Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

He158c (A4)

Caricato da

Mohd Hafizil Mat YasinDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

He158c (A4)

Caricato da

Mohd Hafizil Mat YasinCopyright:

Formati disponibili

SOLTEQ

Equipment for Engineering Education & Research

HEAT EXCHANGER TRAINING APPARATUS

MODEL: HE 158C

HIS Heat Exchanger Training Apparatus (Model: HE 158C) is a bench type unit designed to allow students to get familiarised with different kinds of heat exchangers and to collect the necessary experimental data for the calculation of heat loss, heat transfer coefficient, log mean temperature difference, etc. Student will also be able to study the effect of flow rate on the heat transfer rate. Later, students may use this knowledge for designing complex industrial heat exchangers.

The HE 158C is supplied with four types of heat exchangers with two 50-L stainless steel sump tanks as the source for the hot and cold water circuit. The hot tank is fitted with a 11.5 kW immersion type heater which is protected against possible over heating. Each tank has a centrifugal pump to deliver the hot and cold water to the heat exchangers. The pumps are somehow protected from dry-run by level switch installed in each of the sump tanks. A temperature sensor and temperature controller are also provided to maintain a constant desired temperature inside the hot water tank.

The unit is supplied with all necessary instruments to measure the inlet and outlet temperatures of the hot and cold water as well as the flow rates of the hot and cold water and the pressure drops across the heat exchangers. Piping and fittings are made of stainless steel materials to prevent rust. The hot water and cold water circuits are properly insulated to minimize heat losses or heat gains between the tank and the heat exchangers.

SOLTEQ

Equipment for Engineering Education & Research Coil : O.D. = 9.53 mm I.D. = 7.05 mm Length = 5 m Material = stainless steel 316L Exchange area : 0.15 m2 (approx.) Plate Heat Exchanger No. of plates : 14 Plate material : stainless steel 316L Connections : 3/4 MPT Dimensions : 4.9 x 12.2 x 1.7 (W x L x D) Exchange area : 0.18 m2 Sump Tanks Capacity Material Ports Heater Pumps Type Capacity Head Electrical : : : :

EXPERIMENTAL CAPABILITIES Energy balance determination Temperature profiles in co-current and countercurrent flow Log mean temperature difference Heat transfer coefficient Flow rate effects on heat transfer rate Heat loss estimation Relationship between Nusselt (Nu) and Reynold (Re) numbers SPECIFICATIONS: Bench Epoxy coated mobile steel bench with lockable swivel castors. Shell & Tube Heat Exchanger Shell : I.D. = 82 mm Length = 500 mm Material = borosilicate glass Tubes : O.D. = 9.53 mm I.D. = 7.75 mm Length = 500 mm Tube count = 10 (single pass) Tube pitch = 18 mm (triangle) Baffle = 8 Baffle cut = 20% Material = stainless steel 316L Exchange area : 0.15 m2 (approx.) Concentric (Double Pipe) Heat Exchanger Shell : I.D. = 82 mm Length = 500 mm Material = borosilicate glass Tube : O.D. = 33.4 mm I.D. = 26.64 mm Length = 500 mm Material = stainless steel 316L Exchange area : 0.05 m2 (approx.) Spiral Heat Exchanger Shell : I.D. = 82 mm Length = 500 mm Material = borosilicate glass

Instrumentations Flow meters : 0 to 10 LPM (cold water) 0 to 10 LPM (hot water) Temperatures : 0 to 100 C Manometer : 0 to 50 cm of water Temperature sensor and controller

Control Panel Temperature controller for heater input to maintain the hot water temperature and prevent over heating. On/off buttons for pumps and heater. OPTIONAL ITEMS

- EI DIGITAL INSTRUMENTATIONS i) 8 units of digital indicators ii) 4 units of temperature sensors c/w transmitter iii) 2 units of electronic flow meters iv) 2 units of differential pressure transmitters

SOLTEQ

50 L Stainless steel Inlet/outlet/drain 11.5 kW for hot tank with temperature control Centrifugal, stainless steel 0 to 50 LPM 10 m 240VAC/1-phase/50 Hz : : : :

SOLTEQ

Equipment for Engineering Education & Research iv) Full experiment manuals REQUIREMENTS

i) ii) iii) iv)

A PC with latest Pentium Processor An electronic signal conditioning system Stand alone data acquisition modules Windows based data acquisition software Data Logging Signal Analysis Process Control Real-Time Display Tabulated Results Graph of Experimental Results AIDED LEARNING

Electrical supply: 415VAC/3-phase/50Hz Water supply Drainage points OVERALL DIMENSIONS Height : 1.50 m Width : 1.52 m Depth : 0.91 m MANUAL

- CAL SOLCAL COMPUTER SOFTWARE

i) Interactive multimedia features ii) Graphical simulation iii) Experiment results samples

The unit is supplied with Operating and Experiment Manuals in English giving full descriptions of the unit, summary of theory, experimental procedures and typical experimental results.

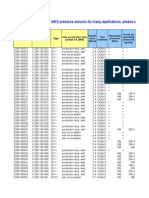

TYPICAL EXPERIMENT RESULTS

Shell & Tube Heat Exchanger with Variable Hot Water Flow Rate

1200 Overall heat transfer coeff. (W/m2.K)

1000

800

600

400

200

0 0 2,000 4,000 6,000 8,000 10,000 Tube side (hot water) Reynolds number Cold w ater at 20 LPM Cold w ater at 15 LPM

Cold w ater at 10 LPM

SOLTEQ

Cold w ater at 20 LPM Cold w ater at 15 LPM Cold w ater at 10 LPM 12,000 14,000 16,000

-DAS SOLDAS DATA ACQUISITION SYSTEM

SOLTEQ

Equipment for Engineering Education & Research

SOFTWARE & E - LEARNING Our range of teaching equipment can be complemented with our SOLDAS and SOLCAL software.

SOLDAS - Supervisory Control & Data Acquisition - Data Logging - Signal Analysis - Process Control - Real-Time Display - Tabulated Results - Graph of Experimental Results

SOLCAL - Computer Aided Learning - Multimedia Features - Interactive - Graphic Simulation - Experiment Result Samples - Full Experiment Manuals

Contact us for a catalog CD SOLUTION ENGINEERING SDN. BHD.

(Co. No. 174876-M) Sales Office :

AGENT:

No.3, Jalan TPK 2/4, Taman Perindustrian Kinrara, 47100 Puchong, Selangor Darul Ehsan, Malaysia. Tel. No. : +(603) 80758000 Fax. No. : +(603) 80755784

R&D Office : G-2A, Incubator 3, Technology Park Malaysia, Bukit Jalil, 57000 Kuala Lumpur, Malaysia. Tel. No. : +(603) 8996 0023 Email : solution@solution.com.my Web site : http//www.solution.com.my/

BUATAN MALAYSIA

MSC- Status

Company

Potrebbero piacerti anche

- EKC 291 9 Heat ConductionDocumento11 pagineEKC 291 9 Heat ConductionLia HolmanNessuna valutazione finora

- Practical Chemical Thermodynamics for GeoscientistsDa EverandPractical Chemical Thermodynamics for GeoscientistsNessuna valutazione finora

- HTL-04 Thermal Conductivity of LiquidDocumento2 pagineHTL-04 Thermal Conductivity of Liquidvindiesel9222Nessuna valutazione finora

- Chlorine: International Thermodynamic Tables of the Fluid StateDa EverandChlorine: International Thermodynamic Tables of the Fluid StateNessuna valutazione finora

- He158c Experimental Manual PDFDocumento113 pagineHe158c Experimental Manual PDFElizabeth Thomas0% (1)

- Influence of Air Velocity on Drying Rate of Wet SandDocumento3 pagineInfluence of Air Velocity on Drying Rate of Wet SandJohanNessuna valutazione finora

- CPB30004 Process Dynamics and Control Experiment 5: Heat Exchanger Process Control Lab ReportDocumento24 pagineCPB30004 Process Dynamics and Control Experiment 5: Heat Exchanger Process Control Lab ReportSiti Hajar Mohamed100% (1)

- Cooling Tower ReportDocumento11 pagineCooling Tower Reportbae zazNessuna valutazione finora

- CRE Lab ManualDocumento19 pagineCRE Lab ManualMayursinh Solanki100% (1)

- The Heat of Solution LabDocumento4 pagineThe Heat of Solution Labapi-310957734Nessuna valutazione finora

- Sec01 - GroupE - (Unsteady State Heat Transfer)Documento11 pagineSec01 - GroupE - (Unsteady State Heat Transfer)Dzulfadhly ShaariNessuna valutazione finora

- 7 Fluid Dynamics Tutorial SolutionDocumento25 pagine7 Fluid Dynamics Tutorial SolutionAldhaAhmadyaningratNessuna valutazione finora

- IYOHA COLLINS 16CF020531 Batch Reactor ReportDocumento19 pagineIYOHA COLLINS 16CF020531 Batch Reactor ReportDavid OvieNessuna valutazione finora

- AFPT921 Air Flow Pressure Temperature Control TrainingDocumento2 pagineAFPT921 Air Flow Pressure Temperature Control TrainingKamalanathen ChlvnNessuna valutazione finora

- S-Lab Manual Exp 3 - Air Flow Process ControlDocumento12 pagineS-Lab Manual Exp 3 - Air Flow Process Controlarif arifinNessuna valutazione finora

- Thermal Laboratory - Lab Experiment-1Documento7 pagineThermal Laboratory - Lab Experiment-1Raj PratyushNessuna valutazione finora

- Experiment: Batch Reactor Unit Operations Lab I (CHEGR3787L) Fall 2004Documento5 pagineExperiment: Batch Reactor Unit Operations Lab I (CHEGR3787L) Fall 2004Janice YanNessuna valutazione finora

- CHE 463 Heat Transfer Assignment 2: Group Member Id NumberDocumento6 pagineCHE 463 Heat Transfer Assignment 2: Group Member Id NumberFakrul HakimiNessuna valutazione finora

- CELCHA2 Study GuidesDocumento7 pagineCELCHA2 Study GuidesEsther100% (1)

- Measurement of The Drag Coefficients of Spherical ParticlesDocumento10 pagineMeasurement of The Drag Coefficients of Spherical Particlessr3shNessuna valutazione finora

- Geothermal HTE for Hydrogen ProductionDocumento9 pagineGeothermal HTE for Hydrogen ProductionAnonymous d2K8lZPRugNessuna valutazione finora

- Optimal cleaning cycle heat exchanger foulingDocumento1 paginaOptimal cleaning cycle heat exchanger foulingBahadır KayaNessuna valutazione finora

- RI Vs Composition Methanol-Water MixtureDocumento12 pagineRI Vs Composition Methanol-Water MixtureAnonymous VeJYFSMWLINessuna valutazione finora

- Energy Balance For Distillation ColumnDocumento2 pagineEnergy Balance For Distillation ColumnKarar AlalihNessuna valutazione finora

- Evaporation: Kevin A. OlegarioDocumento6 pagineEvaporation: Kevin A. OlegarioKitty VNessuna valutazione finora

- Computer FileDocumento13 pagineComputer FileAnand MajumderNessuna valutazione finora

- A Study On The PH of Commonly Used Soaps/cleansers Available in The Indian MarketDocumento3 pagineA Study On The PH of Commonly Used Soaps/cleansers Available in The Indian MarketpalliNessuna valutazione finora

- Apparatus, Procedure, Recommendation Tray DryerDocumento4 pagineApparatus, Procedure, Recommendation Tray DryerillyzlNessuna valutazione finora

- Concentric Tube Heat ExchangerDocumento10 pagineConcentric Tube Heat Exchangeramirhazwan93% (14)

- Plate Column Distillation EfficiencyDocumento7 paginePlate Column Distillation EfficiencyVijay PrasadNessuna valutazione finora

- Gas UnitDocumento4 pagineGas UnitZalina SamsuddinNessuna valutazione finora

- Free/Force Convection H.T From Pinned&finnedDocumento14 pagineFree/Force Convection H.T From Pinned&finnedIbrahimNessuna valutazione finora

- Lab 1Documento12 pagineLab 1JoeJeanNessuna valutazione finora

- CHEM3002 Tutorial Sheet 3Documento1 paginaCHEM3002 Tutorial Sheet 3Sunmoon Al-HaddabiNessuna valutazione finora

- Colling Tower: Mechanical Lab / Exp. NO.Documento10 pagineColling Tower: Mechanical Lab / Exp. NO.Dalal Salih100% (1)

- Assignment 1 PDFDocumento1 paginaAssignment 1 PDFRoydia SimanNessuna valutazione finora

- Effect of Temperature on Chemical ReactionDocumento8 pagineEffect of Temperature on Chemical ReactionnajihahNessuna valutazione finora

- Expt. 4 Heat Transfer in Fluidized BedsDocumento8 pagineExpt. 4 Heat Transfer in Fluidized BedsPradeep DiwakarNessuna valutazione finora

- Questions (Cod Lab Report)Documento1 paginaQuestions (Cod Lab Report)putriyusairah_91Nessuna valutazione finora

- Batch ReactorDocumento4 pagineBatch ReactorFoo Xiao BingNessuna valutazione finora

- Heat ExchangerDocumento4 pagineHeat ExchangerIzwanaRahimiNessuna valutazione finora

- Thermal Conductivity of Pipe Insulation Using Lagged PipeDocumento6 pagineThermal Conductivity of Pipe Insulation Using Lagged PipeanbuvrpNessuna valutazione finora

- CHAPTER 4 Process Control COMPLETEDocumento42 pagineCHAPTER 4 Process Control COMPLETEkhairitajurusNessuna valutazione finora

- Electroplating Experiment Determines Faraday's ConstantDocumento3 pagineElectroplating Experiment Determines Faraday's ConstantMaiSakurajima100% (1)

- PHE Control Mechanism PDFDocumento6 paginePHE Control Mechanism PDFNaren VmdNessuna valutazione finora

- Energy Transport Notes 2Documento102 pagineEnergy Transport Notes 2Faisal MumtazNessuna valutazione finora

- Condensation in Drop and Film FormDocumento5 pagineCondensation in Drop and Film FormAshish VermaNessuna valutazione finora

- Effux Time EquationsDocumento7 pagineEffux Time EquationsDhananjay KadamNessuna valutazione finora

- Boiling Heat Transfer - Annurev - Fluid.30.1Documento37 pagineBoiling Heat Transfer - Annurev - Fluid.30.1agnotts09Nessuna valutazione finora

- Horizontal Shell-and-Tube Condenser CapacityDocumento4 pagineHorizontal Shell-and-Tube Condenser Capacitykero_the_heroNessuna valutazione finora

- Refrigeration Unit (DONE)Documento33 pagineRefrigeration Unit (DONE)Eimint Mansor Applez100% (1)

- Heat Exchangers Design: Effectiveness - NTU MethodDocumento35 pagineHeat Exchangers Design: Effectiveness - NTU MethodSaurabh SengarNessuna valutazione finora

- Gas Absorption LabDocumento8 pagineGas Absorption Labsolehah misni100% (1)

- Latent Heat of Vaporization of Ethanol Using Clausius-Clapeyron EquationDocumento5 pagineLatent Heat of Vaporization of Ethanol Using Clausius-Clapeyron EquationMel DyNessuna valutazione finora

- Specific Heat of Metals ExperimentDocumento8 pagineSpecific Heat of Metals ExperimentRobert MarcoliniNessuna valutazione finora

- He158 (A4)Documento4 pagineHe158 (A4)MUzair5Nessuna valutazione finora

- Plate Heat Exchanger: SolteqDocumento0 paginePlate Heat Exchanger: SolteqbabeNessuna valutazione finora

- He165 (A4) PDFDocumento4 pagineHe165 (A4) PDFLina ShakirNessuna valutazione finora

- Vle SolteqDocumento3 pagineVle SolteqFarhan AhmadNessuna valutazione finora

- Catia ABSI CV5 MoldTrainingCrse 062206 STDocumento8 pagineCatia ABSI CV5 MoldTrainingCrse 062206 STaliNessuna valutazione finora

- JJ618 Silibus PDFDocumento10 pagineJJ618 Silibus PDFMohd Hafizil Mat YasinNessuna valutazione finora

- Catia Fem TutorialDocumento21 pagineCatia Fem TutorialnicolassaltarNessuna valutazione finora

- Mold Tooling Design (V5R16) - CatiaDocumento306 pagineMold Tooling Design (V5R16) - Catiageorge_ichim100% (1)

- Presentation1nx TrainingDocumento23 paginePresentation1nx TrainingMohd Hafizil Mat YasinNessuna valutazione finora

- Course Outline JF609-December 2012Documento3 pagineCourse Outline JF609-December 2012Mohd Hafizil Mat YasinNessuna valutazione finora

- Jf609-Rm Dtp6-s2 December 2012Documento6 pagineJf609-Rm Dtp6-s2 December 2012Mohd Hafizil Mat YasinNessuna valutazione finora

- Four-Stroke Diesel Engine Characteristic Curve and EfficiencyDocumento10 pagineFour-Stroke Diesel Engine Characteristic Curve and EfficiencyYosra RamadhanNessuna valutazione finora

- Dynamo Meter Fact SheetDocumento98 pagineDynamo Meter Fact SheetMohd Hafizil Mat Yasin100% (1)

- CFD Lecture1Documento25 pagineCFD Lecture1GCVishnuKumar100% (1)

- MAK 411E Project ListDocumento4 pagineMAK 411E Project ListMohd Hafizil Mat YasinNessuna valutazione finora

- 3.environmental Evaluation p.15-32Documento18 pagine3.environmental Evaluation p.15-32Mohd Hafizil Mat YasinNessuna valutazione finora

- Final Report 3Documento10 pagineFinal Report 3Mohd Hafizil Mat YasinNessuna valutazione finora

- Testo 435 Technical SpecsDocumento8 pagineTesto 435 Technical SpecsMohd Hafizil Mat YasinNessuna valutazione finora

- About The AuthorsDocumento1 paginaAbout The AuthorsArthur CostaNessuna valutazione finora

- User Manual Gd30fdcDocumento17 pagineUser Manual Gd30fdcdedo3Nessuna valutazione finora

- Greece WasteDocumento64 pagineGreece WasteYiannis AntonopoulosNessuna valutazione finora

- Method of Statement-RTDocumento7 pagineMethod of Statement-RTbuddhikasat50% (2)

- Boiler Steam CycleDocumento35 pagineBoiler Steam CycleMichał KisielewskiNessuna valutazione finora

- Cooling Tower Research PaperDocumento13 pagineCooling Tower Research PaperBhaskar KumarNessuna valutazione finora

- Project Report - TarunDocumento5 pagineProject Report - TarunrajuNessuna valutazione finora

- Bosch Injector Data SheetDocumento124 pagineBosch Injector Data SheetThibaut Lrt56% (9)

- Exercise-01 Check Your Grasp: O CH HO HODocumento7 pagineExercise-01 Check Your Grasp: O CH HO HOChesta MalhotraNessuna valutazione finora

- Techniques de Commande Des Machines Electriques - Cours Et Problèmes..Documento2 pagineTechniques de Commande Des Machines Electriques - Cours Et Problèmes..Tko ToolNessuna valutazione finora

- Molecular Orbital TutorialDocumento28 pagineMolecular Orbital TutorialehmedNessuna valutazione finora

- Tk09 Report Assignment 4Documento112 pagineTk09 Report Assignment 4Bella Novia BerlianaNessuna valutazione finora

- Chapter 5 (2nd Law of ... )Documento64 pagineChapter 5 (2nd Law of ... )yohannes lemiNessuna valutazione finora

- J300, J4ATS, J7ATS Transfer Switches 260, 400, and 600 Amp SizesDocumento6 pagineJ300, J4ATS, J7ATS Transfer Switches 260, 400, and 600 Amp SizesMatt PittmanNessuna valutazione finora

- Pratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342Documento18 paginePratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342EstebanNessuna valutazione finora

- SUNSLATES™ 6 PV Roof Tile - Award Winning Architectural AppealDocumento2 pagineSUNSLATES™ 6 PV Roof Tile - Award Winning Architectural AppealFaeria20Nessuna valutazione finora

- Electrician Training - Troubleshooting and Fault FindingDocumento11 pagineElectrician Training - Troubleshooting and Fault FindingOgunjimi Taofiki AdebisiNessuna valutazione finora

- Mooring System Analysis of Multiple Wave Energy Converters in A Farm ConfigurationDocumento10 pagineMooring System Analysis of Multiple Wave Energy Converters in A Farm ConfigurationAleix Jesus Maria ArenasNessuna valutazione finora

- ATSDocumento8 pagineATSserban_elNessuna valutazione finora

- Gas Turbine Heat Rejection and Refrigeration Cycle CalculationsDocumento8 pagineGas Turbine Heat Rejection and Refrigeration Cycle CalculationsRENE JOSHUA PECASONessuna valutazione finora

- Parts Crane Hitachi FK600 - PRDocumento2 pagineParts Crane Hitachi FK600 - PRDefly Gusti100% (1)

- AC192Documento1 paginaAC192soares_alexNessuna valutazione finora

- Window U-Value ModuleDocumento46 pagineWindow U-Value ModuleSze Yan LamNessuna valutazione finora

- FCRR19 (6) Kirkwood Matura-ShepherdDocumento5 pagineFCRR19 (6) Kirkwood Matura-ShepherdRuslan ZakirovNessuna valutazione finora

- Water Supply Sanitary Eng PDFDocumento5 pagineWater Supply Sanitary Eng PDFReddy NaveenNessuna valutazione finora

- UNIVERSITY QUIZDocumento4 pagineUNIVERSITY QUIZJericko Lian Del RosarioNessuna valutazione finora

- NERC Reactive Support and Control WhitepaperDocumento307 pagineNERC Reactive Support and Control WhitepapersulemankhalidNessuna valutazione finora

- Depanshu Belwal Power PointDocumento12 pagineDepanshu Belwal Power PointvickyvermaNessuna valutazione finora

- An Assessment of Singapore Airlines Environmentally Sustainable Energy ManagementDocumento15 pagineAn Assessment of Singapore Airlines Environmentally Sustainable Energy ManagementMamta AgarwalNessuna valutazione finora

- 1st PU Chemistry May 2015 PDFDocumento2 pagine1st PU Chemistry May 2015 PDFPrasad C M69% (16)