Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

API 650 Tank Design Calculation

Caricato da

Mohamed AlkhawagaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

API 650 Tank Design Calculation

Caricato da

Mohamed AlkhawagaCopyright:

Formati disponibili

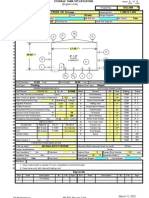

STORAGE TANK SPECIFICATION (English Units)

Project No.

1 Service : 2 Location : 3 Manufacturer : 4 P&ID No. 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Shell Diameter : 25 Roof Type : 26 27 Fluid Stored : Model : Plot Plan No. :

Sheet

1 of 1

RvN . e. o

1952.000 T-400 & T-405

No. Req'd :

CRUDE OIL Storage

Unit :

Equipment No. :

Kirwin

Mfr Ref. No. :

Design Engineer :

Two

PID115-EPF-01-112A1

Other Ref. Dwg No. :

M G

50.00 Ft 32.00 Ft E L F N1

50.00 Cone

Feet Shell Height :

H

48" X 48" FLUSH CLEANOUT

E D

N2

J

32.00 Feet

I

Nominal Volume :

11,191

Barrels

Bottom Floor Type: Sp. Gr. : Cyclic

Sloped

NOZZLES/CONNECTIONS Qty 2 2 1 1 1 1 1 1 1 1 1 1 1 1 Size 24" 24" 48"x48" 6" 1" 8" 10" 30" 4" 8" 3/4" 3/4" 4" 2"

OPERATING/DESIGN DATA CRUDE OIL

0.7900 5.5

psia Design 0.50 2.00

Mark A E F G H I J K L M N1 N2 P D

Service Roof Manway Shell Manway Flush Cleanout MW Stilling Vent Temperature Indicator Outlet Nozzle Fill Nozzle Mixer Manway Water Draw Nozzle Top Center Vent Sample Tap Sample Tap Roof Nozzle Spare

28 This Tank Service is considered: 30 Flash Point (Closed Cup) : 31 Negative Pressure 32 Positive Pressure 33 (Hydro)test Pressure expressed in Psig 34 Minimum Fluid Temperature 35 Maximum Fluid Temperature 36 Emergency Vacuum Design ? 37 38 40 Roof 41 Lining/Coating 42 43 Stress Relieve ? 44 45 Code (as appl.): 46 Design Specifications: 47 Tank Insulation ? 48 Insulation Type: 49 Fireproofing ? 50 Remarks 51 52 No Hot Yes for: Component 39 Shell & Bottom Material 57370 516 Grade 55 Yes F F F

29 Vapor Pressure @ Max. Operating Temperature oz/in.2 psig 0.00 1.00

Operating

----25 200

Set @ CA, in. 0.1250 0.1250 0.0.3 oz/in.2

METALLURGY Remarks Normalized Normalized

Rating 150# 125# 125# 125# 150# 150# 150# 150# 150# 150# 150# 150# 150# 150# 150# 150#

Others: 100 Yes

Face F. F. R. F. R. F. F. F. L. J. API L. J. F. F. R. F. API R. F. F. F. L. J. API API API

CONSTRUCTION/FABRICATION

API 650 LATEST EDITION

Thickness : Paint Spec. in.

Internals (attach separate sheet, as req'd): Sump Seismic Zone Radiograph 85 EmptyTank Weight

Design Wind Velocity % Inspection Req'd ? lb Full of Water

mph lb

Yes

1. Items marked with an asterisk (*) to be completed by Vendor/Fabricator. 2. Fixed cone roof with internal floating roof.

Approvals

Rev 0 Date Description For Inquiry By Chk. Appr. Rev Date Description By Chk. Appr.

Art Montemayor

API 650 Storage Tank

March 12, 2002 Rev: 0

API 650 Design Calculations

D = Normal tank diameter , in feet H = depth of tank , in feet Shell Design : 50.00 32.00

FROM ( BOTTOM COURSE) PLATE TO (TOP COURSE) PLATE td = 2.6(D)(H -1)(G)/Sd= td =

0.174 in. Wall Thickness Miniumum shell thickness, in inches, td = td / tt = 2.6(D)(H-1)/(St) 0.224 in. (Includes Corrosion Allowance)

G = design Specific gravity of liquid 1 Sd = allowable Stress for Design condition 23,200 E = joint efficiency 0.85% St = allowable stress 516-60 Hydro Test 24,900 CA = Corrosion Allowance 0.0625 For First Course (Bottom) 516-60 Plate td = 2.6(D)(H -1)(G)/Sd = td =td / tt = 2.6(D)(H-1)/(St) = td = Miniumum shell thickness, in inches = D = Normal tank diameter , in feet = H = depth of tank , in feet = G = design Specific gravity of liquid = Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress516-60 Hydro Test CA = Corrosion Allowance For Second Course 516-60 Plate td = 2.6(D)(H -1)(G)/Sd= td =td / tt = 2.6(D)(H-1)/(St) td = Miniumum shell thickness, in inches D = Normal tank diameter , in feet H = depth of tank , in feet G = design Specific gravity of liquid Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress 516-60 Hydro Test CA = Corrosion Allowance For Third Course 516-60 Plate 0.209 50.00 28 1 21,300 0.85% 24,000 0.0625 0.3750 0.230 50.00 32.00 1 21,300 0.85% 24,000 0.0625 0.5000 0.165 0.236 0.189

Page 2 of 8

FileName: 58389297.xls WorkSheet: Steel Design

Art Montemayor

API 650 Storage Tank

March 12, 2002 Rev: 0

API 650 Design Calculations

Shell Design : td = 2.6(D)(H -1)(G)/Sd= td =td / tt = 2.6(D)(H-1)/(St) = td = Miniumum shell thickness = D = Normal tank diameter , in feet H = depth of tank , in feet G = design Specific gravity of liquid Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress 516-60 Hydro Test CA = Corrosion Allowance For Fourth Course 516-60 Plate td = 2.6(D)(H -1)(G)/Sd= td =td / tt = 2.6(D)(H-1)/(St) td = Miniumum shell thickness, in inches D = Normal tank diameter , in feet H = depth of tank , in feet G = design Specific gravity of liquid Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress 516-60 Hydro Test CA = Corrosion Allowance For Fifth Course 516-60 Plate Annular Bottom Plate Thickness D = Diameter in Feet H = Height in Feet V = Volume in Cubic Feet Tank Shell surface = Tank Roof surface = Tank Floor surface = 50.00 32.00 0.1342 94.5 8 1 21,300 0.85% 24,000 0.0625 0.2500 0.3750 0.2365 inches 94.5 18 1 21,300 0.85% 24,000 0.0625 0.2500 0.081 0.196

D*H = D2/4 = D2/4 =

5,027 Ft2 of Shell surface area 1,963 Ft2 of Roof Area (estimated) 1,963 Ft2 of Bottom Floor area

Page 3 of 8

FileName: 58389297.xls WorkSheet: Steel Design

Art Montemayor FOUNDATION DESIGN: Per API 650 (Appendix E)

API 650 Storage Tank

March 12, 2002 Rev: 0

Tank is unanchored, use equations pertaining to unanchored tanks, for seismic loading. DATA GIVEN: Seismic Zone; Zone Coefficient Importance Factor Diameter of Tank Height of Liquid Content (Design) Shell Height Design Specific Gravity Thickness of Bottom PL Under Shell Yeild Strength of Bottom PL Weight of Shell Weight of Roof + Live Load = 107.4 + 210.4 Weight of Product PI()/4(94.5)2 (44.5)(.79)(62.4) CALCULATIONS: Seismic Coefficients: Xs = C1 = D/H = Per Fig. E-2 W1 / Wt = W2 / Wt = Per Fig. E-3 X1 /H = X2 /H = Per Fig. E-4 K = 0.6 Lateral Force Coefficients: T =K (D 0.5 ) =.6 *(94.5 0.5) = If Greater Than 4.5 seconds 3.375 (s/T2) = 3.375*1.5/5.832 = E-3.3 5.83 Seconds 0.149 Seconds 0.38 0.59 X1 = X2 = 16.7 26.3 0.54 0.45 W1 = W2 = 8,231 6,924 19.69 Ft 0.60 2.12 3 0.3 1.0 94.5 44.5 48 0.79 0.3750 36,000 PSI 221 Kips 317.8 Kips 15,386 Kips

Z= I = D= H= Hs = G= tb = Fby = Ws = Wy = Wt =

Page 4 of 8

FileName: 58389297.xls WorkSheet: Foundation Design - 1

Art Montemayor

API 650 Storage Tank

March 12, 2002 Rev: 0

FOUNDATION DESIGN: Seismic Loads: M = (Z)(I) { (C1)(Ws)(Xs)+(C1)(Wr)(Ht)+(C1)(W)(X)+(C2)(W2)(X2)} (0.3)*(1.0)[ 0.6(221)(19.685)+ 0.6(317.8)(48.0)+ 0.6(8232)(16.7)+ 0.149(6924)(26.3)] 0.3 2610 9155 82485 27133 36415 Ft-Kips V = (Z)(I) {(C1)(Ws)+(C1)(Wr)(Ht)+(C1)(W)(X)+(C2)(W2)(X2)} (0.3)*(1.0)[ 0.6(221)+ 0.6(317.8)+ 0.6(8232)+ 0.149(6924)] 0.3 132.6 190.68 4939.2 Reistance to Overturning:( E.4.1) API 650

WL = 7.9tb Fby G H (G18)*(G16)*(G14)/(G13)2 )

1031.68

1888 kips

3,333 1125

# / ft

Constant = 3,333 # / ft

1265580 7.9 Not to exceed 1.25*GHD

4153 USE 4153

# / ft # / ft

Shell Compression: Per E-5 M= 36415 ft-kips 6 Kips

Wt + WL = 583.8 / (PI()*94.5) + 4.153 M / D2 (Wt + WL) (G76)/(G13)2(6.12) 36415

54653 b =

0.666 > 0.785 7.0 7.0

b = 1.815+1.273*36415/94.5^2 Max. Longitudinal Compressive Force

UnAnchored Longitudinal Compressive Stress 7000 / 6 Allowable Longitudinal Compressive Stress GHD2/t2 1.255 * 106 = Fa=106 (t) / D = Anchorage Not Required

1167 5.29 Kips

Page 5 of 8

FileName: 58389297.xls WorkSheet: Foundation Design - 1

Art Montemayor

API 650 Storage Tank

March 12, 2002 Rev: 0

FOUNDATION DESIGN:

Max. Overturning Moment Due To Seismic Loads. Compression or Tension Due To Moment: Seismic Base Shear: RINGWALL DESIGN: Use Following Weight Values for Materials Wt. of Steel Wt. Of Compacted Soil Wt. Of Concrete Wall Wt. Of Product in Tank Horizontal Pressure on Ring Wall: F=Kah(*p*H+1/2 soh)+270 0.3*6.0[(50*44.5+0.5*110*6.0)]+270 Hoop Tension: 1/2FD= 1/2(4869)(94.5) As= 231/24.0 USE - 6 # 9 Bars Ea. Face USE - # 4 Bars at 12" on Center Minimum RingWall Thickness: T = 2W / *p*h - 2h ( c - so) W = 1100 1.26 Use 16" Thick Concrete Wall 230 kips 10 in. 490lb/ft3 110 lb/ft3 150 lb/ft3 50 lb/ft3 36,415 Kips 5.19 kpf 0.27 kips

4,869 kips

(2)(1100)/50(44.5)-2(6.0)(150-110)

12" 16" 48"

Top of Ground Elevation

12"

Page 6 of 8

FileName: 58389297.xls WorkSheet: Foundation Design - 2

Art Montemayor

API 650 Storage Tank

March 12, 2002 Rev: 0

Concrete Tensile Stress: fct = c(Es)(As)+T / Ac + n (As) .0003(29*106)(10)+231000/(16*72)+(9*10) 318000 1242 .15(3000) Soil Bearing: Try 3'- 6" Footing Weight. of Wall = 1.33*5.0*.150 Weight of Footing = 3.5*1.0*.150 Weight of Fill = 2.17*4.0*.110 1.0 kips 0.525 kips 0.95 kips 2.48 kips 256 psi 450 psi OK

Case 1 Load from Shell + Roof + Live Load = Weight of Wall +Footing + Fill = Bearing Pressure = Case 2 Dead + Live Load + Earthquake Load = P = 3.58 + 5.19 = H= Moment at Base of Footing = 8.77 kips 0.270 kips 1.62 kips 3.58/3.50 1.1 kips 2.48 kips 1.0 kips

.270(6.0)

Bearing Pressure Under Footing = 8.77/3.5*1 2.51+.79 Allowable Pressure = 3.0*1.33

2.51 kips 3.30 kips 3.99 OK

USE -4 # 9 Bars in Footing USE - # 4 Bars at 12" Horizontal

Page 7 of 8

FileName: 58389297.xls WorkSheet: Foundation Design - 2

Art Montemayor DETAILED FOUNDATION DESIGN:

API 650 Storage Tank

March 12, 2002 Rev: 0

47" - 3"

Center Line of Tank

Slope 1" per ft.

12"

10" Pad of Sand Well-Compacted Gravel 95% Compacted 50 / 100 % Passing # 4 Sieve 6 # 9 Bars Each Face Eq. Spaced

10"

4'0"

# 4 Bars 12" O/C Each Face

95 % Compacted Subgrade or fill Material

1'-4" Wall 12"

(4) # 9 Bars Eq. Spaced 3' - 6"

NOTES:

1. Oiled sand to be mixture of sand and liquid asphalt (mc70): 2. Use 10 gallons of asphalt per cubic yard of sand: 3. Top of concrete to be smooth and level with 1/8" +/- in any 30 feet of circumferential length: 4. Maximum Deiation to be less than 1/4" overall:

Page 8 of 8

FileName: 58389297.xls WorkSheet: Foundation Design - 3

Potrebbero piacerti anche

- Southern Marine Engineering Desk Reference: Second Edition Volume IDa EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INessuna valutazione finora

- Tank Stability 10.0: Shell Dimension, NewDocumento4 pagineTank Stability 10.0: Shell Dimension, NewjonedNessuna valutazione finora

- Fresh HDO Storage TankDocumento42 pagineFresh HDO Storage TankHgagselim SelimNessuna valutazione finora

- Ldo Storage Tank Calculation 170Documento12 pagineLdo Storage Tank Calculation 170Alvin SmithNessuna valutazione finora

- Boiler Specification 2Documento3 pagineBoiler Specification 2AbdulBasitNessuna valutazione finora

- SECURE SoR 09.07.2019Documento39 pagineSECURE SoR 09.07.2019anuragNessuna valutazione finora

- B ABK 5000 1 API 650 Calculation ReportDocumento50 pagineB ABK 5000 1 API 650 Calculation ReportZackNessuna valutazione finora

- Ldo Storage Tank CalculationDocumento7 pagineLdo Storage Tank CalculationchetanmaleNessuna valutazione finora

- 7-12-0006 Rev6 (Angle Leg Support)Documento2 pagine7-12-0006 Rev6 (Angle Leg Support)sumit kumarNessuna valutazione finora

- Bundwall SampleDocumento1 paginaBundwall Samplewawen03Nessuna valutazione finora

- AMETank Product BrochureDocumento6 pagineAMETank Product BrochureSYedZYnAleNessuna valutazione finora

- Tank Volume CalculationDocumento9 pagineTank Volume CalculationMangesh MandgeNessuna valutazione finora

- Superheated Steam Condensate TankDocumento4 pagineSuperheated Steam Condensate TankGanesh BhardwajNessuna valutazione finora

- Sample Calculation For Ammonia Tank - API 620 11th EdDocumento43 pagineSample Calculation For Ammonia Tank - API 620 11th EdAde FaruroziNessuna valutazione finora

- Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Documento1 paginaShell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Karthic KeyanNessuna valutazione finora

- Etank Full ReportDocumento108 pagineEtank Full ReportFaizal SattuNessuna valutazione finora

- 019-02 - 50 KL Mee Feed Storage Tank 21ST-017 & 21ST-018Documento26 pagine019-02 - 50 KL Mee Feed Storage Tank 21ST-017 & 21ST-018Bhaumik BhuvaNessuna valutazione finora

- Sight GlassDocumento10 pagineSight GlassAnonymous EKxXjqyVHNessuna valutazione finora

- Molasses Tank 18092020Documento31 pagineMolasses Tank 18092020Keshav GopaulNessuna valutazione finora

- Design of Steel Storage Tank with Self-Supported Cone RoofDocumento29 pagineDesign of Steel Storage Tank with Self-Supported Cone RoofJoeNessuna valutazione finora

- Design partition plate for refinery distillation columnDocumento5 pagineDesign partition plate for refinery distillation columnpippo2378793Nessuna valutazione finora

- Tank Data Sheet.Documento4 pagineTank Data Sheet.Ranjan Kumar100% (1)

- Tank Agitator Data Sheet Engineering Procurement Project ManagementDocumento10 pagineTank Agitator Data Sheet Engineering Procurement Project ManagementAliZenatiNessuna valutazione finora

- Vacuum catch pot specificationsDocumento1 paginaVacuum catch pot specificationssushant_jhawerNessuna valutazione finora

- RectangularDocumento6 pagineRectangularhgag selimNessuna valutazione finora

- Dyke Wall CalculationDocumento6 pagineDyke Wall CalculationSwapnil MisalNessuna valutazione finora

- Bunded Steel Fuel Tanks - SmallDocumento1 paginaBunded Steel Fuel Tanks - SmallNAHASALI11Nessuna valutazione finora

- Tender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Documento7 pagineTender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Shilpa SinghNessuna valutazione finora

- 1 Process VesselsDocumento4 pagine1 Process VesselsARIANA NICOLE RELIGIOSONessuna valutazione finora

- AFMC (Medical) Solved Paper 2013 PDFDocumento32 pagineAFMC (Medical) Solved Paper 2013 PDFAnkur BanerjeeNessuna valutazione finora

- New Storage Tanks Design GuidelinesDocumento6 pagineNew Storage Tanks Design GuidelineschrisevabNessuna valutazione finora

- Rect TankDocumento6 pagineRect TankSasikumar JothiNessuna valutazione finora

- DheerajDocumento7 pagineDheerajSaksham KakarNessuna valutazione finora

- Freeboard Claculation For Stoarage Tanks As Per Api-650 12Th Edition V V D D H H K K Q Q I IDocumento2 pagineFreeboard Claculation For Stoarage Tanks As Per Api-650 12Th Edition V V D D H H K K Q Q I IAnonymous JWI6rqt100% (1)

- Hih 060216Documento337 pagineHih 060216Asif IqbalNessuna valutazione finora

- Fluid Handling Engineers: U S Agency - Taco DivDocumento5 pagineFluid Handling Engineers: U S Agency - Taco DivsitehabNessuna valutazione finora

- Tank DesignDocumento2 pagineTank DesignkamleshyadavmoneyNessuna valutazione finora

- Spherical Tank PDFDocumento1 paginaSpherical Tank PDFevrim77Nessuna valutazione finora

- Dish End Weight CalculationDocumento5 pagineDish End Weight CalculationAniket royNessuna valutazione finora

- API 650-Water SS Tank-060914Documento84 pagineAPI 650-Water SS Tank-060914A.K.M Shafiq MondolNessuna valutazione finora

- Fresh Water and Disposal Water Tank DetailsDocumento1 paginaFresh Water and Disposal Water Tank DetailscliffrajjoelNessuna valutazione finora

- ETP DBR Rev B-16.08Documento26 pagineETP DBR Rev B-16.08rajnishojha100% (1)

- Indian Oil Corporation Limited: Ahmedabad Divisional OfficeDocumento3 pagineIndian Oil Corporation Limited: Ahmedabad Divisional OfficeKrishiv ChanglaniNessuna valutazione finora

- ITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpDocumento20 pagineITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpHamid MansouriNessuna valutazione finora

- API 650 Water Storage TankDocumento6 pagineAPI 650 Water Storage TankJoeNessuna valutazione finora

- Venting CalculationDocumento14 pagineVenting CalculationValen MaselaNessuna valutazione finora

- Designing an I-beam cross section for maximum load capacityDocumento10 pagineDesigning an I-beam cross section for maximum load capacitySyahmie DaudNessuna valutazione finora

- Column Data Sheet Distillation Column (T-2010)Documento12 pagineColumn Data Sheet Distillation Column (T-2010)John Patrick Sanay NunezNessuna valutazione finora

- Data Sheet For T-8101.RevCDocumento5 pagineData Sheet For T-8101.RevCSuresh SjNessuna valutazione finora

- Scope Matrix PDFDocumento5 pagineScope Matrix PDFNathanNessuna valutazione finora

- Bulk Air Eliminator R1Documento1 paginaBulk Air Eliminator R1hydrothermsNessuna valutazione finora

- API Standard 650 Storage Tank Data SheetDocumento3 pagineAPI Standard 650 Storage Tank Data SheetLuis JaraNessuna valutazione finora

- API 650 Crude Oil Storage Tank DesignDocumento8 pagineAPI 650 Crude Oil Storage Tank Designlecongdinh100% (1)

- API 650 Storage Tank DesignDocumento8 pagineAPI 650 Storage Tank DesignCarey Rich67% (3)

- API 650 Tank Design CalculationsDocumento8 pagineAPI 650 Tank Design Calculationsツ ツNessuna valutazione finora

- API 650 Tank Design CalculationsDocumento8 pagineAPI 650 Tank Design CalculationsVinoth Rajendra50% (4)

- API 650 Tank Design CalculationDocumento9 pagineAPI 650 Tank Design CalculationSunday PaulNessuna valutazione finora

- API 650 Tank Design CalculationDocumento8 pagineAPI 650 Tank Design Calculationmail_younes659283% (29)

- API 650 Tank Design CalculationDocumento8 pagineAPI 650 Tank Design CalculationNorazlan Shah Mahadi100% (1)

- API 650 Tank Design CalculationDocumento8 pagineAPI 650 Tank Design CalculationHoracio RodriguezNessuna valutazione finora

- SC PDFDocumento10 pagineSC PDFMohammed EljammalNessuna valutazione finora

- Activated Sludge ModelDocumento30 pagineActivated Sludge Modelvikas2504Nessuna valutazione finora

- WRD Ot Clarifier Calculations 445211 7Documento118 pagineWRD Ot Clarifier Calculations 445211 7royal inNessuna valutazione finora

- Seconardy TreatmentDocumento43 pagineSeconardy TreatmentMohammed EljammalNessuna valutazione finora

- PV Quick StartDocumento30 paginePV Quick StartMinh Nguyen VanNessuna valutazione finora

- ModiconPremium ScraperChain PDFDocumento6 pagineModiconPremium ScraperChain PDFMohammed EljammalNessuna valutazione finora

- Shakedown and Limit Load of Pipe Bends With Local Wall Thinning Under Combined Internal Pressure and Cyclic In-Plane Bending Moment PDFDocumento24 pagineShakedown and Limit Load of Pipe Bends With Local Wall Thinning Under Combined Internal Pressure and Cyclic In-Plane Bending Moment PDFMohammed EljammalNessuna valutazione finora

- Influence of Local Wall Thinning On Elastic Shakedown Boundary of Pipe BendDocumento9 pagineInfluence of Local Wall Thinning On Elastic Shakedown Boundary of Pipe BendMohammed EljammalNessuna valutazione finora

- CA46S Austenitic Stainless Steel Air and Gas Trap DN40 and DN50Documento3 pagineCA46S Austenitic Stainless Steel Air and Gas Trap DN40 and DN50Mohammed EljammalNessuna valutazione finora

- Chain CalculationsDocumento3 pagineChain CalculationsTeguh Nugraha KusnanNessuna valutazione finora

- Fourier Series TutorialDocumento80 pagineFourier Series TutorialJose VillegasNessuna valutazione finora

- BS6399 P 1Documento16 pagineBS6399 P 1Gopan PillaiNessuna valutazione finora

- Pages 285-295 From Complete Idler Roller Catalog-6 PDFDocumento11 paginePages 285-295 From Complete Idler Roller Catalog-6 PDFMohammed EljammalNessuna valutazione finora

- 2Documento18 pagine2Beny AbdouNessuna valutazione finora

- ULC UL142 Comparison SpreadsheetDocumento43 pagineULC UL142 Comparison SpreadsheetMohammed EljammalNessuna valutazione finora

- Asme PVP2011 57108 Final PDFDocumento12 pagineAsme PVP2011 57108 Final PDFMohammed EljammalNessuna valutazione finora

- Leak DetectionDocumento36 pagineLeak Detectionliyana_anuar_3Nessuna valutazione finora

- Din 2576 Manufacture Din2576 Flange and Flanges Plate of Din 2576 Pn10, PN 10Documento3 pagineDin 2576 Manufacture Din2576 Flange and Flanges Plate of Din 2576 Pn10, PN 10Mohammed EljammalNessuna valutazione finora

- Using The Failure Assessment Diagram Method With Fatigue Crack Growth To Determine Leak-before-RuptureDocumento15 pagineUsing The Failure Assessment Diagram Method With Fatigue Crack Growth To Determine Leak-before-RuptureMohammed EljammalNessuna valutazione finora

- 2012Sept-IPC2012-90582 OvalityDocumento13 pagine2012Sept-IPC2012-90582 OvalityMohammed EljammalNessuna valutazione finora

- 2012Sept-IPC2012-90582 OvalityDocumento13 pagine2012Sept-IPC2012-90582 OvalityMohammed EljammalNessuna valutazione finora

- Rectangular Tank Design PDFDocumento71 pagineRectangular Tank Design PDFPrajwal Shetty87% (15)

- Weights CalculationDocumento10 pagineWeights CalculationMohammed EljammalNessuna valutazione finora

- Conveyor Design-DraftDocumento42 pagineConveyor Design-Draftmkchy1295% (21)

- NT-BELT CONVEYOR TRANSPORTS SOLIDS IN WATER TREATMENTDocumento2 pagineNT-BELT CONVEYOR TRANSPORTS SOLIDS IN WATER TREATMENTMohammed EljammalNessuna valutazione finora

- WHP-East Piatu-Roark Calc & Stiffener-Rev0Documento18 pagineWHP-East Piatu-Roark Calc & Stiffener-Rev0namasral100% (4)

- Effect of Internal Pressure and Shape Imperfections On Plastic Loads of Pipe Bends Under In-Plane Closing MomentDocumento46 pagineEffect of Internal Pressure and Shape Imperfections On Plastic Loads of Pipe Bends Under In-Plane Closing MomentMohammed EljammalNessuna valutazione finora