Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

3-934584-65-9 VP44

Caricato da

raddumocanuDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

3-934584-65-9 VP44

Caricato da

raddumocanuCopyright:

Formati disponibili

Contents

4 Overview of diesel fuel-injection systems 4 Requirements 6 Overview of distributor fuel-injection pump systems 6 Areas of application 6 Designs 8 Helix and port-controlled systems 10 Solenoid-valve controlled systems 14 14 14 15 Fuel supply (low pressure stage) Fuel tank Fuel lines Diesel fuel filters

78 High-pressure stage of the radialpiston distributor injection pump 82 Delivery valves 83 High-pressure solenoid valve 84 Injection timing adjustment 90 Electronic control unit 91 Summary 92 94 96 100 102 104 105 106 107 Nozzles Pintle nozzles Hole-type nozzles Future development of the nozzle Nozzle holders Standard nozzle holder Stepped nozzle holders Two-spring nozzle holders Nozzle holder with needle-motion sensor

16 Helix and port-controlled distributor injection pumps 17 Applications and installation 19 Design 22 Low-pressure stage 25 High-pressure pump with fuel distributor 34 Auxiliary control modules for distributor injection pumps 34 Overview 36 Governors 43 Timing device 46 Mechanical torque-control modules 59 Load switch 59 Potentiometer 60 Delivery-signal sensor 61 Shutoff devices 62 Electronic Diesel Control 65 Diesel-engine immobilizers 66 Solenoid-valve-controlled distributor injection pumps 66 Areas of application 66 Designs 68 Fitting and drive system 70 Design and method of operation 72 Low-pressure stage 74 High-pressure stage of the axialpiston distributor injection pump

108 High-pressure lines 108 High-pressure connection fittings 109 High-pressure delivery lines 112 112 112 113 114 Electronic diesel control (EDC) Technical requirements System overview System blocks Helix and port-controlled axial-piston distributor pumps 115 Solenoid-valve-controlled axial-piston and radial-piston distributor pumps 116 116 118 122 124 Service technology Overview Testing EDC systems Fuel-injection pump test benches Testing helix and port-controlled distributor injection pumps 128 Nozzle tests 130 Index of technical terms 130 Technical terms 132 Abbreviations

Diesel engines are becoming ever more interesting for use in motor vehicles. They are traditionally known for fuel economy and long service life. In the past few years they have now become more powerful, quieter and cleaner. Here, the fuel-injection system has played a decisive role. Diesel fuel-injection systems from Bosch have been a major contributor to a resurgence of diesel engines embracing every automotive sector, including the high-speed engines employed in passenger cars. The rotary, or distributor injection pump, has been the prime mover behind diesel propulsion for a number of years. This pumps inherently immense precision allows it to meter exactly the correct fuel dosage, even in minute inject-fuel quantities. Continuous evolution has spawned control racks and electronic control systems that contribute to the diesel cars smooth, spontaneous performance and supremely sensitive response. When the VP44 radial-piston high-pressure pumps fitted with a high-pressure solenoid valve was launched in 1996, it opened up a range of new opportunities, for example pre-injection to reduce noise or regulating injected-fuel quantity to individual cylinders to achieve torque control. In 1998 the solenoid-valve-controlled axial-piston distributor pump appeared on the scene. The electronic control unit integrated in the pump created a system that links technological innovation to low system costs. This Bosch Yellow Jacket booklet from the Expert Know-How on Automotive Technology series deals with the design and construction of port-controlled and solenoid-valve-controlled distributor injection pumps and how their components interact within the system. The section on workshop technology provides insights in testing and tuning these fuel-injection systems. The basics of Diesel-Engine Management and Electronic Diesel Control EDC are described in detail in separate booklets.

78

Solenoid-valve controlled distributor injection pumps

High-pressure stage of the radial-piston distributor injection pump

High-pressure stage of the radial-piston distributor injection pump

Radial-piston high-pressure pumps (Fig. 1) produce higher injection pressures than axial-piston high-pressure pumps. Consequently, they also require more power to drive them (as much as 3.5...4.5 kW compared with 3 kW for axial-piston pumps).

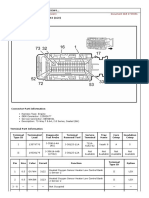

Design The radial-piston high-pressure pump (Fig. 2 overleaf) is driven directly by the distributor-pump drive shaft. The main pump components are the cam ring (1) the roller supports (4) and rollers (2) the delivery plungers (5) the drive plate, and the front section (head) of the distributor shaft (6)

The drive shaft drives the drive plate by means of radially positioned guide slots. The guide slots simultaneously act as the locating slots for the roller supports. The roller supports and the rollers held by them run around the inner cam profile of the cam ring that surrounds the drive shaft. The number of cams corresponds to the number of cylinders in the engine. The drive plate drives the distributor shaft. The head of the distributor shaft holds the delivery plungers which are aligned radially to the drive-shaft axis (hence the name radial-piston high-pressure pump). The delivery plungers rest against the roller supports. As the roller supports are forced outwards by centrifugal force, the delivery plungers follow the profile of the cam ring and describe a cyclical-reciprocating motion (plunger lift 3.5...4.15 mm).

Solenoid-valve-controlled radial-piston distributor pump (cutaway view)

4 3

2 5

1

Fig. 1 1 Pump drive shaft 2 Vane-type supply pump 3 Angle-of-rotation sensor 4 Pump ECU 5 Radial-piston highpressure pump 6 Distributor shaft 7 High-pressure solenoid valve 8 Delivery valve

6 7

UMK1533-2Y

Solenoid-valve controlled distributor injection pumps

High-pressure stage of the radial-piston distributor injection pump

79

When the delivery plungers are pushed inwards by the cams, the volume in the central plunger chamber between the delivery plungers is reduced. This compresses and pumps the fuel. Pressures of up to 1,200 bar are achievable at the pump. Through passages in the distributor shaft, the fuel is directed at defined times to the appropriate outlet delivery valves (Fig. 1, Pos. 8 and Fig. 3, Pos. 5).

There may be 2, 3 or 4 delivery plungers depending on the number of cylinders in the engine and the type of application (Fig. 2). Sharing the delivery work between at least two plungers reduces the forces acting on the mechanical components and permits the use of steep cam profiles with good delivery rates. As a result, the radial-piston pump achieves a high level of hydraulic efficiency. The direct transmission of force within the cam-ring drive gear minimizes the amount of give, which also improves the hydraulic performance of the pump.

Fig. 2 a For 4- or 6-cylinder engines b For 6-cylinder engines c For 4-cylinder engines 1 2 3 Cam ring Roller Guide slot in drive shaft Roller support Delivery plunger Distributor shaft Plunger chamber

Delivery-plunger configurations for radial-piston high-pressure pumps (examples)

1 2 3 4 a b

6 7 c

UMK1561-2Y

3

High-pressure stage within a solenoid-valve controlled radial-piston distributor injection pump

1 2 3 4 5

4 5 6 7

Fig. 3 For the sake of clarity, various components are shown end-on rather than side-on. 1 2 Pump ECU Radial-piston highpressure pump (end-on view) Distributor shaft High-pressure solenoid valve Delivery valve

UMK1534-6Y

3 4 5

Potrebbero piacerti anche

- Fuel Injection PumpsDocumento2 pagineFuel Injection PumpsZeeshan Ahmad0% (1)

- Bib - For Accommodating The Component Parts of The Apparatus. He HasDocumento3 pagineBib - For Accommodating The Component Parts of The Apparatus. He Hasghanbari8668Nessuna valutazione finora

- Opel Astra H - Radiator Fan Failure Engine Overheats PDFDocumento2 pagineOpel Astra H - Radiator Fan Failure Engine Overheats PDFsamasca_serbanNessuna valutazione finora

- Delphi's Diesel Unit Pump Common Rail System 2012Documento6 pagineDelphi's Diesel Unit Pump Common Rail System 2012qingcaohe100% (1)

- Injection Pump History BasicDocumento2 pagineInjection Pump History BasicJIMSCO CALIBRATIONNessuna valutazione finora

- Fuel Injection SystemsDocumento37 pagineFuel Injection SystemsKaran Umralkar100% (4)

- Instruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionDocumento42 pagineInstruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionVladimirNessuna valutazione finora

- The Common Rail Diesel Injection System Explained: Technical FeaturesDocumento3 pagineThe Common Rail Diesel Injection System Explained: Technical FeaturesDejan MihajlovicNessuna valutazione finora

- Simens VDO K16 Pump Reman Line Preliminary Plan v1.0Documento8 pagineSimens VDO K16 Pump Reman Line Preliminary Plan v1.0安靖Nessuna valutazione finora

- Common Rail ReportDocumento4 pagineCommon Rail Reportnuwan_nishaNessuna valutazione finora

- Common RailDocumento11 pagineCommon RailnitishghosalNessuna valutazione finora

- HDI Direct Injection OperationDocumento31 pagineHDI Direct Injection OperationdjautoNessuna valutazione finora

- Deteqstandart PDFDocumento4 pagineDeteqstandart PDFMoaed KanbarNessuna valutazione finora

- Vehicle Identification: Notes Specified Value Measured ValueDocumento5 pagineVehicle Identification: Notes Specified Value Measured ValueПан ТелемонNessuna valutazione finora

- Common Rail Direct InjectionDocumento9 pagineCommon Rail Direct InjectionJoe SparksNessuna valutazione finora

- Liebherr Hydraulic Components For Heavy Duty On Highway Engines Application Flyer Es WebDocumento4 pagineLiebherr Hydraulic Components For Heavy Duty On Highway Engines Application Flyer Es WebDaniel Castillo PeñaNessuna valutazione finora

- Heui InjectorDocumento1 paginaHeui InjectorJuan Gabriel OchoaNessuna valutazione finora

- Nantai Catalog NewDocumento30 pagineNantai Catalog Newspalomos100% (1)

- High-Pressure Common-Rail Fuel InjectionDocumento6 pagineHigh-Pressure Common-Rail Fuel InjectionAndi Anzar0% (1)

- Manual NCT-3000 (En) PDFDocumento15 pagineManual NCT-3000 (En) PDFvintiloiusNessuna valutazione finora

- A5 Common RailDocumento24 pagineA5 Common RailanshelNessuna valutazione finora

- Test BenchesDocumento7 pagineTest BenchesAnderson LondonNessuna valutazione finora

- 6 Gasoline Electronic Fuel Injection SystemsDocumento34 pagine6 Gasoline Electronic Fuel Injection Systemsloganathanpalani100% (1)

- Sistema Inyección CR BoschDocumento8 pagineSistema Inyección CR BoschRodolfo Leiva100% (1)

- Repair VP 44 PumpDocumento11 pagineRepair VP 44 PumpBenji Guardo100% (1)

- vp44 Pump Detail Schematic PDF FreeDocumento7 paginevp44 Pump Detail Schematic PDF Freepablo pérezNessuna valutazione finora

- TECHNEWS 12 2016 - Piezo RegenerationDocumento3 pagineTECHNEWS 12 2016 - Piezo RegenerationAbraaj-TTSNessuna valutazione finora

- Parts VDO 2008Documento30 pagineParts VDO 2008Edinson Ariel Chavarro QuinteroNessuna valutazione finora

- Fuel Injection EvolutionDocumento9 pagineFuel Injection EvolutioncarechimbacomemierdaNessuna valutazione finora

- Catalogue 2016 EngDocumento256 pagineCatalogue 2016 Engdiagnopro100% (2)

- YT BTM ManualDocumento10 pagineYT BTM ManualenriquefreireNessuna valutazione finora

- Fuel Injection SystemDocumento22 pagineFuel Injection SystemAlkaf Quraishi100% (2)

- CRDiDocumento18 pagineCRDiSuhel InamdarNessuna valutazione finora

- Diesel Engine Mixture Formation: 5.4. Fuel Injection SystemDocumento30 pagineDiesel Engine Mixture Formation: 5.4. Fuel Injection SystemGODNessuna valutazione finora

- Bosch MaquinasDocumento13 pagineBosch MaquinasnomecNessuna valutazione finora

- EHVSDocumento24 pagineEHVSCochintu RaduNessuna valutazione finora

- Hilux Surf - Error 5 - Correction Resistance (Pump) The Ramblings of GaloophDocumento29 pagineHilux Surf - Error 5 - Correction Resistance (Pump) The Ramblings of GaloophesyjamNessuna valutazione finora

- Service Manual Nissan PDFDocumento39 pagineService Manual Nissan PDFayi darwisNessuna valutazione finora

- 2013 Technical-Service-Bulletin No-04 en PDFDocumento2 pagine2013 Technical-Service-Bulletin No-04 en PDFSutiknoNessuna valutazione finora

- Reverse Engineering of A Rotary Injection Fuel Pump Project ReportDocumento38 pagineReverse Engineering of A Rotary Injection Fuel Pump Project ReportZuber AbbunaverNessuna valutazione finora

- 3G63 TurboDocumento108 pagine3G63 TurboLuis Felipe Dominguez del CastilloNessuna valutazione finora

- CZ 2012 2013 DieselDocumento14 pagineCZ 2012 2013 DieselSoeAyeNessuna valutazione finora

- The New Mercedes Benz Four Cylinder Diesel Engine For Passenger CarsDocumento8 pagineThe New Mercedes Benz Four Cylinder Diesel Engine For Passenger CarsBobCavNessuna valutazione finora

- Piezo CR Bosch Manual - Nozzle Assembling Disassembling and Injector AdjustingDocumento10 paginePiezo CR Bosch Manual - Nozzle Assembling Disassembling and Injector AdjustingZdravko DudicNessuna valutazione finora

- 05 Fuel Injection SystemDocumento42 pagine05 Fuel Injection SystemVishal JohaheerNessuna valutazione finora

- Introduction Common RailDocumento2 pagineIntroduction Common Railfaris khairuddinNessuna valutazione finora

- NAVEDTRA 14050A Construction Mechanic Advanced Part 3 PDFDocumento160 pagineNAVEDTRA 14050A Construction Mechanic Advanced Part 3 PDFSon Do100% (1)

- Dismantling Process of Fuel Injection PumpDocumento47 pagineDismantling Process of Fuel Injection PumpJonoAlexisDang-awanQuibanNessuna valutazione finora

- Compresores Reciprocantes Sabroe CMODocumento2 pagineCompresores Reciprocantes Sabroe CMOJesus N RodriguezNessuna valutazione finora

- Bosch Fuel System Common RailDocumento4 pagineBosch Fuel System Common RailAlaa saidNessuna valutazione finora

- Injection SystemDocumento75 pagineInjection SystemSlobodan100% (1)

- Cara Kerja PlungerDocumento4 pagineCara Kerja PlungerGaLih Pancaran SentirNessuna valutazione finora

- 2.0L FsiDocumento46 pagine2.0L Fsismellybum67% (3)

- 001 - Common Rail Diesel 1Documento25 pagine001 - Common Rail Diesel 1Encik Rafa BenitezNessuna valutazione finora

- Service Manual: Pub. No. EE14E-11130Documento39 pagineService Manual: Pub. No. EE14E-11130Marcelo Diesel81% (16)

- Camless Engine ReportDocumento29 pagineCamless Engine Reportsushant kumar80% (5)

- New Microsoft Office Word DocumentDocumento11 pagineNew Microsoft Office Word DocumentJunaid YNessuna valutazione finora

- Isuzu Common RailDocumento40 pagineIsuzu Common RailManos Stavrou100% (25)

- Camless Engines Seminar ReportDocumento23 pagineCamless Engines Seminar ReportVineet Jason64% (11)

- K20 Engine Control Module X2 (LGX) Document ID# 4739091Documento3 pagineK20 Engine Control Module X2 (LGX) Document ID# 4739091Data TécnicaNessuna valutazione finora

- Ad 600Documento2 pagineAd 600MohamedBenMansourNessuna valutazione finora

- 810 - 150 Cab With Heating 14284681Documento2 pagine810 - 150 Cab With Heating 14284681DmitryNessuna valutazione finora

- Brochure Valve Positioning System Shafer en 83896Documento6 pagineBrochure Valve Positioning System Shafer en 83896rizky ListyawanNessuna valutazione finora

- GTO Radio InstallDocumento8 pagineGTO Radio InstallAnthony_Blacksna_646Nessuna valutazione finora

- Sport - Ty3 Brake Disc 59.e115.44Documento2 pagineSport - Ty3 Brake Disc 59.e115.44Bruno BrunacciNessuna valutazione finora

- RENAULT LOGAN 2007 k9k 1.5wiring Diagram-01-01Documento6 pagineRENAULT LOGAN 2007 k9k 1.5wiring Diagram-01-01manuel.garcia007Nessuna valutazione finora

- 01 5055L ReparacionDocumento292 pagine01 5055L Reparacionjose vidal100% (1)

- Engg Econ Quiz 1 ME Equiv Aug26.2021Documento2 pagineEngg Econ Quiz 1 ME Equiv Aug26.2021Hane MinasalbasNessuna valutazione finora

- CF-R 520 Manual - Compressed PDFDocumento51 pagineCF-R 520 Manual - Compressed PDFSebastian Nicușor PărăoanuNessuna valutazione finora

- High Performance Compressors For Water Well Drilling: Exceeding Your Expectations!Documento2 pagineHigh Performance Compressors For Water Well Drilling: Exceeding Your Expectations!AnkitNessuna valutazione finora

- 1999 Coda Expert Crank InstructionsDocumento8 pagine1999 Coda Expert Crank InstructionsaPaCz42Nessuna valutazione finora

- Lapl SRDocumento190 pagineLapl SRHarneet SinghNessuna valutazione finora

- Yamaha SZ16R (2DY1) Parts CatalogueDocumento58 pagineYamaha SZ16R (2DY1) Parts CatalogueMarvin MedesNessuna valutazione finora

- Thermo King MD 200 Alarm CodesDocumento3 pagineThermo King MD 200 Alarm CodesPAVLOS80% (5)

- 2006 Can-Am Outlander Max 400 H.O. XT ManualDocumento164 pagine2006 Can-Am Outlander Max 400 H.O. XT Manualprotrek777Nessuna valutazione finora

- CPT CATALOG 2019 (Smallest Quality)Documento14 pagineCPT CATALOG 2019 (Smallest Quality)Alejandro Medina100% (1)

- Skoda Superb ManualDocumento246 pagineSkoda Superb ManualMihai Tinta100% (2)

- The Architecture of Automobile and Building Design: Learning From 100 Years of Parallel ProcessesDocumento107 pagineThe Architecture of Automobile and Building Design: Learning From 100 Years of Parallel ProcessesIhsan MuhtadiNessuna valutazione finora

- Sym Jolie Service ManualDocumento0 pagineSym Jolie Service ManualBen ConnonNessuna valutazione finora

- O235l2c OvhDocumento285 pagineO235l2c Ovhaviacion gnaNessuna valutazione finora

- Sandvik Dd210-V Development Drill: Technical SpecificationDocumento4 pagineSandvik Dd210-V Development Drill: Technical SpecificationIng del PeleNessuna valutazione finora

- Hallite Quick Reference GuideDocumento264 pagineHallite Quick Reference GuideMarcio RibeiroNessuna valutazione finora

- Yamaha Gauges and Gauge KitsDocumento20 pagineYamaha Gauges and Gauge KitsFilipe PratasNessuna valutazione finora

- Tracking Mantra Solutions Pvt. LTD.: Track Any Where Any TimeDocumento6 pagineTracking Mantra Solutions Pvt. LTD.: Track Any Where Any TimeDeepanshu SharmaNessuna valutazione finora

- York YK Series Operation and Maintenance Form Number 160.76-EG1 - 222 - Supersedes 160.76-EG1 - 1121Documento100 pagineYork YK Series Operation and Maintenance Form Number 160.76-EG1 - 222 - Supersedes 160.76-EG1 - 1121Asaad ChughtaiNessuna valutazione finora

- Camshaft Opel Zafira-BDocumento3 pagineCamshaft Opel Zafira-Bmr & mrsNessuna valutazione finora

- Shutdown: No Equipment Selected No Equipment SelectedDocumento6 pagineShutdown: No Equipment Selected No Equipment SelectedFrezgi BirhanuNessuna valutazione finora

- Dodge 45RFE/545RFE Service ManualDocumento263 pagineDodge 45RFE/545RFE Service Manuallilfroger94% (51)

- OMC 80S Seires - Manual (Pneu. Controller)Documento17 pagineOMC 80S Seires - Manual (Pneu. Controller)winhlaingooNessuna valutazione finora