Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Qap For Transient Heater Rev (1) .0

Caricato da

maniyar_sajeed123Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Qap For Transient Heater Rev (1) .0

Caricato da

maniyar_sajeed123Copyright:

Formati disponibili

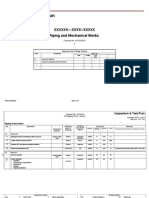

Quality Assurance Plan

1.0 JOB SPECIFIC DATA TRANSIENT HEATER Non IBR W0082101001 Thyssenkrupp Industries India Pvt. Ltd. Red Sugar , Russia : Centrifugal spares KA-3715-3/0 Thyssenkrupp Industries India Pvt. Ltd. 2500004140 Dt. 13/06/2011 EPE/2K10/008 -01,02,03,04

Name Of Equipment Drawing Number Client Project Part No. Inspection Agency Owners P.O.Number W.O. Number 2.0 ABBREVIATIONS

DESIGN PQR DP QA CAS WPQ WPS WI

Design Department Procedure Qualification Record Penetrant Testing Quality Control Department Company Acceptance Standard Welders Performance Qualification Welding Procedure Specification Work Instruction

3.0

INSPECTION POINTS

INSPECTION POINTS ARE INDICATED BY

H Hold Point W Witness

Point Point

R Review

H under control by column indicates authorized inspectors hold point This means the job cannot proceed further unless cleared by authorized Inspector. W under control by column indicates that authorized inspector shall be notified and he may exercise his option to witness and verify a specific operation. further operation shall proceed where the authorized inspector does not validate his option. R under control by column indicates that only documents will be submitted to authorized inspector for review.

0 Rev No

20/06/11 Date

NSP Prepared By

SP Checked & Accepted By

Approved By

Remarks

1 of 3

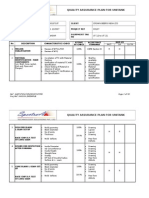

Quality Assurance Plan

2.0

Sr N o

QUALITY STAGES AND INSPECTION

DESCRIPTION CHARACTERISTI C CHECK METHOD Review 100% Design Parameters requirements Review 100% Manufacturer / Mill certificate Review Measurements Specification EXTEN T ACCEPTANCE STANDARD CHEC K BY CONTROL BY Q A QA H INSP AGENC Y R

Review of QAP Indication of Hold, Review, & Witness Points Review and approval of detailed drawing

Scope

Technical Specification & Contract

Design

Material Chemical & Identification (plates, Physical tubes, pipes, flanges) Properties Dimensions

100%

Drawing/Std./ material specification Drawing

QA

Tube Sheet

4 Dimensions Hole Size No. Of Holes Pitch Straightness Measurements Scale Drawing 100% Standard QA H R

Flange-Pipe Assembly

5 Weld set up Groove Angle Root Gap Root Face Weld size , visual inspection Measurement Measurement Visual 100% 100% Drawing QA H R

Welding of above

Drawing

QA

Casing

7 Dimensions Weld set-up of Casing Nozzles to Casing weld set up Welding of above Size Bevel Angle Root Gap Root Face Bevel Angle Root Gap Root Face Weld size , visual inspection Measurement Measurements Scale Measurements Scale Measurement Visual 100% Drawing 100% Standard Drawing 100% Standard Drawing QA H R

QA

100%

QA

1 0

Drawing

QA

0 Rev

20/06/11 Date

NSP Prepared By

SP Checked &

Approved By

Remarks

2 of 3

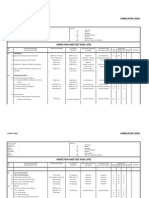

Quality Assurance Plan

No Accepted By

Sr N o

DESCRIPTION CHARACTERIS TIC

CHECK METHOD EXTEN T

ACCEPTANCE STANDARD

CHECK BY

CONTROL BY Q A INSP AGENCY R R

Tube to Tube sheet Assembly

11 12 Tube to Tube Sheet Set up Tube to Tube Sheet Dimensions Expansion Measureme nts Measureme nts Gauge Visual Visual Visual 100% 100% Drawing Drawing QA QA H H

Final Assembly

13 14 15 Hydro test Shot Blasting Painting Welding leakages Surface roughness Surface Finish 100% 100% 100 % Drawing Drawing As per Standard Method QA QA QA H H H R/W R R

0 Rev No

20/06/11 Date

NSP Prepared By

SP Checked & Accepted By

Approved By

Remarks

3 of 3

Potrebbero piacerti anche

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDa Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideValutazione: 3.5 su 5 stelle3.5/5 (7)

- Diagrama Electronico EGED 285Documento2 pagineDiagrama Electronico EGED 285Carlos Juarez Chunga100% (1)

- 1849 1862 Statutes at Large 601-779Documento200 pagine1849 1862 Statutes at Large 601-779ncwazzyNessuna valutazione finora

- ITP For Piping SystemsDocumento6 pagineITP For Piping SystemsP SHANKAR BABU100% (16)

- QA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)Documento10 pagineQA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)miaicarba100% (2)

- ITP ValveDocumento5 pagineITP ValveJayaram MV100% (3)

- ITP For Boiler ErectionDocumento6 pagineITP For Boiler ErectionUmair Awan100% (2)

- Inspection Test Plan - Piping FabricationDocumento5 pagineInspection Test Plan - Piping Fabricationhassan_ndt80% (5)

- Tank Erection Itp & Org ChartDocumento34 pagineTank Erection Itp & Org Charthasan_676489616100% (2)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Da EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Valutazione: 3.5 su 5 stelle3.5/5 (3)

- Pharmacology NCLEX QuestionsDocumento128 paginePharmacology NCLEX QuestionsChristine Williams100% (2)

- Well Testing Project Management: Onshore and Offshore OperationsDa EverandWell Testing Project Management: Onshore and Offshore OperationsNessuna valutazione finora

- Samples ITPDocumento4 pagineSamples ITPHassan SajidNessuna valutazione finora

- Inspection and Test Plan (KDBK)Documento5 pagineInspection and Test Plan (KDBK)Abdul Wadood Gharsheen100% (1)

- Reference MQPDocumento12 pagineReference MQPuday narayan singhNessuna valutazione finora

- ITP-001 Steelwork Fabrication Rev ADocumento5 pagineITP-001 Steelwork Fabrication Rev AMarcus Cox100% (2)

- Inspection Test Plan For Fabrication & Erection 2016Documento14 pagineInspection Test Plan For Fabrication & Erection 2016Boj Mingi0% (1)

- Sample ItpDocumento4 pagineSample ItpWijayanto BekasiNessuna valutazione finora

- Itp-Shop Fabricated PipingDocumento4 pagineItp-Shop Fabricated PipingkamlNessuna valutazione finora

- Siemens: 1200 MW DGEN Mega Power ProjectDocumento4 pagineSiemens: 1200 MW DGEN Mega Power ProjectJuzer MadarwalaNessuna valutazione finora

- Itp VesselDocumento4 pagineItp VesselHakim BaihaqiNessuna valutazione finora

- Muster List: Vessel: M/T "Stena President" Call Sign: ZCDR6 Master: YURIY YASHINDocumento9 pagineMuster List: Vessel: M/T "Stena President" Call Sign: ZCDR6 Master: YURIY YASHINwwaallNessuna valutazione finora

- KBR Inspection Test Plan For Bus Duct: NO. Inspection Activity 1 Pre-Inspection Meeting 2 Documentation ReviewDocumento2 pagineKBR Inspection Test Plan For Bus Duct: NO. Inspection Activity 1 Pre-Inspection Meeting 2 Documentation ReviewkamlNessuna valutazione finora

- ITP-000 Piping Fabrication (Exemple)Documento5 pagineITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- Quality Assurance PlanDocumento6 pagineQuality Assurance Planvkrishnamoorthy100% (2)

- E-Payment (Telecom Operatoers)Documento12 pagineE-Payment (Telecom Operatoers)Ahmed SelimNessuna valutazione finora

- Quality Assurance Plan For Unitank:: QAP/AAV/MFG/00107/UT Crown Beers India LTD: AAVI-GA-003, R0, 210507 00107Documento10 pagineQuality Assurance Plan For Unitank:: QAP/AAV/MFG/00107/UT Crown Beers India LTD: AAVI-GA-003, R0, 210507 00107Narayana Mugalur100% (1)

- Inspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Documento7 pagineInspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Akhilesh KumarNessuna valutazione finora

- Sample Itp For VesselDocumento10 pagineSample Itp For VesselWijayanto BekasiNessuna valutazione finora

- Standard Inspection and Test Plan For API6D Valves PDFDocumento4 pagineStandard Inspection and Test Plan For API6D Valves PDFWaqas JawaidNessuna valutazione finora

- ITP For Piping WorksDocumento3 pagineITP For Piping WorksOrlando1949100% (3)

- Pocket Guide to Preventing Process Plant Materials Mix-upsDa EverandPocket Guide to Preventing Process Plant Materials Mix-upsNessuna valutazione finora

- Sample ITP BoilerDocumento6 pagineSample ITP Boilerintolscrib100% (1)

- KBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3Documento4 pagineKBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3kamlNessuna valutazione finora

- Validating Chromatographic Methods: A Practical GuideDa EverandValidating Chromatographic Methods: A Practical GuideNessuna valutazione finora

- Marketing Research ProjectDocumento37 pagineMarketing Research ProjectVijay100% (15)

- QAPDocumento31 pagineQAPlohitha100% (1)

- FInal QAP HDPE WeldingDocumento2 pagineFInal QAP HDPE Weldingkannagi198Nessuna valutazione finora

- APV STD Insp & Test Plan API6D ValvesDocumento4 pagineAPV STD Insp & Test Plan API6D ValvesdbmingoNessuna valutazione finora

- Pipeline Integrity: Management and Risk EvaluationDa EverandPipeline Integrity: Management and Risk EvaluationValutazione: 4.5 su 5 stelle4.5/5 (6)

- 011 Itp Culvert Works 1Documento3 pagine011 Itp Culvert Works 1MikiRoniWijayaNessuna valutazione finora

- Manual de Partes Dm45-50-lDocumento690 pagineManual de Partes Dm45-50-lklausNessuna valutazione finora

- Cracking the Case of ISO 9001:2015 for Service: A Simple Guide to Implementing Quality Management in Service OrganizationsDa EverandCracking the Case of ISO 9001:2015 for Service: A Simple Guide to Implementing Quality Management in Service OrganizationsNessuna valutazione finora

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksDocumento4 pagineRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksAjoy Prasad75% (4)

- Itp Non AsmeDocumento7 pagineItp Non AsmeAkhilesh Kumar100% (1)

- Pp4 CM Ir 1004 001 - Rev. A - Itp For PipingDocumento7 paginePp4 CM Ir 1004 001 - Rev. A - Itp For PipingHungManhNessuna valutazione finora

- Maturity AssessmentDocumento228 pagineMaturity AssessmentAli ZafarNessuna valutazione finora

- ITP Format For New PVDocumento8 pagineITP Format For New PVDavid LambertNessuna valutazione finora

- Visual Check List For Control Valve: Rock Payvand Sanat ArvandDocumento1 paginaVisual Check List For Control Valve: Rock Payvand Sanat Arvandarmin heidariNessuna valutazione finora

- Inspection Test Plan Equipment - AFC Header Plug Seal Weld 1Documento4 pagineInspection Test Plan Equipment - AFC Header Plug Seal Weld 1Mohd Shafuaaz KassimNessuna valutazione finora

- Inspection Test Plan: 07 Station BOP Controlm UnitDocumento2 pagineInspection Test Plan: 07 Station BOP Controlm Unitaboo2uNessuna valutazione finora

- Prabha Steel Industries Inspection & Test PlanDocumento2 paginePrabha Steel Industries Inspection & Test PlansesabcdNessuna valutazione finora

- QIPDocumento9 pagineQIPzahid_497Nessuna valutazione finora

- Revision History: Inspection and Test PlanDocumento4 pagineRevision History: Inspection and Test PlanHmilkNessuna valutazione finora

- QAP For Conical StrainerDocumento2 pagineQAP For Conical StrainersatishchidrewarNessuna valutazione finora

- 102-V-5 QipDocumento8 pagine102-V-5 QipSaleemSahabNessuna valutazione finora

- Inspection and Test Plan For Cable Tray, Trunking & AccessoriesDocumento1 paginaInspection and Test Plan For Cable Tray, Trunking & AccessoriesVelaga SumanthNessuna valutazione finora

- Annex BDocumento14 pagineAnnex BPercy Junior Berrios Muñoz100% (1)

- Kaysafe ITPDocumento2 pagineKaysafe ITPSteve NewmanNessuna valutazione finora

- R05323 P 001a X009 0042 PDFDocumento464 pagineR05323 P 001a X009 0042 PDFcquibajoNessuna valutazione finora

- Example ITPDocumento1 paginaExample ITPPaulSwinbankNessuna valutazione finora

- Asme Utf ReportDocumento2 pagineAsme Utf ReportMHORN727Nessuna valutazione finora

- Wiley Practitioner's Guide to GAAS 2016: Covering all SASs, SSAEs, SSARSs, PCAOB Auditing Standards, and InterpretationsDa EverandWiley Practitioner's Guide to GAAS 2016: Covering all SASs, SSAEs, SSARSs, PCAOB Auditing Standards, and InterpretationsNessuna valutazione finora

- Practical Attribute and Variable Measurement Systems Analysis (MSA): A Guide for Conducting Gage R&R Studies and Test Method ValidationsDa EverandPractical Attribute and Variable Measurement Systems Analysis (MSA): A Guide for Conducting Gage R&R Studies and Test Method ValidationsNessuna valutazione finora

- Wiley Practitioner's Guide to GAAS 2017: Covering all SASs, SSAEs, SSARSs, and InterpretationsDa EverandWiley Practitioner's Guide to GAAS 2017: Covering all SASs, SSAEs, SSARSs, and InterpretationsNessuna valutazione finora

- Wiley Practitioner's Guide to GAAS 2012: Covering all SASs, SSAEs, SSARSs, and InterpretationsDa EverandWiley Practitioner's Guide to GAAS 2012: Covering all SASs, SSAEs, SSARSs, and InterpretationsNessuna valutazione finora

- Industrial Pipe FittingsDocumento15 pagineIndustrial Pipe FittingsHendri Arief SetyawanNessuna valutazione finora

- Bill No.2Documento2 pagineBill No.2maniyar_sajeed123Nessuna valutazione finora

- Fill in The Applications As Per The Sample Guidelines 2. Fill in The Details in Yellow Strip Only 3. Incomplete Applications Will Not Be ConsideredDocumento40 pagineFill in The Applications As Per The Sample Guidelines 2. Fill in The Details in Yellow Strip Only 3. Incomplete Applications Will Not Be Consideredmaniyar_sajeed123Nessuna valutazione finora

- CompanyDocumento1 paginaCompanymaniyar_sajeed123Nessuna valutazione finora

- Assignment of Killamsetty Rasmita Scam 1992Documento8 pagineAssignment of Killamsetty Rasmita Scam 1992rkillamsettyNessuna valutazione finora

- The Application of A Continuous Strip of Woven Material To A Body PartDocumento15 pagineThe Application of A Continuous Strip of Woven Material To A Body Partczeremar chanNessuna valutazione finora

- Software Test ISO StandardsDocumento2 pagineSoftware Test ISO StandardsTony DavisNessuna valutazione finora

- Aquamaster 3 Flow Measurement: Saving Every Drop of Energy and Cost Naturally!Documento7 pagineAquamaster 3 Flow Measurement: Saving Every Drop of Energy and Cost Naturally!FIRMANSYAHNessuna valutazione finora

- Objectives in DraftingDocumento1 paginaObjectives in Draftingshannejanoras03Nessuna valutazione finora

- Feasibility QuestionnaireDocumento1 paginaFeasibility QuestionnaireIvy Rose Torres100% (1)

- 7a.simple InterestDocumento50 pagine7a.simple InterestJanani MaranNessuna valutazione finora

- Ruggedbackbone Rx1500 Rx1501Documento13 pagineRuggedbackbone Rx1500 Rx1501esilva2021Nessuna valutazione finora

- Analisa SWOT Manajemen Pendidikan Di SMK Maarif 1 KebumenDocumento29 pagineAnalisa SWOT Manajemen Pendidikan Di SMK Maarif 1 Kebumenahmad prayogaNessuna valutazione finora

- Table of Contents - YmodDocumento4 pagineTable of Contents - YmodDr.Prakher SainiNessuna valutazione finora

- Ca50c584 MAYTAGE00011 1 2Documento2 pagineCa50c584 MAYTAGE00011 1 2Michael MartinNessuna valutazione finora

- Expanded Breastfeeding ActDocumento9 pagineExpanded Breastfeeding ActJohn Michael CamposNessuna valutazione finora

- TrustworthinessDocumento24 pagineTrustworthinessJamsheed Raza100% (1)

- 1.2 Server Operating SystemDocumento20 pagine1.2 Server Operating SystemAzhar AhmadNessuna valutazione finora

- Solution Problem 1 Problems Handouts MicroDocumento25 pagineSolution Problem 1 Problems Handouts MicrokokokoNessuna valutazione finora

- WCN SyllabusDocumento3 pagineWCN SyllabusSeshendra KumarNessuna valutazione finora

- Copyright IP Law Infringment of CopyrightDocumento45 pagineCopyright IP Law Infringment of Copyrightshree2485Nessuna valutazione finora

- Define Constitution. What Is The Importance of Constitution in A State?Documento2 pagineDefine Constitution. What Is The Importance of Constitution in A State?Carmela AlfonsoNessuna valutazione finora

- C.F.A.S. Hba1C: English System InformationDocumento2 pagineC.F.A.S. Hba1C: English System InformationtechlabNessuna valutazione finora

- Level of Life Skills Dev 5Documento59 pagineLevel of Life Skills Dev 5MJ BotorNessuna valutazione finora

- Wind Flow ProfileDocumento5 pagineWind Flow ProfileAhamed HussanNessuna valutazione finora

- Public Instructions For Death CorrectionsDocumento4 paginePublic Instructions For Death CorrectionsMukuru TechnologiesNessuna valutazione finora