Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Laboratory Apparatus For Evaluating Slurry Pipeline Wear (Cooke, Johnson & Goosen)

Caricato da

Engr SakherDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Laboratory Apparatus For Evaluating Slurry Pipeline Wear (Cooke, Johnson & Goosen)

Caricato da

Engr SakherCopyright:

Formati disponibili

1 SAIT SEMINAR ECONOMICS OF WEAR MATERIALS 13 March 2000

Laboratory Apparatus for Evaluating Slurry Pipeline Wear

Robert Cooke, Graeme Johnson and Peter Goosen Paterson & Cooke Consulting Engineers (Pty) Ltd P O Box 23621, Claremont 7735, Cape Town, South Africa Tel: +27 21 683 4734, Fax: +27 21 683 4168, E-mail: rob@pcce.co.za

Synopsis

The accurate prediction of wear rate is an important aspect in the design and economic evaluation of slurry pipeline systems. This papers reviews techniques to establish pipeline wear rates:- tests on operating pipelines, laboratory pipe loop tests, axially rotating pipes and a toroidal pipe rotating in a vertical plane. The relative merits of each of these techniques are discussed. A toroidal pipeline wear tester developed by PCCE is described. Experimental results collected using the apparatus are presented. The importance of considering particle degradation is emphasised and a procedure for accounting for the change in slurry abrasivity during a test is presented.

1.

INTRODUCTION

The accurate prediction of wear rate is an important aspect in the design and economic evaluation of slurry pipeline systems. This is particularly important when the pipeline is designed to operate for the systems life without replacement, as is the case for long distance and buried pipelines. A great deal of research has been undertaken into the understanding of slurry flow behaviour and the prediction of pipeline pressure gradients. Sufficient knowledge and tools are now available so that most slurry pipelines can be designed with a high level of confidence in the operational performance of the system. This is not the case for pipeline wear. McKibben and Shook (1991) note that despite the importance of wear in slurry pipelines, the mechanisms by which it occurs are not well understood and that the quantity of experimental wear data is still meagre. They note that the primary obstacle to the systematic study of wear is that it is usually a slow process. Wear is the progressive removal of material from a solid surface due to a combination of abrasion and corrosion. Pipeline wear tests are required to establish the relative wear rates for different slurry types, to determine the wear resistance of materials and to specify wear allowances for new pipelines. A number of test procedures developed to determine pipeline wear rates are reviewed.

2 A toroidal pipeline wear tester developed by PCCE based on the concept pioneered by Worster and Denny (1955) and Traynis (1977) is described in this paper. Experimental results collected using the apparatus are presented. The importance of considering particle degradation is emphasised and a procedure for accounting for the change in slurry abrasivity during a test is presented. This paper is an update of a previously presented paper (Cooke and Johnson, 1999).

2.

2.1

PREVIOUS WORK

Tests on operating pipelines

The best method for evaluating the performance of pipe materials is to monitor the performance of spool pieces installed in an actual operating pipeline (eg Wright and Garrett, 1986 and Enright, 1987). In this way the actual flow conditions are achieved (flow rate, solids concentration, pH and dissolved oxygen level) and there are no concerns regarding particle degradation. Useful data regarding the distribution of wear around the pipe circumference can also be collected. McKibben and Shook (1991) note that no simulation to date is capable of replacing wear data collected in actual slurry pipelines. Shook et al (1981) point out that as higher wear is eventually observed at even the most carefully constructed butt joint, the test spools must be long enough for this effect to be negligible when measuring mass losses. Care must to taken to ensure that corrosion problems are not created between different metallic materials. Information gathered from operating pipelines is the best method for determining wear allowances for new pipelines intended to convey similar slurries. The limitations of tests conducted on operating pipelines are: (i) Generally it is not possible to vary parameters such as solids concentration, slurry velocity, particle size distribution, pH and dissolved oxygen level. This makes it difficult to conduct a systematic investigation into slurry wear on an operating pipeline. Pipe material manufacturers may not always find a pipeline owner willing to test their materials.

(ii)

Considering these limitations, there will always be a need for laboratory tests which simulate slurry wear. Simulation techniques suitable for slurry pipeline wear are discussed below.

3 2.2 Pipe loop tests

The advantage of conducting tests in a recirculating pipe loop is that actual pipeline flow conditions are achieved. Parameters such as solids concentration, slurry velocity and particle size distribution can easily be changed to suit the investigation. It is more difficult to control the slurry pH and dissolved oxygen level. Faddick (1975) notes that it is a formidable task to scale up data measured over a few days operation in a small diameter pipe to a large pipe with operating life of 20 to 30 years. The major disadvantage of conducting tests in a recirculating loop is the change in slurry abrasivity with time due to particle degradation. Results reported by Henday (1988) for tests conducted using a granite chip slurry (12.5% solids by mass, d 50 for fresh slurry = 12.5 mm) illustrates that particle degradation is particularly severe in a recirculating loop compared with other test methods:

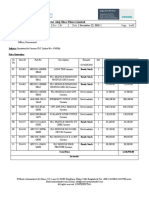

Test rig Recirculating pipe loop tests Axially rotating pipe BHRA toroid wheel Test duration 5 hours 100 hours 100 hours d50 particle size after test 8.6 mm 9.8 mm 9.5 mm

Most of the particle degradation probably occurs in the pump and consequently the degree of degradation is related to the number of slurry passes through the pump. For a fixed loop volume, the number of pump passes will increase with flow rate making it difficult to investigate the effect of slurry velocity if the change in particle abrasivity is not considered. Another limitation is that usually a substantial amount of material is required for a test series. Care must also be taken to ensure that the operating parameters (including slurry temperature) remain constant during a test. 2.3 Axially rotating pipe

Truscott (1975) notes that Johns used this concept for work done for the US Bureau of Reclamation in 1963. Jacobs and James (1984), Lowe and Marshall (1987) and Henday (1988) used an axially rotating horizontal section of pipe to determine pipeline wear rates. Henday (1988) notes that a disadvantage of this test is that the slurry flow is not representative of horizontal pipeline flow. The rotational speed of the pipe must be kept low to avoid centrifuging the slurry around with the pipe. This speed limit varies with the nature of the slurry. McKibben and Shook (1991) note that while the rotating pipe may be used to compare wear rates of different materials, it is not possible to predict actual pipeline wear rates due to the complicated nature of the flow.

4 2.4 Ring pipe or wheel stand

Worster and Denny (1955) developed the ring pipe to study the degradation of coal travelling through a pipeline. The rig consisted of a 1.2 m diameter ring of 150 mm square section pipe rotating in a vertical plane. About three-quarters of the pipe was filled with water and a sample of coal added. When the ring was rotated, the water and coal remained approximately stationary with the resulting velocity of the water and coal relative to the pipe very similar to that in horizontal transport. Centrifugal forces do not act on the particles as they do not rotate. Traynis (1977) reports on three pipe rings, or wheel stands, that were made to study the hydraulic drag of slurries, particle degradation and pipeline wear. The smallest pipe ring was constructed from 100 mm glass pipe (wheel diameter of 1.0 m), with the other two wheels made from 200 mm and 300 mm steel pipe (wheel diameters of 2.6 m and 5.0 m respectively). Traynis tests on the degradation of coal showed that the quantity of fine fraction of coal formed in horizontal pipes and the wheel stands is practically identical. Traynis considered the wheel stand to be a suitable simulation for studying pipeline wear based on the agreement between hydraulic drag and coal degradation in the wheel and straight pipe, as well as visual observation and high speed photography of the slurry inside the wheel. A red copper wear insert made in the form of the pipe section was installed on the cover of the loading hatch and wear tests conducted with quartz, granite and sand. Truscott (1975) suggested that the pipe ring may give the best simulation for pipeline wear studies. Boothroyde and Jacobs (1977) report that they considered the use of the pipe ring concept, but noted that there would be difficulty in fabricating specimens for the rig and that alignment would be an important factor. Lowe and Marshall (1987) note that it will be difficult to obtain samples of materials in pipe to the required curvature. 2.5 BHRA toroid wheel

Henday (1988) describes a toroidal wheel developed by BHRA for generating wear in straight pipes. The wheel consists of five straight pipe sections connected by bends to form a 3.2 m diameter wheel as shown in Figure 1. The wheel is filled with slurry to a third of its volume and the wheel rotated while the slurry remains relatively stationary in the bottom of the wheel. The rotational speed of the wheel is limited by particle carry around but higher speeds can be achieved than with the axially rotating pipe. Lowe and Marshall (1987) expressed concern that the bends and pipe joints may cause additional turbulence which could affect the test conditions. However, Henday (1998) notes that the toroid wheel produces wear distributions similar to those found in real pipelines.

Figure 1: BHRAs toroid wheel (Henday, 1988)

3.

3.1

PCCES PIPELINE WEAR TESTER

Objectives

PCCE have conducted recirculating pipe loop tests for a wide range of slurries since 1992. However, due the drawbacks of pipe loop tests as discussed above, in 1997 it was decided to develop a small scale wear simulation test rig to meet the following requirements: (i) (ii) (iii) Simulation of pipeline wear conditions. Evaluation of material wear resistance. Evaluation of the abrasivity of various slurry types. This would allow field experience with one type of slurry to be applied to another slurry type using an abrasivity ranking. If possible, prediction of absolute wear rates for operating pipelines. Description

(iv) 3.2

After evaluation of techniques used by previous researchers it was decided to adopt the pipe ring principle as it was felt that this would give the best simulation of actual pipe flow conditions.

Figure 2: PCCEs Pipeline Wear Tester

PCCEs Pipeline Wear Tester is illustrated in Figure 2. The wear tester consists of four square section toroids mounted on a single axle driven by an electric motor via a V-belt coupling. Four flat wear plates are mounted on each toroid as shown in Figure 3. The wear plates are sealed using a polyurethane foam gasket and held in place using clamps. Figure 4 shows the dimensional details of the toroids. The advantages of this arrangement are: (i) Flat wear sample plates are used so there is no need to obtain samples of pipe with the correct curvature as is the case for the ring pipe or straight lengths of pipe with same internal diameter as is the case for the BHRA toroid. The plates are subjected to wear similar to that occurring on the bottom of a pipeline (i.e. the zone of highest wear). A small volume (2 R) of slurry is required for each test. Having four wear wheels each with four wear plates allows a number of combinations of slurries and materials to be tested at the same time.

(ii)

(iii) (iv)

The disadvantages of the Pipeline Wear Tester are: (i) By using a flat sample with a sealing gasket, flow disturbances are created on the upstream and downstream edges of the wear plate. As can be seen from Figure 3, the disturbance is not great and it was felt that the advantages of using flat wear plates justified this compromise. There is an upper speed limit above which tests cannot be conducted due to slurry carry over. This upper speed limit depends on the particle properties and the solids concentration.

(ii)

7 (iii) There is a lower speed limit below which particles do not slide on the bottom of the toroid, but are carried with the toroid returning through a tumbling action. This lower speed limit is a function of the particle properties. The slurry in the wheels will degrade with test duration and a procedure is required to account for the change in particle abrasivity during a test.

(iv)

Figure 3: Wear plate detail

Figure 4: Pipeline Wear Tester dimensional details

8 3.3 Test procedure

A dimensionally identical transparent acrylic toroid has been fabricated. This toroid is used to determine the upper and lower velocity limits before starting a test series. To minimise corrosion during a test, the slurry is de-oxygenated and the space above the slurry in each toroid filled with nitrogen. If required, tests can be conducted with oxygenated slurry to determine corrosion rates for various pH and dissolved oxygen levels. The basic procedure for a set of tests is as follows: (i) A preliminary run is conducted using the slurry to be tested to remove any coating or mill scale from the wear plates. This is normally conducted over a 20 hour period. After the preliminary test, the wear plates are thoroughly dried and weighed to an accuracy of 0.01 g. The toroids are filled with 2 R of slurry and a wear test performed. Normally the slurry is replaced every 20 hours. After completion of the specified test duration, the plates are dried and weighed.

(ii)

(iii)

(iv)

For absolute pipeline wear rate predictions, the change in slurry abrasivity with test duration must be taken into account. This procedure is described in the following section.

4.

4.1

PARTICLE DEGRADATION

Background

Ideally wear tests should be conducted using a single slurry pass system. This is best achieved by monitoring the performance of operating pipelines. It is possible to conduct pipe loop wear tests with a single pass of the slurry, but this is rarely done in practice due to the excessive amount of material required. Particles will degrade (i.e. change in size and shape) in any re-circulating system. While the abrasivity of most slurries will decrease with degradation, Want (1979) notes that in isolated cases an increase in abrasivity is possible with a reduction in particle size. Some coals exhibit this phenomenon due to the exposure of pyrite or silica as the coal breaks down. Wilson et al (1992) note that slurry abrasivity is determined by the particle size distribution, shape, hardness and friability. Shook et al (1981) observe that although the particles in their tests were replaced on a regular schedule, significant changes in particle shape occurred. They conclude that particle shape effects appear to be very important in determining wear rates. It is not possible to quantify changes in abrasivity by examining changes in particle size distribution only as has been done by some researchers.

9 Jacobs and James (1984) note that for tests conducted using a rotating pipe, the measured wear rates increased considerably for shorter test durations. They point out that degradation causes uncertainty regarding the nature of the slurry that caused the measured amount of wear. Lowe and Marshall (1987) found that the rate of particle degradation was independent of the pipe material for tests conducted using an axially rotating pipe. Henday (1988) suggested that it may be possible to extrapolate curves of wear rates measured for different test durations to determine the wear rate for undegraded slurry. Cooke (1996) presented a procedure for accounting for the effect of particle degradation in closed loop pipeline wear tests. This procedure is used to predict absolute pipeline wear rates from tests conducted using the Pipeline Wear Tester. 4.2 Procedure for accounting for particle degradation

The procedure for determining the wear rate for fresh (undegraded slurry) is as follows: (i) Conduct a wear test. The duration of the test varies, but typically a test will be conducted over a period of 80 to 100 hours with the slurry being replaced every 20 to 40 hours. Determine the wear rate (expressed as mm of material lost per year). Conduct further wear tests with the slurry replaced at different intervals (eg, 5, 10 or 20 hours). Determine the wear rate for each of these slurry replacement intervals. Plot the variation in measured wear rate with slurry replacement interval as shown in Figure 5. We have found that the wear rate decreases exponentially with the slurry replacement interval. By fitting an exponential curve to the data, the wear rate for fresh slurry can be extrapolated from the curve.

(ii)

(iii)

10

Figure 5: Wear rate versus slurry replacement interval

5.

TEST RESULTS

The Pipeline Wear Tester is under development and more work needs to be done to complete a systematic investigation of all the parameters influencing wear. However, a number of interesting tests have been conducted over the last few years and some of these results are presented below. 5.1 Flow behaviour

Figures 6 to 9 illustrate the flow behaviour of a fine beach sand slurry in the transparent toroid at different velocities. The following observations are noted:

Figure Velocity Observations The particles settle on the bottom of the toroid and are carried upwards by the movement of the toroid without sliding occurring. Particles return to the bottom of the toroid through a cascading and tumbling action. This velocity is considered to be too low for a meaningful wear test. The bed of particles slide relative to the toriod and the particles are more uniformly distributed than at 0.5 m/s. This represents typical test conditions with a good distribution of particles and a sliding bed of particles. At this velocity a small amount of carry over of slurry is observed and this condition is close to the upper velocity limit for operating the Pipeline Wear Tester.

0.5 m/s

7 8

1.0 m/s 2.0 m/s

3.0 m/s

11 The flow observations vary with slurry type and solids concentration. Consequently flow visualisation tests are conducted before starting each test series to ensure that the flow behaviour is representative of pipeline conditions.

Figure 6: Flow behaviour (V = 0.5 m/s)

Figure 7: Flow behaviour (V = 1.0 m/s)

12

Figure 8: Flow behaviour (V = 2.0 m/s)

Figure 9: Flow behaviour (V = 3.0 m/s)

5.2

Effect of solids concentration

Figure 10 shows the variation of mass loss with solids concentration for a coarse backfill slurry. The results show that there is a slight increase in wear rate with increasing solids concentration. This trend is in line with the expected wear rate at the bottom of a pipeline conveying a settling slurry.

13

5 Mass Loss (g / 1000 hr)

2 Mild steel wear plates V = 3 m/s d50 particle size = 70 m Particle relative density = 3.64

0 0.0%

10.0%

20.0% 30.0% Solids Concentration (% vol)

40.0%

50.0%

Figure 10: Effect of solids concentration on measured mass loss

5.3

Particle degradation

Figure 11 shows the variation of measured wear rate with slurry replacement interval for fine and coarse gold tailings (d50 = 39 m and 114 m respectively). The abrasivity of the coarse material decreases with increasing slurry replacement interval at a faster rate than the fine material. This trend is expected and it emphasises the following important points: (i) It is not possible to establish the relative abrasivity of different slurries by conducting fixed duration tests due to the different rates of particle degradation. Figure 11 clearly shows that a relative abrasivity ranking obtained from a 94 hour test is very different to that obtained from a 23.5 hour test. The wear rate for fresh slurry must be determined to establish a valid slurry abrasivity ranking. The above discussion also applies to tests conducted at two velocities using the same slurry. More particle degradation will occur for the test conducted at the higher velocity and so it is not possible to directly correlate the results from two tests conducted over the same period. To obtain a valid comparison, the wear rate for fresh slurry must be considered. Many researchers do not provide an explanation of how particle degradation was accounted for in their work and this may partly explain the large discrepancies in reported values for the wear velocity exponent (eg, Truscott, 1975).

(ii)

14

4.00 3.50 3.00 Wear Rate (mm/yr) 2.50 2.00 1.50 1.00 0.50 0.00 0 20 40 60 80 Slurry Replacement Interval (hours) 100 Mild steel wear plates V = 2 m/s Fine tailings d50 particle size = 39 m Coarse tailings d50 partice size = 114 m Solids concentration = 25% vol Particle relative density = 2.70 Fine tailings Coarse tailings

Figure 11: Wear rate versus slurry replacement interval

5.4

Absolute wear rates

The predicted wear for the fine tailings data shown in Figure 11 is 0.60 mm/year. The actual wear rate at the bottom of 550 mm diameter operating pipelines conveying the fine tailings is between 0.88 and 1.23 mm/year. Considering that the material supplied for the test work appears to be slightly finer than the material transported by the pipelines and that the tests were conducted in a de-oxygenated environment, there is a reasonable correlation between the predicted data and field experience. The actual measured wear rate for a 100 mm polyethylene pipeline conveying -8 mm quartz tailings is 19.3 mm/year. Based on tests conducted using the Pipeline Wear Tester, the predicted wear rate is 12.5 mm/year. We were disappointed with this result and ran a test in the transparent toriod to observe the slurry flow behaviour. It was apparent that the solid particles were only in contact with 48% of the slurry contact area due to their fast settling characteristics. Correcting for the contact area, this increases the predicted wear rate to 18.1 mm/ year which is very close to the actual measured wear rate. Therefore, a correction must be made for non-homogeneous slurries. Although further work is required before the experimental results can be applied with confidence to the design of slurry pipeline systems, we are encouraged by the results to date and believe that the Pipeline Wear Tester will be a useful design tool in the future.

15 5.5 Dissolved oxygen level

Figure 12 shows how the measured wear rate increases with dissolved oxygen level for tests conducted using a fine gold tailings. For dissolved oxygen values less than 2 ppm, the wear rate increases rapidly with increasing oxygen level. The wear rate increases less rapidly with oxygen level for values greater than 2 ppm.

5 Wear Rate (mm/yr)

0 0 2 4 6 8 Average Dissolved Oxygen (ppm) 10 12

Figure 12: Wear rate versus dissolved oxygen level

6.

CONCLUSION

The development of PCCEs Pipeline Wear Tester based on the vertical toroid concept first used by Worster and Denny (1955) has been presented. The wear tester is capable of determining slurry abrasivity and establishing the wear resistance of pipe materials. The wear tester may also prove to be a useful tool for predicting absolute slurry pipeline wear rates. The importance of considering the effect of particle degradation is emphasised and a procedure for accounting for the change in slurry abrasivity during a test is presented. Conclusions regarding the effect of particle properties (size, shape, hardness, etc), conveying velocity and solids concentration on wear rate cannot be made unless a correction is made for the changes in slurry abrasivity.

16

7.

ACKNOWLEDGEMENTS

The authors would like to thank the East Rand Gold and Uranium Companys management for permission to publish data from tests conducted for ERGO. The bulk of the test work presented in this paper was conducted by Mr Fritz van Sittert.

REFERENCES

Boothroyde, J. and B.E.A. Jacobs (1977) Pipe Wear Testing 1976 - 1977", BHRA Report PR 1448, December. Cooke, R. (1996) Pipeline Material Evaluation for the Mina Grande Hydrohoist System, Proc. 13 t h International Conference of Slurry Handling and Pipeline Transport, BHR, Johannesburg, September. Cooke, R. and G. Johnson (1999) Laboratory Apparatus for Evaluating Slurry Pipeline Wear, Proc. 14th International Conference of Slurry Handling and Pipeline Transport, BHR, Masstricht, September. Enright, D.P. (1987) The Testing of Abrasion Resistance in Pipeline Materials, Mintek Report M313, Council for Mineral Technology, South Africa, November. Faddick, R.R. (1975) Pipeline Wear from Abrasive Slurries, Proc. 1st International Conference on Internal and External Protection of Pipes, BHRA, Durham, September. Henday, G. (1988) A Comparison of Commercial Pipe Materials Intended for the Hydraulic Transport of Solids, BHRA Report RR 2988, November. Jacobs, B.E.A. and J.G. James (1984) The Wear Rate of Some Abrasion Resistant Materials, Proc. 9th International Conference on Hydraulic Transport of Solids in Pipes, BHRA, Rome, October. Lowe, D. and G.P. Marshall (1987) Wear of Polymeric Pipes and Linings in Hydraulic Slurry Transportation, Proc. 7th International Conference of Internal External Protection of Pipes, BHRA, London, September. McKibben, M.J. and C.A. Shook (1991) Erosive Wear of Pipeline Systems, Slurry Handling: Design of Solid-Liquid Systems, edited by N.P. Brown and N.I. Heywood, Elsevier Applied Science. Shook, C.A., D.B. Haas, W.H.W. Husband and M. Small (1981) Relative Wear Rate Determinations for Slurry Pipelines, Journal of Pipelines, 1, 273-80. Traynis, V.V. (1977) Parameters and Flow Regimes for Hydraulic Transport of Coal by Pipelines, Translated from Russian by W.C. Cooley and R.R. Faddick, Terraspace Inc.

17 Truscott, G.F.(1975) A Literature Survey on Wear on Pipelines, BHRA Report TN 1295, May. Wright, G.J. and G.G. Garrett (1986) Wear and Performance of Materials in Pipelines for the Hydraulic Conveyance of Fused Ash, Mintek Report M242, Council for Mineral Technology, South Africa, February. Want, F.M. (1979) Wear in Slurry Pipelines, Mechanical Engineering Transactions, The Australian Institution of Engineers, 17-27. Wilson, K.C., G.R. Addie and R. Clift (1992) Slurry Transport Using Centrifugal Pumps, Elsevier Science. Worster, R.C. and D.F. Denny (1955) The Hydraulic Transport of Solid Material in Pipes, Proc. General Meeting of the Institution of Mechanical Engineers, London, March.

Potrebbero piacerti anche

- National Interest Waiver Software EngineerDocumento15 pagineNational Interest Waiver Software EngineerFaha JavedNessuna valutazione finora

- CD225M Dri-Prime Pump: Features SpecificationsDocumento2 pagineCD225M Dri-Prime Pump: Features SpecificationsDodyNessuna valutazione finora

- Wagons Modern Bulk Material HandlingDocumento4 pagineWagons Modern Bulk Material Handlingparuchurivenkat5272Nessuna valutazione finora

- Parametric Experimental Analysis of Erosion Wear On Mild Steel Material - Response Surface MethodologyDocumento7 pagineParametric Experimental Analysis of Erosion Wear On Mild Steel Material - Response Surface MethodologyGRD JournalsNessuna valutazione finora

- MinPro Thickening TechnologiesDocumento12 pagineMinPro Thickening TechnologiescecilinauNessuna valutazione finora

- Secondary and Tertiary Cone CrushersDocumento4 pagineSecondary and Tertiary Cone CrushersDanielSantosNessuna valutazione finora

- Is 8531 1986Documento6 pagineIs 8531 1986Srini KumarNessuna valutazione finora

- Fulltext01 PDFDocumento244 pagineFulltext01 PDFanush Jain100% (1)

- Dunlop Conveyor Belt Design ManualDocumento16 pagineDunlop Conveyor Belt Design ManualTabor TamiruNessuna valutazione finora

- PasteThickener TechnologyDocumento5 paginePasteThickener TechnologyRodri GermánNessuna valutazione finora

- DRC1200 - Hard Rock Sizer A Twin Roll Sizer Designed For Mobility PDFDocumento2 pagineDRC1200 - Hard Rock Sizer A Twin Roll Sizer Designed For Mobility PDFfran01334Nessuna valutazione finora

- New Material For Auxiliary EquipmentDocumento12 pagineNew Material For Auxiliary EquipmentxtusNessuna valutazione finora

- Kwsengineering PDFDocumento126 pagineKwsengineering PDFargaNessuna valutazione finora

- Current Number of Specifications: View Articles On This Item Print SpecificationDocumento3 pagineCurrent Number of Specifications: View Articles On This Item Print SpecificationShash ShaNessuna valutazione finora

- How To Size A ThickenerDocumento7 pagineHow To Size A ThickenerJesus Sing RoblesNessuna valutazione finora

- Telescopic ChuteDocumento2 pagineTelescopic Chutebiswajit sabuiNessuna valutazione finora

- Stuart-Dick&Royal-Design Principles For Chutes To Handle Bulk SolidsDocumento4 pagineStuart-Dick&Royal-Design Principles For Chutes To Handle Bulk SolidsJoaquín NarváezNessuna valutazione finora

- Presentacion Rotary Drum Composting of Mixed OrganicDocumento35 paginePresentacion Rotary Drum Composting of Mixed OrganicAntonio J PurielNessuna valutazione finora

- Metallurgical Failure Analysis: by DR - Yahya WaqadDocumento130 pagineMetallurgical Failure Analysis: by DR - Yahya WaqadYahya Faiez WaqqadNessuna valutazione finora

- Clarifier - 1Documento13 pagineClarifier - 1wasin2543Nessuna valutazione finora

- 11.1.06 Warman Pump Shaft SealsDocumento12 pagine11.1.06 Warman Pump Shaft SealsMartin Calderon100% (1)

- 4 - Paste Pumping Deposition Field Trials and Concepts On Syncrudes Dewawtered MFT - Ahmed Et Al PDFDocumento18 pagine4 - Paste Pumping Deposition Field Trials and Concepts On Syncrudes Dewawtered MFT - Ahmed Et Al PDFenazarioenjNessuna valutazione finora

- Slurry Treatment PlantDocumento29 pagineSlurry Treatment PlantKathirgamanathan SivanathanNessuna valutazione finora

- The Influence of Liner Wear On Milling EfficiencyDocumento21 pagineThe Influence of Liner Wear On Milling EfficiencyW ZuoNessuna valutazione finora

- SAIL BSBK Visit Docx-15.06. R-1rtfDocumento7 pagineSAIL BSBK Visit Docx-15.06. R-1rtfsssadangi100% (1)

- Thickners Methods & SystemsDocumento13 pagineThickners Methods & SystemslucianotigreNessuna valutazione finora

- Brochure Paste ThickenerDocumento8 pagineBrochure Paste ThickenerAndré BranchesNessuna valutazione finora

- 24941-100-30R-G01-00073 Tunra 6299 Report FinalDocumento96 pagine24941-100-30R-G01-00073 Tunra 6299 Report FinalcmahendrNessuna valutazione finora

- Is - 1161 - Steel TubesDocumento8 pagineIs - 1161 - Steel TubesAsif Ali100% (1)

- Asce2001critical Flow Velocity in Slurry Transporting Horizontal PipelinesDocumento10 pagineAsce2001critical Flow Velocity in Slurry Transporting Horizontal PipelinesRodolfo Kock SchulmeyerNessuna valutazione finora

- Table of Bond Work Index by MineralsDocumento8 pagineTable of Bond Work Index by MineralsirfanNessuna valutazione finora

- 09 Tailings Pumps MCU Oct 2017 John OttenDocumento48 pagine09 Tailings Pumps MCU Oct 2017 John OttenYerko VillcaNessuna valutazione finora

- Indian Boiler ActDocumento18 pagineIndian Boiler ActYogesh DhekaleNessuna valutazione finora

- FinePowderFlow Bins Hoppers JenikeDocumento10 pagineFinePowderFlow Bins Hoppers JenikesaverrNessuna valutazione finora

- Spiral Brochure 3-2007Documento8 pagineSpiral Brochure 3-2007MikeWalsheNessuna valutazione finora

- Pellest de IronDocumento12 paginePellest de IronOmar CutsNessuna valutazione finora

- Wear in Pumps and Pipelines (Truscott 1979)Documento22 pagineWear in Pumps and Pipelines (Truscott 1979)cmahendrNessuna valutazione finora

- Pebble Crusher Specific EnergyDocumento10 paginePebble Crusher Specific Energy12milehillNessuna valutazione finora

- Walker and Goulas - Perf Characteristics of Pumps Handling Non-Newtonian Slurries - IMechE 1984Documento9 pagineWalker and Goulas - Perf Characteristics of Pumps Handling Non-Newtonian Slurries - IMechE 1984Cristian RANessuna valutazione finora

- Arw314124523secunda RioDocumento1 paginaArw314124523secunda Rioalonsooo_Nessuna valutazione finora

- Training Manual Green Anode Plant Vedanta - Jharsuguda: File: 138-02-043 - 08 - 0.doc, Codeword: VedantaDocumento47 pagineTraining Manual Green Anode Plant Vedanta - Jharsuguda: File: 138-02-043 - 08 - 0.doc, Codeword: VedantaSubhransu MohapatraNessuna valutazione finora

- Outotec - Seismic Design of Elevated Slurry Storage Tanks For As NZS 1170 (Rosart)Documento8 pagineOutotec - Seismic Design of Elevated Slurry Storage Tanks For As NZS 1170 (Rosart)Serguei DobrinNessuna valutazione finora

- Slurry PipelinesDocumento49 pagineSlurry Pipelinesqdnguyen100% (3)

- PeletizadoDocumento8 paginePeletizadoJavier GómezNessuna valutazione finora

- Conveyor Idler StandardsDocumento10 pagineConveyor Idler StandardsObiwan1483100% (1)

- Diemme 2500x2500Documento8 pagineDiemme 2500x2500Cristian Mena HidalgoNessuna valutazione finora

- ScreeningDocumento16 pagineScreeninganthony ijigaNessuna valutazione finora

- Short Course On Comminution & Semi-Autogenous Grinding: Session 8 Functional PerformanceDocumento26 pagineShort Course On Comminution & Semi-Autogenous Grinding: Session 8 Functional PerformanceFredy Peña100% (1)

- Potash Solution Mining All GradesDocumento43 paginePotash Solution Mining All Gradesbharathkumarsingu100% (2)

- SGS MIN TP2011 08 SAG Mill Testing For Ore Grindability PDFDocumento10 pagineSGS MIN TP2011 08 SAG Mill Testing For Ore Grindability PDFjazz_2012Nessuna valutazione finora

- Apron Feeder Data SheetDocumento1 paginaApron Feeder Data SheetPat AuffretNessuna valutazione finora

- Engineers Proceedings of The Institution of Mechanical: Hydraulic Transport of Solid Material in PipesDocumento27 pagineEngineers Proceedings of The Institution of Mechanical: Hydraulic Transport of Solid Material in PipesPrantik DasNessuna valutazione finora

- Tools For Mining 2Documento165 pagineTools For Mining 2Ferudun AkyolNessuna valutazione finora

- Wagon Loader SystemDocumento12 pagineWagon Loader Systemayaskant751001100% (1)

- 5530 Solvent Extraction ExampleDocumento14 pagine5530 Solvent Extraction ExampleSenthilkumar PragasamNessuna valutazione finora

- Jaw Crusher Kinematics Simulation and AnalysisDocumento5 pagineJaw Crusher Kinematics Simulation and AnalysisInternational Journal of Research in Engineering and ScienceNessuna valutazione finora

- Pressureloss in Slurry PipesDocumento10 paginePressureloss in Slurry PipesKarthick Velayutham100% (1)

- (17CrNiMo6) 4317 Case Hardening SteelDocumento3 pagine(17CrNiMo6) 4317 Case Hardening Steelazhar mohammedNessuna valutazione finora

- Examination of Copper Electrowinning Smoothing Agents. Part I: A ReviewDocumento7 pagineExamination of Copper Electrowinning Smoothing Agents. Part I: A ReviewHelen HuancaNessuna valutazione finora

- Operating Variables in Knelson ConcentratorDocumento13 pagineOperating Variables in Knelson Concentratorjoegb2919Nessuna valutazione finora

- Preene - Design and Interpretation of Packer TestingDocumento43 paginePreene - Design and Interpretation of Packer TestingTechan EshetuNessuna valutazione finora

- Unit 1 PrinciplesDocumento17 pagineUnit 1 PrinciplesRohit YadavNessuna valutazione finora

- PDFDocumento653 paginePDFconstantinNessuna valutazione finora

- Hitachi Vehicle CardDocumento44 pagineHitachi Vehicle CardKieran RyanNessuna valutazione finora

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Documento2 pagineLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulNessuna valutazione finora

- RSW - F - 01 " ": Building UtilitiesDocumento4 pagineRSW - F - 01 " ": Building Utilities62296bucoNessuna valutazione finora

- Waste Biorefinery Models Towards Sustainable Circular Bioeconomy Critical Review and Future Perspectives2016bioresource Technology PDFDocumento11 pagineWaste Biorefinery Models Towards Sustainable Circular Bioeconomy Critical Review and Future Perspectives2016bioresource Technology PDFdatinov100% (1)

- Pitch DeckDocumento21 paginePitch DeckIANessuna valutazione finora

- Raiders of SuluDocumento1 paginaRaiders of SuluBlexx LagrimasNessuna valutazione finora

- Jurnal Job DescriptionDocumento13 pagineJurnal Job DescriptionAji Mulia PrasNessuna valutazione finora

- Documentation Report On School's Direction SettingDocumento24 pagineDocumentation Report On School's Direction SettingSheila May FielNessuna valutazione finora

- CIPD L5 EML LOL Wk3 v1.1Documento19 pagineCIPD L5 EML LOL Wk3 v1.1JulianNessuna valutazione finora

- Construction Project - Life Cycle PhasesDocumento4 pagineConstruction Project - Life Cycle Phasesaymanmomani2111Nessuna valutazione finora

- Ficha Tecnica Bomba Inyeccion MiniFlex EDocumento1 paginaFicha Tecnica Bomba Inyeccion MiniFlex Ejohn frader arrubla50% (2)

- TIA Guidelines SingaporeDocumento24 pagineTIA Guidelines SingaporeTahmidSaanidNessuna valutazione finora

- IJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyDocumento12 pagineIJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyImpact JournalsNessuna valutazione finora

- Use of The Internet in EducationDocumento23 pagineUse of The Internet in EducationAlbert BelirNessuna valutazione finora

- File RecordsDocumento161 pagineFile RecordsAtharva Thite100% (2)

- Maximum and Minimum PDFDocumento3 pagineMaximum and Minimum PDFChai Usajai UsajaiNessuna valutazione finora

- Problem Solving No. 123Documento5 pagineProblem Solving No. 123Christy Joy BarboNessuna valutazione finora

- Ficha Técnica Panel Solar 590W LuxenDocumento2 pagineFicha Técnica Panel Solar 590W LuxenyolmarcfNessuna valutazione finora

- Civil Rights Vocabulary Lesson PlanDocumento4 pagineCivil Rights Vocabulary Lesson PlanKati ArmstrongNessuna valutazione finora

- 'Causative' English Quiz & Worksheet UsingEnglish ComDocumento2 pagine'Causative' English Quiz & Worksheet UsingEnglish ComINAWATI BINTI AMING MoeNessuna valutazione finora

- Transportation of CementDocumento13 pagineTransportation of CementKaustubh Joshi100% (1)

- HRM Practices in NepalDocumento22 pagineHRM Practices in NepalBodhiNessuna valutazione finora

- Nominal GroupDocumento3 pagineNominal GroupSrourNessuna valutazione finora

- Pearson R CorrelationDocumento2 paginePearson R CorrelationAira VillarinNessuna valutazione finora

- Chapter 2 HydrateDocumento38 pagineChapter 2 HydrateTaha Azab MouridNessuna valutazione finora

- Determinant of Nurses' Response Time in Emergency Department When Taking Care of A PatientDocumento9 pagineDeterminant of Nurses' Response Time in Emergency Department When Taking Care of A PatientRuly AryaNessuna valutazione finora

- CycleMax IntroDocumento13 pagineCycleMax IntroIslam AtefNessuna valutazione finora