Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pasos de Ppap

Caricato da

JoseLuisMartinezGarciaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pasos de Ppap

Caricato da

JoseLuisMartinezGarciaCopyright:

Formati disponibili

Production Part Approval Process PPAP

Third Edition

SECTION I

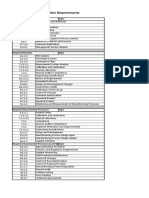

1.1 GENERAL 1.2 PPAP PROCESS REQUIREMENTS 1.2.1 Significant Production Run 1.2.2 PPAP Requirements 1.2.2.1 Design Records 1.2.2.2 Any authorized Engineering Change documents 1.2.2.3 Engineering Approval, when required 1.2.2.4 Design Failure Mode and Effects Analysis (Design FMEA), if the supplier is design responsible. 1.2.2.5 Process flow diagrams 1.2.2.6 Process Failure Mode and Effects Analysis (Process FMEA) 1.2.2.7 Dimensional results 1.2.2.8 Records of material / performance test results 1.2.2.8.1 Material Test Results 1.2.2.8.2 Performance Test Results 1.2.2.9 Initial Process Studies 1.2.2.9.1 General 1.2.2.9.2 Quality Indices 1.2.2.9.3 Acceptance Criteria For Initial Study 1.2.2.9.4 Unstable Processes 1.2.2.9.5 Processes With One-Specifications or Non-Normal Distributions 1.2.2.9.6 Strategy when Acceptance Criteria Are Not Satisfied 1.2.2.10 Measurement System Analysis Studies 1.2.2.11 Qualified Laboratory Documentation 1.2.2.12 Control Plan 1.2.2.13 Part Submission Warrant (PSW) 1.2.2.13.1 Part Weight (Mass) 1.2.2.14 Appearance Approval Report (AAR) 1.2.2.15 Bulk Material Requirements Checklist (applies only to bulk material PPAP) 1.2.2.16 Sample Production Parts 1.2.2.17 Master Sample 1.2.2.18 Checking Aids 1.2.2.19 Customer- Specific Requirements 1.3 CUSTOMER NOTIFICATION AND SUBMISSION REQUIREMENTS 1.3.1 1.3.2 Customer Notification Submission Customer

1.3.3 Situations Where Customer Notification is not Required 1.4 SUBMISSION TO CUSTOMER-LEVELS OF EVIDENCE 1.4.1 Submission Levels 1.4 PART SUBMISSION STATUS 1.5.1 General 1.5.2 Customer PPAP Status 1.5.2.1 Full Approval 1.5.2.2 Interim Approval 1.5.2.3 Rejected 1.5 RECORD RETENTION SECTION II II.1 DamilerChrysler Corpotation-Specific Instructions II.1.1 SUBMISSION LEVLES II.1.2 SUBBMISSION 11.1.3 CHECKING AIDS II.1.4 APPEARANCE APPROVAL REQUERIMENTS II.1.5 SUPPLIER REQUEST FOR PRODUCT CHANGE II.1.6 INTERIM APPROVAL II.1.6.1 INTERIM APPROVAL AUTHORIZATIONS II.1.7 DamilerChrysler Corporation Procurement and Supply Representative II.1.8 Third Party Laboratories II.2 Ford-Specific Instructions II.2.1 Part Approval Activity II.2.2 ES (Engineering Specification) II.2.3 Substance Use Restrictions II.2.4 Interim Approvals II.2.5 Control Plans II.2.6 Appearance Item Approvals II.2.7 Part Submission Level II.2.8 Manage the Change II.2.9 Family of Parts II2.10 Labeling Requirement II.2.11 Run at Rate II.2.12 Qualified Laboratory Documentation II.2.13 Supplier Request for Engineering Approval (SREA) II.3 General Motors Specific Instructions II.3.1 Applicability II.3.2 Requirements For Part Approval II.3.2.1 PSW Form (CFG-1001) (seeI.2.2.13) II.3.2.2. Appearance Approval Report ( see I.2.2.14) II.3.2.3 Sample Product (see I.2.2.16) II.3.2.4 Design Records (see I.2.2.1) II.3.2.5 Material, Performance and Durability test results (seeI.2.2.8) II.3.2.6 Control Plans (see I.2.2.12) II.3.2.7 Initial Process Study (see I2.2.9) II.3.3 Customer Notification of Supplier-Initiation Changes II.3.4 Situations Where Customer Notification is not Required II.3.5 Submission Levels (see I.4.1)

II.3.6 Part Submission Status II.3.7 Packaging and Labels II.4 Truck OEM-Specific Instructions PPAP PROCESS REQUERIMENTS II.4.1 Significant Production Run (see I.2.1) 11.4.2 Dimensional and test Results Clarification (see I.2.2.7 and I.2.2.8) II.4.3 Initial Process Studies General (see I.2.2.9) II.4.7 Part Submission Warrant

Appendices

Appendix A: Completion of the part Submission Warrant Part Submission Warrant Index Form Blank Form Appendix B: Completion of the Appearance Approval Report Appearance Approval Report Index Form Blank Form Appendix C: Dimensional Report Appendix D: Material Test Report Appendix E: Performance Test Report Appendix F: Bulk Material Specific Requirements Appendix G: Tire Industry Specific Requirements

Potrebbero piacerti anche

- Design & Process ReviewDocumento33 pagineDesign & Process ReviewFarm AgrobotNessuna valutazione finora

- How to Get Nigeria Passport in 40 StepsDocumento42 pagineHow to Get Nigeria Passport in 40 Stepsgynn100% (1)

- Insulation e BookDocumento48 pagineInsulation e BookAl7amdlellah100% (1)

- Water Cad Users GuideDocumento456 pagineWater Cad Users GuideGjorgji1234Nessuna valutazione finora

- John Deere Design, Process, and Assembly ReviewDocumento33 pagineJohn Deere Design, Process, and Assembly ReviewcucuNessuna valutazione finora

- PR 1051Documento28 paginePR 1051Arsalan AhmadNessuna valutazione finora

- Nondestructive Inspection Program RequirementsDocumento28 pagineNondestructive Inspection Program Requirements320338Nessuna valutazione finora

- UFGS 01 33 00 Submittal ProceduresDocumento36 pagineUFGS 01 33 00 Submittal Proceduresrhunter2010Nessuna valutazione finora

- Reinforced and Filled Poly (Phenylene Sulfide) (PPS) Injection Molding and Extrusion Materials Using ASTM MethodsDocumento6 pagineReinforced and Filled Poly (Phenylene Sulfide) (PPS) Injection Molding and Extrusion Materials Using ASTM MethodsJosé Miguel Palomino GarciaNessuna valutazione finora

- Ray Prasad, Surface Mount Technology (SMT) 2-Nd Edition (Технология поверхностного монтажа)Documento791 pagineRay Prasad, Surface Mount Technology (SMT) 2-Nd Edition (Технология поверхностного монтажа)Михаил100% (1)

- WBS For Exercise 4 Corporate Website DevelopmentDocumento6 pagineWBS For Exercise 4 Corporate Website Developmentyash shahNessuna valutazione finora

- MATRIXDocumento5 pagineMATRIXSerchecko JaureguiNessuna valutazione finora

- IHG Engineering Design Guidelines Nov 2015Documento238 pagineIHG Engineering Design Guidelines Nov 2015zueklate75% (8)

- Vdocuments - MX - cg4338 GM 1927 03 Supplier Quality Statement of RequirementsDocumento28 pagineVdocuments - MX - cg4338 GM 1927 03 Supplier Quality Statement of RequirementsRene Tapia100% (1)

- Low Voltage Power Distribution and Motor Control Center Technical SpecificationDocumento25 pagineLow Voltage Power Distribution and Motor Control Center Technical Specificationalstom100% (1)

- IATF 16949 DocumenDocumento1 paginaIATF 16949 Documenpunitg_2Nessuna valutazione finora

- Flyaudio in An 08 Is250 With Factory Nav InstructionsDocumento2 pagineFlyaudio in An 08 Is250 With Factory Nav InstructionsAndrewTalfordScottSr.Nessuna valutazione finora

- IATF 16949 Required Documentation For TransitionDocumento2 pagineIATF 16949 Required Documentation For TransitionAnkurNessuna valutazione finora

- Marcel Breuer: Hungarian-American Designer, Architect and Bauhaus PioneerDocumento8 pagineMarcel Breuer: Hungarian-American Designer, Architect and Bauhaus PioneerYosaphat Kiko Paramore DiggoryNessuna valutazione finora

- GTS, PTS & Technical Data Sheet of Pakaldul H.E.projectDocumento121 pagineGTS, PTS & Technical Data Sheet of Pakaldul H.E.projectSujeet Kumar50% (2)

- Pcbdesignguide 1Documento67 paginePcbdesignguide 1Beta-Ömega CircuitsNessuna valutazione finora

- Swilliams Lesson6Documento11 pagineSwilliams Lesson6api-276783092Nessuna valutazione finora

- OGP Work Breakdown Structure for Production Platform ProjectDocumento5 pagineOGP Work Breakdown Structure for Production Platform ProjectZak ArisNessuna valutazione finora

- Improving Product Reliability and Software Quality: Strategies, Tools, Process and ImplementationDa EverandImproving Product Reliability and Software Quality: Strategies, Tools, Process and ImplementationNessuna valutazione finora

- Apqp Stages AIAG-1Documento49 pagineApqp Stages AIAG-1Jose Antonio Santoyo RayaNessuna valutazione finora

- 19 - Part III - Section 4.0 - Scope of WorkDocumento100 pagine19 - Part III - Section 4.0 - Scope of Workابومحمد الكنانيNessuna valutazione finora

- FPC AsfDocumento24 pagineFPC AsfSherif YehiaNessuna valutazione finora

- Multivariable Predictive Control: Applications in IndustryDa EverandMultivariable Predictive Control: Applications in IndustryNessuna valutazione finora

- Lecture Notes in Airport Engineering PDFDocumento91 pagineLecture Notes in Airport Engineering PDFMaya RajNessuna valutazione finora

- ISO 9001 Cross Reference ChartDocumento21 pagineISO 9001 Cross Reference ChartAnkur Dhir100% (2)

- CSR Matrix (Example Only)Documento24 pagineCSR Matrix (Example Only)hmp90100% (1)

- Unit 8 Risk in The WorkplaceDocumento11 pagineUnit 8 Risk in The WorkplaceAnonymous WalvB8Nessuna valutazione finora

- Barcelona Traction Case DigestDocumento3 pagineBarcelona Traction Case DigestCheCheNessuna valutazione finora

- Aiag Ppap4Documento75 pagineAiag Ppap4tamtom75Nessuna valutazione finora

- Documented-ProcessesDocumento2 pagineDocumented-ProcessesnormalNessuna valutazione finora

- Petroleum Design Integrity ProcedureDocumento9 paginePetroleum Design Integrity ProcedurekattabommanNessuna valutazione finora

- Handbook of Quality Integrated Circuit ManufacturingDa EverandHandbook of Quality Integrated Circuit ManufacturingValutazione: 5 su 5 stelle5/5 (1)

- GRP Specification BY CKDocumento44 pagineGRP Specification BY CKchandana kumar100% (2)

- MODEL QUESTION PAPER OF HRM Open CourceDocumento2 pagineMODEL QUESTION PAPER OF HRM Open CourceTitus Clement100% (3)

- ANPQP 2.3 - Phase DiagramDocumento2 pagineANPQP 2.3 - Phase DiagramM80% (5)

- Final Mother DairyDocumento59 pagineFinal Mother DairyAnup Dcruz100% (4)

- Etag 002-1Documento75 pagineEtag 002-1DerRennerNessuna valutazione finora

- Garments A ZDocumento6 pagineGarments A ZZaman ParvezNessuna valutazione finora

- Revised Sow & GRDocumento5 pagineRevised Sow & GRkroskowickNessuna valutazione finora

- 2010.06.09 Microsoft Word - Mechanical Particular Spec V2Documento26 pagine2010.06.09 Microsoft Word - Mechanical Particular Spec V2samanNessuna valutazione finora

- High Level Project Statement of Requirement For Capex: (QN LNG)Documento11 pagineHigh Level Project Statement of Requirement For Capex: (QN LNG)Dở hơiNessuna valutazione finora

- Ufgs 01 33 16.00 10 Design Data (Design After Award)Documento58 pagineUfgs 01 33 16.00 10 Design Data (Design After Award)Sheryl BrionesNessuna valutazione finora

- Aptiv Customer Specific RequirementsDocumento41 pagineAptiv Customer Specific RequirementsHemant GuptaNessuna valutazione finora

- Ufgs 01 33 16.00 10Documento58 pagineUfgs 01 33 16.00 10jackcan501Nessuna valutazione finora

- CG4338 GM 1927 03 Supplier Quality Statement of Requirements Rev 19 0Documento30 pagineCG4338 GM 1927 03 Supplier Quality Statement of Requirements Rev 19 0masprast.devegaNessuna valutazione finora

- UFGS 01 33 16.00 10 متطلبات التصميمDocumento58 pagineUFGS 01 33 16.00 10 متطلبات التصميمahmed11 engyemenNessuna valutazione finora

- CSR Map ToolDocumento51 pagineCSR Map ToolSarah JohnsonNessuna valutazione finora

- ZF QD83-2018 - English-French - WebDocumento70 pagineZF QD83-2018 - English-French - WebBESNessuna valutazione finora

- Water Cad Users GuideDocumento440 pagineWater Cad Users GuideCak UlinNessuna valutazione finora

- Simulation of High Pressure Die CastingDocumento5 pagineSimulation of High Pressure Die CastingJonathan NgNessuna valutazione finora

- ISO 9001:2008 TO ISO 9001:2015 CROSS REFERENCE Chart 343874980Documento21 pagineISO 9001:2008 TO ISO 9001:2015 CROSS REFERENCE Chart 343874980ivanNessuna valutazione finora

- Pro V10 IrricadHelp ManualDocumento964 paginePro V10 IrricadHelp ManualNzar HamaNessuna valutazione finora

- Saep 325Documento43 pagineSaep 325AbdullahNessuna valutazione finora

- Tsec ManualDocumento88 pagineTsec Manualmba213Nessuna valutazione finora

- Kevin Potter (Auth.) - Resin Transfer Moulding-Springer Netherlands (1997)Documento259 pagineKevin Potter (Auth.) - Resin Transfer Moulding-Springer Netherlands (1997)TEKİN ÖRNEKNessuna valutazione finora

- Etq 114Documento12 pagineEtq 114Alex Acosta100% (1)

- Requirements For Preparing and Implement 22MDZD v2 1Documento10 pagineRequirements For Preparing and Implement 22MDZD v2 1MohamedNessuna valutazione finora

- CP5062 Project Reports GuidelinesDocumento5 pagineCP5062 Project Reports GuidelinesNoel KristianNessuna valutazione finora

- Part - I Instruction To Tenderers and 1.1Documento19 paginePart - I Instruction To Tenderers and 1.1Hemanth KumarNessuna valutazione finora

- Sabp G 010Documento8 pagineSabp G 010Eagle SpiritNessuna valutazione finora

- QMS 1004255revlDocumento23 pagineQMS 1004255revlmarco chavezNessuna valutazione finora

- Tata Steel en 15804 Verified EPD ProgrammeDocumento16 pagineTata Steel en 15804 Verified EPD Programmeashutosh mishraNessuna valutazione finora

- Chapter 1Documento3 pagineChapter 1Sameer KapoorNessuna valutazione finora

- 09 2 PDFDocumento10 pagine09 2 PDFMurli RavishankarNessuna valutazione finora

- Philips Lighting Annual ReportDocumento158 paginePhilips Lighting Annual ReportOctavian Andrei NanciuNessuna valutazione finora

- Money and Financial InstitutionsDocumento26 pagineMoney and Financial InstitutionsSorgot Ilie-Liviu100% (1)

- bq76pl455 RegistersDocumento132 paginebq76pl455 RegistersAhmet KARANessuna valutazione finora

- Opening Up The Prescriptive Authority PipelineDocumento10 pagineOpening Up The Prescriptive Authority PipelineJohn GavazziNessuna valutazione finora

- 2021 A Review of Image Based Pavement Crack Detection AlgorithmsDocumento7 pagine2021 A Review of Image Based Pavement Crack Detection Algorithmsgandhara11Nessuna valutazione finora

- Klasifikasi Industri Perusahaan TercatatDocumento39 pagineKlasifikasi Industri Perusahaan TercatatFz FuadiNessuna valutazione finora

- Guidelines For Planning Conjunctive Use of SUR Face and Ground Waters in Irrigation ProjectsDocumento34 pagineGuidelines For Planning Conjunctive Use of SUR Face and Ground Waters in Irrigation Projectshram_phdNessuna valutazione finora

- Sonydsp v77 SM 479622 PDFDocumento41 pagineSonydsp v77 SM 479622 PDFmorvetrNessuna valutazione finora

- CS547Documento11 pagineCS547Usman Suleman AhmadNessuna valutazione finora

- Leader in CSR 2020: A Case Study of Infosys LTDDocumento19 pagineLeader in CSR 2020: A Case Study of Infosys LTDDr.Rashmi GuptaNessuna valutazione finora

- Education, A Vital Principle For Digital Library Development in IranDocumento23 pagineEducation, A Vital Principle For Digital Library Development in Iranrasuli9Nessuna valutazione finora

- Is 4032 - 1985Documento45 pagineIs 4032 - 1985yogeshbadyalNessuna valutazione finora

- COA Full Syllabus-CSEDocumento3 pagineCOA Full Syllabus-CSEAMARTYA KUMARNessuna valutazione finora

- Philippine Supreme Court Acquits Man of Estafa Due to Lack of KnowledgeDocumento2 paginePhilippine Supreme Court Acquits Man of Estafa Due to Lack of KnowledgeUrsulaine Grace FelicianoNessuna valutazione finora

- Cough: by Dr. Meghana Patil (Intern Batch 2016)Documento24 pagineCough: by Dr. Meghana Patil (Intern Batch 2016)Meghana PatilNessuna valutazione finora

- Direct FileActDocumento17 pagineDirect FileActTAPAN TALUKDARNessuna valutazione finora

- Stock Futures Are Flat in Overnight Trading After A Losing WeekDocumento2 pagineStock Futures Are Flat in Overnight Trading After A Losing WeekVina Rahma AuliyaNessuna valutazione finora

- Essential earthquake preparedness stepsDocumento6 pagineEssential earthquake preparedness stepsRalphNacisNessuna valutazione finora

- Patient Safety IngDocumento6 paginePatient Safety IngUlfani DewiNessuna valutazione finora