper. For example, 6061-T6 means 6061 alloy and T6 temper. 3004-H12 means 3004 alloy and H12 temper. The first of the four numbers defines the major alloying ingredients. For example, the major alloying ingredient of 3004 is manganese. The major alloying ingredient of 6061 is magnesium and silicon. Temper defines fabrication treatment. For example, H means strain-hardened and T6 means solution heat-treated and then artificially aged.

Mechanical properties:

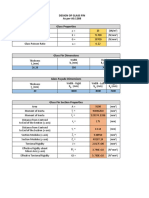

Mechanical properties of aluminum used in structural calculations are F tu: Tensile ultimate strength. F ty: Tensile yield strength. F cy : Compressive yield strength, F su : Shear ultimate strength. Mechanical properties of some aluminum products from Aluminum Design Manual, Table A3.4 are shown below: Alloy-Temper 1100-H12 2014-T6 3003-H34 5454-O 6005-T6 Product Sheet, plate Sheet Drawn tube Extrusions Extrusions F tu ksi 14 66 35 31 38 F ty ksi 11 58 28 12 35 F cy ksi 11 11 27 12 34 F su ksi 10 11 20 19 24 E ksi 10,100 10,100 10,100 10,400 10,100

6061-T6 6061-T6 6063-T5

Drawn tube Pipe Extrusions

42 38 22

35 35 16

35 35 16

25 24 13

10,100 10,100 10,100

Other Engineering Properties:

Coefficient of thermal expansion: 13x10-6 / o F or 23x10-6 / o C Density: 0.10 lb/in 3 or 2.7x103 kg/m 3 .

Temperature limits:

Aluminum is sensitive to temperature. For example, 5083 alloy or similar aluminum shall not be subjected to temperatures greater than 150 o F. 6061-T5 is limited to 5 minutes for temperature greater than 450 o F.

Design Methods:

Design loads and load combinations

Building-type Structures: Use loads and load combinations from ASCE 7, Minimum Design loads for Building and Other Structures. Bridge-type Structures Use loads and load combinations from AASHTOs Guide Standard Specifications for Highway Bridges.

Load and Resistance Factor Design (LRFD)

Ru fRn Rn = required strength Rn = nominal strength f = resistance factor fRn = design strength

Allowable Strength Design (ASD)

Ru Rn /W W = safety factor Rn /W = allowable strength

Strength of Unwelded Member and Weld Member

It is common to have two or more aluminum members weld together welded together to form a new shape. The heat from weld reduces strength of material around welded area. The strength of member is reduced to account for welding in Aluminum Design Manual.

Disclaimer: The content of this website was obtained and edited from various resources. The editor made reasonable effort of editing. Nevertheless, the editor does not warrant, and assume no liability for accuracy and completeness of its content. The viewer shall use his/her professional knowledge and judgment in use of the web content. Webmaster: www.ce-ref.com

Potrebbero piacerti anche

- Aluminum Structures FAQ GuideDocumento3 pagineAluminum Structures FAQ GuideZebNessuna valutazione finora

- Aluminum DesignDocumento2 pagineAluminum DesignUmesh ChamaraNessuna valutazione finora

- Aluminium Design Manual 2010 - The Aluminium AssociationDocumento440 pagineAluminium Design Manual 2010 - The Aluminium AssociationQuang Hoành Lê100% (15)

- ADM 2015 Aluminum Design Manual - Tables 2-19Documento2 pagineADM 2015 Aluminum Design Manual - Tables 2-19Louis Liu100% (1)

- 1-ADM-Aluminum Design Manual & SpecificationDocumento83 pagine1-ADM-Aluminum Design Manual & SpecificationAyham Aljawhary100% (2)

- Cold-formed Tubular Members and Connections: Structural Behaviour and DesignDa EverandCold-formed Tubular Members and Connections: Structural Behaviour and DesignValutazione: 5 su 5 stelle5/5 (2)

- Aluminum DesignDocumento8 pagineAluminum Designxhq08100% (1)

- Wind load calculations for steel canopy fabricDocumento11 pagineWind load calculations for steel canopy fabricamitkukna100% (3)

- Handrail CalculationDocumento8 pagineHandrail Calculationsuresh_viki100% (1)

- DIRECT STRENGTH DESIGN OF COLD FORMED STEEL MEMBERS WITH PERFORATIONS - Report - RP09-1 PDFDocumento564 pagineDIRECT STRENGTH DESIGN OF COLD FORMED STEEL MEMBERS WITH PERFORATIONS - Report - RP09-1 PDFAravind BhashyamNessuna valutazione finora

- Glass Chart ASTM E1300Documento15 pagineGlass Chart ASTM E1300mercab15Nessuna valutazione finora

- Alum SampleDocumento2 pagineAlum Samplewaweng22Nessuna valutazione finora

- Cold-Formed Steel Design Manual 290 PDFDocumento526 pagineCold-Formed Steel Design Manual 290 PDFOmar Eduardo Alvarado ValleNessuna valutazione finora

- Accommodation of Structural Movement inDocumento9 pagineAccommodation of Structural Movement inwal1547Nessuna valutazione finora

- GLASS BALUSTRADE DESIGN CALCULATIONSDocumento8 pagineGLASS BALUSTRADE DESIGN CALCULATIONSmsiddiq1100% (2)

- Structural Glass Design-BS6399Documento6 pagineStructural Glass Design-BS6399msiddiq1100% (2)

- Cold-Formed Steel Structures To The AISI Specification - 0824792947Documento405 pagineCold-Formed Steel Structures To The AISI Specification - 0824792947irdl92% (12)

- DESIGN CALCULATIONS FOR ALUMINIUM GLAZINGDocumento8 pagineDESIGN CALCULATIONS FOR ALUMINIUM GLAZINGmsiddiq1100% (1)

- Hancock's NotesDocumento104 pagineHancock's Noteschernl2004Nessuna valutazione finora

- AAMA TIR-A9-14 - Design Guide For Metal Cladding Fasteners - CommentedDocumento99 pagineAAMA TIR-A9-14 - Design Guide For Metal Cladding Fasteners - CommentedMarco BenedettiNessuna valutazione finora

- Aisi Cold FormedDocumento53 pagineAisi Cold FormedDJ BartraNessuna valutazione finora

- E 1300 - 12ae1Documento59 pagineE 1300 - 12ae1Prabartak Das100% (6)

- 3 Ken Watsons - Design of Frames Using NASH StandardsDocumento66 pagine3 Ken Watsons - Design of Frames Using NASH StandardsWei Hong TehNessuna valutazione finora

- Asce Wind Load Examples PDFDocumento126 pagineAsce Wind Load Examples PDFbrionkettler100% (3)

- Steel Stud Brick Veneer Design GuideDocumento39 pagineSteel Stud Brick Veneer Design Guideelidstone@hotmail.com100% (3)

- Section Classification BS 8118-1-1991Documento1 paginaSection Classification BS 8118-1-1991AthumizNessuna valutazione finora

- Design of Cold Formed Steel StructuresDocumento104 pagineDesign of Cold Formed Steel StructuresAbdurrahman ÇINARNessuna valutazione finora

- Structural Glass Design-UBCDocumento6 pagineStructural Glass Design-UBCmsiddiq1100% (1)

- Design of Bearing Stiffeners in Cold Formed Steel C-SectionsDocumento151 pagineDesign of Bearing Stiffeners in Cold Formed Steel C-SectionsFabio Saraiva BoxNessuna valutazione finora

- CFSEI Shear Wall Design GuideDocumento23 pagineCFSEI Shear Wall Design GuideJaypee Chang100% (1)

- ASCE710 - Wind 1Documento25 pagineASCE710 - Wind 1xxazninvasionxx2697Nessuna valutazione finora

- Steel ManualDocumento114 pagineSteel ManualkysucoNessuna valutazione finora

- Connections in Steel Structures III: Behaviour, Strength and DesignDa EverandConnections in Steel Structures III: Behaviour, Strength and DesignValutazione: 4 su 5 stelle4/5 (6)

- !!! 1 Cold-Formed Steel Framing Standards Design Aids Roger LaBoubeDocumento108 pagine!!! 1 Cold-Formed Steel Framing Standards Design Aids Roger LaBoubeAnonymous hprsT3WlP100% (2)

- Ste 03350Documento34 pagineSte 03350WNessuna valutazione finora

- Design of Cold Formed Steel Members 2003 LibroDocumento246 pagineDesign of Cold Formed Steel Members 2003 LibroFelipeNessuna valutazione finora

- Glass Balustrade DesignDocumento18 pagineGlass Balustrade Designveereshan100% (1)

- Base Plate Design - HiltiDocumento38 pagineBase Plate Design - HiltiVictor IkeNessuna valutazione finora

- Steel Bracket DesignDocumento3 pagineSteel Bracket Designrandy_pabilona50% (4)

- Aluminum Design Manual 2015Documento505 pagineAluminum Design Manual 2015Charlie Henke100% (2)

- Notes on axial load, bending moment and section capacity calculationsDocumento33 pagineNotes on axial load, bending moment and section capacity calculationsWisnuPratamaPutraNessuna valutazione finora

- Steel Deck Institute Diaphragm Design Manual - Third EditionDocumento295 pagineSteel Deck Institute Diaphragm Design Manual - Third Editioneurose91100% (5)

- Failures - Lamellar Tearing Overview and Failures CasesDocumento4 pagineFailures - Lamellar Tearing Overview and Failures Cases^passwordNessuna valutazione finora

- Cold Formed SteelDocumento66 pagineCold Formed Steelarkirthi1175Nessuna valutazione finora

- IS: 8147 - Code of Practice For Use of Aluminium Alloys in StructuresDocumento170 pagineIS: 8147 - Code of Practice For Use of Aluminium Alloys in StructuresbccharanNessuna valutazione finora

- Design Guide 11 Welded Beam To Column Moment ConnectionsDocumento8 pagineDesign Guide 11 Welded Beam To Column Moment ConnectionsVeerabhadrayya KatapurmathNessuna valutazione finora

- Hansen Architectural Systems ClearVue Railing System Design GuideDocumento53 pagineHansen Architectural Systems ClearVue Railing System Design GuidescreechingpelicanNessuna valutazione finora

- Specifying An Equivalent 3-Second Duration Design Loading For Blast Resistant Glazing Fabricated With Laminated GlassDocumento3 pagineSpecifying An Equivalent 3-Second Duration Design Loading For Blast Resistant Glazing Fabricated With Laminated GlassFrancisco GuerraNessuna valutazione finora

- Glass analysis calculations for structural wall projectDocumento8 pagineGlass analysis calculations for structural wall projectARYA100% (1)

- As1288 Glass Deflection CriteriaDocumento1 paginaAs1288 Glass Deflection Criteriaahsan khanNessuna valutazione finora

- CFSD - Pub - Aisi d310-14 - Design Guide For Aisi s310-13Documento104 pagineCFSD - Pub - Aisi d310-14 - Design Guide For Aisi s310-13Dante RojasNessuna valutazione finora

- Design of Buildings for Wind: A Guide for ASCE 7-10 Standard Users and Designers of Special StructuresDa EverandDesign of Buildings for Wind: A Guide for ASCE 7-10 Standard Users and Designers of Special StructuresValutazione: 3.5 su 5 stelle3.5/5 (2)

- Project Name: Glass BalustradeDocumento11 pagineProject Name: Glass BalustradeNp Pw100% (1)

- Design of Glass Fin for Glass FaçadeDocumento4 pagineDesign of Glass Fin for Glass FaçadeZaido Al HalabiNessuna valutazione finora

- Onshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesDa EverandOnshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesValutazione: 4.5 su 5 stelle4.5/5 (13)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDa EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNessuna valutazione finora

- Using Resistance Spot Welding For Joining Aluminium Elements in Automotive IndustryDocumento9 pagineUsing Resistance Spot Welding For Joining Aluminium Elements in Automotive IndustryagungNessuna valutazione finora

- Review On Comparative Study of Steel and Aluminiumalloy Roof TrussDocumento4 pagineReview On Comparative Study of Steel and Aluminiumalloy Roof TrussManikanta SharmaNessuna valutazione finora

- Aluminium Alloy Guide - Properties, Grades & ApplicationsDocumento22 pagineAluminium Alloy Guide - Properties, Grades & ApplicationsAashish Gharde0% (1)

- "Microwave" Bread 5-7Documento1 pagina"Microwave" Bread 5-7Ray CoelloNessuna valutazione finora

- "Microwave" Bread 7-7Documento1 pagina"Microwave" Bread 7-7Ray CoelloNessuna valutazione finora

- "Microwave" Bread 4-7Documento1 pagina"Microwave" Bread 4-7Ray CoelloNessuna valutazione finora

- "Microwave" Bread 6-7Documento1 pagina"Microwave" Bread 6-7Ray CoelloNessuna valutazione finora

- "Microwave" Bread 2-7Documento2 pagine"Microwave" Bread 2-7Ray CoelloNessuna valutazione finora

- Design Guidelines For Interactive FountainsDocumento66 pagineDesign Guidelines For Interactive FountainsgoutammandNessuna valutazione finora

- CBD Aisc 360 10Documento211 pagineCBD Aisc 360 10Aamir Hossain JewelNessuna valutazione finora

- Etabs Steel DesignDocumento60 pagineEtabs Steel DesignChayanon Hansapinyo100% (2)

- Tutorial FountainDocumento7 pagineTutorial FountainAzi AzhaniNessuna valutazione finora

- Easy Microwave Bread Recipe in MinutesDocumento2 pagineEasy Microwave Bread Recipe in MinutesRay CoelloNessuna valutazione finora

- DEFO CatalogueDocumento99 pagineDEFO CatalogueRay Coello67% (3)

- Food and Wine HarmonyDocumento12 pagineFood and Wine HarmonyRay Coello100% (3)

- Wind & Food Harmony 2Documento52 pagineWind & Food Harmony 2Ray CoelloNessuna valutazione finora

- C-SAS-2012 - Concrete Anchor Bolts Catalogue - SimpsonDocumento252 pagineC-SAS-2012 - Concrete Anchor Bolts Catalogue - SimpsonRay CoelloNessuna valutazione finora

- Designing For WindDocumento5 pagineDesigning For WindRay CoelloNessuna valutazione finora

- Food and Wine HarmonyDocumento12 pagineFood and Wine HarmonyRay Coello100% (3)

- ETABS User's ManualDocumento895 pagineETABS User's ManualDiquan83% (18)

- American Fastener - ASTM, SAE, and ISO Grade MarkingsDocumento4 pagineAmerican Fastener - ASTM, SAE, and ISO Grade MarkingsRay CoelloNessuna valutazione finora

- Complete Guide To FermenttationDocumento202 pagineComplete Guide To FermenttationBill Young97% (35)

- Catalogo Pedrollo No 1 - 2010 PDFDocumento1 paginaCatalogo Pedrollo No 1 - 2010 PDFRay CoelloNessuna valutazione finora

- Culinary Oxford Visual DictionaryDocumento16 pagineCulinary Oxford Visual DictionaryRay CoelloNessuna valutazione finora

- Beam-Column Base Plate Design On ScribdDocumento1 paginaBeam-Column Base Plate Design On ScribdRay CoelloNessuna valutazione finora

- ETABS User's ManualDocumento895 pagineETABS User's ManualDiquan83% (18)

- ASTM A325 SpecificationDocumento2 pagineASTM A325 SpecificationRay CoelloNessuna valutazione finora

- EML3500 CH 8 SlidesDocumento134 pagineEML3500 CH 8 SlidesGanesh Dongre100% (1)

- UDI Productcatalogue 2015Documento4 pagineUDI Productcatalogue 2015Ryan TayNessuna valutazione finora

- Turan Balik - ResumeDocumento3 pagineTuran Balik - Resumeapi-250561031Nessuna valutazione finora

- Codigos Ford Escape ReneDocumento1 paginaCodigos Ford Escape ReneKandy KnNessuna valutazione finora

- Teacher's PlannerDocumento66 pagineTeacher's PlannerYeeyee AungNessuna valutazione finora

- Atheros Valkyrie BT Soc BriefDocumento2 pagineAtheros Valkyrie BT Soc BriefZimmy ZizakeNessuna valutazione finora

- KomatsuHydraulicBreaker8 29Documento22 pagineKomatsuHydraulicBreaker8 29Ke HalimunNessuna valutazione finora

- CatDocumento27 pagineCatGovarthanan GopalanNessuna valutazione finora

- 32LS3400 KoreaDocumento60 pagine32LS3400 KoreaNightin VargheseNessuna valutazione finora

- Lesson Plan Template: The Pearl AcademiesDocumento3 pagineLesson Plan Template: The Pearl Academiesapi-300023217Nessuna valutazione finora

- Tips For Internship ReportDocumento1 paginaTips For Internship ReporthummayounnasirNessuna valutazione finora

- Side Sealing Machine Operation GuideDocumento30 pagineSide Sealing Machine Operation GuideRocio GimenezNessuna valutazione finora

- Eschmann VP35 Suction Pump - Service ManualDocumento18 pagineEschmann VP35 Suction Pump - Service Manualelvis oheneba manuNessuna valutazione finora

- Forbes Investor Jan2014 Master Buy List PDFDocumento1 paginaForbes Investor Jan2014 Master Buy List PDFForbesNessuna valutazione finora

- Problems - SPCDocumento11 pagineProblems - SPCAshish viswanath prakashNessuna valutazione finora

- R07 Set No. 2Documento8 pagineR07 Set No. 2dileepNessuna valutazione finora

- SKF Hybrid BearingsDocumento4 pagineSKF Hybrid BearingsLLNessuna valutazione finora

- 23 - Eave StrutsDocumento2 pagine23 - Eave StrutsTuanQuachNessuna valutazione finora

- Report on Industrial Visit to ACC Limited Chaibasa Cement WorksDocumento8 pagineReport on Industrial Visit to ACC Limited Chaibasa Cement WorksRohit Vishal PandeyNessuna valutazione finora

- Steel Design DocumentDocumento198 pagineSteel Design Documentpudumai100% (5)

- Alert Operators Transmission - Aot: Customer Services DirectorateDocumento8 pagineAlert Operators Transmission - Aot: Customer Services DirectorateIbrahim KhalilNessuna valutazione finora

- Ac Split Inverter PDFDocumento69 pagineAc Split Inverter PDFjewd100% (1)

- Slice 3 Choice BoardDocumento3 pagineSlice 3 Choice Boardapi-463991923Nessuna valutazione finora

- Group 6 - Chapter 1 RevisedDocumento15 pagineGroup 6 - Chapter 1 RevisedJAMES ELIJAH BALDERRAMANessuna valutazione finora

- Bendix King Avionics SystemDocumento45 pagineBendix King Avionics SystemJavierNessuna valutazione finora

- FULLTEXT01Documento14 pagineFULLTEXT01Văn Tuấn NguyễnNessuna valutazione finora

- Diccionario de Urbanismo Geografia Urbana y Ordenacion Del TerritorioDocumento10 pagineDiccionario de Urbanismo Geografia Urbana y Ordenacion Del TerritorioGpe. MercadoNessuna valutazione finora

- Maintenance Manual LH 350 Flight Helmet: Confidential IndustryDocumento18 pagineMaintenance Manual LH 350 Flight Helmet: Confidential Industrynelson vasquezNessuna valutazione finora

- EE331 Lab 1 v2Documento13 pagineEE331 Lab 1 v2Áo ĐenNessuna valutazione finora

- Evadeee ReadmeDocumento11 pagineEvadeee Readmecostelmarian2Nessuna valutazione finora