Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pulsar Wiper Relay Location

Caricato da

Murray HopkinsDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pulsar Wiper Relay Location

Caricato da

Murray HopkinsCopyright:

Formati disponibili

WIPER/WASHER SYSTEM

1990 Nissan 240SX

1990-92 ACCESSORIES & EQUIPMENT Wiper/Washer Systems Axxess, Maxima, Pathfinder, Pickup, Pulsar NX, Sentra, Stanza, 240SX, 300ZX NOTE: This article has been updated according to Technical Service Bulletin No. TS89-115, dated August 10, 1989.

SYSTEM DESCRIPTION & OPERATION

All models are equipped with a 2-speed wiper system with time delay feature. Some models are equipped with a rear wiper/washer system.

WIPER MOTOR DESCRIPTION & OPERATION

All wiper motors include an integral park switch inside the motor housing. The motor cover can be removed and the switch adjusted if wipers do not park correctly. Some models have an externally mounted circuit breaker to protect the wiper motor.

WIPER AMPLIFIER DESCRIPTION & OPERATION

Axxess, Pathfinder, Pulsar NX and Sentra use a wiper amplifier to control the delayed front wiper cycle. The amplifier is a solid-state unit which interrupts current flow to the motor. The time delay is either fixed or adjustable with a knob at the end of the wiper stalk. Some models use an amplifier in the rear wiper circuit. See WIPER COMPONENT LOCATION table. All Maxima, Stanza, 240SX and 300ZX models have a Time Control Unit (TCU) which controls the delayed wiper cycle. This unit also operates the clock, turn and hazard flashers, seat belt chimes and other timed delayed circuits.

WASHER DESCRIPTION & OPERATION

NOTE: A check valve is located in washer line between reservoir tank and nozzle. If removed, install valve with arrow toward nozzle.

All models have windshield washer systems. A separate pump is used for the rear washer. On all models except Maxima, a common reservoir is used for both washer systems. Maxima models have a rear washer reservoir mounted in luggage compartment. NOTE: Not all vehicles have front or rear wiper relays or amplifiers.

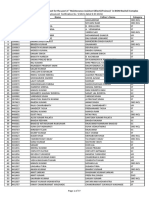

WIPER COMPONENT LOCATION TABLE Application

1990 Axxess Amplifier Front .................................. Underhood, Near Prop Rod Rear ...................................... Right Side Rear Panel

Location

Relay Rear

...............................

Under Dash, Behind Glove Box

Maxima Relay ......................... Left Front Underhood, In Relay Box Time Control Unit ............... Under Dash, Near Steering Column Pathfinder Amplifier Rear ..................................... Left Side Middle Panel Relay Rear ....................................... Left Side Rear Panel Pulsar NX Amplifier Sentra Amplifier .......................... .......................... Underhood, Left Side Firewall Underhood, Left Side Firewall

Stanza Relay ......................... Left Front Underhood, In Relay Box Time Control Unit ........................... Left Side Kick Panel 240SX Amplifier Front .................. Location Not Available From Manufacturer Rear .......................................... Center Rear Panel Time Control Unit ........................... Left Side Kick Panel 300ZX Amplifier Front .............................. Left Rear Engine Compartment Time Control Unit ........................... Left Side Kick Panel

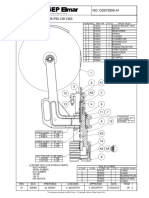

Fig. 1: Typical Wiper/Washer Components Courtesy of Nissan Motor Co., U.S.A.

WIPER ARM ADJUSTMENT

1) Prior to installing wiper arm, turn wiper motor switch ON then OFF (Auto Stop). Install wiper arm but do not tighten nut. Set blade down on glass. 2) Set blade so that centerline of wiper blade is at specified distance from edge of glass in the STOP position (horizontal stop wipers). On vertical stop wipers, the distance is measured from centerline of wiper blade to edge of black print on glass. See WIPER BLADE CLEARANCE table. Tighten wiper arm nut. 3) Operate washer motor to spray washer fluid on glass. Turn wiper switch ON to operate wiper motor. Turn wiper switch OFF. Ensure proper clearance is maintained. WIPER BLADE CLEARANCE TABLE Application

Axxess Front Left ............................. 1.9-2.3 (49-59) Right ................................ 0-.4 (0-10) Rear Horizontal Stop Type ............. 1.4-1.8 (35-45) Vertical Stop Type ...................... 1.0 (24) Maxima Left .............................. 1.7-2.1 (43-53) Right .............................. .9-1.3 (22-32) Pathfinder & Pickup Front .............................. .8-1.2 (20-30) Rear ........................ Rests On Blade Lifter Pulsar NX ................................ 0-.2 (0-5)

Sentra Front .............................. .6-1.2 (16-31) Rear Coupe ............................. .6-1.0 (15-25) Wagon ............................ 1.0-1.4 (25-35) 1991 Sentra Front Left ............................ .98-1.38 (25-35) Right ........................... .79-1.18 (20-30) Rear ......................... 4.13-4.53 (105-115) Stanza Left .............................. 1.7-2.1 (43-53) Right .............................. .9-1.3 (22-32) 240SX Front .............................. .7-1.3 (25-35) Rear .............................. 1.0-1.4 (25-35) 300ZX Front ................................. 0-.4 (0-10) Rear .............................. 2.9-3.5 (73-88)

WIPER SWITCH TEST

Clearance In. (mm)

For wiper switch testing, see STEERING COLUMN SWITCHES article in the ACCESSORIES & EQUIPMENT section.

WIPER AMPLIFIER TEST AXXESS, PATHFINDER, PULSAR, SENTRA, 240SX & 300ZX

1) Disconnect and remove amplifier from vehicle or position so test leads, battery and test light can be connected to amplifier terminals. Use care to prevent improper connections since amplifier can be damaged. 2) Connect test leads and test light as shown to battery and terminals of amplifier. See Fig. 2. Leaving test lead from terminal No. 6 for last, connect test lead to battery ground. If test light comes on, amplifier is normal. If not, replace amplifier.

Fig. 2: Testing Wiper Amplifier Courtesy of Nissan Motor Co., U.S.A.

Fig. 3: Testing Wiper Amplifier (Except Axxess) Courtesy of Nissan Motor Co., U.S.A.

WIPER RELAY TEST

Connect test leads and test light as shown to battery and to terminals of wiper relay. See Fig. 4. Leaving test lead from terminal No. 6 for last, connect test lead to battery ground. Relay is normal if test light comes on. If test light does not come on, replace wiper relay.

Fig. 4: Testing Wiper Relay Courtesy of Nissan Motor Co., U.S.A.

WIPER RELAY TEST (1992 MODELS)

Remove relay. There should be continuity between terminals No. 3 and 4, and no continuity between terminals No. 6 and 7. See Fig. 5. Apply battery voltage across terminals No. 1 and 2. There should now be no continuity between terminals No. 3 and 4, and continuity between terminals No. 6 and 7. If continuity is not as specified, replace relay.

Fig. 5: Testing Wiper Relay Courtesy of Nissan Motor Co., U.S.A.

TIME CONTROL UNIT TEST

NOTE:

The Time Control Unit (TCU) is used on Maxima, Stanza, 240SX and 300ZX models. Control unit operates many different systems for each vehicle. The following circuit test procedures only check circuits that control the wiper delay operation.

Fig. 6: Harness Connectors On Time Control Unit Courtesy of Nissan Motor Co., U.S.A. When testing time control unit, insert probes into harness side of connector while still plugged into control unit. See Figs. 4 and 5. Ensure ignition key is in correct position when testing each circuit. Perform tests in order: * * * * Power Circuit TCU Output Wiper Relay Circuit Wiper Switch Circuit Intermittent Wiper Volume

POWER CIRCUIT

1) Turn ignition off. Access time control unit with harness still connected. Using an ohmmeter, check continuity between terminal No. 15 and ground. Continuity should exist. If not, inspect TCU harness circuit and repair or replace as needed. 2) Connect a voltmeter between terminals No. 9 (+) and 15 (-) at harness side of connector. Voltmeter should show 12 volts when ignition switch is in any position. 3) Connect voltmeter to terminals No. 5 (+) and 15 (-). With ignition switch in the OFF or ACC position, voltmeter should show zero volts. With ignition switch in the ON position, voltmeter should show 12 volts. If results are incorrect, inspect TCU harness circuit. If correct, test TCU output wiper relay circuit. 4) Connect voltmeter leads to terminals No. 2 (+) and 15 (-). With ignition switch in the ACC or ON position, voltmeter should read 12 volts. There should be no voltage reading when ignition switch is in the OFF position. If results are incorrect, inspect TCU harness circuit. If correct, test TCU output wiper relay circuit.

TCU OUTPUT WIPER RELAY CIRCUIT

Turn ignition switch to the ACC position and wiper switch in the INT position, measure voltage across terminals No. 1 (+) and

15 (-). Voltage reading should be zero volts, then should read 12 volts in 3 to 12 second intervals. If not, check wiper switch circuit.

WIPER SWITCH CIRCUIT

Turn ignition switch to the OFF position and wiper switch to the INT position. Using an ohmmeter, check for continuity between terminals No. 12 (+) and 15 (-). Continuity should exist. If not, check wiper switch.

INTERMITTENT WIPER VOLUME CIRCUIT

Turn ignition off. Using an ohmmeter, measure resistance between terminals No. 14 and 15 while turning intermittent wiper volume switch. Reading should be from zero ohms with switch in the "S" position, and should read approximately one ohm in the "L" position. If reading is incorrect, replace wiper switch.

FRONT WIPER MOTOR R & I

Removal 1) Disconnect battery ground cable and motor wiring. Remove wiper motor mounting bolts. Remove nut and clip holding linkage arm to motor shaft. Remove motor assembly. 2) Remove wiper arm cap and nut. Remove wiper arm and wiper shaft nut. Remove inspection cover (if equipped) and remove linkage. NOTE: Before installing wiper arm(s), wiper motor must be cycled at lowest speed, then turned off to allow motor to find its parked position.

Installation 1) Clean wiper arm splines (on each pivot actuator) with a wire brush before installing wiper arm. To install, reverse removal procedure. 2) On some models, wiper arm lengths differ from side to side. Compare arm lengths before installation. Drivers side arm can be identified by a "D" and is usually the shorter arm. The passengers side arm can be identified by an "A" and is usually the longer arm. 3) Ensure clearance (position) of wiper blade is correct when installing wiper arms. Clearance is measured between edge of windshield and end of wiper blade. See WIPER BLADE CLEARANCE table.

WIPER RELAYS R & I

For removal and installation of wiper relays, see WIPER COMPONENT LOCATION table in this article. Remove panels and fasteners as necessary. To install, reverse removal procedure.

REAR WIPER MOTOR R & I

Removal Remove wiper shaft nut and wiper arm. Open hatch or tailgate and remove inner panel. Disconnect wiring from motor. Remove motor mounting bolts. Remove wiper motor. Installation To install, reverse removal procedure. Install wiper arm so blade is in correct position. See WIPER BLADE CLEARANCE table.

COMBINATION SWITCH R & I

Remove steering wheel pad and steering wheel. Disconnect all wiring. Remove retaining screw or clip and pull combination switch off column. Wiper switches can be separated from combination switch. To install, reverse removal procedure. Align tab on switch with hole in column.

WIRING DIAGRAMS

See appropriate chassis wiring diagram in WIRING DIAGRAMS.

TORQUE SPECIFICATIONS

WIPER ARM TORQUE SPECIFICATIONS Application

*Axxess Front ............................... Maxima ................................ Pathfinder & Pickup ................... Pulsar NX ............................. Sentra ................................ Stanza ................................ 240SX Front ............................... Rear ................................ 300ZX Front ...............................

Axxess Rear 300ZX Rear

* Revised according to Technical Service Bulletin No. TS89-115

9-13 12-17 10-13 10-13 10-13 12-17 ................................ ................................

FT Lbs. (N.m) (12-18) (17-23) (14-18) (14-18) (14-18) (17-23)

12-17 (17-23) 10-13 (14-18) 12-17 (17-23) INCH Lbs.(N.m) 56-104 (6-12) 78-104 (9-12)

Potrebbero piacerti anche

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDa EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideValutazione: 4.5 su 5 stelle4.5/5 (8)

- Isuzu Trooper Workshop ManualDocumento3.573 pagineIsuzu Trooper Workshop Manualvit otio89% (19)

- PV776 TSP23760 1Documento100 paginePV776 TSP23760 1Registr Registr100% (1)

- Isuzu Trooper 20workshop 20manual (Petrol Engine)Documento3.573 pagineIsuzu Trooper 20workshop 20manual (Petrol Engine)Syed Azhar HussainNessuna valutazione finora

- ATDocumento164 pagineATjacor96100% (1)

- Civic Transeje Aut CVTDocumento300 pagineCivic Transeje Aut CVTCarlos Mendoza CambrónNessuna valutazione finora

- Auto Trans DiagnosisDocumento31 pagineAuto Trans Diagnosissonny1234Nessuna valutazione finora

- Electric Over Air (EOA) Range Shift System All ZF Meritor 9 and 10speedDocumento57 pagineElectric Over Air (EOA) Range Shift System All ZF Meritor 9 and 10speedmatt powellNessuna valutazione finora

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Da EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Valutazione: 5 su 5 stelle5/5 (1)

- STC PDFDocumento38 pagineSTC PDFTony JenNessuna valutazione finora

- LANCER Workshop ManualDocumento21 pagineLANCER Workshop ManualHameed0% (1)

- 98 Arctic Cat 300 2x4 Parts ListDocumento43 pagine98 Arctic Cat 300 2x4 Parts ListMark100% (1)

- Alternator and Regulator NippondensoDocumento16 pagineAlternator and Regulator NippondensoToua YajNessuna valutazione finora

- Montero INSTRUMENT PANELDocumento51 pagineMontero INSTRUMENT PANELHernando MontenegroNessuna valutazione finora

- Lg4hk We 0229domDocumento0 pagineLg4hk We 0229domKarl O. Munroe100% (6)

- Yamaha R6 2007 Varios Modelos PDFDocumento538 pagineYamaha R6 2007 Varios Modelos PDFCARLOSNessuna valutazione finora

- Ce BM 021004Documento1.391 pagineCe BM 021004Ravinder Singh100% (1)

- 2002 Subaru WRX Wiring DiagramDocumento154 pagine2002 Subaru WRX Wiring Diagramsiolfor100% (2)

- Checkmate in 3 Moves PDFDocumento5 pagineCheckmate in 3 Moves PDFChandaKunda75% (4)

- King Air 300: Operating HandbookDocumento92 pagineKing Air 300: Operating HandbookMoises Sanchez100% (2)

- Subaru - WIRINGDocumento154 pagineSubaru - WIRINGIS52100% (2)

- Komatsu 930E-3 DUMP TRUCK Service ManualDocumento904 pagineKomatsu 930E-3 DUMP TRUCK Service Manualatommota100% (2)

- Rear AxleDocumento6 pagineRear AxleThomas A. EDISSONNessuna valutazione finora

- Johnson ManualDocumento108 pagineJohnson Manualfirebird197286% (7)

- 82 Fuller RTO 6613 Transmission Service ManualDocumento114 pagine82 Fuller RTO 6613 Transmission Service Manualfdpc1987Nessuna valutazione finora

- MAriner 20 25 HP Manual 11046910Documento19 pagineMAriner 20 25 HP Manual 11046910Karl Ullman0% (1)

- Ryobi: 18 Volt Circular Saw Model No. P508 Repair SheetDocumento4 pagineRyobi: 18 Volt Circular Saw Model No. P508 Repair SheetVictor Perez100% (1)

- VW Transporter T4 Workshop Manual Diesel 2000-2004Da EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Valutazione: 5 su 5 stelle5/5 (5)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Da EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Valutazione: 1 su 5 stelle1/5 (3)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Ford Think Service Manual - Section 3 PowertrainDocumento16 pagineFord Think Service Manual - Section 3 PowertrainDennis Jason AntiNessuna valutazione finora

- Rover 100Documento106 pagineRover 100Daniel Card100% (1)

- Vento Zip R3i Service ManualDocumento85 pagineVento Zip R3i Service ManualMichael Lance70% (10)

- EstoperoDocumento2 pagineEstoperoMARIO100% (1)

- Suspension - Comparative Oil Weights Table-1Documento8 pagineSuspension - Comparative Oil Weights Table-1Vennia PapadipoulouNessuna valutazione finora

- Electronics and Wiring Diagram EPA13 Part 1 PDFDocumento32 pagineElectronics and Wiring Diagram EPA13 Part 1 PDFIvan Valentić0% (1)

- Alternator Hitachi Nissan 240sxDocumento6 pagineAlternator Hitachi Nissan 240sxredservimax100% (1)

- Instrument Panel: 1991 Mitsubishi MonteroDocumento11 pagineInstrument Panel: 1991 Mitsubishi MonteroAnimemanuel MuñozNessuna valutazione finora

- Wiper Washer SystemDocumento6 pagineWiper Washer SystemAnimemanuel MuñozNessuna valutazione finora

- Exhaust System: SectionDocumento11 pagineExhaust System: SectionRafaelCazalesFuentesNessuna valutazione finora

- Basic Testing Pajero 1991Documento12 pagineBasic Testing Pajero 1991nadaNessuna valutazione finora

- Motor Liftmaster bmt5011 PDFDocumento24 pagineMotor Liftmaster bmt5011 PDFmotik1205Nessuna valutazione finora

- BTM250 TSM300 112700 112701 112703 EngDocumento31 pagineBTM250 TSM300 112700 112701 112703 Engmartin_jaitmanNessuna valutazione finora

- MaintenanceDocumento32 pagineMaintenancehamblin76Nessuna valutazione finora

- Manual ASTATPlus English Ed2Documento50 pagineManual ASTATPlus English Ed2Michelle WebsterNessuna valutazione finora

- STORAGE MANUAL VMT 865 GR Rev00Documento7 pagineSTORAGE MANUAL VMT 865 GR Rev00nigelNessuna valutazione finora

- mx500 ManualDocumento21 paginemx500 ManualFurqan hussainNessuna valutazione finora

- 18 CccfozDocumento120 pagine18 CccfozHalit YalçınkayaNessuna valutazione finora

- Sunpro Cp7678 DVM User ManualDocumento36 pagineSunpro Cp7678 DVM User ManualGeza Levai100% (2)

- Maintenance: SectionDocumento51 pagineMaintenance: Sectiontomallor101Nessuna valutazione finora

- Wiper Washer System - Nissan Sentra 1993Documento6 pagineWiper Washer System - Nissan Sentra 1993Alessandro BaffaNessuna valutazione finora

- Altistart 46: Open Style Soft Start Motor ControllersDocumento46 pagineAltistart 46: Open Style Soft Start Motor ControllersHazem Al-kayaliNessuna valutazione finora

- Megger BiddleDocumento30 pagineMegger BiddleDante FilhoNessuna valutazione finora

- Stenner Classic Series Installation InstructionsDocumento48 pagineStenner Classic Series Installation InstructionsWattsNessuna valutazione finora

- G-5500 Im Eng E12901004Documento12 pagineG-5500 Im Eng E12901004ampetreNessuna valutazione finora

- Chrysler Dakota Part16Documento10 pagineChrysler Dakota Part16Sašo Brunšek-BrunoNessuna valutazione finora

- User'S Manual: Have A Technical Question?Documento76 pagineUser'S Manual: Have A Technical Question?Julio CorzoNessuna valutazione finora

- XJ Wiper and Washer Systems 8K - 1Documento14 pagineXJ Wiper and Washer Systems 8K - 1hottubdocNessuna valutazione finora

- Instrument Panel Analog - Nissan Sentra 1993Documento8 pagineInstrument Panel Analog - Nissan Sentra 1993Alessandro BaffaNessuna valutazione finora

- Yamaha FZ6-N 2004 (Europe) Supplementary Service ManualDocumento77 pagineYamaha FZ6-N 2004 (Europe) Supplementary Service Manualm.kelleci7248Nessuna valutazione finora

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationDa EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNessuna valutazione finora

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationDa EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNessuna valutazione finora

- Motorcycle, Solo (Harley-Davidson Model WLA)Da EverandMotorcycle, Solo (Harley-Davidson Model WLA)Nessuna valutazione finora

- Auto Pricelist at CDO YardDocumento1 paginaAuto Pricelist at CDO YardMat i Naawan NHS (R X - Misamis Oriental)Nessuna valutazione finora

- 01 The Characteristics of Lens MaterialsDocumento54 pagine01 The Characteristics of Lens MaterialsEye KnowledgeNessuna valutazione finora

- Monster Stack PDFDocumento1 paginaMonster Stack PDFAnonymous HNNAdSFzzmNessuna valutazione finora

- Assignment - Rotational KinematicsDocumento1 paginaAssignment - Rotational Kinematicsarqam SaadNessuna valutazione finora

- Appsc Polytechnic Lecturers 19-05-2011Documento9 pagineAppsc Polytechnic Lecturers 19-05-2011बोले तो भरद्वाजNessuna valutazione finora

- List of Eligible Candidates For Written Test For The Post of "Maintenance Assistant (Elect) (Trainee) " in BIOM Bacheli ComplexDocumento77 pagineList of Eligible Candidates For Written Test For The Post of "Maintenance Assistant (Elect) (Trainee) " in BIOM Bacheli ComplexPrashikp PrashikpNessuna valutazione finora

- Project 3 - Kozhikode Indoor Stadium - Presentation - CompressedDocumento36 pagineProject 3 - Kozhikode Indoor Stadium - Presentation - CompressedDeepa AnoopNessuna valutazione finora

- Skyrim Mods 2Documento3 pagineSkyrim Mods 2Ineedit4Nessuna valutazione finora

- Alex Crook: Athletic Media Relations ProfessionalDocumento1 paginaAlex Crook: Athletic Media Relations ProfessionalAlex CrookNessuna valutazione finora

- Up 180 15762Documento2.303 pagineUp 180 15762Uday kumarNessuna valutazione finora

- PG&E EV Fleet Program: Summary of Zero Emission Vehicles and Equipment For Distribution and Delivery FleetsDocumento71 paginePG&E EV Fleet Program: Summary of Zero Emission Vehicles and Equipment For Distribution and Delivery FleetsCRUZENessuna valutazione finora

- Hormone STPMDocumento1 paginaHormone STPMjennieNessuna valutazione finora

- Wheel: Hub MotorDocumento7 pagineWheel: Hub Motormilou88Nessuna valutazione finora

- No Tanggal No. Kartu Nama Pes Sex Jenis Pes Diagnosa: MastayahDocumento33 pagineNo Tanggal No. Kartu Nama Pes Sex Jenis Pes Diagnosa: MastayahIc-tika Siee ChuabbieNessuna valutazione finora

- Modulo 6Documento6 pagineModulo 6janet71% (7)

- The EMG SignalDocumento37 pagineThe EMG SignalIrina GatuNessuna valutazione finora

- Chain Sling Toolbox TalkDocumento6 pagineChain Sling Toolbox Talkfathul syaafNessuna valutazione finora

- Activity 2 - Effect of Blood Viscosity On Blood Flow RateDocumento4 pagineActivity 2 - Effect of Blood Viscosity On Blood Flow RateTadhg Ó MaoldhomhnaighNessuna valutazione finora

- Front Squat - CrossFit Training GuideDocumento2 pagineFront Squat - CrossFit Training GuideKarim HaridiNessuna valutazione finora

- Exercises and Relaxation Technique During PregnancyDocumento2 pagineExercises and Relaxation Technique During PregnancyIndrawati ShresthaNessuna valutazione finora

- FORM SSC.2 School Sports Club Attachment Form v1Documento6 pagineFORM SSC.2 School Sports Club Attachment Form v1Super JNessuna valutazione finora

- Roguish Archetype - Shadow Dancer (DND)Documento3 pagineRoguish Archetype - Shadow Dancer (DND)Lennox StevensonNessuna valutazione finora

- Play Chess Online For Free With Friends & FamilyDocumento1 paginaPlay Chess Online For Free With Friends & Familyhma nasrtNessuna valutazione finora

- Fortnite Solo Showdown RulesDocumento1 paginaFortnite Solo Showdown RulesDorianNessuna valutazione finora

- Soccer Formation Lineup Sheet 11v11 4132Documento1 paginaSoccer Formation Lineup Sheet 11v11 4132داود ميلاحNessuna valutazione finora

- Iron Game HistoryDocumento12 pagineIron Game Historysteppenwolf88100% (1)