Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

JPL Bolt Torque

Caricato da

gotstogoDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

JPL Bolt Torque

Caricato da

gotstogoCopyright:

Formati disponibili

JPL Spec ES504255 I

General Specification

CODE IDENT NO.

23835

SPEC NO.

ES504255, REV I

ISSUE DATE

2/9/99

SUPERSEDING

ES504255 H

DATED

6 JANUARY 1999

TORQUE REQUIREMENTS

MECHANICAL THREADED FASTENERS

(SPACECRAFT STRUCTURE EQUIPMENT)

GENERAL SPECIFICATION FOR

* Printed copies of this document may not be current and should not be used for official

purposes. The current version is in the DMIE Information System at http://dmie

Jet Propulsion Laboratory

California Institute of Technology

JPL Spec ES504255 I

JPL Spec ES504255 I

TABLE OF CONTENTS

Section

Page

1.

SCOPE................................................................................................................................ 3

1.1

1.2

1.3

Contents............................................................................................................................... 3

Purpose................................................................................................................................ 3

Nonstandard Torques .......................................................................................................... 3

2.

APPLICABLE DOCUMENTS ........................................................................................ 3

2.1

Listing .................................................................................................................................. 3

3.

REQUIREMENTS ............................................................................................................ 6

3.1

3.2

3.2.1

3.2.1.1

3.2.1.2

3.2.1.3

3.2.1.4

3.2.1.5

3.3

3.3.1

3.3.2

3.3.3

3.3.4

3.3.5

3.3.6

3.4

3.4.1

3.4.2

3.4.3

3.4.3.1

3.4.3.2

3.4.3.2.1

3.4.4

3.4.5

3.4.6

3.4.6.1

3.4.7

3.4.8

3.4.8.1

3.4.9

3.4.9.1

3.4.10

3.4.11

3.4.11.1

3.4.11.2

3.4.11.3

Conflicting Requirements .................................................................................................... 6

Installation Holes ................................................................................................................ 6

Hole Preparation ................................................................................................................ 6

Diameters. ........................................................................................................................... 6

Perpendicularity .................................................................................................................. 6

Finish................................................................................................................................... 6

Circularity ........................................................................................................................... 6

Cleaning .............................................................................................................................. 6

Fastener Threads ................................................................................................................ 6

Unified National Thread ..................................................................................................... 6

J Form Thread ..................................................................................................................... 6

Preferred Threads ............................................................................................................... 6

Bolt Stress Area ................................................................................................................... 6

Bolts, Screws and Nuts ........................................................................................................ 6

Preferred Parts.................................................................................................................... 6

Installation .......................................................................................................................... 6

Quantity of Fasteners Used ................................................................................................. 6

Wrenches ............................................................................................................................. 7

Torque Application.............................................................................................................. 7

Installation Torque .............................................................................................................. 7

Standard Torque Values ...................................................................................................... 7

Self-Locking Fasteners ........................................................................................................ 7

Thread Engagement ............................................................................................................ 7

Washer Identification .......................................................................................................... 7

Self-Locking Features ......................................................................................................... 7

Replacement Criteria .......................................................................................................... 7

Thread Length ..................................................................................................................... 7

Bolt and Screw Length ........................................................................................................ 8

Grip Adjustment .................................................................................................................. 8

Washers ............................................................................................................................... 8

Washers with Flush Head Fasteners................................................................................... 8

Design Torque Requirements .............................................................................................. 8

Preloads .............................................................................................................................. 8

Fasteners assembly ............................................................................................................. 8

Tapped Holes....................................................................................................................... 8

Preloads for Bolts/Screws Installed Into Inserts ................................................................ 8

JPL Spec ES504255 I

3.4.11.4

3.4.11.5

3.4.11.6

3.4.11.7

3.5

3.5.1

3.5.1.1

3.5.2

3.5.3

3.5.3.1

3.5.4

3.5.5

3.5.6

3.5.6.1

Special Preloads................................................................................................................. 8

Special Torque Values......................................................................................................... 8

Electronic Equipment and Assembly ................................................................................... 9

Nylon Screws and Nuts........................................................................................................ 9

Torque ................................................................................................................................. 9

Installation Torque .............................................................................................................. 9

Torque Coefficient K ........................................................................................................... 9

Torque Wrench Personnel ................................................................................................... 9

Overtorqued Fasteners........................................................................................................ 9

Retorquing ........................................................................................................................... 9

Multiple Installations ......................................................................................................... 9

Lubrication .......................................................................................................................... 9

Torque Tables...................................................................................................................... 9

Self-Locking Fasteners ...................................................................................................... 10

4.

QUALITY ASSURANCE ............................................................................................... 10

4.1

4.2

4.3

4.3.1

4.3.1.1

4.3.1.2

4.3.1.3

4.3.1.4

4.3.1.5

4.3.1.6

Torque Inspection.............................................................................................................. 10

Thread Length Inspection ................................................................................................. 10

Tooling .............................................................................................................................. 10

Torque Wrenches............................................................................................................... 10

Tool Accuracy ................................................................................................................... 10

Tool Selection .................................................................................................................... 10

Calibration ........................................................................................................................ 10

Sealing and Marketing ...................................................................................................... 10

Recalibration ..................................................................................................................... 10

Adapters ............................................................................................................................ 10

5.

PREPARATION FOR DELIVERY .............................................................................. 10

6.

NOTES ............................................................................................................................. 10

6.1

6.2

6.3

6.3.1

6.3.2

Intended Use...................................................................................................................... 10

Formulas Used .................................................................................................................. 11

Definitions ......................................................................................................................... 12

Maximum Locking Torque ................................................................................................ 12

Breakaway Torque ............................................................................................................ 12

ii

JPL Spec ES504255 I

TABLE OF CONTENTS (cont'd)

Table

I.

II.

III.

IV.

V.

VI.

VII.

VIII.

IX.

X.

XI.

XII.

Page

Rivnuts ............................................................................................................................... 13

Inserts, Bolts/Screws, and Nuts at 80 ksi .......................................................................... 13

Blind Nuts and Anchor Nuts at 125 ksi ............................................................................. 14

Bolts/Screws, at 160 ksi, Into Inserts Assembled in

6061-T6 Aluminum ............................................................................................................ 15

Bolts/Screws, at 190 ksi, Installed Into Inserts

Assembled in 6061-T6 Aluminum Alloy. ........................................................................... 16

Bolts/Screws, at 160 ksi, Into Invar and

Higher Shear Strength Aluminum Alloy ............................................................................ 17

Bolts/Screws, at 190 ksi, Into Invar and

Higher Shear Strength Aluminum Alloy ............................................................................ 18

Bolts/Screws, at 160 ksi, assembled in Tapped Material.................................................. 19

Bolts/Screws, at 190 ksi, assembled in Tapped Material.................................................. 20

Maximum Prevailing and Minimum Breakaway Torque .................................................. 21

Nylon Fasteners Assembly Torque .................................................................................... 21

Thread Engagement and Protrusion ................................................................................. 21

iii

JPL Spec ES504255 I

1.

SCOPE

Contents. This engineering specification defines the standard torque to be applied to

1.1

threaded fasteners during spacecraft assembly.

Purpose. The amount of torque applied establishes the preload in the fastener and the joint

1.2

clamp-up. Incorrect preload may result in:

a. Static failure of the fastener.

b. Static failure of a joint member.

c. Fatigue failure of the fastener.

d. Joint Separation.

e. Joint Slip.

Nonstandard Torques. Nonstandard torque values not covered in this specification shall be

1.3

called out on the controlling drawing, with any applicable procedures to be applied, as a drawing note.

2.

APPLICABLE DOCUMENTS

Listing. The following documents, of the issue as specified in the contractual instrument (or

2.1

as specified for use within JPL), form a part of this specification to the extent specified herein:

SPECIFICATIONS

JPL

ES516101

Torque Requirements, Threaded Fasteners, Electronic

Packaging Equipment, General Specification for

Federal

GGG-W-686

Wrench, Torque

Military

MIL-S-7742

Screw Threads, National and Unified National, Preferred Sizes

MIL-S-8879

Screw Threads, Controlled Radius Root with Increased Minor

Diameter, General Specification for

MIL-DTL-18240

Fastener Element, Self-Locking, Threaded Fastener, 250? F Max.

MIL-DTL-25027

Nut, Self-Locking, 250 Deg F, 450 Deg F, and 800 Deg F

NASC

NAS618

Fastener-Recommended Shank, Hole and Head-to-Shank Fillet

Radius for

3

JPL Spec ES504255 I

STANDARDS

JPL

DS83

Screw, Internal Wrenching, 160 ksi and 190 ksi

DS132

Screw, Pan Head, Hi-Torque Recess, Full Thread, 160

ksi CRES

DS134

Screw, Countersunk Head, Hi-Torque Recess, Full Thread, 160

ksi and 190 ksi, CRES

DS136

Bolt, Close Tolerance 12-Point External Wrench, 160 ksi and

190 ksi, CRES

QAI85-15-6-001

Calibration Torque Devices

ST10051

Screw, Cap, Socket Head Hexagon, 80 ksi, CRES

ST10060

Nut, Hexagon, Self-Locking, CRES

ST10072

Screw, Pan Head, Cross Recess, 80 ksi, CRES

ST10073

Screw, Pan Head, Hi-Torque Recess, 160 ksi, CRES

ST10224

Rivnut, Blind, Flat Head, Closed End, Keyed, Aluminum Alloy

ST10225

Rivnut, Blind, Countersunk Head, Closed End, Keyed,

Aluminum Alloy

ST11326

Insert, Non-Locking, Threaded, Miniature, Open End

ST11294

Rivnut, Blind, Flat Head, Open End, Keyed, Aluminum Alloy

90273

Washer, Countersunk, CRES

Federal

FED-STD-H28

Screw Thread Standards for Federal Services

Military

MS21076

Nut, Self-Locking, Plate, Two Lug Floating, UNC and

UNF2A CRES

MS24693

Screw, Machine, Flat Countersunk Head, Gross Recess

MS35649

Nut, Plain, Hexagon, Machine, UNC-2B, CRES

MS35650

Nut, Plain, Hexagon, Machine, UNF-2B, CRES

MS35691

Nut, Plain, Hexagon, UNF-2B, CRES

4

JPL Spec ES504255 I

MS51957

Screw, Machine, Panhead, Cross Recess, UNC-2A, CRES

MS51958

Screw, Machine, Panhead, Cross Recess, UNF-2A, CRES

NASC

NAS1216

Screw, Pan Head Slotted Dovetail Recess, Full Threaded

Self-Locking Optional

NAS1351

Screw, Cap, Socket Head Undrilled and Drilled, Plain and

Self-Locking Alloy Steel, Corrosion-Resistant Steel and

Heat-Resistant Steel, UNRF-3A

NAS1352

Screw, Cap, Socket Head Undrilled and Drilled, Plain and

Self-Locking Alloy Steel, Corrosion-Resistant Steel and

Heat-Resistant Steel, UNRC-3A and UNRC-2A

NAS1348

Fasteners - Recommended Tensile Stress Areas for

External Threaded

NAS1394

Insert, Threaded, Metal, Lightweight, CRES

NAS1395

Insert, Threaded, Metal, Heavy Duty, CRES

NAS1580C

Bolt, Countersunk Head, CRES

Commercial

Hi-Shear Corp. (CAGE 73197)

BB414

Blind Nut Assembly, Blind Expander

BB415

Blind Nut Assembly, Expander

Rexnord, Inc. (CAGE 29372)

KNB( )J

Insert, Non-Locking, Lightweight, Blind

KNCB( )J

Insert, Non-Locking, Miniature, Blind

KNC( )J

Insert, Non-Locking, Miniature

KNHB( )J

Insert, Non-Locking, Heavy Duty, Blind

Shur-Lok Corp. (CAGE 97393)

SL6061C

Insert, Blind, Threaded Molded-in, CRES

SL6096C

Insert, Threaded, Molded-in, CRES

JPL Spec ES504255 I

(Copies of specifications, standards, procedures, drawings, and publications required

by suppliers in connection with specific procurement functions should be obtained from the procuring

activity or as directed by such activity.)

3.

REQUIREMENTS

Conflicting Requirements. Conflicts arising between the requirements of this specification

3.1

and the requirements of any document referenced herein shall be referred to the procurement activity, if

any, or if not, to the cognizant engineer of the Mechanical Engineering Section (352) for resolution.

3.2

Installation Holes.

3.2.1

Hole Preparation.

3.2.1.1

Diameters. Where possible, hole diameters and tolerances shall conform to NAS618.

3.2.1.2

Perpendicularity. Holes shall be drilled perpendicular to the surface within 0.5 degree.

3.2.1.3

Finish. Holes shall be smooth and free from any drill chatter or scoring marks.

Circularity (Roundness). Holes shall be round within the best shop practice. Holes may be

3.2.1.4

reamed for shear and critical applications.

Cleaning. After the holes are machined, they shall be cleaned to remove all contaminants

3.2.1.5

before the bolts are installed.

Fastener Threads. There will be two different fastener thread series referenced in this

3.3

document.

Unified National Thread. The Unified National inch thread conforms to FED-STD-H28 and

3.3.1

MIL-S-7742.

3.3.2

J Form Thread. The J form thread has the MIL-S-8879 thread form.

Preferred Threads. The J form threads are preferred. The J form external thread shall not

3.3.3

be used with internal Unified National form, MIL-S-7742, without the specific approval of the cognizant

engineer.

3.3.4

Bolt Stress Area. Bolt root areas are used to calculate the preloads listed herein. (See 6.2a)

Bolts, Screws and Nuts. The bolt, screw or nut shall not be reworked in any manner; this

3.3.5

includes drilling, filing, cutting, using a tap or die, or any other mutilation, unless approved by the

cognizant engineer, reidentified and inspected by QA.

Preferred Parts. The listing of a part in the Torque Tables does not imply the part is

3.3.6

approved for general use. See Section 352 Fastener Specialist for approvals.

3.4

Installation.

3.4.1

Quantity of Fasteners Used. Only as many fasteners as are anticipated to be installed and

6

JPL Spec ES504255 I

tightened during a work shift shall be taken from protective stores. Fasteners not used shall be returned

to protective storage containers at the end of the shift.

Wrenches. Sockets and wrenches shall not have sharp edges or burrs that could damage the

3.4.2

fastener plating or coating.

Torque Application. Torque shall be applied to the nut to the maximum extent possible

3.4.3

when a nut is present. Whenever clearance is a problem, torque may be applied to the bolt head, to the

high side of the torque range specified in the torque tables.

Installation Torque. The torque applied at final assembly shall include the net effect of the

3.4.3.1

following:

a.

The torque required to overcome kinetic friction between mating bearing faces and

between mating threads, plus;

b.

The torque required to overcome the self-locking feature (if any), plus;

c.

The torque required to apply the desired axial load to a fastener assembly.

The installation torque shall be measured only in the tightening direction.

Standard Torque Values. The torque values selected from Tables I through IX are based on

3.4.3.2

the maximum preload capability of the weaker member of the joint (either the internally threaded or

externally threaded part).

3.4.3.2.1 Self-Locking Fasteners. The self-locking and breakaway torque of fasteners shall be

measured as specified in 6.3. The self-locking torque shall be added to the value listed in the applicable

table and the fastener installed to that torque value.

Thread Engagement. The nut, nutplate, insert, etc., shall not engage any incomplete threads

3.4.4

adjacent to the bolt or screw shank.

Washer Identification. Any identification mark on the washer used under the nut shall be

3.4.5

placed opposite the face of the nut.

Self-Locking Features. Threaded fasteners should contain a self-locking feature in either

3.4.6

the external, or internally threaded part to prevent joint loosening. Self-locking bolts and screws shall be

readily identifiable by marking or discrete part number.

Replacement Criteria. The locking elements of self-locking screws and nuts are gradually

3.4.6.1

degraded with use (an average life of 5 to 10 installations). The prevailing (or running) torque of each

screw shall be measured during installation, prior to type approval (TA) and flight acceptance (FA)

testing and final assembly. The minimum breakaway torque requirements for certain fastener

combinations are listed in Table X. When a screw or nut fails to develop the minimum breakaway

torque, replace it with a new screw or nut.

Thread Length. Install fastener threads to extend through nuts, or nutplates to comply with

3.4.7

the thread minimum protrusion requirements shown in Table XII. Depth of fastener threads into tapped

holes or free running inserts shall be one diameter minimum. Depth of fastener threads into locking

inserts shall be as above or a minimum of 1.5 threads through the locking element, whichever is greater.

7

JPL Spec ES504255 I

Bolt and Screw Length. A bolt or screw one size longer or shorter than that specified on the

3.4.8

engineering drawing may be substituted providing:

a.

They are only replaced by flight certified fasteners from flight store.

b.

They are stock items, controlled or special order bolts and screws readily available in

next length sizes.

Grip Adjustment. When a longer bolt or screw is substituted, additional washers may be

3.4.8.1

added to the ones specified on the engineering drawing subject to the following limitations:

a.

The number of washers used on a fastener shall be limited to three: one washer under

the head and two under the nut, or two under the head and one under the nut.

b.

Countersunk washers shall be installed under bolt heads with the countersunk side

facing the bolt head.

Washers. Washers shall be used in accordance with the engineering drawing, applicable

3.4.9

process bulletins and design standards, to reduce or eliminate threads in bearing, or to prevent dissimilar

metal contact. Normally, washers shall be placed under the part of the fastener that is to be wrenched

(turned) to prevent galling of the substructure. Countersunk washers (90273 or equivalent) shall be used

to provide sufficient clearance for the fillet radius under the head.

Washers with Flush Head Fasteners. Washers shall not be used under flush heads unless

3.4.9.1

specified on the engineering drawing.

Design Torque Requirements. Design may specify torque values not listed in the Tables

3.4.10

herein when the design requirements dictate.

3.4.11

Preloads. Preloads shall be as specified in Tables I through IX, as applicable.

Fastener Assembly. Fastener assembly preload shall be based on 50 percent of the fastener

3.4.11.1

tensile strength (see 6.2b).

Tapped Holes. Preloads for bolts/screws assembled into tapped holes shall be limited by the

3.4.11.2

parent materials shear yield strength (Fsy) (see 6.2c).

Preloads for Bolts/Screws Installed Into Inserts. Preloads for bolts/screws installed into

3.4.11.3

inserts that are assembled in various materials shall be based on the applicable Fsy of the parent material

(see 6.2d).

Special Preloads. For critical preloaded structural assembly tension and shear applications,

3.4.11.4

torque values based on higher percentages of tensile yield strength shall be permitted with the approval

of the cognizant engineer and the Structures and Materials Review Committee. The special torque values

shall be specified on the engineering drawing.

Special Torque Values. Preload torque may be determined by analysis as the torque value

3.4.11.5

required to ensure joint assembly integrity, considering all loading, thermal, and operational

environments and applicable safety factors, where torque-tension testing is not justifiable, or where data

exists with similar design configuration which support the analysis.

3.4.11.6

Electronic Equipment and Assembly. Torque values for electric and electronic packaging

8

JPL Spec ES504255 I

equipment shall be in accordance with ES516101.

3.4.11.7

Table XI.

Nylon Screws and Nuts. Torque values for nylon screws and nuts shall be as specified in

3.5

Torque.

Installation Torque. Installation torque shall be in inch-ounces, inch-pounds, or foot-pounds

3.5.1

(see 6.2e).

Torque Coefficient K. The torque coefficient (K) shall be determined by torque-tension

3.5.1.1

tests or may be estimated as follows:

0.25 -

No lubrication on nut or bolt

0.21 -

Lubricated threads or lubricated head/washer only and silver plated nuts onto bare

A-286 bolts when torques applied to the head.

0.15 -

Silver plated nuts with unlubricated A-286 bolts, torque applied to the nut.

Bolts/screws with dry film lubricated threads and head/washer, torque applied to

the head, going into unlubricated inserts and tapped holes.

Torque Wrench Personnel. All tightening of fasteners shall be accomplished by

3.5.2

experienced personnel using certified equipment.

Overtorqued Fasteners. Bolts, screws, inserts, and nuts which are tightened to torques

3.5.3

which exceed values specified shall be removed and replaced with new fasteners.

Retorquing. The effect of retorquing on a fastener torque-load relationship can be

3.5.3.1

significant. All activities which install fasteners should consider the potential effects on preload that

retorquing fasteners can have on installed hardware.

Multiple Installations. On multiple bolt, screw, or nut installations (e.g., circular bolted

3.5.4

joints, etc.) the following procedure for torquing shall apply:

a.

Finger tighten all fasteners.

b.

Snug up diagonally opposite fasteners until all fastener heads are seated.

c.

Torque to within proper limits in a criss-cross pattern; do not successively tighten

fasteners that are next to each other.

Lubrication. Fasteners shall be installed in the received condition without additional

3.5.5

lubrication.

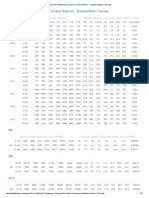

Torque Tables. Torque Tables I through VII shall be used to determine the torque for the

3.5.6

specific combinations of inserts, nuts, bolts or screws, and washers listed therein. Torque Tables VIII

and IX shall be used to determine the installation torque required for installation of bolts/screws in

tapped holes.

Self-Locking Fasteners. When self-locking fasteners are used, the torque required to

3.5.6.1

overcome the locking feature's torque (running torque) shall be added to the torque value indicated in the

9

JPL Spec ES504255 I

Table.

4.0

QUALITY ASSURANCE

Torque Inspection. All threaded fasteners torqued to the requirements of this specification

4.1

shall be 100 percent inspected for proper torque during assembly.

Thread Length Inspection. Fastener thread length shall be inspected for conformance to the

4.2

requirements of 3.4.7.

4.3

Tooling.

Torque Wrenches. Torque shall be applied to the fasteners using torque wrenches

4.3.1

conforming to QAI 85-15-6-001 and GGG-W-686.

Tool Accuracy. Wrenches shall be capable of indicating torque within 4 percent. New

4.3.1.1

tools may require two applications before the accuracy is within the 4 percent requirements.

Tool Selection. The torque wrench to be used shall be chosen such that the specified torque

4.3.1.2

values for a particular fastener shall be between 20 and 80 percent of the full-scale torque.

Calibration. Torque wrench calibration shall be checked prior to the first use and thereafter

4.3.1.3

at intervals not to exceed 30 calendar days. The interval may also be adjusted by individual gage

inspection card. A dated certification of such check shall be securely attached to the wrench.

Sealing and Marking. Torque presetting wrenches shall be sealed after adjustment and

4.3.1.4

calibration check with a suitable tamperproof material. The torque to which the wrench is set shall be

clearly and conspicuously marked on the wrench.

Recalibration. If a torque wrench is dropped, struck or otherwise damaged, or suspected of

4.3.1.5

being out of calibration, the wrench shall be checked before further use and, if found to be out of

calibration, the wrench shall not be used until recalibrated.

Adapters. Adapters or extensions shall be used with torque wrenches only when necessary.

4.3.1.6

Adapters or extensions shall be used only with wrenches designed for their use and the wrench or adapter

combination shall be calibrated prior to use, or correction made for actual torque by an acceptable

analytical method.

5.0

PREPARATION FOR DELIVERY

Not applicable.

6.0

NOTES

Intended Use. Torque values are to be used in the assembly of spacecraft structure,

6.1

subassemblies, and other areas as indicated.

6.2

Formulas Used:

10

JPL Spec ES504255 I

a. Bolt/Screw Tensile Strength (F0)

F0 = As x Ftu

F0 = Tensile Strength (lbs)

As = Root Area From FED-STD-H28 (in)

Ftu = Tensile Strength (psi)

b. Preload (F) Fastener Assembly

F = 0.5 x Ftu x As

F = Fastener preload (lbs)

As = Root Area (in)

c. Preload (F) for Fastener Assembly Into Tapped Hole

F=3x

1

n

7 x x

Fsy d x

8

F = Preload (lbs)

n = Fasteners Threads per inch (in-1)

Fsy = Tapped Material Shear Yield Strength (psi)

d = Thread Major Diameter (in)

d.

Preload (F), fastener assembled into insert that has been installed in a tapped hole.

F = Ase x

1

L

3x

Fsy

n

F = Preload (lbs)

L = External Thread Length of Insert (in)

n = Threads per inch, External Insert Threads (in-1)

Ase= Shear Engagement Area(*) of External Insert Threads (in2)

Fsy = Shear Yield Strength of Parent Material (psi)

(*) Supplied by manufacturer of insert.

e.

Torque (T) Necessary to Achieve Specified Preload.

T = KFd (0.95)

T = Assembly Torque (in-lbs)

K = Constant:Required Loading Factor, Non-dimensional

F = Preload (lbs)

d = Major Diameter of External Thread (in)

0.95 = Allowance for Torque Wrench Error.

Definitions. For the purpose of clarification and interpretation, the following definitions are

6.3

applicable to this specification.

11

JPL Spec ES504255 I

Maximum Locking Torque. The maximum torque is measured during the installation or

6.3.1

removal cycle with no load on the base of the nut. On the first installation cycle, maximum locking

torque is defined as the highest reading measured during the turn of the nut after the top of the nut is

flush with the end of the bolt.

Breakaway Torque. After assembly, the nut shall be backed-off (counterclockwise) until the

6.3.2

preload on the assembly is removed and then the turning shall be stopped. The breakaway torque is the

torque required to start the nut turning again in a counterclockwise direction.

12

JPL Spec ES504255 I

Table I. Rivnuts

Rivnut Numbers:

ST10224, ST10225

Mating Bolts/Screws: Any with 25ksi or greater tensile strength.

Preferred

Thread Size

Preload

Pounds

0.112-40

0.138-32

0.164-32

0.190-32

58

87

141

209

Torque Wrench Reading (Inch-Ounces)

K=0.15

K=0.21

K=0.25

Max

Min

Max

Min

Max

Min

14.8

12.0

20.7

16.8

24.7

20.0

27.4

22.2

38.3

31.0

45.6

37.0

52.7

42.7

73.8

59.8

87.9

71.2

90.5

73.3

127

103

151

122

Table II. Inserts, Bolts/Screws and Nuts at 80ksi

Part Numbers

Inserts:

SL6061C, SL6096C

Bolts/Screws: MS24693[1], MS51957, MS51958

ST10051, ST10072, NAS1352C, NAS1351C

Nuts:

MS35649, MS35650, MS35691 [2]

Mating Bolt/Screw:

Any with 80ksi or greater tensile strength.

Preferred

Thread Size

Preload

Pounds

0.060-80

0.086-56

0.112-40

Preferred

Thread Size

58

120

192

Preload

Pounds

0.138-32

0.164-32

0.190-32

0.250-28

288

473

700

1300

Torque Wrench Reading(Inch-Ounces)

K=0.15

K=0.21

K=0.25

Max

Min

Max

Min

Max

Min

7.9

6.5

11.1

9.0

13.2

10.7

23.5

19.1

32.9

26.7

39.2

31.8

49.0

39.7

68.6

55.6

81.7

66.2

Torque Wrench Reading(Inch-Pounds)

K=0.15

K=0.21

K=0.25

Max

Min

Max

Min

Max

Min

5.7

4.6

7.9

6.4

9.4

7.6

11.1

9.0

15.5

12.6

18.4

14.9

18.9

15.3

26.5

21.5

31.6

26.6

46.3

37.5

64.8

52.5

77.2

62.5

Notes:

[1] Use 80 percent of the listed torque for MS24693 and other flush head screws.

[2] MS35691 is a jam nut, use 50 percent of the listed torque.

13

JPL Spec ES504255 I

Table III. Blind Nuts and Anchor Nuts at 125ksi.

Part Numbers:

Blind Nuts: BB414, BB415

Anchor Nuts: MS21076

Mating Bolts/Screws: Any with 125ksi or greater tensile Strength

Torque Wrench Reading(Inch-Pounds)

Preferred

Preload

Thread Size

Pounds

K=0.21

K=0.25

K=0.15

Max

Min

Max

Min

Max

Min

0.138-32

435

8.6

6.9

12.0

9.7

14.3

11.5

0.164-32

707

16.5

13.4

23.1

18.7

27.5

22.3

0.190-32

1040

28.2

22.8

39.4

31.9

46.9

38.0

0.250-28

1950

69.5

56.3

97.3

78.8

116

93.8

14

JPL Spec ES504255 I

Table IV. Bolts/Screws at 160ksi, into Inserts Assembled in

Al 6061-T6 and Higher Strength Materials.

Bolts/Screws:

DS83A-()-(), DS132-()-(), DS134A-()-()[1], DS136A-()-(),NAS1580C()H[1],

NAS1216E(), NAS1351N(),NAS1352N(), ST10073-().

Parent Material: Al 6061-T6 and all other materials having higher than Fsy=22.5ksi

Miniature Inserts

Preferred

Closed Insert

Thread Size

Number

Open Insert

Number

Preload

Pounds

KNC0080J

ST11326-1

ST11326-2

ST11326-3

ST11326-4

120

233

371

557

905

Open Insert

Number

Preload

Pounds

KNCB0256J

KNCB0440J

KNCB0632J

KNCB0832J

KNB1032J

KNB428J

NAS1394C3

NAS1394C4

233

371

557

905

1340

2500

Heavy Duty Inserts

Preferred

Closed Insert

Thread Size

Number

Open Insert

Number

Preload Pounds

NAS1395C08

NAS1395C3

NAS1395C4

905

1340

2500

0.060-80

0.086-56

0.112-40

0.138-32

0.164-32

Lightweight Inserts

Preferred

Closed Insert

Thread Size

Number

0.086-56

0.112-40

0.138-32

0.164-32

0.190-32

0.250-28

0.164-32

0.190-32

0.250-28

KNHB0832J

KNHB1032J

KNHB428J

Torque Wrench Reading(Inch-Pounds)

K=0.15

K=0.21

K=0.25

Max

Min

Max

Min

Max

Min

1.0

0.8

1.4

1.2

1.7

1.4

2.9

2.3

4.0

3.2

4.8

3.9

5.9

4.8

8.3

6.7

9.9

8.0

11.0

8.9

15.3

12.4

18.3

14.8

21.1

17.1

29.6

24.0

35.2

28.6

Torque Wrench Reading(Inch-Pounds)

K=0.21

K=0.25

K=0.15(2)

Max

Min

Max

Min

Max

Min

2.9

2.3

4.0

3.2

4.8

3.9

5.9

4.8

8.3

6.7

9.9

8.0

11.0

8.9

15.3

12.4

18.3

14.8

21.1

17.1

29.6

24.0

35.2

28.6

36.3

29.4

50.8

41.1

60.5

49.0

89.1

72.1

125

101

148

120

Torque Wrench Reading(Inch-Pounds)

K=0.15(2)

K=0.21

K=0.25

Max

Min

Max

Min

Max

Min

21.1

17.1

29.6

24.0

35.2

28.6

36.3

29.4

50.8

41.1

60.5

49.0

89.1

72.1

125

101

148

120

Note [1]. Use 80 percent of the indicated torque values for DS134A-()-() and NAS1580C()H

countersunk head parts.

[2]. For 0.190-32 fasteners and larger use the low end of the torque range .

15

JPL Spec ES504255 I

Table V. Bolts/Screws at 190ksi, into Inserts Assembled in

Al 6061-T6 and Higher Strength Materials.

Bolts/Screws:

DS83-()-(), DS134-()-()[1], DS136-()-()

Parent Material: Al 6061-T6 and all other materials having higher than Fsy=22.5ksi

Miniature Inserts

Preferred

Closed Insert

Thread Size

Number

Open Insert

Number

Preload

Pounds

KNC0080J

ST11326-1

ST11326-2

ST11326-3

ST11326-4

143

277

441

635

922

Open Insert

Number

Preload

Pounds

KNCB0256J

KNCB0440J

KNCB0632J

KNCB0832J

KNB1032J

KNB428J

NAS1394C3

NAS1394C4

277

441

662

1010

1625

2703

Heavy Duty Inserts

Preferred

Closed Insert

Thread Size

Number

Open Insert

Number

Preload Pounds

NAS1395C08

NAS1395C3

NAS1395C4

1080

1625

2970

0.060-80

0.086-56

0.112-40

0.138-32

0.164-32

Lightweight Inserts

Preferred

Closed Insert

Thread Size

Number

0.086-56

0.112-40

0.138-32

0.164-32

0.190-32

0.250-28

0.164-32

0.190-32

0.250-28

KNHB0832J

KNHB1032J

KNHB428J

Torque Wrench Reading(Inch-Pounds)

K=0.15

K=0.21

K=0.25

Max

Min

Max

Min

Max

Min

1.2

1.0

1.7

1.4

2.0

1.7

3.4

2.8

4.8

3.9

5.7

4.6

7.0

5.7

9.9

8.0

11.7

9.5

12.5

10.1

17.5

14.2

20.8

16.9

21.5

17.5

30.2

24.4

35.9

29.1

Torque Wrench Reading(Inch-Pounds)

K=0.15(2)

K=0.21

K=0.25

Max

Min

Max

Min

Max

Min

3.4

2.8

4.8

3.9

5.7

4.6

7.0

5.7

9.9

8.0

11.7

9.5

13.0

10.5

18.2

14.8

21.7

17.6

23.6

19.1

33.0

26.8

39.3

31.9

44.0

35.6

61.6

49.9

73.3

59.4

96.3

78.0

135

109

160

130

Torque Wrench Reading(Inch-Pounds)

K=0.15(2)

K=0.21

K=0.25

Max

Min

Max

Min

Max

Min

25.2

20.4

35.3

28.6

42.1

34.1

44.0

35.6

61.6

49.9

73.3

59.4

106

85.7

148

120

176

143

Note [1]. Use 80 percent of the indicated torque values for DS134-()-() countersunk head parts.

[2]. For 0.190-32 fasteners and larger use the low end of the torque range.

16

JPL Spec ES504255 I

Table VI. Bolts/Screws at 160ksi, into Inserts Assembled in

Invar and Higher Strength Aluminum Alloys.

Bolts/Screws:

Parent Material:

DS83A-()-(), DS132-()-(), DS134A-()-()[1], DS136A-()-(),NAS1580C()H[1],

NAS1216E(), NAS1351N(),NAS1352N(), ST10073-().

Invar and other materials having higher than Fsy=24ksi

Miniature Inserts

Preferred

Closed Insert

Thread Size

Number

Open Insert

Number

Preload

Pounds

KNC0080J

ST11326-1

ST11326-2

ST11326-3

ST11326-4

120

233

371

557

905

Open Insert

Number

Preload

Pounds

KNCB0256J

KNCB0440J

KNCB0632J

KNCB0832J

KNB1032J

KNB428J

NAS1394C3

NAS1394C4

233

371

557

905

1340

2500

Heavy Duty Inserts

Preferred

Closed Insert

Thread Size

Number

Open Insert

Number

Preload Pounds

NAS1395C08

NAS1395C3

NAS1395C4

905

1340

2500

0.060-80

0.086-56

0.112-40

0.138-32

0.164-32

Lightweight Inserts

Preferred

Closed Insert

Thread Size

Number

0.086-56

0.112-40

0.138-32

0.164-32

0.190-32

0.250-28

0.164-32

0.190-32

0.250-28

KNHB0832J

KNHB1032J

KNHB428J

Torque Wrench Reading(Inch-Pounds)

K=0.15

K=0.21

K=0.25

Max

Min

Max

Min

Max

Min

1.0

.8

1.4

1.2

1.7

1.4

2.9

2.3

4.0

3.2

4.8

3.9

5.9

4.8

8.3

6.7

9.9

8.0

11.0

8.9

15.3

12.4

18.3

14.8

21.1

17.1

29.6

24.0

35.2

28.6

Torque Wrench Reading(Inch-Pounds)

K=0.25

K=0.15(2)

K=0.21

Max

Min

Max

Min

Max

Min

2.9

2.3

4.0

3.2

4.8

3.9

5.9

4.8

8.3

6.7

9.9

8.0

11.0

8.9

15.3

12.4

18.3

14.8

21.1

17.1

29.6

24.0

35.2

28.6

36.3

29.4

50.8

41.1

60.5

49.0

89.1

72.1

125

101

148

120

Torque Wrench Reading(Inch-Pounds)

K=0.25

K=0.15(2)

K=0.21

Max

Min

Max

Min

Max

Min

21.1

17.1

29.6

24.0

35.2

28.6

36.3

29.4

50.8

41.1

60.5

49.0

89.1

72.1

125

101

148

120

Note [1]. Use 80 percent of the indicated torque values for DS134A-()-() and NAS1580C()H

countersunk head parts.

[2]. For 0.190-32 fasteners and larger use the low end of the torque range.

17

JPL Spec ES504255 I

Table VII. Bolts/Screws at 190ksi, into Inserts Assembled in

Invar and Higher Strength Aluminum Alloys.

Bolts/Screws:

DS83-()-(), DS134-()-()[1], DS136-()-()

Parent Material:

Invar and other materials having higher than Fsy=24ksi

Miniature Inserts

Preferred

Closed Insert

Thread Size

Number

Open Insert

Number

Preload

Pounds

KNC0080J

ST11326-1

ST11326-2

ST11326-3

ST11326-4

143

277

441

662

983

Open Insert

Number

Preload

Pounds

KNCB0256J

KNCB0440J

KNCB0632J

KNCB0832J

KNB1032J

KNB428J

NAS1394C3

NAS1394C4

277

441

662

1080

1625

2880

Heavy Duty Inserts

Preferred

Closed Insert

Thread Size

Number

Open Insert

Number

Preload Pounds

NAS1395C08

NAS1395C3

NAS1395C4

1080

1625

2970

0.060-80

0.086-56

0.112-40

0.138-32

0.164-32

Lightweight Inserts

Preferred

Closed Insert

Thread Size

Number

0.086-56

0.112-40

0.138-32

0.164-32

0.190-32

0.250-28

0.164-32

0.190-32

0.250-28

KNHB0832J

KNHB1032J

KNHB428J

Torque Wrench Reading(Inch-Pounds)

K=0.15

K=0.21

K=0.25

Max

Min

Max

Min

Max

Min

1.2

1.0

1.7

1.4

2.0

1.7

3.4

2.8

4.8

3.9

5.7

4.6

7.0

5.7

9.9

8.0

11.7

9.5

13.0

10.5

18.2

14.8

21.7

17.6

23.0

18.6

32.2

26.1

38.3

31.0

Torque Wrench Reading(Inch-Pounds)

K=0.25

K=0.15(2)

K=0.21

Max

Min

Max

Min

Max

Min

3.4

2.8

4.8

3.9

5.7

4.6

7.0

5.7

9.9

8.0

11.7

9.5

13.0

10.5

18.2

14.8

21.7

17.6

25.2

20.4

35.3

28.6

42.1

34.1

44.0

35.6

61.6

49.9

73.3

59.4

103

83.1

144

116

171

139

Torque Wrench Reading(Inch-Pounds)

K=0.25

K=0.15(2)

K=0.21

Max

Min

Max

Min

Max

Min

25.2

20.4

35.3

28.6

42.1

34.1

44.0

35.6

61.6

49.9

73.3

59.4

106

85.7

148

120

176

143

Note [1]. Use 80 percent of the indicated torque values for DS134-()-() countersunk head parts.

[2]. For 0.190-32 fasteners and larger use the low end of the torque range.

18

JPL Spec ES504255 I

Table VIII. Bolts/Screws at 160ksi, Assembled into Tapped Material

Bolts/Screws:

DS83A-()-(), DS132-()-(), DS134A-()-()[1], DS136A-()-(), NAS1216E(),

NAS1351N(), NAS1352N(), NAS1580C()H[1], ST10073-().

Tapped Thread

Size

0.060-80

0.086-56

0.112-40

0.138-32

0.164-32

0.190-32

0.250-28

Tapped Thread

Size

0.060-80

0.086-56

0.112-40

0.138-32

0.164-32

0.190-32

0.250-28

Tapped Thread

Size

0.060-80

0.086-56

0.112-40

0.138-32

0.164-32

0.190-32

0.250-28

Part A. Tapped Al 6061-T6, Fsy=22.5 ksi

Torque Wrench Reading(Inch-Pounds)

Preload Pounds

K=0.25

K=0.15(2)

K=0.21

Max

Min

Max

Min

Max

Min

120

1.0

.8

1.4

1.2

1.7

1.4

233

2.9

2.3

4.0

3.2

4.8

3.9

371

5.9

4.8

8.3

6.7

9.9

8.0

557

11.0

8.9

15.3

12.4

18.3

14.8

905

21.1

17.1

29.6

24.0

35.2

28.6

1100

29.8

24.1

41.7

33.8

49.6

40.2

1660

59.1

47.9

82.8

67.1

98.6

79.8

Part B. Tapped Invar, Fsy=24 ksi

Preload Pounds

Torque Wrench Reading(Inch-Pounds)

K=0.21

K=0.25

K=0.15(2)

Max

Min

Max

Min

Max

Min

120

1.0

.8

1.4

1.2

1.7

1.4

233

2.9

2.3

4.0

3.2

4.8

3.9

371

5.9

4.8

8.3

6.7

9.9

8.0

557

11.0

8.9

15.3

12.4

18.3

14.8

905

21.1

17.1

29.6

24.0

35.2

28.6

1180

31.9

25.9

44.7

36.2

53.2

43.1

1770

63.1

51.1

88.3

71.5

105

85.1

Part A. Tapped Al 7075-T73 Fsy=27.5 ksi

Torque Wrench Reading(Inch-Pounds)

K=0.21

K=0.25

Preload Pounds

K=0.15(2)

Max

Min

Max

Min

Max

Min

120

1.0

.8

1.4

1.2

1.7

1.4

233

2.9

2.3

4.0

3.2

4.8

3.9

371

5.9

4.8

8.3

6.7

9.9

8.0

557

11.0

8.9

15.3

12.4

18.3

14.8

905

21.1

17.1

29.6

24.0

35.2

28.6

1340

36.3

29.4

50.8

41.1

60.5

49.0

2025

72.1

58.4

101

81.8

120

97.4

Part A. Tapped Titanium and Steel, Fsy=50.5 ksi

Torque Wrench Reading(Inch-Pounds)

Tapped Thread

Preload Pounds

K=0.21

K=0.25

K=0.15(2)

Size

Max

Min

Max

Min

Max

Min

0.060-80

120

1.0

.8

1.4

1.2

1.7

1.4

0.086-56

233

2.9

2.3

4.0

3.2

4.8

3.9

0.112-40

371

5.9

4.8

8.3

6.7

9.9

8.0

0.138-32

557

11.0

8.9

15.3

12.4

18.3

14.8

0.164-32

905

21.1

17.1

29.6

24.0

35.2

28.6

0.190-32

1340

36.3

29.4

50.8

41.1

60.5

49.0

0.250-28

2500

89.1

72.1

125

101

148

120

Note [1]. Use 80 percent of the listed torque values for DS134A-()-() and NAS 1580C()H Flush fasteners.

[2] Use the high end of the torque range when applying torque to a nut. Use the low end of the torque

range when applying torque to the bolt head and using lubricated threads and a lubricated head/washer

and using fasteners 0.190-32 and larger.

19

JPL Spec ES504255 I

Table IX. Bolts/Screws at 190ksi, Assembled into Tapped Material

Bolts/Screws:

DS83-()-(), DS134-()-()[1], DS136-()-()

Tapped Thread

Size

0.060-80

0.086-56

0.112-40

0.138-32

0.164-32

0.190-32

0.250-28

Tapped Thread

Size

0.060-80

0.086-56

0.112-40

0.138-32

0.164-32

0.190-32

0.250-28

Tapped Thread

Size

0.060-80

0.086-56

0.112-40

0.138-32

0.164-32

0.190-32

0.250-28

Part A. Tapped Al 6061-T6, Fsy=22.5 ksi

Preload Pounds

Torque Wrench Reading(Inch-Pounds)

K=0.15(2)

K=0.21

K=0.25

Max

Min

Max

Min

Max

Min

139

1.2

1.0

1.7

1.4

2.0

1.6

277

3.4

2.8

4.8

3.9

5.7

4.6

441

7.0

5.7

9.9

8.0

11.7

9.5

662

13.0

10.5

18.2

14.8

21.7

17.6

951

22.2

18.0

31.1

25.2

37.0

30.0

1100

29.8

24.1

41.7

33.8

49.6

40.2

1660

59.1

47.9

82.8

67.1

98.6

79.9

Part B. Tapped Invar, Fsy=24 ksi

Torque Wrench Reading(Inch-Pounds)

Preload Pounds

K=0.15(2)

K=0.21

K=0.25

Max

Min

Max

Min

Max

Min

139

1.2

1.0

1.7

1.4

2.0

1.6

277

3.4

2.8

4.8

3.9

5.7

4.6

441

7.0

5.7

9.9

8.0

11.7

9.5

662

13.0

10.5

18.2

14.8

21.7

17.6

1010

23.6

19.1

33.0

26.8

39.3

31.9

1180

31.9

25.9

44.7

36.2

53.2

43.1

1770

63.1

51.1

88.3

71.5

105

84.1

Part A. Tapped Al 7075-T73 Fsy=27.5 ksi

Preload Pounds

Torque Wrench Reading(Inch-Pounds)

K=0.15(2)

K=0.21

K=0.25

Max

Min

Max

Min

Max

Min

139

1.2

1.0

1.7

1.4

2.0

1.6

277

3.4

2.8

4.8

3.9

5.7

4.6

441

7.0

5.7

9.9

8.0

11.7

9.5

662

13.0

10.5

18.2

14.8

21.7

17.6

1080

25.2

20.4

35.3

28.6

42.1

34.1

1347

36.5

29.5

51.1

41.4

60.8

49.2

2025

72.1

58.4

101

81.8

120

97.4

Part A. Tapped Titanium and Steel, Fsy=50.5 ksi

Preload Pounds

Torque Wrench Reading(Inch-Pounds)

K=0.15(2)

K=0.21

K=0.25

Max

Min

Max

Min

Max

Min

0.060-80

139

1.2

1.0

1.7

1.4

2.0

1.6

0.086-56

277

3.4

2.8

4.8

3.9

5.7

4.6

0.112-40

441

7.0

5.7

9.9

8.0

11.7

9.5

0.138-32

662

13.0

10.5

18.2

14.8

21.7

17.6

0.164-32

1080

25.2

20.4

35.3

28.6

42.1

34.1

0.190-32

1625

44.0

35.6

61.6

49.9

73.3

59.4

0.250-28

2970

106

85.7

148

120

176

143

Note [1]. Use 80 percent of the listed torque values for DS134A-()-() and NAS 1580C()H Flush fasteners

Tapped Thread

Size

[2] Use the high end of the torque range when applying torque to a nut. Use the low end of the torque

range when applying torque to the bolt head and using lubricated threads and a lubricated head/washer

and using fasteners 0.190-32 and larger.

20

JPL Spec ES504255 I

Table X. Maximum Prevailing and Minimum Breakaway Torque.

Thread Size

Prevailing Torque [1]

Breakaway Torque

Maximum (Inch-Pounds)

Minimum (Inch-Pounds)

Nuts [2]

Bolts [3]

Nuts [2]

Bolts[3]

0.086-56

2.5

0.2

0.112-40

5

5

0.5

0.5

0.138-32

10

8

1.0

1.0

0.164-32

15

12

1.5

1.5

0.190-32

18

18

2.0

2.0

0.250-28

30

30

3.5

3.0

[1] Prevailing torque on or off.

[2] Nut torque values from MIL-DTL-25027

[3] Bolt torque values from MIL-DTL-18240

Table XI. Nylon Fastener Assembly Torque

Nylon Screw/ Nut

Size

0.112-40

0.138-32

0.164-32

Assembly Torque

(Inch-Ounces)

8

16

27

Table XII. Thread Engagement and Protrusion.

Thread Size

Thread Engagement

Thread Protrusion

with Insert Minimum

Through Nut

Minimum

0.060-80

0.060

0.019

0.086-56

0.086

0.027

0.112-40

0.112

0.038

0.138-32

0.138

0.047

0.164-32

0.164

0.047

0.190-32

0.190

0.047

0.250-28

0.250

0.054

21

Potrebbero piacerti anche

- Ms33537e PDFDocumento11 pagineMs33537e PDFstaedtlerpNessuna valutazione finora

- Prediction of Fatigue Failure in A Camshaft Using The Crack MethodDocumento9 paginePrediction of Fatigue Failure in A Camshaft Using The Crack MethodDiego PovedaNessuna valutazione finora

- Aisi 316LDocumento2 pagineAisi 316LMichael DouglasNessuna valutazione finora

- Iso 3506 1 2020Documento46 pagineIso 3506 1 2020Anna BubblegumNessuna valutazione finora

- NASA - Fastners Torque LimitsDocumento44 pagineNASA - Fastners Torque Limitspi31415926535Nessuna valutazione finora

- Screws With External Hexalobular Driving Feature: Mercedes-Benz MBN 10 142Documento6 pagineScrews With External Hexalobular Driving Feature: Mercedes-Benz MBN 10 142achin123Nessuna valutazione finora

- Example Workshop Dynamic FatigueDocumento60 pagineExample Workshop Dynamic Fatiguesumatrablackcoffee453Nessuna valutazione finora

- Fatiguehandbook Small PDFDocumento532 pagineFatiguehandbook Small PDFmanishpali100% (1)

- Thermocouples, Sheathed, Type K, For Nuclear or For Other High-Reliability ApplicationsDocumento5 pagineThermocouples, Sheathed, Type K, For Nuclear or For Other High-Reliability ApplicationsROHITNessuna valutazione finora

- Aluminium Alloys Jan2020.6310.1580092925.3362Documento75 pagineAluminium Alloys Jan2020.6310.1580092925.3362EudoNessuna valutazione finora

- Foundation Bolts - Specification: Indian StandardDocumento4 pagineFoundation Bolts - Specification: Indian StandardakmlogaNessuna valutazione finora

- Grommets, Bushings and Cable GlandsDocumento13 pagineGrommets, Bushings and Cable GlandsLukiana AtmanegaraNessuna valutazione finora

- Material SpecificationDocumento9 pagineMaterial SpecificationMuthu GaneshNessuna valutazione finora

- Design Requirements For Bonded and Bolted Composite StructuresDocumento52 pagineDesign Requirements For Bonded and Bolted Composite Structuresarun_justin_1Nessuna valutazione finora

- Bolt Torque ChartDocumento7 pagineBolt Torque ChartMarco BacianNessuna valutazione finora

- Fatigue Curve - S235JR ExperimantalDocumento9 pagineFatigue Curve - S235JR ExperimantalPrabath MadusankaNessuna valutazione finora

- An818 Rev-20 2Documento5 pagineAn818 Rev-20 2Senthil KumarNessuna valutazione finora

- 2041682-b (Bolt Modeling)Documento22 pagine2041682-b (Bolt Modeling)danaosajoNessuna valutazione finora

- Vibration Loosening PDFDocumento24 pagineVibration Loosening PDFrahul_patil85Nessuna valutazione finora

- Aluminium 6063Documento23 pagineAluminium 6063Jaya VijayanNessuna valutazione finora

- MSC Fastener Modeling For Joining Composite Parts 06-SpiritAero - BoshersDocumento22 pagineMSC Fastener Modeling For Joining Composite Parts 06-SpiritAero - BoshersSergey Fedorinov100% (1)

- Measuring The Force-Displacement of A Membrane Switch: Standard Test Method ForDocumento5 pagineMeasuring The Force-Displacement of A Membrane Switch: Standard Test Method Formasoud132Nessuna valutazione finora

- Temperature Sensor Manual 2016 BDocumento41 pagineTemperature Sensor Manual 2016 BFARHANUDDIN100% (1)

- Workshop 5 Direct Frequency Response Analysis: WS5-1 NAS122, Workshop 5, January 2004 © 2004 MSC - Software CorporationDocumento18 pagineWorkshop 5 Direct Frequency Response Analysis: WS5-1 NAS122, Workshop 5, January 2004 © 2004 MSC - Software CorporationmasatusNessuna valutazione finora

- ANSYS Mechanical APDL Programmers ReferenceDocumento398 pagineANSYS Mechanical APDL Programmers ReferenceFelipe QuevedoNessuna valutazione finora

- Sec4 Optimization of Composites 021712Documento34 pagineSec4 Optimization of Composites 021712FradjNessuna valutazione finora

- 15 5PH Bars Sheets Plates SpecificationsDocumento2 pagine15 5PH Bars Sheets Plates SpecificationsSachin RoutNessuna valutazione finora

- Flux Cored WireDocumento38 pagineFlux Cored WireKentDemeterioNessuna valutazione finora

- (Bolt Science) BOLTCALC Program Brochure PDFDocumento3 pagine(Bolt Science) BOLTCALC Program Brochure PDFAbdulrahman Al HuribyNessuna valutazione finora

- Aeromat 2007 - MMPDS - 060407Documento29 pagineAeromat 2007 - MMPDS - 060407luism2743Nessuna valutazione finora

- Pre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsDocumento3 paginePre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsmukeshkumarjNessuna valutazione finora

- (Eng) Aluminium 14Documento79 pagine(Eng) Aluminium 14HENGKIMHACHNessuna valutazione finora

- Demonstration of SpringbackDocumento7 pagineDemonstration of SpringbackDan Wolf100% (1)

- AN818 Rev-20 PDFDocumento5 pagineAN818 Rev-20 PDFaldiNessuna valutazione finora

- ECSS E ST 32 11C (31july2008)Documento78 pagineECSS E ST 32 11C (31july2008)jsadachi100% (1)

- NX Nastran Advanced Nonlinear - Solution 601-701Documento3 pagineNX Nastran Advanced Nonlinear - Solution 601-701Rubén GabrielNessuna valutazione finora

- Nonlinear Total Strain Vs Linear Strai1Documento32 pagineNonlinear Total Strain Vs Linear Strai1Dasaka BrahmendraNessuna valutazione finora

- THE Q Shock and Vibration Bulletin: RRG: Tlnon VR RDocumento332 pagineTHE Q Shock and Vibration Bulletin: RRG: Tlnon VR Rskr2010Nessuna valutazione finora

- 1.4 - Precipitation HardeningSteelDocumento1 pagina1.4 - Precipitation HardeningSteelMuhammad Khizer KhanNessuna valutazione finora

- Fastener PDFDocumento12 pagineFastener PDFdiegomilitojNessuna valutazione finora

- Pyromation Product Catalog Part Number Application GuideDocumento8 paginePyromation Product Catalog Part Number Application GuideSakahi SharmaNessuna valutazione finora

- Abaqus Tutorial 1Documento11 pagineAbaqus Tutorial 1Dg IRfan100% (1)

- Aerospace Parts 2 Quick Disconnect CouplingsDocumento104 pagineAerospace Parts 2 Quick Disconnect CouplingsSohail100% (1)

- Making Efficient Connections With RBE2 RBE3 Constraint Equations and CBUSH ElementsDocumento24 pagineMaking Efficient Connections With RBE2 RBE3 Constraint Equations and CBUSH Elementsjejep4Nessuna valutazione finora

- 4140 Alloy SteelDocumento9 pagine4140 Alloy Steelsmg26thmayNessuna valutazione finora

- Alloy 7050 Tech Sheet RevDocumento4 pagineAlloy 7050 Tech Sheet RevDoni N RahmanNessuna valutazione finora

- VDA Classification - Material - List - 205 - EN PDFDocumento31 pagineVDA Classification - Material - List - 205 - EN PDFgogger100% (1)

- 6066 T6 Aircraft Aluminum Alloy Sheet SuppliersDocumento12 pagine6066 T6 Aircraft Aluminum Alloy Sheet Supplierssanghvi overseas incNessuna valutazione finora

- Astm G116 99Documento5 pagineAstm G116 99hadi ebrahimfathNessuna valutazione finora

- GS52Documento3 pagineGS52S.Hasan MirasadiNessuna valutazione finora

- Significance of - Reduction of Area in A Tensile TestingDocumento6 pagineSignificance of - Reduction of Area in A Tensile Testinglram70Nessuna valutazione finora

- Hammer Drive ScrewDocumento1 paginaHammer Drive ScrewNisa BN QANessuna valutazione finora

- Dimensional Measurement PlanningDocumento4 pagineDimensional Measurement PlanningKeith AdminNessuna valutazione finora

- 15-5 PH Technical DataDocumento7 pagine15-5 PH Technical Datasmith will100% (1)

- Bent Tubes: DocumentationDocumento17 pagineBent Tubes: DocumentationAkmal NizametdinovNessuna valutazione finora

- MSC Nastran v67 - Nonlinear HandbookDocumento729 pagineMSC Nastran v67 - Nonlinear HandbookAndrew RamesNessuna valutazione finora

- Catalogo SewDocumento740 pagineCatalogo SewAlejandro Tapia100% (1)

- Det-653a Manual de OperacionDocumento76 pagineDet-653a Manual de OperacionEulalio HortaNessuna valutazione finora

- Eicedriver™: Asic & Power IcsDocumento28 pagineEicedriver™: Asic & Power Icsy2k_yah7758Nessuna valutazione finora

- Kawasaki Programming Guide RIV0005 SDDocumento91 pagineKawasaki Programming Guide RIV0005 SDRafael Luiz GilliNessuna valutazione finora

- VERTI-G Cuttings DryerDocumento4 pagineVERTI-G Cuttings DryerLoganBohannon100% (1)

- Plane Motion of Rigid BodiesDocumento42 paginePlane Motion of Rigid BodiespektophNessuna valutazione finora

- Research: John W. HutchinsonDocumento25 pagineResearch: John W. HutchinsonskcNessuna valutazione finora

- Air Starting System Slide Set 1Documento10 pagineAir Starting System Slide Set 1Jigar PatelNessuna valutazione finora

- Energy Saving Hydraulic DriveDocumento20 pagineEnergy Saving Hydraulic DriveJamin SmtpngNessuna valutazione finora

- Straightforward EfficiencyDocumento19 pagineStraightforward EfficiencyJukiuzNessuna valutazione finora

- Ee6601 SSD PDFDocumento21 pagineEe6601 SSD PDFRohithNessuna valutazione finora

- C2 - RevADocumento16 pagineC2 - RevAChirag ShahNessuna valutazione finora

- Double Mechanical Seals, Tandem ArrangementDocumento10 pagineDouble Mechanical Seals, Tandem ArrangementViwek MertiyaNessuna valutazione finora

- Low Heating Value Fuel BurningDocumento17 pagineLow Heating Value Fuel BurningalirezaNessuna valutazione finora

- 02 MotorDocumento99 pagine02 Motorkarol1177Nessuna valutazione finora

- PHYSICS Matters For GCE O' Level Subject Code:5054: Unit 2: KinematicsDocumento34 paginePHYSICS Matters For GCE O' Level Subject Code:5054: Unit 2: KinematicsIqra ArshadNessuna valutazione finora

- 3xGE 9E.04 (GT Only)Documento1 pagina3xGE 9E.04 (GT Only)Ade Okta YurwendraNessuna valutazione finora

- Total Oil Too Tracktor - 13Documento1 paginaTotal Oil Too Tracktor - 13oleg7962Nessuna valutazione finora

- +++ Off-Road Vehicle DynamicsDocumento37 pagine+++ Off-Road Vehicle Dynamicsnadjib62Nessuna valutazione finora

- Composite Action in BeamsDocumento21 pagineComposite Action in BeamsAlemayehu DargeNessuna valutazione finora

- Conceptual Questions: Unit 1: Mechanics Chapter 9: Linear Momentum and CollisionsDocumento22 pagineConceptual Questions: Unit 1: Mechanics Chapter 9: Linear Momentum and CollisionsEsther Kaye Joana PanaliganNessuna valutazione finora

- Wire Line ch-1Documento20 pagineWire Line ch-1Ammar HrzNessuna valutazione finora

- Rai Rac-18cDocumento24 pagineRai Rac-18cKyaw San OoNessuna valutazione finora

- Simple Spur Gear Calculator SpreadSheetDocumento2 pagineSimple Spur Gear Calculator SpreadSheetRandyWilsonNessuna valutazione finora

- Pressure Purging Case 1 Nitrogen Requirement For Pressure Purging Case 1Documento1 paginaPressure Purging Case 1 Nitrogen Requirement For Pressure Purging Case 1BalasubramanianNessuna valutazione finora

- Hughes 500 C IpcDocumento479 pagineHughes 500 C IpcRodolfo Rol100% (1)

- Las2 PSDocumento1 paginaLas2 PSlukewendellrNessuna valutazione finora

- Steelwork Design Guide To BS 5950-1-2000. Volume 2. Worked Examples. Part 6 - Example 6 Beam Under Combined Bending and Torsion Using A UC Section.Documento11 pagineSteelwork Design Guide To BS 5950-1-2000. Volume 2. Worked Examples. Part 6 - Example 6 Beam Under Combined Bending and Torsion Using A UC Section.Yilin ZuoNessuna valutazione finora

- DC Motor Modeling and Controller DesignDocumento26 pagineDC Motor Modeling and Controller DesignMauricio bonilla GarageNessuna valutazione finora

- Homelite String Trimmer Parts Manual HBC30 String Trimmer UT 15085Documento12 pagineHomelite String Trimmer Parts Manual HBC30 String Trimmer UT 15085marcosNessuna valutazione finora

- Manual de Partes Perforadoras MD6240Documento589 pagineManual de Partes Perforadoras MD6240fergusxxx100% (1)

- Filtro Autolimpiante Af 113 MahleDocumento6 pagineFiltro Autolimpiante Af 113 MahleHIDRAFLUIDNessuna valutazione finora

- Thesis Brandon Berisford PDFDocumento55 pagineThesis Brandon Berisford PDFBeyondBeliefNessuna valutazione finora

- Yamaha Nmax 155 - Safety Pre-Operation ChecksDocumento1 paginaYamaha Nmax 155 - Safety Pre-Operation Checksmotley crewzNessuna valutazione finora