Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MD Eng 340

Caricato da

MaqsoodDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MD Eng 340

Caricato da

MaqsoodCopyright:

Formati disponibili

Fermilab

Particle Physics Division Mechanical Department Engineering Note

Number: MD-ENG- 340 Date: April 29, 2011

Project Internal Reference: Project: SCDMS Title: The new design of the monorail for the Drift C3 area of the Ladder Lab @ Snolab Author(s): Edward Chi Reviewer(s): Key Words: Super CDMS, Monorail, Hoist, Lifting, Hook, Adapter, Slot, Alignment, Angular, Cavern, Beam, Connector, Ceiling.

Abstract Summary: The new version of the monorail design will retrofit the existing 12 ton lifting hitches of the Ladder Lab @ Snolab; the new connecting adapters will align the monorail in lateral, vertical and angular direction, and will also create the maximum lifting distance under the hoist hook.

Applicable Codes: Allowable Stress Design, AISC, 9th edition Below-the-Hook Lifting Devices, ASME B30.20 #5022, ES&H Manual, FermiLab.

1

The Main function of the Monorail:

As a guide device for the crane hoist, the crane hoist with the lifting object moves in the axial direction of the monorail. As a structural support device for the lifting hoist and the lifting objects within its lifting specifications per applicable industrial codes.

The main feature & specification of the Monorail:

Retrofits with the existing 12 ton ceiling lifting hitches. To connect different hitches by the alignment in lateral, vertical and angular dir. through the special design features of the Monorail. 3 ton (metric) lifting capacity, 241 under the hook in vertical lifting distance, 39 ft axial rail travel distance.

2

Main features of the new Monorail design

Angular alignment

Ladder Lab Drift C3 ceiling Crane axial movement

Lateral alignment

Vertical alignment

Angular alignment: +/_ 13 deg., see page 11 Lateral alignment: 24, see page 12 Vertical alignment: See page 10 & page 13. Crane hoist movement: 39 ft, see pages 14 & 15. Under hook net height: 241, see page 15.

Ladder Lab Floor and Headroom Area

The views of the experimental area

12 ton lifting hitch

The views of tunnel ceiling, the configuration of the 12 Ton Lifting Hitch

The view of the existing 12 Ton Lifting Hitch mounted on the ceiling (per dwg. #99-071-E-02649)

The view of the existing 4 Dywidag Threadbar From the tunnel ceiling (after removed the existing mtg. bracket and the 12 Ton anchor shackle

1.25 x 7 UNC, 4.5 lg. bolt (1)

Install both Adapter brackets with the Lifting Hitch

- 10, UNC, 4 lg. bolts (2) Lifting Hitch with Adapter bracket 1 only

Lifting Hitch with both Adapter brackets installed

Adapter bracket #2 (~ 23 lbs)

Adding shims for leveling if its necessary

Install the angular adjust connector underneath of the two adapter brackets (63 lbs).

10

Angular adjustability ~ +/_ 13 deg.

T-slots beam connector (28 x 17 x 2.25) (279 lbs)

11

Ceiling

Install the I-Beam with the new version of mounting Adapter.

View from the bottom of the Adapter bracket

Adjustability along the T-slots (beam lateral direction)

W12 x 65 I-Beam, 156 (13) length, Mounted on the new ceiling bracket.

12

Adding shims between slot connector & the top surface of the beam for vertical (Y dir.) adjustment if its required.

13

The adjustable value in beam lateral direction of the current design

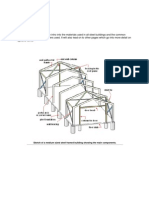

Ceiling w/4 threadbars End Beam Middle Beam

Ceiling w/4 threadbars Ceiling w/4 threadbars

Central Middle Beam Beam Connector End Beam

End Beam

Keep as a flat surface for hoist trolley moves smoothly and easily.

DEMAG Rope Hoist (3 ton)

14

Overall view of the Monorail with some dimensions

15

More view from Drift C3 area with some facilities & utilities.

16

Potrebbero piacerti anche

- Minimum Horizontal Loads For BalustradesDocumento1 paginaMinimum Horizontal Loads For Balustradessbandara77Nessuna valutazione finora

- Article - Structural BoltsDocumento6 pagineArticle - Structural Boltsing_weroNessuna valutazione finora

- CANAL VIEW - Wind Load (BS6399-2)Documento3 pagineCANAL VIEW - Wind Load (BS6399-2)MaqsoodNessuna valutazione finora

- Bolt Design For Steel Connections As Per AISCDocumento24 pagineBolt Design For Steel Connections As Per AISCJayachandra PelluruNessuna valutazione finora

- Structural Steel Design Project: Calculation SheetDocumento14 pagineStructural Steel Design Project: Calculation SheetJoey Johnson100% (2)

- Welding CalculationDocumento10 pagineWelding CalculationMaqsood100% (1)

- Steel To Concrete Joints Design-Manual II enDocumento292 pagineSteel To Concrete Joints Design-Manual II enSujeevan Tharmakulasingam100% (2)

- Pad Footing Analysis & Design (BS8110)Documento6 paginePad Footing Analysis & Design (BS8110)Maqsood100% (1)

- Topic - Connections - Typical Joints PDFDocumento3 pagineTopic - Connections - Typical Joints PDFMaqsoodNessuna valutazione finora

- Spiral StaircasesDocumento16 pagineSpiral Staircasesvrajan1988100% (1)

- Guide To Design Criteria For Bolts and Riveted JointsDocumento352 pagineGuide To Design Criteria For Bolts and Riveted JointsHomero Silva96% (24)

- Design Guide For Metal Roofing and Cladding To Comply With Energy Requirements of Uk Building REGULATIONS (2006)Documento36 pagineDesign Guide For Metal Roofing and Cladding To Comply With Energy Requirements of Uk Building REGULATIONS (2006)MaqsoodNessuna valutazione finora

- BS5950 Load CasesDocumento46 pagineBS5950 Load CasesthespecifierNessuna valutazione finora

- Strength of Materials - Quick ReviewDocumento7 pagineStrength of Materials - Quick ReviewMaqsood100% (2)

- SSB04 Detailed Design of Portal Frames 2010-05-24 PDFDocumento135 pagineSSB04 Detailed Design of Portal Frames 2010-05-24 PDFSebastian PopNessuna valutazione finora

- Tekla Structural Modeling 140 EnuDocumento232 pagineTekla Structural Modeling 140 EnuMaqsoodNessuna valutazione finora

- Design Guide For Metal Roofing and Cladding To Comply With Energy Requirements of Uk Building REGULATIONS (2006)Documento36 pagineDesign Guide For Metal Roofing and Cladding To Comply With Energy Requirements of Uk Building REGULATIONS (2006)MaqsoodNessuna valutazione finora

- Steel Sheds IntroductionDocumento9 pagineSteel Sheds IntroductionMaqsood100% (1)

- Tensile Test and Stress-Strain DiagramDocumento24 pagineTensile Test and Stress-Strain DiagramMaqsoodNessuna valutazione finora

- KDOT Bridge Construction Manual Chapter on Structural SteelDocumento23 pagineKDOT Bridge Construction Manual Chapter on Structural SteelMaqsoodNessuna valutazione finora

- Connection FailureDocumento8 pagineConnection FailureMaqsoodNessuna valutazione finora

- Structural Steel Engineering Basic ConceptsDocumento40 pagineStructural Steel Engineering Basic ConceptsMaqsood100% (17)

- Design of Beams in Structural SteelDocumento15 pagineDesign of Beams in Structural SteelMaqsood92% (13)

- Design of Beams in Structural SteelDocumento15 pagineDesign of Beams in Structural SteelMaqsood92% (13)

- Design of Columns and Struts in Structural SteelDocumento20 pagineDesign of Columns and Struts in Structural SteelMaqsood83% (18)

- Shear and Moment in Beams CH No 4Documento48 pagineShear and Moment in Beams CH No 4Maqsood86% (7)

- Physics Grade 10Documento228 paginePhysics Grade 10Jan92% (26)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Chut Feed System ProcessDocumento7 pagineChut Feed System ProcessShivam babyNessuna valutazione finora

- Answer THREE Questions.: (Part Marks)Documento5 pagineAnswer THREE Questions.: (Part Marks)Roy VeseyNessuna valutazione finora

- Lab Manual 15B17CI574 Artificial Intelligence Lab PDFDocumento45 pagineLab Manual 15B17CI574 Artificial Intelligence Lab PDFAviral TanwarNessuna valutazione finora

- A320 71-80v2500jarb1 PDFDocumento415 pagineA320 71-80v2500jarb1 PDFHoang L A TuanNessuna valutazione finora

- Online Class Assignment VI Unit XI (LogisticsDocumento3 pagineOnline Class Assignment VI Unit XI (LogisticsAftin ArdheasariNessuna valutazione finora

- Manual de Feeder Gravimetrico PDFDocumento0 pagineManual de Feeder Gravimetrico PDFEfrain SaldañaNessuna valutazione finora

- Brinsmade, El Latifundismo Mexicano, Su Origen y Su RemedioDocumento265 pagineBrinsmade, El Latifundismo Mexicano, Su Origen y Su RemedioAnonymous iH3yyVw100% (1)

- Telling Time and Telephone Communication: He O LLDocumento33 pagineTelling Time and Telephone Communication: He O LLnovaNessuna valutazione finora

- Microwave Engineering Objective QuestionsDocumento3 pagineMicrowave Engineering Objective QuestionsddipyenduNessuna valutazione finora

- Unit Plan - Grade 5 Social StudiesDocumento30 pagineUnit Plan - Grade 5 Social Studiesapi-31065556975% (4)

- Notes On Module 3 PDFDocumento2 pagineNotes On Module 3 PDFabby jacksonNessuna valutazione finora

- Checklist for Teaching Strategies for Learners with Special NeedsDocumento2 pagineChecklist for Teaching Strategies for Learners with Special NeedsJasmin Aldueza100% (6)

- Daily Lesson LogDocumento6 pagineDaily Lesson LogShae UstaresNessuna valutazione finora

- Geberit Bathroom Collection BrochureDocumento125 pagineGeberit Bathroom Collection BrochureThanhNessuna valutazione finora

- Gutter Design and Selection For Roof Rainwater Catchment SystemsDocumento16 pagineGutter Design and Selection For Roof Rainwater Catchment SystemsMichael HiiNessuna valutazione finora

- Why Me?' The Problem of Chronic Pain After Surgery: JurnalDocumento8 pagineWhy Me?' The Problem of Chronic Pain After Surgery: JurnalnurismafadhliahNessuna valutazione finora

- Catalogo Boquillas TanquesDocumento32 pagineCatalogo Boquillas TanquesPunta De Lobos VisionsurfNessuna valutazione finora

- The Alphabet of Technical WritingDocumento3 pagineThe Alphabet of Technical WritingAdeel RazaNessuna valutazione finora

- Engine Valve Lash PDFDocumento4 pagineEngine Valve Lash PDFJose PichinteNessuna valutazione finora

- Electrical wiring diagram for secondary phase CDocumento12 pagineElectrical wiring diagram for secondary phase CDaniel Alvarez AltamiranoNessuna valutazione finora

- Logic NotesDocumento19 pagineLogic NotesCielo PulmaNessuna valutazione finora

- BSS Steel Guide CataloguesDocumento52 pagineBSS Steel Guide Cataloguessaber66Nessuna valutazione finora

- Asme Sec Ix 2019 381Documento1 paginaAsme Sec Ix 2019 381Balkishan DyavanapellyNessuna valutazione finora

- Aerodynamic Studies of Dragonfly Flight ModesDocumento20 pagineAerodynamic Studies of Dragonfly Flight ModesDR. RockyNessuna valutazione finora

- Thread ID Course - OficialDocumento63 pagineThread ID Course - OficialBruno SalasNessuna valutazione finora

- File 1662629170Documento180 pagineFile 1662629170La IrenicaNessuna valutazione finora

- Steam TurbineDocumento102 pagineSteam Turbinerashm006ranjan67% (3)

- Simocode BasicsDocumento63 pagineSimocode BasicsMukesh SahuNessuna valutazione finora

- CaFSET (Antigua) Office Workbook - Sixth Edition - Programming Concepts Sample PagesDocumento4 pagineCaFSET (Antigua) Office Workbook - Sixth Edition - Programming Concepts Sample PagescafsetNessuna valutazione finora

- Theory of ErrorsDocumento43 pagineTheory of Errorsjaybh575Nessuna valutazione finora