Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bharat Oil Company - Case Handout

Caricato da

Suyash JoshiDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bharat Oil Company - Case Handout

Caricato da

Suyash JoshiCopyright:

Formati disponibili

Case Handout: Bharat Oil

BHARAT OIL COMPANY

In 1950, the Bharat Oil Company, an independent refinery, had difficulty in the disposal of sulphuric acid after it had been used to purify kerosene and gasoline. The company was disposing of used acid by returning it to the manufacturers. The problem became acute whenever the acid manufacturers were unable to accept return shipments of the impregnated acid. Other refineries that had experienced the same problem constructed plants to reclaim the acid. A method of purifying the acid had been perfected. This raised the question of reclaiming the waste product again. For the past decade, the company converted (annually) about 500,000 barrels of Mexican crude petroleum into gasoline, kerosene, and various grades of oil and asphalt. The annual consumption of acid for conversion purposes was 1,800 metric tons (MT). This acid was bought as needed and shipped in tank cars to the plant where it was stored until used. If gasoline and kerosene were to be marketed as motor and fuel oil, it was essential to treat them with sulphuric acid in order to remove the impurities. A definite quantity of acid was pumped into an agitator filled with either gasoline or kerosene and the two liquids were mixed. The quality, strength of the acid and the length of time required for mixing depended upon the type of oil that was being treated. After the agitation, the acid was allowed to settle and was drawn off into storage tanks. In this condition it was of no value to the company as it could not be sold. Neither could it be emptied into sewers or dumped into the ocean. In order to dispose of it, the sludge acid was pumped into tank cars and returned to the acid manufacturers. The total weight of sludge returned equaled that of the acid used. The freight on the sludge was prepaid by Bharat Oil Company, and averaged Rs.250 per month. Aside from this freight cost, there was no other charge for the disposal of the sludge. At the manufacturers plant it was atomized in a hot coke fire, and the products of combustion (mainly sulphur dioxide) were sent lead chambers to be regenerated into sulphuric acid. The acid reclaimed by this process was not returned to the Bharat Oil Company as it could not be used for treating petroleum compounds because of the detrimental effect of the nitrogen it contained. By returning impure sulphuric acid to the chemical manufacturer, the company avoided the necessity of maintaining a conversion unit, which was a public nuisance because of the offensive odors that it generated. This method of disposal, however, was not entirely satisfactory to Bharat Oil Company. The acid had value when reclaimed. More important, the manufacturers of the acid were often unable to accept the old acid immediately because of limited storage facilities. Moreover, when there was a shortage of old tank cars, it was necessary to use new ones, which had to be re-cleaned at considerable expense to Bharat Oil before they could be used again for new acid. Freight shipments were often slow, and by returning the sludge acid to the manufacturers the company did not control any part of its acid supply, as it could have done had it operated a reclaiming plant in its refinery. Investigations indicated that no better arrangement could be made with any other chemical manufacturer. When it had last considered the installation of a reclaiming plant, the management of Bharat Oil had decided against it on account of the offensive odors which the process

Page 1 of 2

Case Handout: Bharat Oil

generated, and because at that time the chemical process did not reconvert the acid into a form usable in the refinery. However, a new method of purifying acid was perfected which overcame the problem of obnoxious gases, and left no nitrogen in the reconverted product. The cost of a reclaiming unit of this kind with a capacity of processing 10 tons of sludge per day was Rs.30,000; the unit would have a life of about 20 years; and little floor space was required. The reclaiming operation would require a few unskilled labour, with a minimum of supervision by the companys chemists. The total cost of regenerated acid (exclusive of depreciation charge on the reclaiming unit) was estimated as follows (for varying rates of operation): Percentage of capacity 30% 50% 100% Costs per ton Rs.9.00 Rs.8.00 Rs.7.00

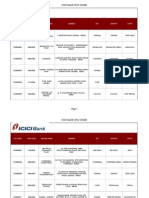

The reclaiming unit would yield as usable acid 75% of the sludge so that with one of these units, the company could meet 75% of its total requirements. Sulphuric acid prices paid by Bharat Oil Company are listed in Exhibit 1. Exhibit 1 BHARAT OIL COMPANY Prices Paid for Sulphuric Acid Year 1935 1936 1937 1938 1939 1940 1941 1942 1943 1944 1945 1946 1947 1948 1949 Monthly Average Price Per MT (FOB) Rs.15.50 Rs.15.50 Rs.16.04 Rs.16.50 Rs.16.50 Rs.16.50 Rs.16.50 Rs.16.50 Rs.16.50 Rs.16.50 Rs.16.50 Rs.16.50 Rs.16.50 Rs.15.53 Rs.17.00 *****************************

Page 2 of 2

Potrebbero piacerti anche

- Low Income Housing in IndiaDocumento32 pagineLow Income Housing in IndiaSuyash JoshiNessuna valutazione finora

- Software Engineering Advice From Building Large-Scale Distributed SystemsDocumento33 pagineSoftware Engineering Advice From Building Large-Scale Distributed Systemspeepeepoo55Nessuna valutazione finora

- Flare Fragrances Presentation FinalDocumento17 pagineFlare Fragrances Presentation FinalSuyash Joshi50% (2)

- Ifsc-Code of Icici Bank Branches in IndiaDocumento10.725 pagineIfsc-Code of Icici Bank Branches in IndiaVenkatachalam KolandhasamyNessuna valutazione finora

- Corpfinance AmchemDocumento12 pagineCorpfinance AmchemSuyash JoshiNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- AFOSP Impact StoryDocumento28 pagineAFOSP Impact StoryAsia Pacific FarmersNessuna valutazione finora

- Starting A Winery in Ontario: Publication 815Documento108 pagineStarting A Winery in Ontario: Publication 815Nab TorNessuna valutazione finora

- June 16 ADM FertilizerDocumento50 pagineJune 16 ADM FertilizerEla LabonosNessuna valutazione finora

- Kiran Mazumdar Shaw: India's Biotech QueenDocumento13 pagineKiran Mazumdar Shaw: India's Biotech QueenRising RevolutionaryNessuna valutazione finora

- Future Solutions Final Project PosterDocumento1 paginaFuture Solutions Final Project Posterapi-395462585Nessuna valutazione finora

- 0083 - en - Key Challenges For Agro-Industry-African Development Bank-Gaif-WorkshopDocumento14 pagine0083 - en - Key Challenges For Agro-Industry-African Development Bank-Gaif-WorkshopPaul ArthurNessuna valutazione finora

- CASH FLOW Sukma FCDocumento8 pagineCASH FLOW Sukma FCvorda buaymadangNessuna valutazione finora

- Depreciation Chart As Per Sec-32 of The Income Tax Act-1961 (43 of 1961)Documento1 paginaDepreciation Chart As Per Sec-32 of The Income Tax Act-1961 (43 of 1961)Rajesh ShiralkarNessuna valutazione finora

- Person's Name With Whom Telecall Was Made His Designation (With Deptt, User/Procurement/ Fin)Documento8 paginePerson's Name With Whom Telecall Was Made His Designation (With Deptt, User/Procurement/ Fin)Arun YashodharanNessuna valutazione finora

- 8d Report Ajax Fiori Stopper PinDocumento4 pagine8d Report Ajax Fiori Stopper PinVengadesh MNessuna valutazione finora

- Operators and Safety Manual Service & Maintenance Manual Illustrated Parts ManualDocumento144 pagineOperators and Safety Manual Service & Maintenance Manual Illustrated Parts ManualCesarSuarezNessuna valutazione finora

- Silo - Tips - Supply Chain Management in Hospital A Case StudyDocumento7 pagineSilo - Tips - Supply Chain Management in Hospital A Case Study398Rishabh RajNessuna valutazione finora

- List of insurance companies in IndiaDocumento11 pagineList of insurance companies in IndiaSushil GuptaNessuna valutazione finora

- 1-BMCG2323 Introduction To ManufacturingDocumento56 pagine1-BMCG2323 Introduction To Manufacturinghemarubini96100% (1)

- Archietcs - All India - 140 PDFDocumento59 pagineArchietcs - All India - 140 PDFBala VishnuNessuna valutazione finora

- Ontario Farmer - Rural Properties and MarketplaceDocumento8 pagineOntario Farmer - Rural Properties and MarketplaceThe London Free PressNessuna valutazione finora

- Complaint Handling SOP SummaryDocumento6 pagineComplaint Handling SOP SummarytesteNessuna valutazione finora

- Aditya Birla Group PPT PDF FreeDocumento21 pagineAditya Birla Group PPT PDF FreeShailesh KumarNessuna valutazione finora

- Tes Praktek Optimizer GoogleDocumento24 pagineTes Praktek Optimizer GooglePramudita BudiantiNessuna valutazione finora

- Renewable Energy Snapshot: SloveniaDocumento4 pagineRenewable Energy Snapshot: SloveniaUNDP in Europe and Central AsiaNessuna valutazione finora

- Raj ImpexDocumento18 pagineRaj Impexkaylakshmi8314Nessuna valutazione finora

- Copia de Copia de Despachos Eduar Ortiz en OTM 12072019 (123Documento1.104 pagineCopia de Copia de Despachos Eduar Ortiz en OTM 12072019 (123eduarandres ortiz gonzalezNessuna valutazione finora

- VDA - 6 - Part 3 - Process Audit 2016-For Training PDFDocumento208 pagineVDA - 6 - Part 3 - Process Audit 2016-For Training PDFJoselyn SaavedraNessuna valutazione finora

- 1) Second Medium Term Plan 2013 - 2017Documento194 pagine1) Second Medium Term Plan 2013 - 2017Anne Waiguru100% (1)

- Anil & Sohan Vendors - Mar 21Documento6 pagineAnil & Sohan Vendors - Mar 21Sahil BarejaNessuna valutazione finora

- Housing loan details and documentsDocumento2 pagineHousing loan details and documentsArun PrasadNessuna valutazione finora

- Executive Chairman Corporate InformationDocumento9 pagineExecutive Chairman Corporate InformationnoreenNessuna valutazione finora

- WWM01 (Assembly)Documento1 paginaWWM01 (Assembly)Evgeni GenkovNessuna valutazione finora

- Final LTM - Pharma AnalysisDocumento25 pagineFinal LTM - Pharma AnalysisSaloni ThakkerNessuna valutazione finora

- Risk Mitigation and Vulnerability Assessment of Nam Dok Mai Mango (Mangifera Indica L.cv. Nam Dok Mai) Supply Chain Using Rapid Agricultural Supply Chain Risk Assessment (RapAgRisk)Documento8 pagineRisk Mitigation and Vulnerability Assessment of Nam Dok Mai Mango (Mangifera Indica L.cv. Nam Dok Mai) Supply Chain Using Rapid Agricultural Supply Chain Risk Assessment (RapAgRisk)Dhiyaa Ulhaq RikavianiNessuna valutazione finora