Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Omala Oil 68

Caricato da

anikit.gujral8000Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Omala Oil 68

Caricato da

anikit.gujral8000Copyright:

Formati disponibili

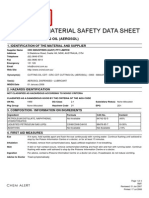

Shell Omala Oil 68

Safety Data Sheet

Shell Omala Oil 68

1. IDENTIFICATION OF THE SUBSTANCE/PREPARATION AND COMPANY/UNDERTAKING

Product Code Infosafe No. Issued Date Product Type/Use Other Names Supplier Shell Company of Australia Ltd. Level 2, 8 Redfern Road, Hawthorn East, Victoria 3123 (ABN 46 004 610 459) AUSTRALIA 001A0773 ACH6P AU/eng/C 9/09/2003 Gear lubricant. Name Shell Omala Oil 68 Code 140000006363

Telephone Numbers Emergency Tel. 1800 651 818 Telephone/Fax Number Tel: 03 9666 5444 Fax: 03 8823 4800

2. COMPOSITION/INFORMATION ON INGREDIENTS Preparation Description Highly refined mineral oils and additives. The highly refined mineral oil contains <3% (w/w) DMSO-extract, according to IP346. 3. HAZARDS IDENTIFICATION Hazards Identification NON-HAZARDOUS SUBSTANCE. NON-DANGEROUS GOODS. Hazard classification according to the criteria of NOHSC. Dangerous goods classification according to the Australia Dangerous Goods Code. Human Health Hazards No specific hazards under normal use conditions. Prolonged or repeated exposure may give rise to dermatitis. Used oil may contain harmful impurities. Safety Hazards Not classified as flammable, but will burn. Environmental Hazards Not classified as dangerous for the environment.

Version No. 1.1 9/09/2003

Page 1 of 7

Shell Omala Oil 68

4. FIRST AID MEASURES Symptoms and Effects Not expected to give rise to an acute hazard under normal conditions of use. Inhalation In the unlikely event of dizziness or nausea, remove casualty to fresh air. If symptoms persist, obtain medical attention. Skin Remove contaminated clothing and wash affected skin with soap and water. If persistent irritation occurs, obtain medical attention. When using high pressure equipment, injection of product under the skin can occur. If high pressure injuries occur, the casualty should be sent immediately to a hospital. Do not wait for symptoms to develop. Eye Flush eye with copious quantities of water. If persistent irritation occurs, obtain medical attention. Ingestion Do not induce vomiting. Wash out mouth with water and obtain medical attention. Advice to Doctor Treat symptomatically. Aspiration into the lungs may result in chemical pneumonitis. Dermatitis may result from prolonged or repeated exposure. High pressure injection injuries require prompt surgical intervention and possibly steroid therapy, to minimise tissue damage and loss of function. 5. FIRE FIGHTING MEASURES Specific Hazards Combustion is likely to give rise to a complex mixture of airborne solid and liquid particulates and gases, including carbon monoxide and unidentified organic and inorganic compounds. Extinguishing Media Foam and dry chemical powder. Carbon dioxide, sand or earth may be used for small fires only. Unsuitable Extinguishing Media Water in jet. Use of halon extinguishers should be avoided for environmental reasons. Protective Equipment Proper protective equipment including breathing apparatus must be worn when approaching a fire in a confined space. 6. ACCIDENTAL RELEASE MEASURES Personal Precautions Avoid contact with skin and eyes. Wear PVC, Neoprene or nitrile rubber gloves. Wear rubber knee length safety boots and PVC Jacket and Trousers. Wear safety glasses or full face shield if splashes are likely to occur. Environmental Precautions Prevent from spreading or entering into drains, ditches or rivers by using sand, earth, or other appropriate barriers. Inform local authorities if this cannot be prevented. Clean-up Methods - Small Spillages Absorb liquid with sand or earth. Sweep up and remove to a suitable, clearly marked container for disposal in accordance with local regulations.

Version No. 1.1 9/09/2003

Page 2 of 7

Shell Omala Oil 68

Clean-up Methods - Large Spillages Prevent from spreading by making a barrier with sand, earth or other containment material. Reclaim liquid directly or in an absorbent. Dispose of as for small spills. 7. HANDLING AND STORAGE Handling Use local exhaust ventilation if there is risk of inhalation of vapours, mists or aerosols. Avoid prolonged or repeated contact with skin. When handling product in drums, safety footwear should be worn and proper handling equipment should be used. Prevent spillages. Cloth, paper and other materials that are used to absorb spills present a fire hazard. Avoid their accumulation by disposing of them safely and immediately. In addition to any specific recommendations given for controls of risks to health, safety and the environment, an assessment of risks must be made to help determine controls appropriate to local circumstances. Storage Keep in a cool, dry, well-ventilated place. Use properly labelled and closeable containers. Avoid direct sunlight, heat sources, and strong oxidizing agents. Storage Temperatures 0C Minimum. 50C Maximum. Recommended Materials For containers or container linings, use mild steel or high density polyethylene. Unsuitable Materials For containers or container linings, avoid PVC. Other Information Polyethylene containers should not be exposed to high temperatures because of possible risk of distortion. 8. EXPOSURE CONTROLS, PERSONAL PROTECTION

Exposure Limits Substance Oil mist, mineral Regulations NOHSC:1003 NOHSC:1003 Exposure Duration TWA STEL Exposure Limit 5 10 Units mg/m3 mg/m3 Notes

NOHSC:1003

Adopted National Exposure Standards for Atmospheric Contaminants in the Occupational Environment [NOHSC:1003(1995)] - 3rd Edition

Exposure Controls Use local exhaust ventilation if there is a risk of inhalation of vapours, mists or aerosols. Respiratory Protection Not normally required. If oil mist cannot be controlled, a respirator fitted with an organic vapour cartridge combined with a particulate pre-filter should be used. Hand Protection PVC or nitrile rubber gloves. Eye Protection Wear safety glasses or full face shield if splashes are likely to occur. Body Protection Minimise all forms of skin contact. Overalls and shoes with oil resistant soles should be worn. Launder overalls and undergarments regularly.

Version No. 1.1 9/09/2003

Page 3 of 7

Shell Omala Oil 68

Environmental Exposure Controls Minimise release to the environment. An environmental assessment must be made to ensure compliance with local environmental legislation. 9. PHYSICAL AND CHEMICAL PROPERTIES

Colour Physical State Odour pH Value Vapour Pressure Initial Boiling Point Solubility in Water Density Flash Point Flammable Limits - Upper Flammable Limits - Lower Auto-Ignition Temperature Kinematic Viscosity Evaporation Rate Vapour Density (Air=1) Partition co-efficient, n-octanol/water Pour Point Brown. Liquid at ambient temperature. Characteristic mineral oil. Data not available. <0.5 Pa at 20C. >280C. Negligible. 887 kg/m3 at 15C. 191C (PMCC). 10%(V/V) (typical). 1%(V/V) (typical). >320 (typical). 68 mm2/s at 40C. Data not available. >1 at 20C. Log Pow >6 (typical). -24C.

10. STABILITY AND REACTIVITY Stability Stable. Conditions to Avoid Extremes of temperature and direct sunlight. Materials to Avoid Strong oxidizing agents. Hazardous Decomposition Products Hazardous decomposition products are not expected to form during normal storage. 11. TOXICOLOGICAL INFORMATION Basis for Assessment Toxicological data have not been determined specifically for this product. Information given is based on a knowledge of the components and the toxicology of similar products. Acute Toxicity - Oral LD50 expected to be > 2000 mg/kg. Acute Toxicity - Dermal LD50 expected to be > 2000 mg/kg. Acute Toxicity - Inhalation Not considered to be an inhalation hazard under normal conditions of use. Eye Irritation Expected to be slightly irritating.

Version No. 1.1 9/09/2003

Page 4 of 7

Shell Omala Oil 68

Skin Irritation Expected to be slightly irritating. Respiratory Irritation If mists are inhaled, slight irritation of the respiratory tract may occur. Skin Sensitisation Not expected to be a skin sensitizer. Carcinogenicity Product is based on mineral oils of types shown to be non-carcinogenic in animal skin-painting studies. Other components are not known to be associated with carcinogenic effects. Mutagenicity Not considered to be a mutagenic hazard. Reproductive Toxicity Not considered to be toxic to reproduction. Other Information Prolonged and/or repeated contact with this product can result in defatting of the skin, particularly at elevated temperatures. This can lead to irritation and possibly dermatitis, especially under conditions of poor personal hygiene. Skin contact should be minimised. High pressure injection of product into the skin may lead to local necrosis if the product is not surgically removed. Used oils may contain harmful impurities that have accumulated during use. The concentration of such impurities will depend on use and they may present risks to health and the environment on disposal. ALL used oil should be handled with caution and skin contact avoided as far as possible. 12. ECOLOGICAL INFORMATION Basis for Assessment Ecotoxicological data have not been determined specifically for this product. Information given is based on a knowledge of the components and the ecotoxicology of similar products. Mobility Liquid under most environmental conditions. Floats on water. If it enters soil, it will adsorb to soil particles and will not be mobile. Persistence / Degradability Not expected to be readily biodegradable. Major constituents are expected to be inherently biodegradable, but the product contains components that may persist in the environment. Bioaccumulation Contains components with the potential to bioaccumulate. Ecotoxicity Poorly soluble mixture. May cause physical fouling of aquatic organisms. Product is expected to be practically non-toxic to aquatic organisms, LL/EL50 >100 mg/l. (LL/EL50 expressed as the nominal amount of product required to prepare aqueous test extract). Mineral oil is not expected to cause any chronic effects to aquatic organisms at concentrations less than 1 mg/l. Other Adverse Effects Not expected to have ozone depletion potential, photochemical ozone creation potential or global warming potential. Product is a mixture of non-volatile components, which are not expected to be released to air in any significant quantities.

Version No. 1.1 9/09/2003

Page 5 of 7

Shell Omala Oil 68

13. DISPOSAL CONSIDERATIONS Waste Disposal Recycle or dispose of in accordance with prevailing regulations, by a recognised collector or contractor. The competence of the contractor to deal satisfactorily with this type of product should be established beforehand. Do not pollute the soil, water or environment with the waste product. Product Disposal As for waste disposal. Container Disposal Recycle or dispose of in accordance with the legislation in force with a recognised collector or contractor. 14. TRANSPORT INFORMATION Transport Information Not dangerous for transport under ADG, IMO and IATA/ICAO regulations. ADG UN Class None Allocated ADG Packing Group None Allocated ADG Hazchem Code None Allocated IMDG Hazard Class None Allocated IMDG Packing Group None Allocated 15. REGULATORY INFORMATION

EC Symbols EC Risk Phrase EC Safety Phrase EINECS None. Not classified. Not classified. All components listed or polymer exempt.

AICS (Australia) All components listed. National Legislation National Code of Practice for the Preparation of Material Safety Data Sheets [NOHSC:2011] List of Designated Hazardous Substances [NOHSC:10005]. Approved Criteria for Classifying Hazardous Substances [NOHSC:1008]. Adopted National Exposure Standards for Atmospheric Contaminants in the Occupational Environment [NOHSC:1003]. Australian Dangerous Goods Code. Standard Uniform Scheduling of Drugs and Poisons. Packaging & Labelling Safety data sheet available for professional user on request.

Version No. 1.1 9/09/2003

Page 6 of 7

Shell Omala Oil 68

16. OTHER INFORMATION References For detailed advice on Personal Protective equipment, refer to the following Australian Standards :HB 9 (Handbook 9) Manual of industrial personal protection. AS/NZS 1337 Eye protectors for industrial applications. AS/NZS 1715 Selection, use and maintenance of respiratory protective devices. AS/NZS 1716 Respiratory protective devices. Poisons Schedule NS. Restrictions This product must not be used in applications other than recommended without first seeking the advice of the SHELL technical department. Technical Contact Numbers (03) 9666 5444. Further Information This information is based on our current knowledge and is intended to describe the product for the purposes of health, safety and environmental requirements only. It does not constitute a guarantee for any specific property of the product. ... End Of SDS ...

Version No. 1.1 9/09/2003

Page 7 of 7

Potrebbero piacerti anche

- Shell Alvania Grease RL 3Documento7 pagineShell Alvania Grease RL 3Alberto PerezNessuna valutazione finora

- Aeroshell Fluid 41Documento7 pagineAeroshell Fluid 41임희훈Nessuna valutazione finora

- Georgia Pest Management Handbook: 2021 Home and Garden EditionDa EverandGeorgia Pest Management Handbook: 2021 Home and Garden EditionEmily CabreraNessuna valutazione finora

- Shell Tivela Oil S 150 Safety Data SheetDocumento7 pagineShell Tivela Oil S 150 Safety Data Sheetabahena1757Nessuna valutazione finora

- Pollution Control in Oil, Gas and Chemical PlantsDa EverandPollution Control in Oil, Gas and Chemical PlantsNessuna valutazione finora

- Shell Tellus Oil 68 Safety Data SheetDocumento9 pagineShell Tellus Oil 68 Safety Data Sheetandi permanaNessuna valutazione finora

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesDa EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNessuna valutazione finora

- Shell Turbo Oil T 46 (MSDS) 1Documento7 pagineShell Turbo Oil T 46 (MSDS) 1Anonymous F2TxS3YoaNessuna valutazione finora

- The Health & Safety Guide for Film, TV & Theater, Second EditionDa EverandThe Health & Safety Guide for Film, TV & Theater, Second EditionValutazione: 4 su 5 stelle4/5 (1)

- Turbo Oil T 68Documento7 pagineTurbo Oil T 68Akbar RoSyidNessuna valutazione finora

- Shell Gadinia AL 40 Safety Data SheetDocumento7 pagineShell Gadinia AL 40 Safety Data SheetArthur Botão MartinsNessuna valutazione finora

- Shell Omala 100Documento7 pagineShell Omala 100PN RaoNessuna valutazione finora

- Shell Omala Oil F 320 Safety Data SheetDocumento7 pagineShell Omala Oil F 320 Safety Data SheetIsabela BoceanuNessuna valutazione finora

- Komatsu Powertrain Oil TO10Documento7 pagineKomatsu Powertrain Oil TO10yoguijojoNessuna valutazione finora

- Hypogear 80W-90 - BP Australia Pty LTDDocumento5 pagineHypogear 80W-90 - BP Australia Pty LTDBiju_PottayilNessuna valutazione finora

- Shell Turbo T 46Documento7 pagineShell Turbo T 46gad480Nessuna valutazione finora

- Triple7 Eor Enhanced Oil Recovery SdsDocumento8 pagineTriple7 Eor Enhanced Oil Recovery SdsHappiness ImuetinyanNessuna valutazione finora

- Material Safety Data SheetDocumento8 pagineMaterial Safety Data SheetMohamed SudanNessuna valutazione finora

- Worthington Creyssensac - Rotair Plus 4000 - GB - enDocumento8 pagineWorthington Creyssensac - Rotair Plus 4000 - GB - enВасилий ЗотовNessuna valutazione finora

- Safety Data Sheet: 1. Identification of The Material and SupplierDocumento5 pagineSafety Data Sheet: 1. Identification of The Material and SupplierRegan RidgeNessuna valutazione finora

- Rimula x30Documento7 pagineRimula x30hastaNessuna valutazione finora

- Shell Spirax ASX-R 75W-90 MSDSDocumento7 pagineShell Spirax ASX-R 75W-90 MSDSAnonymous LfeGI2hMNessuna valutazione finora

- Roto-Z: Safety Data SheetDocumento8 pagineRoto-Z: Safety Data SheetGregory Alan Francisco IINessuna valutazione finora

- Shell Tellus S2 M 46 MSDSDocumento13 pagineShell Tellus S2 M 46 MSDSThomas FungNessuna valutazione finora

- Steyr Motors Lubricant 10W40Documento8 pagineSteyr Motors Lubricant 10W40Rodrigo MonteiroNessuna valutazione finora

- Shell Diala Oil B Safety Data SheetDocumento6 pagineShell Diala Oil B Safety Data Sheetbagus adhitiawarmanNessuna valutazione finora

- Shell Tellus Oil T 32: Safety Data SheetDocumento8 pagineShell Tellus Oil T 32: Safety Data SheetTiago GodinhoNessuna valutazione finora

- 1 - Identification of The Substance/preparation and Company/undertaking Molub-Alloy 412 SFDocumento4 pagine1 - Identification of The Substance/preparation and Company/undertaking Molub-Alloy 412 SFwillowwood666Nessuna valutazione finora

- Antifoam SDSDocumento7 pagineAntifoam SDSUna Si NdésoNessuna valutazione finora

- MSDS - Shell Morlina - Machine OilDocumento7 pagineMSDS - Shell Morlina - Machine OilAnonymous LfeGI2hMNessuna valutazione finora

- Shell Refrigeration Oil S2 FR-A 68Documento8 pagineShell Refrigeration Oil S2 FR-A 68slvmr_estrada1259Nessuna valutazione finora

- Raycol Asphalt Company Limited: Material Safety Data SheetDocumento3 pagineRaycol Asphalt Company Limited: Material Safety Data SheetKongsak AkkharawongwhatthanaNessuna valutazione finora

- MSDSDocumento7 pagineMSDSShahid IqbalNessuna valutazione finora

- Thinner Ms DsDocumento6 pagineThinner Ms DsSetiawan HatmajiNessuna valutazione finora

- Corena Oil PDocumento5 pagineCorena Oil Pmingyu parkNessuna valutazione finora

- Pennzoil MsdsDocumento7 paginePennzoil MsdsSkySupplyUSANessuna valutazione finora

- Safety Data Sheet: 1. Identification of The Material and Supplier Sodium Carboxymethyl CelluloseDocumento6 pagineSafety Data Sheet: 1. Identification of The Material and Supplier Sodium Carboxymethyl CelluloseShola EshoNessuna valutazione finora

- Material Data Safety Sheet Jet A1 ShellDocumento10 pagineMaterial Data Safety Sheet Jet A1 ShellAdnan Haji HarbiNessuna valutazione finora

- Safety Data Sheet (SDS) : Nippon Grease Co., Ltd. E4377005 Date:June 1, 2016 Page.1/5Documento5 pagineSafety Data Sheet (SDS) : Nippon Grease Co., Ltd. E4377005 Date:June 1, 2016 Page.1/5Chanchai PrugpadeeNessuna valutazione finora

- Shell Dromus Oil B: Safety Data SheetDocumento8 pagineShell Dromus Oil B: Safety Data SheetRicky AriefNessuna valutazione finora

- Aeroshell Grease 33Documento8 pagineAeroshell Grease 33barisalmanNessuna valutazione finora

- Aeroshell Fluid 3 PDFDocumento8 pagineAeroshell Fluid 3 PDFNICKYNessuna valutazione finora

- Melina 30 - MSDSDocumento7 pagineMelina 30 - MSDSBeryl FernandesNessuna valutazione finora

- Chockfast Orange Resin GhsDocumento8 pagineChockfast Orange Resin GhsRizky RamadhanNessuna valutazione finora

- Alexia 50 - MSDSDocumento7 pagineAlexia 50 - MSDSBeryl FernandesNessuna valutazione finora

- Omo persil powder - unilever - Bột giặt omoDocumento5 pagineOmo persil powder - unilever - Bột giặt omonhật minh nguyễnNessuna valutazione finora

- Shell Rl3 MsdsDocumento8 pagineShell Rl3 MsdsHitesh ShahNessuna valutazione finora

- Safety Data Sheet: 1 - Identification of The Substance/preparation and of The Company/undertaking Castrol MHP 154Documento4 pagineSafety Data Sheet: 1 - Identification of The Substance/preparation and of The Company/undertaking Castrol MHP 154GhouriNessuna valutazione finora

- Gadus S2 A320 2Documento8 pagineGadus S2 A320 2Beryl FernandesNessuna valutazione finora

- Shell Tellus S22 M22Documento5 pagineShell Tellus S22 M22Hafifi IsmailNessuna valutazione finora

- MSDS - Shell Mysella - Engine OilDocumento7 pagineMSDS - Shell Mysella - Engine OilAnonymous LfeGI2hMNessuna valutazione finora

- Rotair Food Grade SafetyDocumento7 pagineRotair Food Grade SafetyAristideNessuna valutazione finora

- Roto-Xtend Duty Fluid: Safety Data SheetDocumento7 pagineRoto-Xtend Duty Fluid: Safety Data SheetPEDRO PABLO DUQUENessuna valutazione finora

- CDT Cutting Oil (Aerosol) - CRC IndDocumento4 pagineCDT Cutting Oil (Aerosol) - CRC IndBiju_PottayilNessuna valutazione finora

- TDAE (Treated Distillate Aromatic Extract) : Safety Data SheetDocumento6 pagineTDAE (Treated Distillate Aromatic Extract) : Safety Data SheetBumble BeeNessuna valutazione finora

- AeroShell Grease 5Documento8 pagineAeroShell Grease 5Mark Evan SalutinNessuna valutazione finora

- Diala B MsdsDocumento6 pagineDiala B MsdsMarco GodoyNessuna valutazione finora

- Safety Data Sheet: 1. Material and Supplier IdentificationDocumento6 pagineSafety Data Sheet: 1. Material and Supplier IdentificationMatt LNessuna valutazione finora

- Clinical Ultrasound A How-To GuideDocumento146 pagineClinical Ultrasound A How-To GuideNacko Stavreski67% (3)

- GSM Modernization Poster2Documento1 paginaGSM Modernization Poster2leonardomarinNessuna valutazione finora

- Exercise Stress TestingDocumento54 pagineExercise Stress TestingSaranya R S100% (2)

- Schroedindiger Eqn and Applications3Documento4 pagineSchroedindiger Eqn and Applications3kanchankonwarNessuna valutazione finora

- Chapter 7 (Additional Notes) Thermodynamics Review (Power Plant Technology by M Wakil)Documento29 pagineChapter 7 (Additional Notes) Thermodynamics Review (Power Plant Technology by M Wakil)Aries SattiNessuna valutazione finora

- Cumulative List of Notices to MarinersDocumento2 pagineCumulative List of Notices to MarinersResian Garalde Bisco100% (2)

- ATEX Certified FiltersDocumento4 pagineATEX Certified FiltersMarco LoiaNessuna valutazione finora

- Qualtrics Ebook Employee Lifecycle Feedback Apj - q8uL5iqE4wt2ReEuvbnIwfG4f5XuMyLtWvNFYuM5Documento18 pagineQualtrics Ebook Employee Lifecycle Feedback Apj - q8uL5iqE4wt2ReEuvbnIwfG4f5XuMyLtWvNFYuM5RajNessuna valutazione finora

- Animal Names in English and IndonesianDocumento7 pagineAnimal Names in English and IndonesianAndi KurniawanNessuna valutazione finora

- Ub40 LyricsDocumento76 pagineUb40 LyricsJose Lucio Flores SantosNessuna valutazione finora

- Tyfo SDocumento2 pagineTyfo SAndi AsNessuna valutazione finora

- Stories of Prophets - 2Documento19 pagineStories of Prophets - 2Hadis MusaNessuna valutazione finora

- Dimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutDocumento11 pagineDimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutRizqi RamadhanNessuna valutazione finora

- Palm Wine SpecificationDocumento10 paginePalm Wine SpecificationUday ChaudhariNessuna valutazione finora

- PC Assembly PlantDocumento19 paginePC Assembly Plantmuyenzo100% (1)

- Techniques for Studying FossilsDocumento11 pagineTechniques for Studying FossilsP. C. PandeyNessuna valutazione finora

- ME 2141 - Complete ModuleDocumento114 pagineME 2141 - Complete ModuleNICOLE ANN MARCELINONessuna valutazione finora

- Unit 4.2Documento45 pagineUnit 4.2Gundrathi Narendra GoudNessuna valutazione finora

- Porta by AmbarrukmoDocumento4 paginePorta by AmbarrukmoRika AyuNessuna valutazione finora

- Personality Types and Character TraitsDocumento5 paginePersonality Types and Character TraitspensleepeNessuna valutazione finora

- State of The Art Penelitian - Chat GPT 2023Documento137 pagineState of The Art Penelitian - Chat GPT 2023restyNessuna valutazione finora

- Business PlanDocumento63 pagineBusiness PlanKristine BalanayNessuna valutazione finora

- Product:: Electronic, 2 C #18 STR TC, PE Ins, OS, PVC JKT, CMDocumento2 pagineProduct:: Electronic, 2 C #18 STR TC, PE Ins, OS, PVC JKT, CMAnonymous XYAPaxjbYNessuna valutazione finora

- GE - Oil Sheen Detection, An Alternative To On-Line PPM AnalyzersDocumento2 pagineGE - Oil Sheen Detection, An Alternative To On-Line PPM AnalyzersjorgegppNessuna valutazione finora

- Contact GRRSB Team for InquiriesDocumento2 pagineContact GRRSB Team for Inquiriesmsis81Nessuna valutazione finora

- 3 Variable Cramers Rule PDFDocumento4 pagine3 Variable Cramers Rule PDFElton DiocsonNessuna valutazione finora

- Revised fire drill performance standardsDocumento47 pagineRevised fire drill performance standardsKartikeya GuptaNessuna valutazione finora

- Vishwabhanu Oct '18 - Jan '19Documento26 pagineVishwabhanu Oct '18 - Jan '19vedicvision99100% (3)

- 2.gantry Rotation Safety CheckDocumento2 pagine2.gantry Rotation Safety CheckLê Hồ Nguyên ĐăngNessuna valutazione finora