Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

296 - Material Database Ver E4.01

Caricato da

BAHADIRTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

296 - Material Database Ver E4.01

Caricato da

BAHADIRCopyright:

Formati disponibili

1

2 Pressure Vessel Engineering Ltd.

3 Finite Element Analysis ASME Code Calculations

4 Canadian Vessel Registration Vessel Modeling and Drafting

5

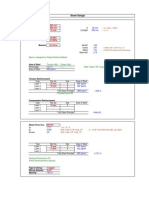

6 Pipe and Shell Design Tool ver E4.01 Page 1 of 1

7 Straight Pipe and Shell Description

8 Dimensions:

9 1200.000 Do [mm] - outside diameter (from drawing) Do

10 4.000 t [mm] - nominal wall thickness (from drawing)

11 1900.000 L [mm] -length (from drawing)

12 0.000 Corr [mm] - corrosion allowance (from drawing) t

13 Material and Conditions:

Length

14 SA-240 304 Material (from drawing)

Long Seam

15 135 S [Mpa] - allowable stress (from Sect.II-D) (see Info)

16 0.85 El - long seam efficiency (circ stress) (from drawing)

17 0.70 Ec - circ seam efficiency (long stress) (from drawing)

18 0.0% UTP [%] - undertolerance allowance (see explanation on the box)

19 0.45 P [Mpa] - interior pressure (Bar/10 = Mpa) (from drawing)

20 Calculated Properties:

21 Volume [m³] = ((Do/2-t)^2)*pi()*L/1000000000 ((1200/2-4)^2)*PI()*1900/100000000 = 2.12

22 Weight [kg] = (Do-t)*pi()*L*t*7,85/1000000 (1200-4)*PI()*1900*4*40.84/144 = 224.16

23 Variables:

24 UT [mm] = t*UTP 4*0 = 0.000

25 nt [mm] = t-Corr-UT 4-0-0 = 4.000

26 Ri [mm] = Do/2-nt 1200/2-4 = 596.000

27 Required Thickness: UG-27(c)(1,2)

28 ta [mm] = P*Ri/(S*El-0.6*P) ~~ long sem 0.5*596/(135*0.85-0.6*0.5) = 2.343

29 tb [mm] = P*Ri/(2*S*Ec+0.4*P) ~~ circ seam 0.5*596/(2*135*0.7+0.4*0.5) = 1.418

30 Treq [mm] = MAX(ta,tb)+Corr ~~ required minimum thickness MAX(2.343,1.418)+0 = 2.343

31 CheckTreq = Treq <= nt 2.343 <= 4 = Acceptable

32 Maximum Pressure: UG-27(c)(1,2)

33 Pint1 [Mpa] = (S*El*nt)/(Ri+0.6*nt) (135*0.85*4)/(596+0.6*4) = 0.77

34 Pint2 [Mpa] = (2*S*Ec*nt)/(Ri-0.4*nt) (2*135*0.7*4)/(596-0.4*4) = 1.27

35 PMax [Mpa] = Min(Pint1,Pint2) ~~ maximum allowed design pressure MIN(1,1) = 0.77

36 CheckP = PMax >= P 0.8 >= 0.5 = Acceptable

37 Treq provides a worst case required thickness for nozzle analysis for a nozzle located on the long seam or circ seam

38 This sheet will not calculate thick walled vessels Check → Not a thick walled vessel, calculations are valid

39 The UG-16(b) minimum thickness requirement has not been taken into consideration here.

40 This sheet cannot be used to check for allowable exterior pressure loads.

41 Use the Weld Efficiency program to calculate El and Ec

42 This sheet is for educational use only - use at your own risk.

43 Pressure Vessel Engineering Ltd.

44 120 Randall Drive, Suite B

45 Waterloo, Ontario, Canada, N2V 1C6

46 www.pveng.com (519) 880-9808

1 Pressure Vessel Engineering Ltd.

2 Finite Element Analysis ASME Code Calculations

3 Canadian Vessel Registration Vessel Modeling and Drafting

4 Material Database ver E4.01 Page 1 of 1

5 Material Properties:

6 525.0 Temp [°F] - maximum design temperature

Ambient Design

7 Material Strength Strength Max ºF

8 SA-36 Plate 16,600 16,600 900 Carbon Steels

9 SA-106 B Seamless Pipe 17,100 17,100 1,000

10 SA-234 WPB Fittings 17,100 17,100 1,000

11 SA-105 Forging 20,000 19,300 1,000

12 SA-516 70 Plate 20,000 19,850 1,000

13 SA-414 G Sheet 21,400 21,400 900

14 SA-213 TP316L Sms Tube 16,700 14,600 850 Stainless Steel 316L

15 SA-240 316L Plate 16,700 14,600 850

16 SA-312 TP316L Sms. and Wld. Pipe 16,700 14,600 850

17 SA-403 316L Sms and Weld Fittings 16,700 14,600 850

18 SA-479 316L Bar 16,700 14,600 850

19 SA-213 TP316 Sms Tube 20,000 17,750 1,500 Stainless Steel 316

20 SA-240 316 Plate 20,000 17,750 1,500

21 SA-312 TP316 Sms. and Wld. Pipe 20,000 17,750 1,500

22 SA-403 316 Sms and Weld Fittings 20,000 17,750 1,500

23 SA-479 316 Bar 20,000 17,750 1,500

24 SA-213 TP304L Sms Tube 16,700 14,525 1,200 Stainless Steel 304L

25 SA-240 304L Plate 16,700 14,525 1,200

26 SA-312 TP304L Sms. and Wld. Pipe 16,700 14,525 1,200

27 SA-403 304L Sms and Weld Fittings 16,700 14,525 1,200

28 SA-479 304L Bar 16,700 14,525 1,200

29 SA-213 TP304 Sms Tube 20,000 12,750 1,500 Stainless Steel 304

30 SA-240 304 Plate 20,000 12,750 1,500

31 SA-312 TP304 Sms. and Wld. Pipe 20,000 17,275 1,500

32 SA-403 304 Sms and Weld Fittings 20,000 17,275 1,500

33 SA-479 304 Bar 20,000 17,275 1,500

34 SB-209 6061-T6 plate 0.051-0.249", wld 6,000 0 400 Aluminum

35 SB-209 6061-T651 plate 0.25-5", wld 6,000 0 400

36 SB-209 6061-T6 plate 0.051-0.249" 10,900 0 400

37 SB-209 6061-T651 plate 0.25-4.0" 10,900 0 400

38 SB-209 6061-T651 plate 4.0-5.0" 10,300 0 400

39 SB-211 A96061-T6 bar 0.125-0.249", wld 6,000 0 400

40 SB-234 A96061-T6 tubes 0.025-0.200", wld 6,000 0 400

41 SB-241 A96061-T6 sms. Pipe, wld 6,000 0 400

42 SB-247 A96061-T6 forging, wld 6,000 0 400

43 SB-308 A96061-T6 shapes, wld 6,000 0 400

44 Material properties are compliant with ASME Section IID Table 1A

45

46 Fluid Properties:

47 200.0 P [psi] - pressure at top of vessel

48 100.00 H [ft] - fluid height

49 1.000 SG - specific gravity

50 Pdesign [psi] = P+0.433*SG*H ~~ design pressure including static head 200+0.433*1*100 = 243.3

51 Pdesign is to be used in the design of subsequent components (shell, head, nozzle, etc)

52 This sheet is for educational use only - use at your own risk.

53 Pressure Vessel Engineering Ltd.

54 120 Randall Drive, Suite B

55 Waterloo, Ontario, Canada, N2V 1C6

56 www.pveng.com (519) 880-9808

1

2 Pressure Vessel Engineering Ltd.

3 Finite Element Analysis ASME Code Calculations

4 Canadian Vessel Registration Vessel Modeling and Drafting

5

6 Elliptical Head Design Tool ver E4.01 Page 1 of 1

7 Elliptical Head Description

8 Dimensions:

9 24.000 Do [in] - outside diameter of head

10 0.188 tb [in] - thickness before forming

11 0.159 tf [in] - thickness after forming (note 1)

12 0.010 Corr [in] - corrosion allowance

13 2.000 Skirt [in] - straight skirt length

14 Material and Conditions:

15 SA-240 304 Material

16 20,000 S [psi] - allowable stress

17 1.00 E - head longitudinal efficiency

18 50.0 P [psi] - interior pressure

19 Calculated Properties:

20 note 1: Suggested thickness after forming Approx. head weight based on steel, lbs = 43.56

21 0.125 in Approx. head volume including skirt, cuft = 1.52

22 Variables:

23 nt [in] = tf-Corr ~~ thickness with corrosion allowance removed 0.159-0.01 = 0.149

24 D [in] = Do-2*nt ~~ ID with corrosion allowance removed 24-2*0.149 = 23.701

25 h [in] = D/4 ~~ inside crown height 23.701/4 = 5.925

26 ho [in] = h+nt 5.925+0.149 = 6.075

27 D/2h = D/(2*h) 23.701/(2*5.925) = 2.000

28 Do/2ho = Do/(2*ho) 24/(2*6.075) = 1.975

29 Ro [in]= Kzero*Do 0.889*24 = 21.334

30 Required Thickness: App. 1-4(c), UG-37(a)(1)

31 App1-4(f) = tf/(Kone*D) 0.159/(0.9*23.701) = 0.0075

32 App1-4(f)Calc = if(AND(0.0005=<App1-4(f),App1-4(f)<0.002),"Calculation Required","Calculation not required")

33 App. 1-4(f) Calculation Not Required

34 Treq [in] = (P*D*K)/(2*S*E-0.2*P)+Corr ~~ required minimum thickness

35 (50*23.701*1)/(2*20000*1-0.2*50)+0.01 = 0.040

36 CheckTreq = Treq<=tf 0.04<=0.159 = Acceptable

37 Maximum Pressure: App. 1-4(c), UG-37(a)(1)

38 Pmax [psi] = (2*S*E*nt)/(K*D+0.2*nt) ~~ maximum allowed design pressure

39 (2*20000*1*0.149)/(1*23.701+0.2*0.149) = 251.8

40 CheckPMax = Pmax >= P 251.8 >= 50 = Acceptable

41 App. 1-4(f) calculation is not included on this sheet

42 The UG-16(b) minimum thickness requirement has not been taken into consideration here.

43 Nozzles may be subject to a smaller required thickness depending on location in the head.

44 Only the knuckle required thickness is calculated on this sheet

45 Heads may be subject to stress relief if large elongation occurs - UCS-79(d), UNF-79(d), UHA-44(d)

46 Use the Weld Efficiency program to calculate E

47 This sheet cannot be used to check for allowable exterior pressure loads.

48 This sheet is for educational use only - use at your own risk.

49 Pressure Vessel Engineering Ltd.

50 120 Randall Drive, Suite B

51 Waterloo, Ontario, Canada, N2V 1C6

52 www.pveng.com (519) 880-9808

1 FS=4 before 1 July 1999

FS=3.5 after 1 July 1999

Potrebbero piacerti anche

- DOCUMENT Sample Vessel CalculationsDocumento10 pagineDOCUMENT Sample Vessel CalculationsCristian Camilo Zapata PardoNessuna valutazione finora

- 297 - Pipe and Shell Design Tool Ver E4.01 MMDocumento1 pagina297 - Pipe and Shell Design Tool Ver E4.01 MMBAHADIRNessuna valutazione finora

- Diseño Del Cuerpo de Un RecipienteDocumento1 paginaDiseño Del Cuerpo de Un RecipientepedroluischoqueNessuna valutazione finora

- Base de Datos de Materiales para RecipientesDocumento1 paginaBase de Datos de Materiales para RecipientespedroluischoqueNessuna valutazione finora

- Pipes and TubesDocumento16 paginePipes and TubesDaniel Sandoval FernándezNessuna valutazione finora

- Strength Calculation ARTDocumento34 pagineStrength Calculation ARTdenstar silalahiNessuna valutazione finora

- EN6114Documento17 pagineEN6114Andrei Cozma67% (3)

- Ubkhep Ob Design CheckDocumento72 pagineUbkhep Ob Design CheckPrayas SubediNessuna valutazione finora

- Rectangular TankDocumento38 pagineRectangular TankSam LowNessuna valutazione finora

- EN6114Documento14 pagineEN6114akayirNessuna valutazione finora

- WPS - EngineerDocumento20 pagineWPS - Engineerhunghoanglong100% (1)

- R1-Ff-Bhadra Dam-30mt Hoist - Under Sluice Gate - r1Documento15 pagineR1-Ff-Bhadra Dam-30mt Hoist - Under Sluice Gate - r1ajwalNessuna valutazione finora

- NAD 3020 ServiceManualDocumento6 pagineNAD 3020 ServiceManualmartin-d-johnsonNessuna valutazione finora

- Pressure Vessel Cone Design ToolDocumento1 paginaPressure Vessel Cone Design ToolssierroNessuna valutazione finora

- Tsa 2Documento6 pagineTsa 2Amit SurtiNessuna valutazione finora

- ASME VIII-1 Calculations for Sample Pressure VesselDocumento21 pagineASME VIII-1 Calculations for Sample Pressure VesselTrishul Nath Pallay100% (1)

- 85SP Single Analysis Report PLS-POLE ResultDocumento6 pagine85SP Single Analysis Report PLS-POLE ResultDESIGNNessuna valutazione finora

- Angle Bar 130x130x9mm Mill CertificateDocumento1 paginaAngle Bar 130x130x9mm Mill Certificatepstechnical_43312697100% (2)

- Pressure Vessel Cone Design ToolDocumento1 paginaPressure Vessel Cone Design ToolPramod KumarNessuna valutazione finora

- UAA10 Canopy Design Report - MergedDocumento11 pagineUAA10 Canopy Design Report - MergedAbilaash VelumaniNessuna valutazione finora

- 85SP Bundlled Analysis Report PLS-POLE ResultsDocumento6 pagine85SP Bundlled Analysis Report PLS-POLE ResultsDESIGNNessuna valutazione finora

- Astm A106Documento5 pagineAstm A106Andy SetyawanNessuna valutazione finora

- DESCON ENGINEERING LIMITED STEAM TRAP QUOTATIONDocumento4 pagineDESCON ENGINEERING LIMITED STEAM TRAP QUOTATIONkhan103Nessuna valutazione finora

- Presentation of CIPL - CompressedDocumento30 paginePresentation of CIPL - CompressedNikhil VermaNessuna valutazione finora

- Dongil SteelDocumento5 pagineDongil SteelJoseph DixonNessuna valutazione finora

- Combined FootingDocumento15 pagineCombined Footingayazmad100% (1)

- Cone Design Tool: Pressure Vessel Engineering LTDDocumento1 paginaCone Design Tool: Pressure Vessel Engineering LTDkedubhajjiNessuna valutazione finora

- W.-Nr. DIN UNI Afnor B.S. UNE Aisi/Sae/Astm JIS SS Gost EN: Italy France England Spain U.S.A. Japan Sweden RussiaDocumento1 paginaW.-Nr. DIN UNI Afnor B.S. UNE Aisi/Sae/Astm JIS SS Gost EN: Italy France England Spain U.S.A. Japan Sweden RussiaDouglas CortezziNessuna valutazione finora

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocumento49 pagineDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Nessuna valutazione finora

- PV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcDocumento8 paginePV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcMayank MittalNessuna valutazione finora

- Note de Calcul Ancrage Rev3Documento3 pagineNote de Calcul Ancrage Rev3Bilel MahjoubNessuna valutazione finora

- Steel components and reinforcement for short span trail bridgeDocumento1 paginaSteel components and reinforcement for short span trail bridgekoklenderNessuna valutazione finora

- Cone Design ToolDocumento1 paginaCone Design ToolLuhur PrandikaNessuna valutazione finora

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocumento1 paginaTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNessuna valutazione finora

- Column Design: 2000 KN 20 KN-MDocumento2 pagineColumn Design: 2000 KN 20 KN-MasluznetNessuna valutazione finora

- Concrete Mixer Machine DesignDocumento8 pagineConcrete Mixer Machine Designzemed bamlakuNessuna valutazione finora

- Internal CoilDocumento2 pagineInternal CoilwhngomjNessuna valutazione finora

- PV Elite 2016 Licensee: SPLM Licensed User Filename: Flare K-41582 Basering Calculations: Step: 16 4:35Pm Jan 6,2020Documento6 paginePV Elite 2016 Licensee: SPLM Licensed User Filename: Flare K-41582 Basering Calculations: Step: 16 4:35Pm Jan 6,2020DarioNessuna valutazione finora

- SAP FILTER-May-2020-1200Dia-Rev - PDocumento4 pagineSAP FILTER-May-2020-1200Dia-Rev - PHasmukh DaveNessuna valutazione finora

- Mechanical Design SpreadsheetDocumento1 paginaMechanical Design SpreadsheetHoney TiwariNessuna valutazione finora

- Po-Ss/14.3 Submersible Motor Pumps: SpecificationDocumento4 paginePo-Ss/14.3 Submersible Motor Pumps: SpecificationYuki ChanNessuna valutazione finora

- KNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectDocumento32 pagineKNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectrichardchiamNessuna valutazione finora

- Raccordi A Inserto Forgiato PDFDocumento3 pagineRaccordi A Inserto Forgiato PDFpeppino di capriNessuna valutazione finora

- FIRE WATER TANK-API-650-Calculation-Report - RVDDocumento42 pagineFIRE WATER TANK-API-650-Calculation-Report - RVDahmed aboyosefNessuna valutazione finora

- Input EchoDocumento6 pagineInput EchohgagNessuna valutazione finora

- Acum#2 RoladoDocumento1 paginaAcum#2 RoladoJuan PabloNessuna valutazione finora

- For Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Documento1 paginaFor Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985premk20Nessuna valutazione finora

- wps63 PDFDocumento4 paginewps63 PDFErick HoganNessuna valutazione finora

- FK76M E LoresDocumento18 pagineFK76M E LoresFRANCONessuna valutazione finora

- Catalogo Asca Valvula RetencaoDocumento2 pagineCatalogo Asca Valvula RetencaoMaurício Duarte de AndradeNessuna valutazione finora

- Bond & Anchorage - Reinforced Concrete Design by S Unnikrishna Pillai & Devdas MenonDocumento4 pagineBond & Anchorage - Reinforced Concrete Design by S Unnikrishna Pillai & Devdas MenonGR KannaNessuna valutazione finora

- Materials Data for Cyclic Loading: Low-Alloy SteelsDa EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsValutazione: 5 su 5 stelle5/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- Pipeline and Energy Plant Piping: Design and TechnologyDa EverandPipeline and Energy Plant Piping: Design and TechnologyValutazione: 5 su 5 stelle5/5 (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- 300 - F&D Head Design Tool Ver E4.01Documento1 pagina300 - F&D Head Design Tool Ver E4.01Honey TiwariNessuna valutazione finora

- MarginDocumento4 pagineMarginZeon GeidlNessuna valutazione finora

- 299 - Elliptical Head Design Tool Ver E4.01Documento1 pagina299 - Elliptical Head Design Tool Ver E4.01BAHADIRNessuna valutazione finora

- MarginDocumento4 pagineMarginZeon GeidlNessuna valutazione finora

- Offshore Containers - DNV Standard 2-7!1!10071901Documento60 pagineOffshore Containers - DNV Standard 2-7!1!10071901Luiz Magri100% (2)

- Advanced Eddy Current Tube Inspection Solutions: Inspection Planning Data Collection Data Analysis ReportingDocumento8 pagineAdvanced Eddy Current Tube Inspection Solutions: Inspection Planning Data Collection Data Analysis ReportingBAHADIRNessuna valutazione finora

- ESREL2006S 154bragattoalDocumento9 pagineESREL2006S 154bragattoalBAHADIRNessuna valutazione finora

- ESREL2006S 154bragattoalDocumento9 pagineESREL2006S 154bragattoalBAHADIRNessuna valutazione finora

- Chapter - 08 Civics Confronting Marginalisation: Invoking Fundamental RightsDocumento2 pagineChapter - 08 Civics Confronting Marginalisation: Invoking Fundamental Rightsnbs saraswathiNessuna valutazione finora

- DRM Act 2015Documento52 pagineDRM Act 2015Gail HoadNessuna valutazione finora

- 6 Review of Related LiteratureDocumento2 pagine6 Review of Related Literaturerusty0% (2)

- CLC Customer Info Update Form v3Documento1 paginaCLC Customer Info Update Form v3John Philip Repol LoberianoNessuna valutazione finora

- Strack 1976 A Single-Potential Solution For Regional Interface Problems in Coastal AquifersDocumento10 pagineStrack 1976 A Single-Potential Solution For Regional Interface Problems in Coastal AquifersMarie.NeigeNessuna valutazione finora

- Trix Price List OCT 2018 PDFDocumento2 pagineTrix Price List OCT 2018 PDFApNessuna valutazione finora

- Instruction: 217 - C Fiber Optic Splice CaseDocumento9 pagineInstruction: 217 - C Fiber Optic Splice CaseHữu Khánh NguyễnNessuna valutazione finora

- Pharma AssignDocumento8 paginePharma AssignTHIS PAHADINessuna valutazione finora

- Stress in The WorkplaceDocumento10 pagineStress in The WorkplaceWendyLu32100% (1)

- Diagnosis in OncologyDocumento22 pagineDiagnosis in OncologyAndi SuryajayaNessuna valutazione finora

- Work Procedure For Temporary Fence GateDocumento19 pagineWork Procedure For Temporary Fence GateAlbert OquindoNessuna valutazione finora

- Diabetes PDFDocumento5 pagineDiabetes PDFErica MailigNessuna valutazione finora

- Starch Industry Effluent Treatment PlantDocumento30 pagineStarch Industry Effluent Treatment PlantBSridhar50% (2)

- VACCINATION LISTDocumento2 pagineVACCINATION LISTRakesh KumarNessuna valutazione finora

- Mini ProjectDocumento14 pagineMini ProjectEli Body ButterNessuna valutazione finora

- Valtek Beta Positioners: For Control ValvesDocumento8 pagineValtek Beta Positioners: For Control Valvesابزار دقیقNessuna valutazione finora

- A Simple and Rapid Method For Colorimetric Determination of Histamine in Fish FleshDocumento8 pagineA Simple and Rapid Method For Colorimetric Determination of Histamine in Fish Fleshmuratout3447Nessuna valutazione finora

- 7.nuclear Chemistry and Environmental Chemistry ExerciseDocumento38 pagine7.nuclear Chemistry and Environmental Chemistry ExerciseYogy YNessuna valutazione finora

- DesignGyan17150517Seating System Components-Seating Terminology - FOR - TRAININGDocumento42 pagineDesignGyan17150517Seating System Components-Seating Terminology - FOR - TRAININGK S RANJITH ランジットNessuna valutazione finora

- Foreign Bodies of Air Passages and Food PassageDocumento20 pagineForeign Bodies of Air Passages and Food PassageRamli HassanNessuna valutazione finora

- Ladipur EVA LiquidDocumento2 pagineLadipur EVA LiquidKalki VermaNessuna valutazione finora

- Eastridge Golf Club, Inc V Eastridge Labor Union-SUPERDocumento3 pagineEastridge Golf Club, Inc V Eastridge Labor Union-SUPERJames Evan I. ObnamiaNessuna valutazione finora

- CSFDocumento5 pagineCSFjalan_zNessuna valutazione finora

- Delhi-HC-Cruelty by WifeDocumento19 pagineDelhi-HC-Cruelty by WifeSachin BansalNessuna valutazione finora

- Soft Skills in The Pharmacy Curriculum: Lilian M. AzzopardiDocumento14 pagineSoft Skills in The Pharmacy Curriculum: Lilian M. Azzopardishailendra patilNessuna valutazione finora

- Caldwell Schizophrenizing LacanDocumento10 pagineCaldwell Schizophrenizing LacanaxisofelvisNessuna valutazione finora

- Root-Knot and Root-Lesion Nematode SuppressionDocumento6 pagineRoot-Knot and Root-Lesion Nematode SuppressionRAMIRO H.S.Nessuna valutazione finora

- Network Marketing BusinessesDocumento1 paginaNetwork Marketing BusinessessukhberNessuna valutazione finora

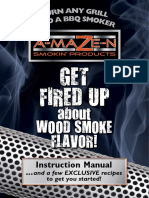

- AMAZEN Manual ForWebONLY 2 5 19 PDFDocumento13 pagineAMAZEN Manual ForWebONLY 2 5 19 PDFkg27r-scribd9325100% (1)

- Irc 097-1987Documento10 pagineIrc 097-1987kruttika_apNessuna valutazione finora