Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Denim, More Than Just A Pair of Jeans

Caricato da

AsifaMalikDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Denim, More Than Just A Pair of Jeans

Caricato da

AsifaMalikCopyright:

Formati disponibili

Denim More Than Just a Pair of Jeans

4.110

Although the term denim originated in France, denim fabric is all-American thanks to Levi Strauss denim work pants dating back to the late 1800s. Comfort, versatility and durability continue to be denims biggest assets, far outweighing the fact that it shrinks, frays and fades in the wash. Denim is best-known for its use in the manufacture of jeans; however, it can be made into just about anything, depending on its weight. Even formalwear designers turn to denim for inspiration occasionally! Denim is a strong, durable fabric constructed in a twill weave with indigo and white yarns. The blue/indigo yarns are the lengthwise or warp threads (parallel to the selvage). The white yarns run across the fabric width (the weft threads). Denim is traditionally woven with 100%-cotton yarn; however, today its blended with polyester, to control shrinkage and wrinkles, and Lycra to add stretch. Today, denim has many faces. It can be printed, striped, brushed, napped and stonewashed, and the indigo blue yarns can be replaced with different colors to create colored denim. Fabric/Pattern Selection The key to sewing with denim, is selecting the proper weight denim for the pattern. Since denim is a twill weave, it has a slight diagonal pattern; avoid patterns that arent suitable for obvious diagonals. Heavy denim (12- to 14-ounce) tends to work best when made into jeans, jackets, overalls and work clothes. Its bulky, stiff and best-suited to designs with straight lines and little or no gathering or easing. Pants, jackets, skirts and accessories, such as bags, work up well in medium-weight, 10- to 12-ounce denim. Lighter denim can handle softer styling and some curved seams that require easing and/or gathering. Skirts, shirts and dresses make up perfectly

Page 1

in lightweight denim (6- to 8-ounce). This denim is the easiest to sew and can be handled like any woven cotton fabric. However, all the seams should be cleanfinished, since denim frays badly. Preparing to Sew Denim shrinks with washing, fades with wear, stretches when worn and its color tends to run in the wash, so prewash and dry the fabric several times before sewing. This also removes any sizing, which can cause skipped stitches, and softens the fabric. If the label on the end of the bolt indicates the fabric is Sanforized, then the fabric has been treated, and the shrinkage will not exceed 1% in any direction. Prior to washing, serge or zigzag the cut edges to minimize raveling. Tip: To test for crocking, the loss of dye from abrasion, rub the denim with a piece of white fabric. If the white fabric picks up color, the dye will continue to fade in the wash and when its rubbed. When cutting out the pattern, consider cutting facings from lining or contrast fabric to reduce bulk. Be sure to use a withnap cutting layout (see Guideline 4.120). The Right Tools Begin every project with a new needle, especially a denim project; denim dulls needles quickly. The heavier the denim, the larger the needle required. Sew heavy denim with a size 100/16 needle, mediumweight denim with an 80/14 needle and lightweight denim with a size 75/11 needle. For the best results purchase a denim needle. It has a longer, sharper point, so it can penetrate the close weave of the cloth easier. Its larger eye accommodates decorative topstitching thread. For standard sewing, use polyester or cotton-wrapped polyester thread, and use

Denim More Than Just a Pair of Jeans

4.110

decorative thread for topstitching. Its helpful, but not necessary, to have an even-feed and/or roller presser foot for sewing over multiple thick layers of fabric. Sewing Sew denim just as you would any firmly woven fabric, but keep in mind that the fabric frays, so seam finishing is essential. Stitch a test seam to determine the best stitch size; heavier fabrics need fewer stitches per inch than lighter weight versions. Sew heavy denim with about 10 stitches per inch and lighter denim with about 12 stitches per inch (3 mm). Reduce the thread tension and the presser-foot pressure slightly, so the fabric feeds evenly. Types of Seams Denim can be sewn with a standard 5/8" (1.6 cm) seam; however, most denim garments feature flat-fell and topstitched seams. Stretch denim requires a stretch stitch. The most popular denim seam is the flat-fell seam; its very durable and gives a nice, clean finish on the inside of the garment. For instructions see Guideline 11.330. Seam Finishes Because denim ravels, its important to clean-finish all seams. Several seam finishes are satisfactory. The easiest seam finish is a pinked edge. Simply trim the seam allowance with pinking shears. For extra protection, run a straight stitch along the raw edge first and then pink it (1). Topstitching Topstitching gives denim its trademark look, as well as decorative appeal. Use heavy contrasting thread such as buttonhole twist or decorative thread designed for topstitching. If you dont have topstitching thread, use two strands of regular thread so the topstitching stands out. Use regular thread in the bobbin. If the threads bind up, loosen the needle-thread tension slightly. Closures & Hems Machine worked buttonholes, zippers and decorative snaps are the most popular types of garment closures on denim. Hems are most often stitched by machine with one or two rows of narrow topstitching. Narrow denim hems have a tendency to curl. To reduce curling, finish the lower edge by pressing it to the wrong side or serging it. Add a strip of fusible web to the hem allowance, and then fold and fuse the hem in place before topstitching. Garment Care Denim garments require some care when laundering. To avoid ruining other clothes, wash denim items separately until you notice the wash water remains clear. To minimize fading, turn items inside out and add a cup of white vinegar to the wash cycle. If you dont want to lose any color, dry-clean the item.

Page 2

It is also easy to zigzag the seam allowance edge (2) or serge the raw edges as you sew (3). On unlined jackets, where the inside of the garment is often visible, bind seam allowances with double-fold bias tape (4). See instructions in Guideline 11.340.

10/05

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- En Cima Market StudyDocumento67 pagineEn Cima Market Studyapi-3838281100% (2)

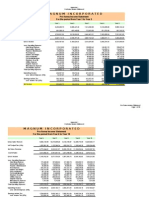

- Magnum Final Finally FsDocumento30 pagineMagnum Final Finally Fsapi-3838281Nessuna valutazione finora

- En Cima Appendix - 5Documento5 pagineEn Cima Appendix - 5api-3838281Nessuna valutazione finora

- Magnum Financial FinalDocumento27 pagineMagnum Financial Finalapi-3838281Nessuna valutazione finora

- En Cima Appendix - 3Documento1 paginaEn Cima Appendix - 3api-3838281Nessuna valutazione finora

- Power PointDocumento7 paginePower Pointapi-3838281Nessuna valutazione finora

- Power Point TechnicalDocumento9 paginePower Point Technicalapi-3838281Nessuna valutazione finora

- En Cima Appendix - 2Documento2 pagineEn Cima Appendix - 2api-3838281Nessuna valutazione finora

- Pant SaloonDocumento27 paginePant Saloonapi-3838281Nessuna valutazione finora

- En Cima Appendix - 4Documento2 pagineEn Cima Appendix - 4api-3838281Nessuna valutazione finora

- Power Point - Market Demand ComputationDocumento9 paginePower Point - Market Demand Computationapi-3838281100% (1)

- Power Point - MarketingDocumento11 paginePower Point - Marketingapi-3838281Nessuna valutazione finora

- My Part For Report FinalDocumento4 pagineMy Part For Report Finalapi-3838281Nessuna valutazione finora

- Technical AppraisalDocumento64 pagineTechnical Appraisalapi-3838281Nessuna valutazione finora

- Technical Appraisal Table of ContentsDocumento5 pagineTechnical Appraisal Table of Contentsapi-3838281Nessuna valutazione finora

- Technical Appraisal FinalDocumento67 pagineTechnical Appraisal Finalapi-3838281Nessuna valutazione finora

- RectoDocumento2 pagineRectoapi-3838281Nessuna valutazione finora

- My Part For ReportDocumento5 pagineMy Part For Reportapi-3838281Nessuna valutazione finora

- Denim Sewing GuidelinesDocumento3 pagineDenim Sewing Guidelinesapi-3838281Nessuna valutazione finora

- Org Structure - HR Matters - Daily OpernsDocumento10 pagineOrg Structure - HR Matters - Daily Opernsapi-3838281Nessuna valutazione finora

- Pattern For Org StructureDocumento8 paginePattern For Org Structureapi-3838281Nessuna valutazione finora

- RRJ JeansDocumento1 paginaRRJ Jeansapi-3838281100% (1)

- Plains and PrintsDocumento2 paginePlains and Printsapi-3838281100% (3)

- Operating CostsDocumento13 pagineOperating Costsapi-3838281Nessuna valutazione finora

- WE'RE NOT Sweatshops - Garments Exporters Worry About Int'l ImageDocumento2 pagineWE'RE NOT Sweatshops - Garments Exporters Worry About Int'l Imageapi-3838281Nessuna valutazione finora

- The Philippine Garments IndustryDocumento4 pagineThe Philippine Garments Industryapi-3838281100% (3)

- Viktor JeansDocumento2 pagineViktor Jeansapi-3838281Nessuna valutazione finora

- PIF2006Documento57 paginePIF2006api-3838281Nessuna valutazione finora

- June Garments Exports Adjust To PriceDocumento2 pagineJune Garments Exports Adjust To Priceapi-3838281Nessuna valutazione finora

- Philippines Cotton and Products Annual 2004Documento3 paginePhilippines Cotton and Products Annual 2004api-3838281Nessuna valutazione finora