Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

BDTC

Caricato da

Shalu SharmaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

BDTC

Caricato da

Shalu SharmaCopyright:

Formati disponibili

Biogas Development and Training Centre Centre for Rural Development and Technology Indian Institute of Technology, Delhi

Floating Drum Type Biogas Plant

Fixed Dome Type Biogas Plant

Contacts:

Dr. Virendra Kumar Vijay Program Coordinator

Biogas Development and Training Centre, Centre for Rural Development and Technology, Block-III, Indian Institute of Technology Delhi, Hauz Khas, New Delhi 110 016 India. Phone: + 91- 11- 26596351, 26591157 Fax: + 91-11- 26591121, 26596351 E-mail: bdtciitd@gmail.com, vkvijay@rdat.iitd.ernet.in

Biogas Scrubbing System

Bio-CNG Cylinder in a Car

Biogas Operated Three Wheeler

BDTC, IIT Delhi: Indian Institute of Technology, Delhi is one of the Indian Institutes of Technology created as centres of excellence for higher training, research and development in science, engineering and technology in India. A new Biogas Development and Training Centre (BDTC) started in IIT Delhi in the year 2008 and engaged in research and development of biogas related technologies. BDTCs are supported by Ministry of New and Renewable Energy (MNRE) under National Biogas and Manure Management Programme (NBMMP) for providing technical training and publicity support for quality implementation of biogas programme.

Objectives of BDTC, IIT Delhi:

BDTC, IIT Delhi is engaged in research and development of biogas related

technologies and its applications. In broader terms, BDTC, IIT Delhi is to provide technical support for National Biogas Manure Management Program (NBMMP) on decided areas with Ministry of New and Renewable Energy and coordinate R&D and consultancy work on biogas technology with expertise available in IIT Delhi.

To organize training courses for developing entrepreneurs and for staff of the state

nodal departments and implementing agencies etc. for the state of Haryana and Delhi and to carry out field testing/adaptive trials on new models of biogas system and demonstration of new models of biogas plants and diversified uses biogas plants effluents.

Development of multidisciplinary network program in the area of biogas

technology and to provide consultancy services to manufactures, NGOs, implementing agencies etc. for developing and testing of new systems. Ongoing Research Activities at BDTC, IIT Delhi:

Biogas production performance from non edible oil seed cakes and other biodegradable raw materials. Enrichment of methane content in biogas by removal of CO2 and H2S through H2S removal from biogas through biological methods. Biogas bottling into CNG cylinders for automotive applications and its testing on

water scrubbing technology and membrane separation.

engines performance and emissions.

Other Ongoing Activities at BDTC, IIT Delhi: Ministry of New and Renewable Energy has recently launched new initiative for the development of projects on Demonstration of Integrated Technology- Package on Medium-size Biogas-Fertilizer Plants (BGFP) for Generation, Purification/ Enrichment, Bottling and Piped distribution of Biogas towards harnessing Near Total Potential of suitable Biomass in Rural Areas. The BDTC, IIT Delhi, has been designated as lead BDTC for providing technical assistance and monitoring of such projects for obtaining feed-back for further improvement in the techno-commercial package. The BDTC, IIT Delhi provides entrepreneurship education program to motivate the beneficiaries/entrepreneurs in the field of biogas and to impart the technology of the system for taking it as a self entrepreneurship. The Entrepreneurship Awareness Camp is an initiative for motivating beneficiaries/entrepreneurs and creating awareness among them for Entrepreneurship in the field of bio-energy.

Services of BDTC IIT Delhi:

R&D related to bio-methanation Training and Human Resource Development Consultancy services related to biogas technology Technical guidance

Biogas Related Imported Links:

http://www.iitd.ac.in/center/crdt/people.html http://en.wikipedia.org/wiki/Biogas http://www.iisc.ernet.in/currsci/jul10/articles13.htm http://www.arti-india.org/content/view/45/52/ http://mnes.nic.in/ http://mnes.nic.in/prog-ftbp.htm http://www.mnre.gov.in/booklets/Book1-e.pdf http://www.kar.nic.in/zpbelgaum/biogas.html http://en.wikipedia.org/wiki/Anaerobic_digestion http://www.anaerobic-digestion.com/html/the_biogas_digester.php http://www.iitg.ernet.in/ceer/bdtc-info.pdf

Biogas Enrichment and Bottling Technology: Introduction: Biogas is so far, has mostly been used as fuel for cooking and running stationary engines. However, its potential has not fully utilized, yet. There is a great enhancement in its utilization potential particularly where bigger plants are in operation e.g. institutional biogas plants in Goshalas, dairy farms or community biogas plants in villages. Goshalas are running generally on charity basis and most of Goshalas are not in sound financial position. Enrichment and bottling of biogas will help to improve it. India has a vast potential of 6.38 X 1010 cubic meter of biogas per annum from 980 million tonnes of cattle dung produced. There are number of Goshalas, dairies, village communities having large number of cattle which have potential of installing biogas enrichment and bottling system. In urban areas, large quantity of biogas can be produced in sewage treatment plants using anaerobic digestion. Biogas comprises of 60-65% methane, 35-40 % carbon dioxide, 0.5-1.0 % hydrogen sulfide and rests of water vapour. It is almost 20% lighter than air. Biogas, like Liquefied Petroleum Gas (LPG) cannot be converted to liquid state under normal temperature. Removing carbon dioxide and compressing it into cylinders makes it easily usable for transport applications, say three wheelers, cars, pick up vans etc and also for stationary applications at various long distances. Already, CNG technology has become easily available and therefore, biomethane (enriched biogas) which is nearly same as CNG, can be used for all applications for which CNG are used. Biogas Enrichment Process: A variety of processes are available for enrichment i.e. removing CO2, H2S and water vapour. Commonly CO2 removal processes also remove H2S. One of the easiest and cheapest methods involves is the use of pressurized water as an absorbent liquid. In this method, the biogas is pressurized and fed to the bottom of a scrubber column where water is sprayed from the top. In counter-currently operated absorption process, the carbon dioxide and hydrogen sulfide present in the biogas is absorbed in down going water and methane goes up and collected in vessel. However, water requirement in this process is high but it is the simplest method of removing impurities from biogas

Concept of Alternative Bio-CNG: Biogas contains a large proportion (about 40 % by volume) of carbon dioxide, a heavier and non combustible gas and some fraction of hydrogen sulphide. Hence it is needed to enrich biogas by removing these undesirable gases to save compression energy and space in bottle and corroding effect, which can be done by scrubbing. The scrubbing system is found to enrich methane about 95 % or more depending upon biogas inlet and water injection pressure. Biogas can be used for all applications designed for natural gas, assuming sufficient purification. Scope of the Technology: Enriched biogas is made moisture free by passing it through filters after that it is compressed upto 200 bar pressure using a three stage gas compressor. Compressed gas is stored in high pressure steel cylinders as used for CNG. There is large potential of this technology in buses, tractors, cars, auto rickshaws, irrigation pump sets and in rural industries. This will help to meet our energy demand for rural masses thus reduces burden of petroleum demand, moves towards energy security and will improve economic status by creating employment generation in rural area. From only one biogas bottling plant, enriched biogas filled cylinders will be able to replace Rs. 9 lakh fuel annually in the country. Increasing the number of bottling plant will subsequently increase the Diesel/Petrol savings. The whole cost can be recovered within twothree years from the installation of the plant.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Implementation of E-Governance To Improve The Civil Administration Service Quality in Public SectorDocumento11 pagineImplementation of E-Governance To Improve The Civil Administration Service Quality in Public SectorChristie YohanaNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Jackson V AEGLive - May 10 Transcripts, of Karen Faye-Michael Jackson - Make-up/HairDocumento65 pagineJackson V AEGLive - May 10 Transcripts, of Karen Faye-Michael Jackson - Make-up/HairTeamMichael100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Clark SM 616 Service ManualDocumento20 pagineClark SM 616 Service Manualenid100% (55)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Sveba Dahlen - SRP240Documento16 pagineSveba Dahlen - SRP240Paola MendozaNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- CV Augusto Brasil Ocampo MedinaDocumento4 pagineCV Augusto Brasil Ocampo MedinaAugusto Brasil Ocampo MedinaNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Lesson 6 - Vibration ControlDocumento62 pagineLesson 6 - Vibration ControlIzzat IkramNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Apple Change ManagementDocumento31 pagineApple Change ManagementimuffysNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- 2022 WR Extended VersionDocumento71 pagine2022 WR Extended Versionpavankawade63Nessuna valutazione finora

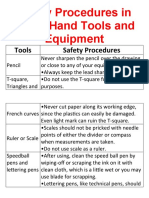

- Safety Procedures in Using Hand Tools and EquipmentDocumento12 pagineSafety Procedures in Using Hand Tools and EquipmentJan IcejimenezNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Quarter 1 - Module 1Documento31 pagineQuarter 1 - Module 1Roger Santos Peña75% (4)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Nanolithography - Processing Methods PDFDocumento10 pagineNanolithography - Processing Methods PDFNilesh BhardwajNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Chhay Chihour - SS402 Mid-Term 2020 - E4.2Documento8 pagineChhay Chihour - SS402 Mid-Term 2020 - E4.2Chi Hour100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Mosfet Irfz44Documento8 pagineMosfet Irfz44huynhsang1979Nessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Inside:: Issue 4 - February 2004 Bi-Monthly Warhammer E-ZineDocumento40 pagineInside:: Issue 4 - February 2004 Bi-Monthly Warhammer E-ZineJoe BloggsNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- National Anthems of Selected Countries: Country: United States of America Country: CanadaDocumento6 pagineNational Anthems of Selected Countries: Country: United States of America Country: CanadaHappyNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Genetics Icar1Documento18 pagineGenetics Icar1elanthamizhmaranNessuna valutazione finora

- Meno's Paradox of Inquiry and Socrates' Theory of RecollectionDocumento10 pagineMeno's Paradox of Inquiry and Socrates' Theory of RecollectionPhilip DarbyNessuna valutazione finora

- Intellirent 2009 CatalogDocumento68 pagineIntellirent 2009 Catalograza239Nessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Modlist - Modlist 1.4Documento145 pagineModlist - Modlist 1.4Tattorin vemariaNessuna valutazione finora

- Fds-Ofite Edta 0,1MDocumento7 pagineFds-Ofite Edta 0,1MVeinte Años Sin VosNessuna valutazione finora

- IMCI Chart BookletDocumento43 pagineIMCI Chart Bookletmysticeyes_17100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Cooperative Learning: Complied By: ANGELICA T. ORDINEZADocumento16 pagineCooperative Learning: Complied By: ANGELICA T. ORDINEZAAlexis Kaye GullaNessuna valutazione finora

- B I o G R A P H yDocumento17 pagineB I o G R A P H yRizqia FitriNessuna valutazione finora

- PSA Poster Project WorkbookDocumento38 paginePSA Poster Project WorkbookwalliamaNessuna valutazione finora

- SOL LogicDocumento21 pagineSOL LogicJa RiveraNessuna valutazione finora

- Applied Economics 2Documento8 pagineApplied Economics 2Sayra HidalgoNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Case Study 2Documento5 pagineCase Study 2api-247285537100% (1)

- ყვავილები ელჯერნონისთვისDocumento348 pagineყვავილები ელჯერნონისთვისNia NorakidzeNessuna valutazione finora

- Application Form InnofundDocumento13 pagineApplication Form InnofundharavinthanNessuna valutazione finora

- Tutorial 5 SolvedDocumento3 pagineTutorial 5 SolvedAshutoshKumarNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)