Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

AMC-51 Expt Manual Ver1.0

Caricato da

mohdnadeem1155Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

AMC-51 Expt Manual Ver1.0

Caricato da

mohdnadeem1155Copyright:

Formati disponibili

AMC- 51 ADVANCED 8051 MICRCONTROLLER TRAINER EXPERIMENTAL MANUAL

AMC-51 Advanced 8051 Microcontroller Trainer

Welcome

Introduction The AMC-51 trainer is designed to study the advanced microcontroller architecture, advanced programming, and interfacing of external devices to the microcontroller.

Companys Motto Light years ahead refers to leadership.

We strive to be the best in what we do and maintain high standards in the areas of Design Quality Value Delivery Support We are indeed light years ahead of the competition in this field. We guarantee our valued customers great satisfaction.

Important Information As you will move through this manual you will quickly discover that we have complete, truly innovative & superior training products. We are so committed to quality that we back our products with a complete and comprehensive warranty.

FALCON ELECTRO-TEK PVT.LTD.

FALCON HOUSE, PLOT-A-194, TTC Industrial Area MIDC, Kopar Khairane, NAVI MUMBAI-400705 MAHARASHTRA, INDIA. TEL.: +91-22-27788551 / 27788552 / 27788553 / 27788554 FAX: 91-22-27788555

Email: falcon@falconindia .biz Website: www.falconindia.biz

Microprocessors & Microcontrollers

AMC-51 Advanced 8051 Microcontroller Trainer

Safety Guidelines

Read carefully and follow the instructions mentioned in this manual. This user manual includes all the important points about the installation, use and the maintenance of the product. Keep this manual always with you, for quick reference. After unpacking the product, arrange all the accessories in proper order, so that their integrity is checked with the packing list. Also, ensure that the accessories have no visible damage. Before connecting the power supply to the kit, be sure that the jumpers and the connecting chords are connected correctly, as per the experiment. This kit must be employed only for the use for which it has been conceived, i.e. as educational kit and must be used under the direct survey of expert personnel. Any other use is inadvisable and dangerous too. The manufacturer cannot be considered responsible for eventual damages due to improper, wrong or unreasonable uses. In case of any fault or malfunctioning in the trainer kit, turn off the power supply. Please do not tamper the kit. If you require our service, kindly contact the service centre for technical assistance. The kits are liable to malfunction/ underperforms if it is not operated under following conditions: Ambient temperature: Between 0 to 45 C Relative humidity: Between 20 to 80 %

Avoid any immediate/significant change of temperature and humidity.

Microprocessors & Microcontrollers

AMC-51 Advanced Microcontroller 8051 Trainer

Warranty

This kit is warranted against defects in workmanship and materials. Any failure due to defect in either workmanship or material should occur under normal use within a year from the original date of purchase, such failure will be corrected free of charge to the purchaser by repair or replacement of defective part or parts. When the failure is result of users neglect, natural disaster or accident, we would charge for repairs, regardless of the warranty period. The warranty does not cover include perishable items like connecting chords, crystals, etc. and other imported items. Conditions and Limitations The warranty is void and inapplicable if the defective product is not brought or sent to our authorized service center or sales outlet within the warranty period. Defective product will be Falcon Electro Tek. Pvt. Ltds sole judgment. The defective product will be replaced with a new one or repaired, without charge or with charge. In the warranty period if the service is needed, the purchaser should get in touch with the service center or the sales outlet. The purchaser should return the product to the service center or the sales outlet at his or her sole expense. The loss and damage in transit will be outside the preview of this warranty. A returned product must be accompanied by a written description of the defects. Type and Model No. of the kit has to be mentioned specifically. We return the product to the purchaser at our expense. In case the warranty does not cover the product on Falcon Electro- Tek Pvt. Ltd.s judgment, we would repair the product after obtaining prior permission from purchaser who would receive an estimate statement about the repairing charges. In such cases, Falcon Electro-Tek Pvt. Ltd. bares the transporting expenses required to send back all the repaired products for the moment, and then repairs and transporting expenses will be charged against the purchaser by the statement of accounts. When the authorized sales agents sell our products, they must notify the purchaser of the warranty contents, but they have no rights to stretch the meaning of original warranty contents or to offer an additional warranty. Falcon Electro-Tek Pvt. Ltd. does not provide any other promise or suggestive warranty and hold no liability for the damage caused by negligence, abnormal use or natural disaster. Falcon Electro-Tek Pvt. Ltd. is not responsible for the damages even if it is notified of above dangers in advance as well. For more special service or overall repairs, maintenance and up gradation of products, be sure to contact our service center or the sales outlet.

Microprocessors & Microcontrollers

AMC-51 Advanced Microprocessor 8051 Trainer

FALCON ELECTRO TEK PVT. LTD Title: Test Report Of Product

PRD / F03 / 0 1- 9 - 04

Test Report

Customer Name Distributor Name : Model Serial No. Sr. No. 1. 2. 3. 4. 5. 6. 7. 8. : AMC- 51 Advanced Microcontroller 8051 Trainer : Types Of Tests Visual Inspection Electrical Check Functional Settings Functional Test Burning Test Final Check Accessories Check As Per List Packing Report :

Checked By Signature Installed By Signature

: _____________________________ : ______________________________ : ______________________________ : ______________________________

Date: ________

Date: ________

Microprocessors & Microcontrollers

AMC-51 Advanced Microcontroller 8051 Trainer

FALCON ELECTRO TEK PVT. LTD Title: Test Report Of Product

PRD / F03 / 0 1- 9 - 04

Test Report

Customer Name Distributor Name : Model Serial No. Sr. No. 1. 2. 3. 4. 5. 6. 7. 8. Checked By Signature Installed By Signature : AMC- 51 Advanced Microcontroller 8051 Trainer : Types Of Tests Visual Inspection Electrical Check Functional Settings Functional Test Burning Test Final Check Accessories Check As Per List Packing : ______________________________ : ______________________________ : ______________________________ : ______________________________ Date: ________ Date: ________ Report :

Microprocessors & Microcontrollers

AMC-51 Advanced Microcontroller 8051 Trainer

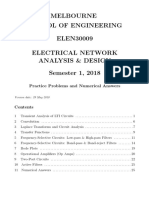

Table of Content

1. Introduction 2. Specification 3. AMC-51 TRAINER ACCESSORIES LIST 4. 5. 6. 7 Software Installation PANAL DISCRIPTION AMC-51 COMMUNICATION SETTING SERIAL DEBUGGER 14 16 21 07 08 10 11

Software experiments

3. Experiment 1: RESET PROGRAM .. 4. Experiment 2: SEPARATION OF 2 DIGIT NUMBER 5. Experiment 3: GET 2 DIGIT NUMBER FROM 2 SINGLE DIGIT NUMBER . 6. Experiment 4: DATA AREA SEND DELIVER SUBROUTINE . 7. Experiment 5: SORTING DATA . 8. Experiment 6: FIND SAME NUMBER .. 30 9. Experiment7: R APID MULTIPLICATION OF UNSIGNEDBYTE SUBROUTINE INPUT 32 10 Experiment8: MULTIBRANCH PROGRAM 11 Experiment 9: COMPUTER CLOCK .. 12 Experiment 10 IMPULSE COUNT: Hardware experiments: 13 Experiment 1: 14 Experiment 2: 15 Experiment 3: 16 Experiment 4: 17 Experiment 5: 18 Experiment 6: 19 Experiment 7: 20 Experiment 8: LIGHT P1 PORT EXPERIMENT P1 PORT TURN LIGHT EXPERIMENT p3.3 PORT INPUT, PI PORT OUTPUT . INDUSTRY SEQUENCE CONTROL 8255 A,B,C PORT OUTPUT SQUARE WAVE 8255PAPORT CONTROL PB PORT 8255 CONTROL TRAFFIC LIGHT SIMPLE I/O EXPANSION EXPERIMENT

4

22 23 . 24 26 28

34

36

44

48 51 54 57 60 62 64 68

AMC-51 Advanced Microcontroller 8051 Trainer

21 Experiment 9: 23 Experiment 11: 24 Experiment 12:

ANALOG TO DIGITAL CONVERSION 8279 KEYBOARD DISPLAYING DISPLAYING EXPERIMENT.. COMMON USED PRINTER

71 77

22 Experiment 10 DIGITAL TO ANALOG CONVERSION.

82 88 91 95 97 105 109 116 127 135 142 153 160 166 170 176 188 190 201 217 220 223 226

25 Experiment13:MICRO PRINTER PRINTCHARACTER/CURVED SHAPE 26 Experiment 14: RELAY CONTROL 27 Experiment 15: STEPPER MOTOR CONTROL 28 Experiment 16: 8253 SQUARE WAVE . 29 Experiment 17: CONTROLLING SMALL DC MOTOR . 30 Experiment 18: LED 16 x 16 LATTICE DISPLAY 31 Experiment 19: 12864 LCD EXPERIMENT 32 Experiment 20: 8250 Serial Interface Experiment . 33 Experiment 21: 8251 PROGRAMMABLE SERIAL INTERFACE & PC COMMUNICATION 34 Experiment 22: DS 18B20 TEMPERATURE MEASUREMENT. 35 Experiment 23: INFRARED COMMUNICATION 36 Experiment 24: TL 549 SERIAL A/D CONVERSION 37 Experiment 25: TL 5615SERIAL D/A CONVERSION 38 Experiment 26: PCF 8563 REAL TIME CLOCK/CALENDAR 39 Experiment 27: MAX 8131 WATCH DOG REPLACEMENT 40 Experiment 28: VOLTAGE/FREQUENCY CONTROLLER 41 Experiment 29: SERIAL MEMORY CHIP93C46 R/W 42 Experiment 30: AT 24C02 IC BUS MEMORY R/W 43 Experiment 31: PWM IMPULSE WIDTH MODULATION 44 Experiment 32: 74LS164 SERIAL INPUT & PARALLEL OUTPUT 45 Experiment 33: 165 PARALLEL /SERIAL CONVERT 46 Experiment 34: PLAYING ELECTRONIC MUSIC

AMC-51 Advanced Microcontroller 8051 Trainer

AMC-51 Advanced Microcontroller 8051 Trainer

INTRODUCTION

The AMC-51 trainer is designed to study the microcontroller architecture, basic programming, advantages of the micro-controller over microprocessor and interfacing of external devices to the microcontroller like ADC, DAC, DC motor, Stepper motor etc.It also allows the study of interfacing devices like programmable keyboard / display, timer and I/O devices etc.. The trainer provides different application sections along with microcontroller. Only we have to connect required device to the microcontroller using patch cord provided with Kit. All application resources are available on AMC-51 trainer board. Trainer supports +5V and 12V fixed power supply. A descriptive experimental manual helps students to gain more insight in to the subject.

AMC-51 Advanced Microcontroller 8051 Trainer

SPECIFICATIONS

1) In built power source: - Inbuilt +5V, +12V and -12V dc power source are provided. 2) Microcontroller unit (Atmel 89s52):- This section includes ZIF socket for microcontroller IC, reset switch, Slide switch to select normal mode and program mode. All IC pins are accessible for connection and testing purpose. 3) Mono-pulse and clock unit: - different frequencies are provided as a clock source such as 8MHz, 4MHz, 2MHz, 1MHz, 500 KHz, 250 KHz, 125 KHz, 62.5 KHz and 31.25 KHz. 4) RS232 section: - for external RS232 serial communication use only. 5) Reset switch section: - provide reset signal to all required circuit. 6) 8251 unit: - Interface the programmable communication interface IC to microcontroller. 7) 8155 unit: - This is RAM and I/O chips to be used in MPU system. 8) 8253 unit: - Interface the programmable interval timer to microcontroller. 9) 8255 unit: - Interface the programmable peripheral I/O to microcontroller. 10) 8279 unit: - Interface the programmable Keyboard and display to microcontroller. 11) 8250 unit: - Interface the serial communication 8250 UART to microcontroller. 12) ADC0809 unit: - Interface the Analog to Digital converter to microcontroller. 13) DAC0832 unit: - Interface the Digital to Analog converter to microcontroller. 14) 8 Switch input unit: - used as user inputs.

15) 6x4 matrix key board: - keyboard used for alpha numeric input and some program

related instructions like transfer program EEPROM to RAM, memory write, memory read , execute and etc. (see appendix for more detail.) 16) 6 dynamic Led 7-seg display: - Used for alpha numeric display. 17) 16 LED output units: - LED display section for indication and checking purpose. 18) 16X16 dot matrix display: - Used for alpha numeric and graphic display. 19) LCD unit: - used for large amount data display. 20) ROM 64k: - used for program code storage.

21) RAM 32K: - for data storage memory.

AMC-51 Advanced Microcontroller 8051 Trainer

22) Expansion module (CAN /USB):- programmer can be used to connect external

CAN or USB module to micro-controller.

23) I/O expansion unit: - used to expand I/O functionality of the micro-controller.

24) Adjustable voltage unit: - used as a variable voltage source. 25) IR receiver and digital temp sensor unit: - interface the external world to microcontroller. 26) RTC and calendar unit: - used for real time clock interface to micro-controller.

27) Watch dog unit: - to monitor power-supply and battery functions in C systems.

28) Serial in parallel out unit: - used to convert serial data into parallel 8-bit data. 29) Serial digital to analog unit: - serial digital data is converted into serial analog form.

30) Buzzer: - to alert the system.

31) Relay unit: - used for relay interface to switch output (on/off). 32) RS485 unit: - used for serial RS485 communication. 33) Logic pen unit: - it shows the either high or low logic level at IN point . 34) Serial analog to digital unit: - serial analog data is converted into serial digital form. 35) V/F unit: - this used to convert voltage into frequency form. 36) PWM unit: - used to provide different width depending upon micro-controller unit. 37) Parallel in serial out: - used to convert parallel 8-bit data into serial data. 38) Dc motor: - used to study the interface of dc motor with micro-controller. 39) Stepper motor: - used to study the interface of stepper motor with micro-controller. 40) Voice recorder unit: - which based on SPI protocol. Pins are provided for connection purpose. This unit provides recording, play, erase, forward, volume, reset and FT switches for select particular function of this unit. 41) Audio amplifier: - to amplify the audio signal. 42) IC card: - to read and write the data on card. 43) Printer interface section: - to interface the external printer device to microcontroller. 44) I2c EEPROM unit: - used for data storage through I2C serial protocol. 45) Serial EEPROM unit: - used for data storage in serial form.

AMC-51 Advanced Microcontroller 8051 Trainer

AMC-51 TRAINER ACCESSORIES LIST

Sr.no. 1 2 3 4 5 6 7 8

Description Mcs-51 trainer kit Power cord 8 pin ribbon cable Remote Small patch cord Yellow- 7,Black-6,Red-4,Blue-8 Serial cable Parallel cable CD contained software, sample program etc. Experiment manual

Quantity 01 01 05 01 25 01 01 01

Check mark

01

10

Emulator

01

10

AMC-51 Advanced Microcontroller 8051 Trainer

SOFTWARE INSTALLATION

1.

Explore the AMC-51 software CD content and access AMC-51trainer / software / 8051setup.exe .Double click on the following icon.

2) Click on Next->

3) click on Next ->

11

AMC-51 Advanced Microcontroller 8051 Trainer

4) click on Install ->

5) click on Finish.

(Note: - Use AMC-51 Communication setting manual for hardware and software setting before start programming and downloading the program.)

12

AMC-51 Advanced Microcontroller 8051 Trainer

SOFTWARE UNINSTALLATION

1) Follow the steps like start->program->8051 simulation system -> uninstall 8051 simulation system-> then click on uninstall 8051 simulation system then following window will appear.

2) Click on Yes. Automatically software starts uninstalling all the required component of software 8051 simulation system. Following window shows the progress of software uninstalling process.

3) Finally following window is appearing on the screen. It shows uninstall successfully completed then Press OK to complete the uninstall process of 8051 Simulation system.

13

AMC-51 Advanced Microcontroller 8051 Trainer

PANAL DISCRIPTION:

38

39

40

41

42

43

37 1 36 35 34 33 32 31 30 29 28 7 3 4 6 5

27 26 25 3 13 12 14 15 24 23 22 21 20 19 18 16 17

10 00 00 00 10 1100

8 9

14

AMC-51 Advanced Microcontroller 8051 Trainer

S.R. NO.

1. 2 3 4 5 6 7 8 19 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42

DISCRIPTION

MICROCONTROLLER UNIT EXPANSION MODULE FOR CAN &USB 8251 UNIT 8253 UNIT RS232 UNIT MATRIX KEYBOARD UNIT DECODING LATCH UNIT 8279 UNIT 8155 UNIT 8255 UNIT SWITCH INPUT UNIT LED OUTPUT UNIT I/O EXPANSION UNIT ADJUSTABLE UNIT I2C EEPROM PWM UNIT DIGITAL TEMPRATURE SENSOR SERIAL D/A DEVICE LOGIC PEN RS485 UNIT SERIAL A/D DEVICE STEPPER MOTOR DC MOTOR VOICE RECORDER AD0809 UNIT RELAY BUZZER REAL TIME CLOCK/CALENDAR SERIAL EEPROM PARALLEL IN SERIAL OUT V/F UNIT WATCHDOG UNIT IN-BUILT POWER ADC 0809 UNIT SERIAL IN PARALLEL OUT LCD UNIT AUDIO AMPLIFIER IC CARD MONOPLUS & CLOCK UNIT 16*16 DOT MATRIX 8250 UNIT DECODR SECTION

15

AMC-51 Advanced Microcontroller 8051 Trainer

AMC-51 COMMUNICATION SETTING (HARDWARE AND SOFTWARE)

1) AMC-51 Trainer kit hardware setting: Refer following picture no.1 for doing hardware setting. a) KB1 Switch: Must be sliding KB1 Switch to NORMAL PATTERN location. b) KB2 Switch: short circuit block must be insert AMC-51 location. c) SW1 Switch: short circuit block must be inserting UP location.

2) Emulator: Emulator is powered by the AMC-51 kit only need not required external supply. For Emulator connection with computer and AMC-51 trainer kit refer following picture no.2. a) Connect one end of Emulator which is having 34 pin FRC female connector to AMC -51 trainer kits box type 34 pin male connector (JF_1) using FRC cable provided with kit.

b) Other end of Emulator which is having 9 pin D-type female connector to

computer COM1 male connector using communication cable provided with kit.

standard

RS232

serial

16

AMC-51 Advanced Microcontroller 8051 Trainer

3) AMC-51 Trainer kit software setting (8051 Simulation Software): a) Check your Computer serial communication port is where COM1 or COM2.

b) Install the 8051 Simulation software software provided with the trainer Kit. Use Installation guide provided with kit. c) Connect computer serial communication port (like COM1) to AMC-51 trainer kit through emulator to JF_1 using serial cable provided with Kit and switch-ON the power of AMC-51 trainer kit. d) Open 8051 Simulation software software using Start->program->8051 simulation software and then 8051 simulation software. Following will appear on the screen. Here user have to select the communication port default is COM 1. User need not enter any Instrumentation code. Then click OK.

17

AMC-51 Advanced Microcontroller 8051 Trainer

e) Immediately following window will appear on the screen. Here 100% connectivity means Computer, Emulator and AMC-51 trainer kit is connected properly.

f) Simulation Model setting of 8051 simulation system:CPU: 8031/8032 RAM: User RAM ROM: System ROM

18

AMC-51 Advanced Microcontroller 8051 Trainer

g) Very Important Notice:Directory and file names not more than eight characters in English are allowed, otherwise the program being compiled are wrong.

Program will display following error window:-

h) When do not get 100% connectivity window then there is a problem in either AMC-51 trainer kit setting or computer communication port setting. Resolve this problem then again follow the same steps as given above. i) Now user can write a program in either Assembly or C language, compile it

19

AMC-51 Advanced Microcontroller 8051 Trainer

properly to generate .hex file and other supported file. Use 8051 simulation system to download the .hex file into microcontroller and check the functionality of program. To compile the software use tab, to run or execute the program use tab and to stop the execution use tab. j) Use the experimental manual provided with kit to do the experiments.

20

AMC-51 Advanced Microcontroller 8051 Trainer

SERIAL DEBUGGER ASSISTANCE HELP

Using this software user can communicate from AMC-51 trainer kit to computer over serial communication. 1) There is no need to install the software. We have to just open the SSCOM32.exe icon which is stored in AMC-51trainer ->software->Serial Debugging Assistance>software folder in CD. Double click on the following icon.

2) Immediately following window shows on the screen. Set the red mark setting in the software as shown in below. a) Com Num = COM1. b) Hex Data = check mark. c) Baud Rate = 9600, Data Bit = 8, Stop Bit = 1, Verify = None, Flow control = none. d) Send Hex = check mark.

3) Connect one end of serial communication RS232 D-type 9 pin cable to computer COM-1and other end is CZ11 PCB mounted D-type 9 pin connector on AMC-51 trainer kit. Finally this software is ready to communicate with AMC-51 trainer kit.

21

AMC-51 Advanced Microcontroller 8051 Trainer

Software Experiments

EXPERIMENT NO-1 RESET PROGRAM

OBJECTIVE: Fill the content between 2000H to 20FFH is other than 00H data THEORY: To reset data stored in memory location 2000h to 20FFh.Firstly we have to clear accumulator & R0 register. R0 is used here as a counter, its counting memory location 00 to FF. where as accumulator holds 00 data to store in memory location. 2000h address is loaded in DPTR. By using move instruction load 00 data in memory & INC instruction to increment both memory location & counter till R0 content becomes 00. PROGRAM: ORG 0000H LJMP SE01 ORG 0080H SE01: MOV R0,#00H MOV DPTR,#2000H LOO1: MOV A,#00H MOVX @DPTR,A INC DPTR INC R0 CJNE R0,#00H,LOO1 LOOP: SJMP LOOP END

; clear content of r0 ; 2000H address send DPTR ; clear accumulator data ; move accumulator data in memory location pointed by DPTR ; DPTR+1 ; Add 1 bytes

PROCEDURE: 1) Switch ON power supply. 2) Open respective program SW01.asm in 8051simulation system software.

3) Press compile and load tab

in the software. We can see the process window in the software at the left bottom corner. 4) Now go to Debug (D) in 8051simulation system software and press Step Over F6 command for single step execution.

5) Press F6 for further single step execution in you can see the stored data on 6)

respective memory location. For memory location please refer program Before check the content , you must stop the running program or Refresh the Data Store memory.

OUTPUT: content between 2000H to 20FFH is 00 H in Data Store Memory.(by right click on status reg.1-progam memory. Table)

22

AMC-51 Advanced Microcontroller 8051 Trainer

EXPERIMENT NO:2 SEPARATION OF 2 DIGIT NUMBER

OBJECTIVE: To separate digits of 2 digit number & store in different memory location. THEORY: Store 12 in 2000h memory location. By anding with 0FH ,get first digit .Store it in 2001 memory location. Then get another digit by using SWAP & ANL instruction .Store in 2002 the second digit. PROGRAM: ORG 0000H LJMP MAIN ORG 0080H MAIN: MOV DPTR,#2000H MOV A,#12H MOVX @DPTR,A MOV B,A SWAP A ANL A,#0FH INC DPTR MOVX @DPTR,A INC DPTR MOV A,B ANL A,#0FH MOVX @DPTR,A END PROCEDURE: 1) Switch ON power supply. 2) Open respective program SW02.asm in 8051simulation system Software. 3) Press compile and load tab in the software. We can see the process window in the software at the left bottom corner. 4) Now go to Debug (D) in 8051simulation system software and press Step Over F6 command for single step execution. 5) Press F6 for further single step execution in you can see the stored data on respective memory location. For memory location please refer program 6) Before check the content, you must stop the running program or Refresh the Data Store memory. OUTPUT: The 2000H to 2002H Data memory location shows 12,01,02 respectively.

23

; load 2000h address to DPTR ; load 12h data to accumulator ; move data stored in accumulator to memory location pointed by DPTR ; move data from accumulator to b reg. ; exchange content of accumulator ; anding 0fh data with data stored in accumulator ; increment address stored in DPTR ; move data from accumulator to memory location pointed by DPTR ; increment address stored in DPTR ; move data from b reg. to accumulator ; anding 0fh data with data stored in accumulator ; move data from accumulator to Memory location pointed by DPTR LOOP: SJMP LOOP

AMC-51 Advanced Microcontroller 8051 Trainer

EXPERIMENT NO:3 GET 2 DIGIT NUMBER FROM TWO SINGLE DIGIT NUMBERS

OBJECTIVE: To send the data of 2000H as lower and 2001H as higher byte in memory location 2002H THEORY: Take 1 & 2 as single digit number .Save 1 in 2000h & 2 in 2001h memory location. By using ANL instruction & SWAP instruction get 1 as MSB .Then by using ANL & ORL instruction get two digit required output .Store it in 2002h memory location. PROGRAM: ORG 0000H LJMP MAIN ORG 0080H MAIN: MOV DPTR,#2000H CLR A MOVX @DPTR,A MOV A,#01H MOVX @DPTR,A INC DPTR MOV A,#02H MOVX @DPTR,A MOV DPTR,#2000H MOVX A,@DPTR ANL A,#0FH SWAP A MOV B,A INC DPTR MOVX A,@DPTR ANL A,#0FH ORL A,B INC DPTR MOVX @DPTR,A END

;load DPTR by memory location address 2000H ; move data 01h to accumulator ; load accumulator data in memory location whose address pointed by DPTR ; increment address pointed by DPTR ; move data 02h to accumulator ; move accumulator data to memory location whose address pointed by DPTR ; load data of memory location 2000h to accumulator ; ANDing content of accumulator with data 0Fh ; exchange content of accumulator ; move accumulator content to b reg. ; Increment address stored in DPTR ; data stored in memory location pointed by DPTR load to accumulator ; ANDing 0fh data with content of accumulator ; oring data content in b reg. & accumulator ; increment address stored in DPTR ; move data of accumulator to memory location pointed by DPTR ; end of program

PROCEDURE: 1) Switch ON power supply. 2) Open respective program SW03.asm in 8051simulation system Software.

24

AMC-51 Advanced Microcontroller 8051 Trainer

3) Press compile and load tab in the software. We can see the process window in the software at the left bottom corner. 4) Now go to Debug (D) in 8051simulation system software and press Step Over F6 command for single step execution. 5) Press F6 for further single step execution and see the parallel effect on Data store memory window. In code memory you can see the stored on respective memory location. For memory location please refer program. 6) Before check the content , must stop the running program or Refresh the Data Store memory. OUTPUT: The 2000H to 2002H Data memory location shows 01,02,12 respectively.

25

AMC-51 Advanced Microcontroller 8051 Trainer

EXPERIMENT NO :4 Data area send Deliver Subroutine OBJECTIVE:

Data stored in memory location (0000h to 0fffh) copy to memory location 2000 to 2fffh THEORY: Store initial address 0000h in R2 & R3 register and 2000h in R4 & R5 respectively. Use R6 & R7 for counting memory location, hence load 1FFF in it. Start data storing from 1. & increase it continuously as memory location increases of source & destination, decrease content of R6 & R7. PROGRAM: ORG 0000H LJMP MAIN ORG 0080H MAIN: MOV A,#01H MOV R2,#00H ;Source address MOV R3,#00H MOV R4,#20H ;Destination address MOV R5,#00H MOV R6,#1FH ;Transmit bytes MOV R7,#0FFH SE22: MOV DPL,R3 MOV DPH,R2 ;build source program address MOVX @DPTR,A ;get number MOV DPL,R5 MOV DPH,R4 ;build Destination program address MOVX @DPTR,A ;transmit data CJNE R3,#0FFH,LO42 INC R2 INC A LO42: INC R3 ;source address add 1 CJNE R5,#0FFH,LO43 INC R4 LO43: INC R5 ;destination address add 1 CJNE R7,#00H,LO44 CJNE R6,#00H,LO45 ;byte number subtract 1 LOOP: SJMP LOOP NOP LO44: DEC R7 SJMP SE22 LO45: DEC R7 DEC R6 SJMP SE22 END PROCEDURE: 1) Switch ON power supply. 2) Open respective program SW04.asm in 8051simulation system

26

AMC-51 Advanced Microcontroller 8051 Trainer

Software. 3) Press compile and load tab in the software. We can see the process window in the software at the left bottom corner. 4) Now go to Debug (D) in 8051simulation system software and press Step Over F6 command for single step execution. 5) Press F6 for further single step execution and see the parallel effect on Data store memory window. In code memory you can see the stored data on respective memory location. For memory location please refer program to press this tab for direct execution . 6) Before check the content ,you must stop the running program or Refresh . the Data Store memory. OUTPUT: Input the source address in R2,R3,(eg:0000H), input destination address in R4,R5, (eg:2000H),input the byte number in R6,R7, (eg:1FFFH), then run the program to check whether the contend in 0000H to 1FFFH and 2000H to 3FFFH are the same. The 2000H to 2002H Data memory location shows 12,01,02 respectively.

EXPERIMENT NO :5

27

AMC-51 Advanced Microcontroller 8051 Trainer

SORTING DATA EXPERIMENT.

OBJECTIVE: Sorting data stored in memory location 50 to 5A in ascending order. THEORY: Load data in memory location 50 to 5A in any order. Use R7 as a counter .First store memory location address in R0.load data of first memory location in R2 & data from next memory to 22h memory location . compare both data, if not equal check carry flag. If flag is set ,keep data as it is . if carry is not set , exchange data & go to next memory location. Till R7 content becomes zero. PROGRAM: ORG 0000H LJMP QUE ORG 0080H QUE: MOV 50H,#08H ;load data 08h to memory location 50h MOV 51H,#01H ;load data 01h to memory location 51h MOV 52H,#07H ;load data 07h to memory location 52h MOV 53H,#02H ;load data 02h to memory location 53h MOV 54H,#06H ;load data 06h to memory location 54h MOV 55H,#09H ;load data 09h to memory location 55h MOV 56H,#02H ;load data 02h to memory location 56h MOV 57H,#04H ;load data 04h to memory location 57h MOV 58H,#08H ;load data 08h to memory location 58h MOV 59H,#03H ;load data 03h to memory location 59h MOV 5AH,#05H ;load data 05h to memory location 5Ah MOV R3,#50H ;load data 50h to reg. r3 QUE1: MOV A,R3 ;load data from r3 to accumulator MOV R0,A ;Pointer send to R0 MOV R7,#0AH ;length send to R7 CLR 00H ;Clear flag MOV A,@R0 ;data saved in memory location whose address stored in r0 moved to accumulator QL2: INC R0 ;increment stored address in r0 MOV R2,A ; move data from accumulator to r2 CLR C ; clear c reg. MOV 22H,@R0 ;move data pointed by r0 to 22h memory location CJNE A,22H,QL3 ; compare & jump if accumulator data is not equal to 22h to ql3 loop SETB C ;set bit c QL3: MOV A,R2 ;move data from r2 to accumulator JC QL1 ;jump if carry to QL1 loop SETB 00H ;set bit 00h XCH A,@R0 ;exchange accumulator data with data in r0 DEC R0 ;decrement r0 XCH A,@R0 ;exchange accumulator data with data pointed by r0 INC R0 ;increment r0 QL1: MOV A,@R0 ;move data pointed by r0 to accumulator DJNZ R7,QL2 ;decrement & jump if not zero to Ql2

28

AMC-51 Advanced Microcontroller 8051 Trainer

JB 00H,QUE1 LOOP: SJMP LOOP END

;jump if bit t0 00h to que1 ;short jump to loop ; end of program

PROCEDURE: 1) Switch ON power supply. 2) Open respective program SW05.asm in 8051simulation system Software. 3) Press compile and load tab in the software. We can see the process window in the software at the left bottom corner. 4) Now go to Debug (D) in 8051simulation system software and press Step Over F6 command for single step execution. 5) Press F6 for further single step execution and see the parallel effect on Internal store memory window. In code memory you can see the stored data on respective memory location . For memory location please refer program . For memory location please refer program or to press this tab for direct execution. 6) Before check the content , you must stop the running program or Refresh the Data Store memory. OUTPUT: The 50H to 5AH is shows the output in the In internal store memory 01,02,02,03,04,05,06,07,08,08,09 respectively.

EXPERIMENT NO-6

29

AMC-51 Advanced Microcontroller 8051 Trainer

FIND THE SAME NUMBER EXPRIMENT

OBJECTIVE: Fill zero in some units between 2000H to 200FH in the data store memory. THEORY: Load 00 in some of the memory location from 2000h to 200F. Use R0 as a counter. Clear R1 data to store number of zero count. Use CJNE instruction to compare it with 00. If it equal then increment R1 and go to next memory location, else keep R1 data as it is. PROGRAM: ORG 0000H LJMP MAIN ORG 0080H MAIN: MOV DPTR,#2000H ; load DPTR by address 2000h MOV A,#00H ; clear accumulator MOV R2,#08H ; Fill in the number of 0 LOOP: MOVX @DPTR,A ; store data from accumulator to memory location pointed by DPTR ; increment address stored in DPTR ; decrement & jump if number stored in r2 is not zero to loop L5800: MOV R0,#10H ; for increasing address location from 2000h to 200f MOV R1,#00H ; for counting number of zeroes MOV DPTR,#2000H ; starts counting L5811: MOVX A,@DPTR ; load data from DPTR memory location to accumulator CJNE A,#00H,L5816 ; Is the result equal with 00 INC R1 ; increment count of zeroes L5816: INC DPTR ; increment to next address DJNZ R0,L5811 ; decrement & jump if not zero data of R0 MOV DPTR,#2100H ; stored number of zeroes in 2100 memory location MOV A,R1 ; move r1 data in accumulator MOVX @DPTR,A ; the same number send to 2100H L581E: SJMP L581E END PROCEDURE: 1) Switch ON power supply. 2) Open respective program SW06.asm in 8051simulation system Software. 3) Press compile and load tab in the software. We can see the process window in the software at the left bottom corner. 4) Now go to Debug (D) in 8051simulation system software and press Step Over F6 command for single step execution. 5) Press F6 for further single step execution and see the parallel effect on Data store memory window. In code memory you can see the stored data on respective memory location. For memory location please refer program or to

30

INC DPTR DJNZ R2,LOOP

AMC-51 Advanced Microcontroller 8051 Trainer

press this tab direct execution. 6) Before check the content ,you must stop the running program or Refresh the Data Store memory. OUTPUT: The number of zeros which is present in the data memory 2000H to 200FH is (count) shown in 2100H data memory.

EXPERIMENT NO-7

31

AMC-51 Advanced Microcontroller 8051 Trainer

RAPID MULTIPLICATION OF UNSIGNED BYTE SUBROUTINE INPUT:

OBJECTIVE: The program doing multiplication operation with the following formula by single-byte multiplication instruction.

THEORY: Store 02 data in R2R3 & 04 data in R6 R7 register respectively. First multiply all 4 registers data with each other .Then add result of all multiplication & add carry of all multiplication. Store result in R6 R7 & store carry result in R4 R5.

PROGRAM: ORG 0000H LJMP QKUL ORG 0080H QKUL: MOV R2,#00 ; store data 0 in r2 MOV R3,#02 ; store 02 data in r3 MOV R6,#00 ; store 0 data in r6 MOV R7,#04 ; store 4 data in r7 MOV A,R3 ; move data from r3 to accumulator MOV B,R7 ; move data from r7 to b reg. MUL AB ; R3*R7 XCH A,R7 ; move multiplication result in r7 &data of r7 in accumulator MOV R5,B ; move content of b reg. in r5 MOV B,R2 ; move data from r2 to b reg. MUL AB ; R2*R7 ADD A,R5 ; result of multiplication add with data stored in accumulator MOV R4,A ; move added result in r4 CLR A ; clear accumulator ADDC A,B ; add content of accumulator & b reg. with carry MOV R5,A ; result of addition store in r5 MOV A,R6 ; move data stored in r6 t0 accumulator MOV B,R3 ; move data from r3 to b reg. MUL AB ; R3*R6 ADD A,R4 ; addition of data content in accumulator & r4 reg. XCH A,R6 ; exchange data content in r6 & accumulator XCH A,B ; exchange content of accumulator & b reg. ADDC A,R5 ; addition of data content in r5 with accumulator MOV R5,A ; move accumulator data in r5 reg. MOV PSW.5,C ; save CY MOV A,R2 ; move content of r2 reg. in accumulator MUL AB ; R2*R6 ADD A,R5 ; addition of accumulator data with r5 reg. data MOV R5,A ; move accumulator data in r5 reg. CLR A ; clear accumulator

32

AMC-51 Advanced Microcontroller 8051 Trainer

MOV ACC.0,C MOV C,PSW.5 ADDC A,B ; addition of accumulator data with b reg. data with carry MOV R4,A ; move accumulator data in r4 reg. LOOP: SJMP LOOP END PROCEDURE: 1) Switch ON power supply. 2) Open respective program SW07.asm in 8051simulation system Software. 3) Press compile and load tab in the software. We can see the process window in the software at the left bottom corner. 4) Now go to Debug (D) in 8051simulation system software and press Step Over F6 command for single step execution. 5) Press F6 for further single step execution and see the parallel effect on Data store memory window. In code memory you can see the stored data on respective memory location. For memory location please refer program or to press this tab direct execution. 6) Before check the content ,you must stop the running program or Refresh the Data Store memory. OUTPUT: Observe result of multiplication 00000008 in R4R5R6R7.

EXPERIMENT NO-8 Multi-branch Program

OBJECTIVE: Write 00,01,02,03 in 20H grade, then run the program to observe the cycle in digital tube

33

AMC-51 Advanced Microcontroller 8051 Trainer

THEORY: To display data from 0 to 3 on display in scrolling mode, store one of data in 20h memory location. RLA instruction used to scroll same number on display. For 0 to 3 number , C0,F9,A4& B0are hex code used in program to display 0,1,2,3 respectively. CPLA used to blank display..

PROGRAM: ORG 0000H LJMP MEMORYS ORG 0080H MEMORYS: MOV P2,#0FFH ;initialize port 2 MOV A,#43H ;move 43 data in accumulator MOV DPTR,#0FF20H ;move ff20 address in DPTR pointer MOVX @DPTR,A ;move accumulator data in memory location pointed by DPTR MOV 20H,#01H ;you can change input 0 or 1 or 2 or 3 MOV A,20H ;move memory location 20h to accumulator MOV DPTR,#KKKK ;branch address RL A ;(20)*2 JMP @A+DPTR ;jump to address of accumulator content + DPTR KKKK: AJMP MEMORYSP0 AJMP MEMORYSP1 AJMP MEMORYSP2 SJMP MEMORYSP3 MEMORYSP0: MOV 20H,#0C0H ;move data c0h to memory location 20h LJMP SOX0 ;to display 0 MEMORYSP1: MOV 20H,#0F9H ;move data f9h to memory location 20h LJMP SOX0 ;to display 1 MEMORYSP2: MOV 20H,#0A4H ;move data a4h to memory location 20h LJMP SOX0 ;to display2 MEMORYSP3: MOV 20H,#0B0H ;move data 0bh to memory location 20h LJMP SOX0 ;to display 3 SOX0: MOV A,20H ;MOV R0,#22H ;MOV R1,#21H MOV DPTR,#0FF22H MOVX @DPTR,A ;MOVX @R0,A MOV A,#01H SOX1: CPL A MOV DPTR,#0FF21H MOVX @DPTR,A ;MOVX @R1,A CPL A MOV R2,#20H LCALL DELY RL A SJMP SOX1 ;Display routines

34

AMC-51 Advanced Microcontroller 8051 Trainer

DELY: DEL2: DEL3: DEL4:

PUSH 02H PUSH 02H PUSH 02H DJNZ R2,DEL4 POP 02H DJNZ R2,DEL3 POP 02H DJNZ R2,DEL2 POP 02H DJNZ R2,DELY RET END

PROCEDURE: 1) Switch ON power supply. 2) Open respective program SW07.asm in 8051simulation system Software. 3) Press compile and load tab in the software. We can see the process window in the software at the left bottom corner. 4) Now go to Debug (D) in 8051simulation system software and press Step Over F6 command for single step execution. 5) Press F6 for further single step execution and see the parallel effect on Data store memory window. In code memory you can see the stored data on respective memory location. For memory location please refer program or to press this tab direct execution. 6) Before check the content, you must stop the running program or Refresh the Data Store memory.

OUTPUT: Observe scrolling data on 7 segment display from 0 to 3 which is available in 20h memory location.

EXPERIMENT NO-9 Computer Clock (Timer, Interrupt Experiment)

OBJECTIVE: To study RTC & see time on seven segment display. THEORY: input current value of hour, minute, second from the keyboard. The timer 0 is selected to give time interval. The hex code loaded in timer is DBE6 to give 10ms

35

AMC-51 Advanced Microcontroller 8051 Trainer

time interval. Formula to calculate time interval is required time= (FFFF-XXYY+1) x cycle time where XXYY is hex code loaded in timer. Program ORG 0000H LJMP CHK0 ORG 000BH LJMP CLOCK ORG 0080H CHK0: MOV SP,#60H ;store 60h data in stack pointer MOV P2,#0FFH ;initialize port2 MOV 7EH,#11H ;move 11h data in 7eh MOV 7DH,#10H ;move 10h data in 7dh MOV 7CH,#10H ;move 10h data in 7ch MOV 7BH,#10H ;move 10h data in 7bh MOV 7AH,#10H ;move 10h data in 7ah MOV 79H,#10H ;move 10h data in 79h MOV A,#43H ;move 43h data in accumulator MOV DPTR,#0FF20H ;store ff20 address in DPTR MOVX @DPTR,A ;move data from accumulator to memory location pointed by DPTR ;MOV r0,#59h ;move 59h to r0 reg. MOV a,#7eh ;move 7eh data to accumulator MOVX @r0,a ;move data from accumulator to memory location MOV DPTR,#2059H ;store address 2059 in DPTR MOVX @DPTR,A ;move data from accumulator to memory location pointed by DPTR LCALL LCK0 LCALL PTDS0 MOV TMOD,#01H ;select timer ORL IE,#82H ;move 82h in i.e. reg. MOV TL0,#0E6H ;set timer time MOV TH0,#0DBH MOV 23H,#00H ;clear 23h memory location SETB TR0 ; set timer LOO5: LCALL SSEE LCALL PTDS0 SJMP LOO5 PTDS0:MOV R0,#79H ;move 79h data in r0 MOV A,22H ;move 22h in accumulator ACALL PTDS MOV A,21H ;move 21h to accumulator ACALL PTDS MOV A,20H ;move 20h to accumulator ACALL PTDS RET PTDS: MOV R1,A ;move accumulator to r1 reg. ACALL PTDS1 MOV A,R1 ;move r1 data to accumulator SWAP A ; exchange higher & lower bit saved in accumulator

36

AMC-51 Advanced Microcontroller 8051 Trainer

PTDS1:ANL A,#0FH MOV @R0,A

INC R0 RET CLOCK:MOV TL0,#0E6H ;set timer time MOV TH0,#0DBH PUSH PSW PUSH ACC SETB 0D3H INC 23H MOV A,23H ;move data stored in memory location CJNE A,#64H,DONE ;compare 64 with content of accumulator & jump if not equal to done loop MOV 23H,#00H MOV A,22H INC A DA A ; decimal adjustment of data stored in accumulator MOV 22H,A CJNE A,#60H,DONE MOV 22H,#00H MOV A,21H INC A DA A MOV 21H,A CJNE A,#60H,DONE MOV 21H,#00H MOV A,20H INC A DA A MOV 20H,A CJNE A,#24H,DONE MOV 20H,#00H DONE: POP ACC POP PSW RETI ORG 0D50H SSEE: SETB RS1 MOV R5,#05H SSE2: MOV 30H,#20H MOV 31H,#7EH MOV R7,#06H SSE1: ;MOV R1,#21H MOV A,30H CPL A ;MOVX @R1,A MOV DPTR,#0FF21H MOVX @DPTR,A MOV R0,31H MOV A,@R0 MOV DPTR,#DDFF

37

; anding 0fh data with content of accumulator ;move accumulator data in memory location pointed by r0 reg. ;increment data in r0

AMC-51 Advanced Microcontroller 8051 Trainer

MOVC A,@A+DPTR MOV R1,#22H ;MOVX @R1,A MOV DPTR,#0FF22H MOVX @DPTR,A MOV A,30H RR A MOV 30H,A DEC 31H MOV A,#0FFH ;MOVX @R1,A MOV DPTR,#0FF22H MOVX @DPTR,A DJNZ R7,SSE1 DJNZ R5,SSE2 CLR RS1 RET DDFF: DB 0C0H,0F9H,0A4H,0B0H,99H,92H,82H,0F8H,80H,90H DB 88H,83H,0C6H,0A1H,86H,8EH,0FFH,0CH,89H,0DEH ORG 1D00H X3: MOV R4,A ;MOV R0,#59H ;MOVX A,@R0 MOV DPTR,#2059H MOVX A,@DPTR MOV R1,A MOV A,R4 MOV @R1,A CLR A POP DPH POP DPL MOVC A,@A+DPTR INC DPTR CJNE A,01H,X30 CLR A MOVC A,@A+DPTR X31: ;MOVX @R0,A INC DPTR PUSH DPL PUSH DPH MOV DPTR,#2059H MOVX @DPTR,A RET X30: DEC R1 MOV A,R1 SJMP X31 X2: MOV R6,#50H X0: ACALL XLE JNB ACC.5,XX0 DJNZ R6,X0 MOV R6,#20H ;MOV R0,#59H

38

AMC-51 Advanced Microcontroller 8051 Trainer

;MOVX A,@R0 MOV DPTR,#2059H MOVX A,@DPTR MOV R0,A MOV A,@R0 MOV R7,A MOV A,#10H MOV @R0,A X1: ACALL XLE JNB ACC.5,XX1 DJNZ R6,X1 MOV A,R7 MOV @R0,A SJMP X2 XX1: MOV R6,A MOV A,R7 MOV @R0,A MOV A,R6 XX0: RET XLE: ACALL DIS ACALL KEY MOV R4,A ;MOV R1,#48H ;MOVX A,@R1 MOV DPTR,#2048H MOVX A,@DPTR MOV R2,A ;INC R1 ;MOVX A,@R1 MOV DPTR,#2049H MOVX A,@DPTR MOV R3,A MOV A,R4 XRL A,R3 MOV R3,04H MOV R4,02H JZ X10 MOV R2,#88H MOV R4,#88H X10: DEC R4 MOV A,R4 XRL A,#82H JZ X11 MOV A,R4 XRL A,#0EH JZ X11 MOV A,R4 ORL A,R4 JZ X12 MOV R4,#20H DEC R2 SJMP X13

39

AMC-51 Advanced Microcontroller 8051 Trainer

X12: x11:

MOV R4,#0FH MOV R2,04H MOV R4,03H X13: ;MOV R1,#48H MOV A,R2 ;MOVX @R1,A MOV DPTR,#2048H MOVX @DPTR,A ;INC R1 MOV A,R3 ;MOVX @R1,A MOV DPTR,#2049H MOVX @DPTR,A MOV A,R4 RET LS3: DB 07H,04H,08H,05H,09H,06H,0AH DB 0BH,01H,00H,02H,0FH,03H,0EH DB 0CH,0DH DIS: PUSH DPH PUSH DPL SETB RS1 MOV R0,#7EH MOV R2,#20H MOV R3,#00H ;MOV DPTR,#LS0 LS2: MOV DPTR,#LS0 MOV A,@R0 MOVC A,@A+DPTR ;MOV R1,#22H ;MOVX @R1,A MOV DPTR,#0FF22H MOVX @DPTR,A MOV A,R2 CPL A ;DEC R1 ;MOVX @R1,A MOV DPTR,#0FF21H MOVX @DPTR,A CPL A DEC R0 LS1: DJNZ R3,LS1 CLR C RRC A MOV R2,A JNZ LS2 ;INC R1 MOV A,#0FFH ;MOVX @R1,A MOV DPTR,#0FF22H MOVX @DPTR,A CLR RS1 POP DPL

40

AMC-51 Advanced Microcontroller 8051 Trainer

POP DPH RET LS0: DB 0C0H,0F9H,0A4H,0B0H,99H,92H DB 82H,0F8H,80H,90H,88H,83H,0C6H DB 0A1H,86H,8EH,0FFH,0CH,89H,7FH,0BFH KEY: SETB RS1 MOV R2,#0FEH MOV R3,#08H MOV R0,#00H LP1: MOV A,R2 ;MOV R1,#21H ;MOVX @R1,A MOV DPTR,#0FF21H MOVX @DPTR,A RL A MOV R2,A ;MOV R1,#23H ;MOVX A,@R1 MOV DPTR,#0FF23H MOVX A,@DPTR CPL A ANL A,#0FH JNZ LP0 INC R0 DJNZ R3,LP1 ;MOVX A,@R1 MOV DPTR,#0FF23H MOVX A,@DPTR JB ACC.4,XP33 MOV A,#19H SJMP XP3 XP33: MOV A,#20H XP3: CLR RS1 RET LP0: CPL A JB ACC.0,XP0 MOV A,#00H SJMP LPP XP0: JB ACC.1,XP1 MOV A,#08H SJMP LPP XP1: JB ACC.2,XP2 MOV A,#10H SJMP LPP XP2: JB ACC.3,XP33 MOV A,#18H LPP: ADD A,R0 CLR RS1 CJNE A,#10H,LX0 LX0: JNC XP35 MOV DPTR,#LS3 MOVC A,@A+DPTR

41

AMC-51 Advanced Microcontroller 8051 Trainer

XP35: RET LCK0: LCALL X2 JNC LCK1 LCALL X3 MOV R1,#7EH SJMP LCK0 LCK1: CJNE A,#16H,LCK0 MOV A,7AH SWAP A ORL A,79H MOV 22H,A location CJNE A,#60H,LCK2 LCK2: JNC EXIT MOV A,7CH SWAP A ORL A,7BH MOV 21H,A CJNE A,#60H,CLK3 CLK3: JNC EXIT MOV A,7EH SWAP A ORL A,7DH MOV 20H,A CJNE A,#24H,CLK4 CLK4: JNC EXIT RET EXIT: AJMP LCK0 END ; move data from 7ch memory location to accumulator ; exchange higher & lower bit data store in accumulator ; oring with data stored in 7bh & accumulator ; move data from accumulator to 21h memory location ;move data from 7eh memory location to accumulator ; exchange higher & lower bit data store in accumulator ; oring with data stored in 7dh & accumulator ; move data from accumulator to 20h memory location ; if hours are not equal to 24 then jump to clk4 loop

; move data from 7ah memory location to accumulator ; exchange higher & lower bit data store in accumulator ; ORing with data stored in 79h & accumulator ; move data from accumulator to 22h memory

PROCEDURE: 1) Switch ON power supply. 2) Open respective program SW07.asm in 8051simulation system Software. 3) write current value of hour , minute & second in program 3) Press compile and load tab in the software. We can see the process window in the software at the left bottom corner. 4) Now go to Debug (D) in 8051simulation system software and press Step Over F6 command for single step execution. 5) Press F6 for further single step execution and see the parallel effect on Data store memory window. In code memory you can see the stored data on respective memory location. For memory location please refer program or to

42

AMC-51 Advanced Microcontroller 8051 Trainer

press this tab direct execution. 6) Before check the content , you must stop the running program or Refresh the Data Store memory. OUTPUT: 7 segment display shows hour, minute & second .

EXPERIMENT NO-10 Impulse Count(Timing/Counter Experiment)

43

AMC-51 Advanced Microcontroller 8051 Trainer

OBJECTIVE: Count the impulse outside the timing 0 ,then send to display.

Experiment Steps Connect 8MHZ and T jack , connect T0 to T7 or single-impulse output hole one by one, run the program, to observe the number and speed of counter impulse in digital tube

OUTPUT: As a assignment for student. Program

ORG 0000H LJMP SE15 ORG 080H SE15: MOV SP,#53H MOV P2,#0FFH MOV A,#43H MOV DPTR,#0FF20H MOVX @DPTR,A pointed by DPTR MOV TMOD,#05H MOV TH0,#00H MOV TL0,#00H SETB TR0 LO29: MOV R2,TH0 MOV R3,TL0 LCALL ZOY0 MOV R0,#79H MOV A,R6 LCALL PTDS MOV A,R5 LCALL PTDS MOV A,R4 LCALL PTDS LCALL SSEE SJMP LO29 ZOY0: CLR A MOV R4,A MOV R5,A MOV R6,A MOV R7,#10H LO30: CLR C MOV A,R3

; ; ; ; ;

store 53h data in stack pointer initialize port2 move 43h data in accumulator move address ff20 in DPTR store data from accumulator to memory location

; select counter 0 ; initialize counter ; set counter ; move timer time data in r2 & r3 ; move 79 data in r0 reg. ; move data from r6 reg. to accumulator

; clear all accumulator ,r4,r5 & r6

44

AMC-51 Advanced Microcontroller 8051 Trainer

RLC A MOV R3,A MOV A,R2 RLC A MOV R2,A MOV A,R6 ADDC A,R6 DA A MOV R6,A MOV A,R5 ADDC A,R5 DA A MOV R5,A MOV A,R4 ADDC A,R4 DA A MOV R4,A DJNZ R7,LO30 RET PTDS: MOV R1,A CALL PTDS1 MOV A,R1 SWAP A PTDS1:ANL A,#0FH MOV @R0,A INC R0 RET SSEE: SETB RS1 MOV R5,#05H SSE2: MOV 30H,#20H MOV 31H,#7EH MOV R7,#06H SSE1: ;MOV R1,#21H MOV A,30H CPL A ;MOVX @R1,A MOV DPTR,#0FF21H MOVX @DPTR,A MOV R0,31H MOV A,@R0 MOV DPTR,#DDFF MOVC A,@A+DPTR ;MOV R1,#22H ;MOVX @R1,A MOV DPTR,#0FF22H MOVX @DPTR,A MOV A,30H RR A MOV 30H,A DEC 31H MOV A,#0FFH ;MOVX @R1,A MOV DPTR,#0FF22H MOVX @DPTR,A

; rotate left with carry content data of accumulator

45

AMC-51 Advanced Microcontroller 8051 Trainer

DJNZ R7,SSE1 DJNZ R5,SSE2 CLR RS1 RET DDFF: DB 0C0H,0F9H,0A4H,0B0H,99H,92H,82H,0F8H,80H,90H DB 88H,83H,0C6H,0A1H,86H,8EH,0FFH,0CH,89H,0DEH END

46

AMC-51 Advanced Microcontroller 8051 Trainer

Hardware Experiments

47

AMC-51 Advanced Microcontroller 8051 Trainer

Experiment 1 Light P1 Port Experiment

OBJECTIVE: To define port1 as output port using LED indication. CIRCUIT DISCRIPTION: P1 port is a bidirectional port. When 1s are written to port1 pins, the pins can be used as input pins. When 0s are written to port1 pins,port1act as output port. LEDs are connected to each pin of port1 in common anode configuration. LEDs are connected to port 1 pins through buffer IC 74LS245 transreceiver. As shown in circuit diagram 74LS245 consist of A0 to A7 as input port, B0 to B7 as output ports. By using pin, the input pins can be enable or disable. Dir pin used to select direction of data flow. Here Connect DIR pin to +5V to select A0 to A7 as input & B0 to B7 as output pins & connected to gnd to enable input pins. CIRCUIT DIAGRAM:

PROCEDURE: 1) Connections:a) Connect LED OUTPUT UNIT L1~L8( 8-pin connector) to DECODER SECTION 8-pin JP1 using 8 pin ribbon cable b) Switch ON power supply. 2) Run program:a) Open respective program LED.ASM in 8051 simulation system software. Press compile and load button in the software. Watch the save message window is displayed. Conform the path where the program supported file was stored and press the YES button.

b)

48

AMC-51 Advanced Microcontroller 8051 Trainer

c) If zero warning and zero error then Compilation and loading-OK message is displayed. d) Current module window is opened and program is loaded into the kit. Here you can debug the whole program step by step using debug tool set or you can press GO button execution. PROGRAM: //program to glow led in rotating pattern// ORG 0000H LJMP SE18 ORG 0790H SE18: MOV P1,#0FFH LO34: MOV A,#0FEH LO33: MOV P1,A LCALL SE19 RL A SJMP LO33 ORG 07A0H SE19: MOV R6,#0A0H LO36: MOV R7,#0FFH LO35: DJNZ R7,LO35 DJNZ R6,LO36 RET END Output: Press GO button to L8. and observe LEDs (L1 to L8) glows in specified manner from L1 ; for delay ; subroutine call for delay ; rotating left data stored in accumulator ; for continuous looping ; initialize port1 ; move data 0fe to the p1 for program execution. Use Stop button to stop the

Assignment:

49

AMC-51 Advanced Microcontroller 8051 Trainer

1.Try the same program by changing delay time. 2. do some changes in program to change rotating direction of led glowing .

50

AMC-51 Advanced Microcontroller 8051 Trainer

Experiment 2 P1 Port Turn Light Experiment

OBJECTIVE: T0 define port 1 as input port & output port CIRCUIT DISCRIPTION: P1.0 & P1.1 Pins of port1 configured as input pins & P1.4,P1.5, P1.6 & P1.7 pins are configured as output port. The input pins are connected to either GND or VCC through switches. The output pins are connected to LEDs through a buffer IC 74LS245. All LEDs are Connected in common anode configuration .When output pin is high , corresponding Led glows. CIRCUIT DIAGRAM:

PROCEDURE: 1) Connections:a) Connect SWITCH INPUT UNITK1 jack to DECODER SECTION-P1.1jack using patch cord. b) Connect SWITCH INPUT UNITK2 jack to DECODER SECTION-P1.0 jack using patch cord. c) Connect LED OUTPUT UNITL1 jack to DECODER SECTION-P1.4 jack using patch cord. d) Connect LED OUTPUT UNITL2 jack to DECODER SECTION-P1.5 jack using patch cord. e) Connect LED OUTPUT UNITL3 jack to DECODER SECTION-P1.6 jack using patch cord. f) Connect LED OUTPUT UNITL4 jack to DECODER SECTION-P1.7 jack using patch cord. g) Switch ON power supply.

51

AMC-51 Advanced Microcontroller 8051 Trainer

2) Run program:a) Open respective program 2switch.ASM in 8051 simulation system software. Press compile and load button in the software. We can see the save message window is displayed. Conform the path where the program supported file was stored and press the YES button. c) If zero warning and zero error then Compilation and loading-OK message is displayed. d) Current module window is opened and program is loaded into the kit. Here you can debug the whole program step by step using debug tool set or you can

b)

press GO button execution. PROGRAM:

for program execution. Use Stop button

to stop the

//program for p1 port to turn light// ORG 0000H LJMP PX00 ORG 0C30H PX00: MOV P1,#0FFH ; make port 1 high PX03: MOV A,P1 ; load data FFH to accumulator MOV B,A ; move data to b reg. ANL A,#03H ; define P1.0 & p1.1 as input & others as output CJNE A,#01H,PX01 ; when p1.0 is high , port 1.6 & p1.7 set ,or jump to Px01 JB 00H,PX04 ; jump if set bit 00h to pxo4 loop CLR P1.4 ; clear pi.4 bit CLR P1.5 ; clear p1.5 SETB P1.6 ; set bit p1.6 SETB P1.7 ; set bit p1.7 MOV R2,#20H ; move data 20h to r2 reg. LCALL DELY SETB 00H ; set bit 00h LJMP PX03 PX04: SETB P1.4 ; set bit of p1.4,p1.5,p1.6,p1.7 SETB P1.5 SETB P1.6 SETB P1.7 MOV R2,#20H LCALL DELY CLR 00H ; clear bit 00h AJMP PX03 PX01: CJNE A,#02H,PX02 ; if P1.1 is high,p1.4 &p1.5 are set or jump to px02 JB 01H,PX05 ; jump if 01h set to px05 loop SETB P1.4 ; set bit p1.4 SETB P1.5 ; set bit p1.5 CLR P1.6 ; clear bit p1.6 CLR P1.7 ; clear bit p1.7 MOV R2,#20H LCALL DELY SETB 01H LJMP PX03

52

AMC-51 Advanced Microcontroller 8051 Trainer

PX05: SETB P1.4 SETB P1.5 SETB P1.6 SETB P1.7 MOV R2,#20H LCALL DELY CLR 01H LJMP PX03 PX02: SETB P1.4 SETB P1.5 SETB P1.6 SETB P1.7 LJMP PX03 DELY: PUSH 02H DEL2: PUSH 02H DEL3: PUSH 02H DEL4: DJNZ R2,DEL4 POP 02H DJNZ R2,DEL3 POP 02H DJNZ R2,DEL2 POP 02H DJNZ R2,DELY RET END Output: -

; set bit p1.4,p1.5,p1.6,p1.7

; clear bit

; decrement data of r2 reg. jump if not zero to del3 loop

Press GO button and observe LED L1 and L2 glows when switch K1 is at high state. LED 3 and LED4 glows when switch K2 is at high state. All LEDs are OFF when both switch K1 and K2 are either at Low or at High. Assignment: write program by increasing output pins P1.2 & P1.3.

53

AMC-51 Advanced Microcontroller 8051 Trainer

Experiment 3 P3.3 Port Input, P1 Port Output

OBJECTIVE: By using one switch ,we can glow led in 16 condition of hex code manner(i.e.00000000 to 11111111). CIRCUIT DISCRIPTION: P3.3 pin of port 3 configured as input pin. This pin connected to VCC or GND through a switch. All pins of port1 configured as output ports. LEDs are connected to output port in a common mode configuration through buffer. CIRCUIT DIAGRAM:

PROCEDURE: 1) Connections:a) Connect SWITCH INPUT UNITK1 jack to DECODER SECTION-P3.3 jack using patch cord. b) Connect LED OUTPUT UNIT L1~L8( 8-pin connector) to DECODER SECTION 8-pin JP1 using 8 pin ribbon cable. Switch ON power supply. 2) Run program:a) Open respective program hex_out.ASM in 8051 simulation system software. Press compile and load button in the software. We can see the save message window is displayed. Conform the path where the program supported file was stored and press the YES button. c) If zero warning and zero error then Compilation and loading-OK message is displayed. d) Current module window is opened and program is loaded into the kit. Here you can debug the whole program step by step using debug tool set or you can

b)

54

AMC-51 Advanced Microcontroller 8051 Trainer

press GO button execution. PROGRAM:

for program execution. Use Stop button

to stop the

//program for using p3.3 as input port & p1 as output port // ORG 0000H LJMP J100 ORG 0100H J100: MOV A,#00H ; clear content of accumulator J101: JB P3.3,J101 ; jump if p3.3 is set MOV R2,#10H ; move data 10h to r2 reg. LCALL DELY JB P3.3,J101 J102: JNB P3.3,J102 ; jump if p3.3 is no bit MOV R2,#10H LCALL DELY JNB P3.3,J102 INC A ; data in accumulator incremented by 1 PUSH ACC CPL A ; complement data of accumulator MOV P1,A ; move data stored in accumulator in port 1 POP ACC AJMP J101 DELY: PUSH 02H ; for creating delay DEL2: PUSH 02H DEL3: PUSH 02H DEL4: DJNZ R2,DEL4 ; decrement & jump if not zero to DEL4 loop POP 02H DJNZ R2,DEL3 POP 02H DJNZ R2,DEL2 POP 02H DJNZ R2,DELY RET END

Output: Press GO button and observe all LEDs are at OFF position. When you toggle K1 (make K1switch low to high) then LED (L1 to L8) will Glows in 15 condition of hex code manner(i.e.00000000 to 11111111). ASSIGNMENT: 1.Modify program, to glow LED in a complement of hex code manner.

Experiment 4

55

AMC-51 Advanced Microcontroller 8051 Trainer

Industry Sequence Control

OBJECTIVE: To define the industry sequence control using interrupt CIRCUIT DISCRIPTION: Port1 configured as output port and port 3 configured as input port.P3.3 & P3.4 connected to VCC or GND through switch. LEDs are connected to port1 through buffer IC 74ls245. All LEDs are common anode configured. Buzzer connected to p1.7 pin through LM386. IC LM386 is a low voltage audio power amplifier. CIRCUIT DIAGRAM:

PROCEDURE: 1) Connections:a) Connect SWITCH INPUT UNITK1 jack to DECODER SECTION-P3.3 jack using patch cord. b) Connect SWITCH INPUT UNITK2 jack to DECODER SECTION-P3.4 jack using patch cord. c) Connect LED OUTPUT UNITL1 jack to DECODER SECTION-P1.0 jack using patch cord. d) Connect LED OUTPUT UNITL2 jack to DECODER SECTION-P1.1 jack using patch cord. e) Connect LED OUTPUT UNITL3 jack to DECODER SECTION-P1.2 jack using patch cord. f) Connect LED OUTPUT UNITL4 jack to DECODER SECTION-P1.3 jack using patch cord.

56

AMC-51 Advanced Microcontroller 8051 Trainer

Connect LED OUTPUT UNITL5 jack to DECODER SECTION-P1.4 jack using patch cord. h) Connect LED OUTPUT UNITL6 jack to DECODER SECTION-P1.5 jack using patch cord. i) Connect LED OUTPUT UNITL7 jack to DECODER SECTION-P1.6 jack using patch cord. j) Connect AUDIO AMPLIFIER UNITVIN jack to DECODER SECTION-P1.7 jack using patch cord. k) AUDIO AMPLIFIER UNIT Short 5V to ON position using shorting jumper link. l) Switch ON power supply.

g)

2)

a) b)

Run program:Open respective program control.ASM in 8051 simulation system software.

Press compile and load button in the software. We can see the save message window is displayed. Conform the path where the program supported file was stored and press the YES button. c) If zero warning and zero error then Compilation and loading-OK message is displayed. d) Current module window is opened and program is loaded into the kit. Here you can debug the whole program step by step using debug tool set or you can press GO button execution. for program execution. Use Stop button to stop the

c) When K1 toggle (external interrupt = high to low) then LED starts glowing from where they stopped. PROGRAM: //program for industry sequence control// ORG 0000H LJMP PO10 ORG 0013H LJMP PO16 ORG 0190H PO10: MOV P1,#7FH ; port 1 as output port ORL P3,#00H ; initialize port 3 PO11: JNB P3.4,PO11 ; jump if p3.4 not set bit ORL IE,#84H ; set EA & ET1 ORL IP,#04H ; set IP with data 04h MOV PSW,#00H ; clear PSW MOV SP,#53H ; store data 53h in stack PO12: MOV P1,#7EH ; move data 7eh to p1 ACALL PO1B MOV P1,#7DH ; load data 7dh to p1 ACALL PO1B MOV P1,#7BH ; load data 7bh to p1 ACALL PO1B MOV P1,#77H ; load data 77h to p1 ACALL PO1B MOV P1,#6FH ; load data 6fh to p1 ACALL PO1B

57

AMC-51 Advanced Microcontroller 8051 Trainer

MOV P1,#5FH ; load data 5fh to p1 ACALL PO1B MOV P1,#0FH ; load data 0fh to p1 ACALL PO1B SJMP PO12 PO16: MOV B,R2 ; move data stored in r2 to b erg PO17: MOV P1,#7FH ; load data 7fh to p1 MOV 20H,#0A0H ; move data 0A0h to memory loc. 20h PO18: SETB P1.7 ; set bit p1.7 ACALL PO1A CLR P1.7 ; clear p1.7 ACALL PO1A DJNZ 20H,PO18 ; decrement data of memory loc. 20h ,jump if not zero to p018 CLR P1.7 ; clear p1.7 ACALL PO1A JNB P3.3,PO17 ; jump if p3.3 not bit to p017 loop MOV R2,B ; move content of b reg. to r2 reg. RETI PO19: MOV R2,#10H ; move data 10h to r2 reg. ACALL DELY RET PO1A: MOV R2,#06H ; move data 06h to r2 reg. ACALL DELY RET PO1B: MOV R2,#30H ; move data 30h to r2 reg. ACALL DELY RET DELY: PUSH 02H DEL2: PUSH 02H DEL3: PUSH 02H DEL4: DJNZ R2,DEL4 POP 02H DJNZ R2,DEL3 POP 02H DJNZ R2,DEL2 POP 02H DJNZ R2,DELY RET END OUTPUT: a) Press GO button & observe all LEDs are at OFF position. When you toggle K2 (make K2switch low to high) then all LEDs (L1 to L7) will start glowing in specified manner. b) When K1 toggle (external interrupt = low to high) then LED stops glowing and system alerts using beep sound. ; to create delay time

58

AMC-51 Advanced Microcontroller 8051 Trainer

Experiment 5 8255A.B.C Port Output Square Wave

OBJECTIVE: To define use of 8255 programmable I/O interface chip. CIRCUIT DISCRIPTION: The 8255 is a widely used , programmable , parallel I/O device. 8255 has 24 I/O pins that can be grouped primarily in two 8 bit s of port C. The 8 bits of port c can be used as individual bits or be grouped in two 4 bit ports as C-upper & C-lower. The function of these ports are defined by writing a control word in control register. The control pins are /RD(read) /WR(write) RESET /CS,A0 & A1 : : : : to read data from selected I/O ports of 8255A Processor writes into selected I/O port or control register. It clears control register & sets all ports in input mode these are device select signals. /CS is connected to a decoded address & A0 & A1 are generally connected to MPU address line, address line.A0 & A1 respectively

CONTROL WORD :The content of control register ,called control word. Specify an I/O function for each port. This register can be accessed to write control word when A0 & A1 at logic 1.The register is not accessible for read operation. CIRCUIT DIAGRAM:

PROCEDURE: 1) Connections:a) Internal connections are done. So no connections are required. b) Switch ON power supply.

59

AMC-51 Advanced Microcontroller 8051 Trainer

2)

Run program:a) Open respective program 8255_sq.ASM in 8051 simulation system software. Press compile and load button in the software. We can see the save message window is displayed. Conform the path where the program supported file was stored and press the YES button. c) If zero warning and zero error then Compilation and loading-OK message is displayed. d) Current module window is opened and program is loaded into the kit. Here you can debug the whole program step by step using debug tool set or you can

b)

press GO button execution.

for program execution. Use Stop button

to stop the

PROGRAM: ORG 0000H LJMP SE09 ORG 0580H SE09: MOV DPTR,#0FF2BH ; SELECT CONTROL REGISTER ADDRESS MOV A,#80H ; ALL PORTS AS OUTPUT MOVX @DPTR,A ; LOAD VALUE TO CONTROL REGISTER MOV A,#55H ; STORE 55H DATA TO ACCUMULATOR LO15: MOV DPTR,#0FF28H ; SELECT PORTA ADDRESS MOVX @DPTR,A ; LOAD DATA FROM ACCUMULATOR TO PORT A INC DPTR ; SELECT PORTB ADDRESS MOVX @DPTR,A ; LOAD SAME DATA ON PORTB INC DPTR ; SELECT PORTC ADDRESS MOVX @DPTR,A ; LOAD SAME DATA ON PORTC MOV R2,#10H ; LOAD COUNT FOR CREATING DELAY LCALL DELY CPL A ; COMPLEMENT CONTENT OF ACCUMULATOR DATA SJMP LO15 ; J UMP TO LOOP ORG 05A0H DELY: PUSH 02H DEL2: PUSH 02H DEL3: PUSH 02H DEL4: DJNZ R2,DEL4 POP 02H DJNZ R2,DEL3 POP 02H DJNZ R2,DEL2 POP 02H DJNZ R2,DELY RET END OUTPUT: Press GO button & observe the Square wave at any port pin of 8255 UNIT on

60

; LOOP FOR DELAY

AMC-51 Advanced Microcontroller 8051 Trainer

the CRO..

Experiment 6 8255 PA Port Control PB Port

OBJECTIVE: To define port A of 8255 as input port & port B as output port CIRCUIT DISCRIPTION: The 8255 is a widely used , programmable , parallel I/O device8255 has 24 I/O pins that can be grouped primarily in two 8 bit s of port C. The 8 bits of port c can be used as individual bits or be grouped in two 4 bit ports as C-upper & C-lower. The function of these ports are defined by writing a control word in control register .The control pins are /RD(read) : to read data from selected I/O ports of 8255A /WR(write) ;microcontroller writes into selected I/O port or control register. RESET :It clears control register & sets all ports in input mode /CS,A0 & A1 :these are device select signals. /CS to a decoded is connected address & A0 & A1 are generally connected to MCU respectively. CONTROL WORD :The content of control register ,called control word . Specify an I/O function for each port .This register can be access data .Write control word when A0 & A1 at logic 1.The register is not accessible for read operation. In 8255 port A is input port connected to VCC or GND through switch .LEDs connected to output port B through buffer. All LEDs are common anode configured . For interfacing of 8255 hardware configuration is as shown in fig below. chip select pin used to select chip. CIRCUIT DIAGRAM::

PROCEDURE: 1) Connections: a) Connect LED OUTPUT UNIT-L1~L8 (8-pin connector) to 8255 UNIT 8-pin JX15 (port B) using 8 pin ribbon cable. (Note: - Make sure LSB or PX.0 of source connector should connect to LSB or 0th bit of destination Connector, where PX = any port). b) Connect SWITCH INPUT UNIT-K1~K8 (8-pin connector) to 8255 UNIT 8-pin JX9 (port A) using 8 pin ribbon cable. (Note: - Make sure LSB or PX.0 of source

61

AMC-51 Advanced Microcontroller 8051 Trainer

connector should connect to LSB or 0th bit of destination Connector, where PX = any port). c) Switch ON power supply. 2)

a) b)

Run program: Open respective program IO.ASM in 8051 simulation system software.

Press compile and load button in the software. We can see the save message window is displayed. Conform the path where the program supported file was stored and press the YES button. c) If zero warning and zero error then Compilation and loading-OK message is displayed. d) Current module window is opened and program is loaded into the kit. Here you can debug the whole program step by step using debug tool set or you can press GO button execution. for program execution. Use Stop button to stop the

PROGRAM: org 0000h LJMP SE17 ORG 0770H SE17: MOV DPTR,#0FF2BH ; SELECT CONTROL REG ADDRESS MOV A,#90H ; port A AS INPUT & PORT b AS OUTPUT MOVX @DPTR,A ; MOV DATA TO CONTROL REG. LO32: MOV DPTR,#0FF28H ; SELECT ADDRESS OF PORT A MOVX A,@DPTR ; MOV DATA FROM PORT A TO ACCUMULATOR INC DPTR ; SELECT PORT B MOVX @DPTR,A ; LOAD DATA FROM ACCUMULATOR TO PORT B SJMP LO32 END OUTPUT: Press GO button & observe as you toggle K1 to K8 switches the respective LEDs L1 to L8 are make either ON or OFF. When switch is high then respective LED is OFF and when switch is low then respective LED is ON.

62

AMC-51 Advanced Microcontroller 8051 Trainer

Experiment 7 8255 Control Traffic Light

OBJECTIVE: To define port1 to control of traffic light CIRCUIT DISCRIPTION: Traffic light controller interface module is designed to simulate the function of two way traffic light controller. Combinations of red, amber and green LEDs are provided to indicate Halt, Wait and Go signals for vehicles. Combination of red and green LEDs are provided for pedestrian crossing. 3 LEDs group are arranged in to control the traffic of East & West. LED L3& L7 (Red) are for the stop signal for the vehicles on the road W & E respectively. L1& L5 (Amber) indicates wait state for vehicles on the road W & E respectively. L2 & L6 (Green) are for left and right turn for the vehicles on road S. 2 red & 2 Green at both side are provided for pedestrian crossing. L2 &L6 (Green) when on allows pedestrians to cross and L7, L3 (Red) . 8255 is interfaced with 8051 in I/O mapped I/O and all ports are output ports. The basic operation of the interface is explained with the help of the enclosed program. At the beginning of the program all red LEDs are switch ON, and all other LEDs are switched OFF. Amber LED is switched ON before switching over to proceed state from Halt state. The sequence of traffic followed in the program is given below. . CIRCUIT DIAGRAM:

PROCEDURE: 1) Connections:a) Connect LED OUTPUT UNITL1 jack to 8255 UNIT-PA2 jack using patch cord. b) Connect LED OUTPUT UNITL2 jack to 8255 UNIT-PA1 jack using patch cord. c) Connect LED OUTPUT UNITL3 jack to 8255 UNIT-PA0 jack using patch cord. d) Connect LED OUTPUT UNITL5 jack to 8255 UNIT-PA5 jack using patch cord. e) Connect LED OUTPUT UNITL6 jack to 8255 UNIT-PA4 jack using patch cord. f) Connect LED OUTPUT UNITL7 jack to 8255 UNIT-PA3 jack using patch cord. g) Switch ON power supply.

63

AMC-51 Advanced Microcontroller 8051 Trainer

2)

a) b)

Run program:Open respective program traffic.ASM in 8051 simulation system software.

Press compile and load button in the software. We can see the save message window is displayed. Conform the path where the program supported file was stored and press the YES button. c) If zero warning and zero error then Compilation and loading-OK message is displayed. d) Current module window is opened and program is loaded into the kit. Here you can debug the whole program step by step using debug tool set or you can press GO button execution. PROGRAM: ORG 0000H LJMP JOD0 ORG 0BB0H JOD0: MOV SP,#60H MOV DPTR,#0FF2BH MOV A,#88H MOVX @DPTR,A MOV DPTR,#0FF28H MOV A,#0B6H MOVX @DPTR,A for program execution. Use Stop button to stop the

INC DPTR MOV A,#0DH MOVX @DPTR,A MOV R2,#25H ; STORE COUNT NO IN R2 TO CREAT DELAY LCALL DELY JOD3: MOV DPTR,#0FF28H ; SELECT PORTA ADDRESS MOV A,#75H ; LOAD 75H DATA TO PORT A MOVX @DPTR,A INC DPTR ; SELECT PORTB MOV A,#0DH ; LOAD 0DH DATA TO PORT B MOVX @DPTR,A MOV R2,#55H ; LOAD 55 TO R2 TO CREAT ANOTHER DELAY LCALL DELY ; CALL DELY MOV R7,#05H ; MOV 05H DATA TO R7 JOD1: MOV DPTR,#0FF28H ; LOAD F3H DATA ON PORT A MOV A,#0F3H MOVX @DPTR,A INC DPTR ; LOAD 0CH DATA ON PORT B MOV A,#0CH MOVX @DPTR,A MOV R2,#20H ; LOAD 20H TO R2 TO CREAT NEW DELAY LCALL DELY ; CALL DELAY MOV DPTR,#0FF28H ; LOAD F7H DATA TO PORT A

64

; SELECT CONTROL REGISTER ADDRESS ; SELECT ALL PORT AS OUTPUT ; LOAD DATA TO CONTROL REGISTER ; SELECT PORT A ADDRESS ; STORE B6H DATA TO ACCUMULATOR ; LOAD THIS ACCUMULATOR DATA TO PORTA ; SELECT PORT B ADDRESS ; LOAD 0dH DATA TO PORTB

AMC-51 Advanced Microcontroller 8051 Trainer

MOV A,#0F7H MOVX @DPTR,A INC DPTR ; LOAD 0DH DATA ON PORTB MOV A,#0DH MOVX @DPTR,A MOV R2,#20H LCALL DELY ; CALL DELAY DJNZ R7,JOD1 ; DECREMENT R7 & JUMP IF ZERO TO LOOP MOV DPTR,#0FF28H ; LOAD DATA 0AEH DATA TO PORT A MOV A,#0AEH MOVX @DPTR,A INC DPTR ; LOAD 0BH DATA TO PORT B MOV A,#0BH MOVX @DPTR,A MOV R2,#55H LCALL DELY ; CALL DELAY MOV R7,#05H ; LOAD 05H DATA TO R7 REG JOD2: MOV DPTR,#0FF28H ; LOAD 9EH DATA ON PORT A MOV A,#9EH MOVX @DPTR,A INC DPTR MOV A,#07H MOVX @DPTR,A ; LOAD 07H DATA TO ACCUMULATOR MOV R2,#20H LCALL DELY ; CALL DELAY MOV DPTR,#0FF28H MOV A,#0BEH ; LOAD 0BE ON PORT A MOVX @DPTR,A INC DPTR MOV A,#0FH ; LOAD 0FH DATA ON PORT B MOVX @DPTR,A MOV R2,#20H LCALL DELY ; CALL DALAY DJNZ R7,JOD2 LJMP JOD3 ORG 0C30H DELY: PUSH 02H DEL2: PUSH 02H DEL3: PUSH 02H DEL4: DJNZ R2,DEL4 POP 02H DJNZ R2,DEL3 POP 02H DJNZ R2,DEL2 POP 02H DJNZ R2,DELY RET END ; LOOP FOR DELAY

65

AMC-51 Advanced Microcontroller 8051 Trainer

OUTPUT: a) Output shows the demonstration of traffic light control signal. First right Red LED is ON and left Green LED is ON. After some time left Green is OFF, left Yellow start blinking. At this time right Red LED is ON. Left yellow blinking is stop then Left Red is ON, Right Red is OFF and Right Green is ON. Stages from 1 to 3 are repetitive process.

66

AMC-51 Advanced Microcontroller 8051 Trainer

Experiment 8 Simple I/O Expansion Experiment

OBJECTIVE: To study the simple I/O expansion method in microcontroller system. CIRCUIT DISCRIPTION: Decoder normally used to enable one of memory devices in system .I /o devices are connected to the microcontroller through decoders. The address of memory location or I /O device is sent out by controller.The relevant memory chip of I/O devices selected by decoder .The decoder 74ls138 has 3 enable pins G1,G2A & G2B. Chip enabled when G1 high and G2A ,G2B are low . A,B&C are select lines When A,B & C are 000,Y0 is selected . The address ,data and control bus lines from microcontroller need to be buffered to prepare them to be connected to many components in system. Further 8051 microcontroller multiplexes address , data & status signals on AD15 to AD0 andA19/S6A16/S3 lines. It outputs address in T1 state of bus cycle and changes to data & status during remaining period of bus cycle .address on address bus should be stable through out a memory or i/o access bus cycle to enable the memory or I/O devices for data transfer .Hence address & data must be demultiplexed . An octal latch has 8 D-latches and 8 tri state buffers. The 74LS173 octal latch has two control inputs Enable(G) & Output Control. The enable control is active high & is connected to CLK inputs of all 8 latches .Logic 1 in clock input will store logic level present at d inputs in respective latches .The output control signal is active low & is connected to control inputs of all 8 tri state buffers. Logic 0 will enable buffers to output data from respective latches. The ALE signal in TI state of a bus cycle .The ale signal enables three octal latches U3,U4 & U5 to capture 20 bit address & store it at its output .The latches provide stable A19 A0 bits of address of through out a bus cycle . It leaves A15 A0 lines for data bus action after TI state . The 8051 data transmit/receive DT/R and data enable signals to enable data bus buffering system for data bus action on AD15-AD0 lines . The signals enables two transreceivers74ls245.74ls245 provides buffered & separated data bus . The buffer 74ls244 buffers control signals , M/IO,WR,RD & DECODER74LS138 CIRCUIT DIAGRAM:

PROCEDURE:

67

AMC-51 Advanced Microcontroller 8051 Trainer

1) Connections:a) Connect I/O EXPANSION UNITCS1 jack to DECODER SECTION-8000H jack using patch cord. b) Connect I/O EXPANSION UNITCS2 jack to DECODER SECTION-9000H jack using patch cord. c) Connect LED OUTPUT UNIT L1~L8 8-pin connector to I/O EXPANSION UNIT Q0~Q7 8-pin connector using 8 pin ribbon cable. (Note: - Make sure LSB or PX.0 of source connector should connect to LSB or 0th bit of destination Connector, where PX = any port). D)Connect SWITCH INPUT UNIT K1~K8 8-pin connector to I/O EXPANSION UNIT Y0~Y7 8-pin connector using 8 pin ribbon cable. (Note: - Make sure LSB or PX.0 of source connector should connect to LSB or 0th bit of destination Connector, where PX = any port). E)Connect JX7 pin connector of I/O EXPANSION UNIT to JX0 pin connector of . DECODER SECTION F) Switch ON power supply. 2) Run program:a) Open respective program IO_EXP.ASM or in 8051 simulation system software. Press compile and load button in the software. We can see the save message window is displayed. Conform the path where the program supported file was stored and press the YES button. c) If zero warning and zero error then Compilation and loading-OK message is displayed. d) Current module window is opened and program is loaded into the kit. Here you can debug the whole program step by step using debug tool set or you can

b)

press GO button execution.

for program execution. Use Stop button

to stop the

PROGRAM: ORG 0000H LJMP GOD0 ORG 0B80H GOD0: MOV DPTR,#8000H MOVX A,@DPTR MOV DPTR,#9000H MOVX @DPTR,A SJMP GOD0 END OUTPUT:

; data from switch transfer to accumulator ; data from accumulator transferring to glow led ; jump to loop

Press GO button & observe as you toggle K1 to K8 switches the respective LEDs L1 to L8 are make either ON or OFF. When switch is high then respective LED is OFF and when switch is low then respective LED is ON.

68

AMC-51 Advanced Microcontroller 8051 Trainer

Experiment 9 Analog to Digital Conversion Experiment

OBJECTIVE: To study Analog to digital conversion using ADC 0809 IC with microcontroller. CIRCUIT DISCRIPTION: Most transducers and sensors such as temperature ,pressure ,velocity ,humidity are analog. Therefore 8051 used ADCs to convert analog signals in to digital. three Address pins A,B &C are grounded to select IN0 as input .A trimmer is connected between +5V and Gnd to provide variable dc VOLTAGE AS INPUT TO ADC , For 5V output is FF & for 0V output is 00 . ADC resolution is 8 bit . CLK IN is an input pin connected to an external clock source , an external clock is used for timing. To calculate data out use below formula Dout = Vin / Step Size for input voltage. of 2.56 volts ( Vref =1.28 volts) and step size of 10mv Dout =2560/10 =256 or FF that is full scale output. ADC808/809 Chip has 8 analog channel, this means this kind of chip allows to monitor 8 different transducers. ALE: Latch in the address Start : Start of conversion OE: output enable EOC: End of Conversion

69

AMC-51 Advanced Microcontroller 8051 Trainer

Channel IN0 IN1 IN2 IN3 IN4 IN5 IN6 IN7

CBA 000 001 010 011 100 101 110 111

CIRCUIT DIAGRAM:

PROCEDURE: 1) Connections: a) Connect Adjustable Voltage Unit VIN jack to IN-BUILD POWER +5V jack using patch cord. b) Connect Adjustable Voltage Unit VOUT jack to ADC0809 UNIT IN0 jack using patch cord. c) Connect ADC0809 UNIT WR jack to DECODER SECTION IOWR jack using patch cord. d) Connect ADC0809 UNIT RD jack to DECODER SECTION IORD jack using patch cord. e) Connect ADC0809 UNIT CLK jack to MONOPULSE AND CLOCK UNIT- 500K jack using patch cord. f) Connect ADC0809 UNIT CS4 jack to DECODER SECTION 8000H jack using patch cord.

70

AMC-51 Advanced Microcontroller 8051 Trainer