Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Kayu

Caricato da

Marlinda OmarDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Kayu

Caricato da

Marlinda OmarCopyright:

Formati disponibili

Journal of Tropical Forest Science 18(3): 149156 (2006)

149

A PRELIMINARY STUDY OF MALAYSIAN WOOD WASTES AS SECONDARY RAW MATERIAL FOR PULPING

I. Rushdan*

Forest Research Institute Malaysia, 52109 Kepong, Selangor Darul Ehsan, Malaysia. E-mail: rushdan@frim.gov.my

Received August 2005 RUSHDAN, I. 2006. A preliminary study of Malaysian wood wastes as secondary raw material for pulping. In this work, we used waste wood from three Malaysian tropical hardwoods to understand the effects of species on the size of chips and pulp properties. The three species were kekatong (Cynometra spp.), merbatu (Parinari oblongifolia) and nyatoh (Madhuca laurifolia), categorized as heavy, medium and light hardwoods respectively. Results showed that wood species had an effect on the distribution of size of chips and on the quantity of chips accepted for kraft pulping. Wood species and chip size had an effect on pulp yield and properties. Screened yield increased as the wood density decreased and kappa number increased as wood density increased. The effects on pulp properties varied depending on wood species and/or chip size. This study showed that the three tropical hardwood wastes studied were not suitable for pulp because of their low yield and strength. Keywords: Chip diameter, chip thickness, Cynometra spp., kraft pulping, Parinari oblongifolia, Madhuca laurifolia, wood chip, wood density, yield RUSHDAN, I. 2006. Kajian awal ke atas sisa kayu Malaysia sebagai bahan mentah sekunder untuk penghasilan pulpa. Kami mengkaji sisa kayu daripada tiga spesies kayu keras tropika Malaysia untuk memahami kesan spesies terhadap saiz serpih dan ciri pulpa. Tiga spesies tersebut ialah kekatong (Cynometra spp.), merbatu (Parinari oblongifolia) dan nyatoh (Madhuca laurifolia), yang masing-masing tergolong sebagai spesies kayu keras berat, sederhana dan ringan. Keputusan menunjukkan spesies kayu memberi kesan terhadap taburan saiz serpih dan kuantiti serpih diterima untuk pempulpaan kraf. Kajian ini juga mendapati spesies kayu dan saiz serpih mempengaruhi hasil pulpa dan sifat-sifatnya. Hasil terskrin meningkat apabila ketumpatan kayu menurun dan nombor kappa meningkat apabila ketumpatan kayu meningkat. Kesan ke atas sifat-sifat pulpa bergantung pada spesies kayu dan/atau saiz serpih. Penyelidikan ini menunjukkan bahawa ketigatiga sisa kayu yang dikaji tidak sesuai untuk penghasilan pulpa dan kertas. Ini kerana keputusan menunjukkan hasil pulpa dan kekuatan kertas yang rendah.

INTRODUCTION

The greatest challenges of wood industries in Malaysia are to address and overcome declining supplies of raw material, to fully utilize available resources, and to take advantage of innovations in wood processing. It is thus not surprising that logging and mill residues are emerging as major sources of raw material. Moreover, dumping of waste and residues is now prohibited or very costly, and now restrictions on open burning are being enforced more rigorously in Malaysia. Mill residues comprise bark, sawdust, slabs, ribs, peeler cores, grading off-cuts, sander dust, shavings, and rejects. In 1999, there were 5300 timber processing mills in Malaysia including sawmills, plywood and veneer mills, furniture mills, and factories for timber preservation, kiln drying facilities, particleboard, MDF, laminated board, prefabricated housing, woodchip, wood cement boards and flooring (MTIB 2001). These mills produced 5 million m3 wood wastes per year (Hoi 2000). These wood wastes can be used for energy production and secondary raw material, e.g. in pulp and paper production. In industrial countries, a large share of wood-processing residues is used by the pulp industries (Hoi 2000). Wood of different species may vary widely in physical and chemical properties. The importance of wood properties to the final product is well known. Wood wastes are

* Rushdan Ibrahim

150

Journal of Tropical Forest Science 18(3): 149156 (2006)

characterized by six dominant attributes, namely, species, segregation, purity, moisture, storage and size (Anonymous 1998). In the pulp and paper industry, wood density is of key importance because it has a major effect on both yield and quality of fibres. Malaysian hardwoods are categorized into three groups according to density: light hardwoods (250450 kg m 3), medium hardwoods (451650 kg m3), and heavy hardwoods (651850 kg m3). Using wood chips of uniform size will ensure highest pulp quality with the most efficient use of pulping chemicals and the least environmental impact (Biermann 1996). Dimension of chips depends on the condition and maintenance of chipper, stability at wood-knife interface, wood moisture content, presence of decay, and wood temperature (Smith & Javid 1992, Uhmeier 1995). Wood wastes from Malaysian tropical hardwoods have never been tried as raw material for the pulping industr y and thus, the importance of this work. The objective of this study was to determine the effects of density of hardwood wastes on size of chips and on kraft pulping. We carried out the pulping process on various sizes of chips to compare the properties of the pulp obtained. This is especially important because the current size limits are based on temperate species and none on tropical hardwood species. Furthermore, currently there is no literature available on the effects of size of chips on pulping properties for tropical hardwood. From this study, we also hope to find out if wood wastes from Malaysian tropical hardwood can be utilized for pulp.

MATERIALS AND METHODS

In this preliminary study, long off-cuts of three species of wood wastes representing the commercial heavy, medium and light Malaysian tropical hardwoods were used; they were kekatong (Cynometra spp.), merbatu (Parinari oblongifolia)

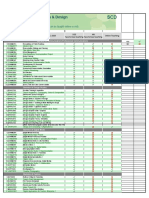

Table 1

and nyatoh (Madhuca laurifolia) respectively. Samples of kekatong and merbatu were construction wastes while nyatoh, furniture manufacturing. Species were confirmed using a hand lens (Sosef et al. 1998, Menon 2004). Basic density and moisture content were determined according to TAPPI T258 (TAPPI 1994). The dimensions, basic densities and moisture contents of woods are shown in Table 1. The woods were chipped at the Forest Research Institute Malaysia (FRIM), Kepong using a drum chipper (30 kW, two knives and operated at 1465 rpm). The chips were classified into five different size fractions by vibrating them through a series of screen slots of 30, 25, 20 and 15 mm diameters. The diameter and thickness of wood chips were measured using a calliper. Following temperate species, we also considered chips that passed 30-mm diameter slots and those retained on the 25-, 20- and 15-mm screen as acceptable for pulping. The rest of the chips were considered as either oversize (retained on 30-mm screen) or undersize (passed 15-mm screen). All chips were kept in polyethylene bags and weighed. A total of 500 g oven-dried chips of each species, grouped into accepted, oversize and undersize diameters, were pulped by kraft process in a four-litre rotating digester at the Universiti Sains Malaysia (USM), Penang. The pulping conditions were 20% active alkali (expressed as Na2O), 25% sulphidity (expressed as Na2O), 170 C maximum temperature, 1.5 hours to maximum temperature, 2 hours at maximum temperature, and 1:5 of wood to liquor ratio. At the end of digestion, the softened pulp was disintegrated for 5 min in a hydrapulper, washed on a screen and screened using Somerville fractionators. The total pulp yield was calculated as the sum of screened pulp and shives or screened reject yields. Kappa number was determined according to TAPPI T236 (TAPPI 1994). Screened pulps of accepted kekatong,

The dimensions and properties of woods used for chipping

Length (mm) 500 500 500 Width(mm) 47 47 80 Thickness(mm) 11 25 18 Density (kg m3) 730 630 430 Moisture content (%) o.d. 17.3 13.9 13.9

Wood species Kekatong (Cynometra spp.) Merbatu (Parinari oblongifolia) Nyatoh (Madhuca laurifolia)

Journal of Tropical Forest Science 18(3): 149156 (2006)

151

merbatu and nyatoh were refined using Lampen ball mill at five different degrees, namely, 1000, 2000, 4000 and 16 000 rpm, and a consistency of 3%. We used the Lampen ball mill as it was the only refiner available at USM and also it was acceptable for comparative studies. Handsheets were made and their physical properties tested under controlled temperature and humidity following TAPPI T220 and T420 (TAPPI 1994).

RESULTS AND DISCUSSION Chip diameter and thickness

The distribution of diameter and thickness of chips are shown in Table 2. The quantity and quality of chip sizes among species are different. Wood chips retained on the screens had diameters and thickness in the range of 119.64 to 17.06 mm and 19.48 to 1.73 mm respectively. Kekatong had the biggest size and nyatoh, the smallest. The average diameter of kekatong, merbatu and nyatoh were 35.64, 39.01 and 32.49 mm respectively and their average thickness were 5.66, 5.84 and 4.59 mm respectively. The quantity of chips retained according to size varied among species; more than 50% of the chips were retained on the 15-mm screen, i.e. 51.3, 58.3 and 51.8% for kekatong, merbatu and nyatoh hardwoods respectively (Figure 1). Of the total chipper output, certain portions are not acceptable as raw material for the pulping process because of size limitation. Chips of 10 to 30 mm long and 3 to 6 mm thick are prime materials for pulping. Chips of these dimensions will produce long, sound fibres, allow quick penetration of steam or cooking liquid, and are easily handled and transported (Smook 1992,

Broderick et al. 1998). Chips > 30 mm long are considered as oversize while that of < 10 mm long, undersize. Oversize chips can be rechipped and returned to the screens. Undersize, consisting of sawdust, small bark particles and very small chips, are removed and used as fuel. Based on diameters and thickness, kekatong had the highest portion of accepted chips (81.45%), followed by nyatoh and merbatu with 80.4 and 74.8% respectively (accepted chip size is the sum of chips retained on 25, 20 and 15 mm screens). The variation in diameter and thickness of chips are due to the difference in their wood density (Koch 1972, Tsoumis 1991). The mechanical properties of the wood being cut strongly influence the type of chips formed and the cutting forces. Types of chips depend on wood resistance to cleavage and bending. The cutting force is positively correlated with wood density. The mechanical properties of wood are not equal in the transverse, radial, and tangential planes. Consequently, when a chipper knife passes through a wood, the shearing forces are not equally transferred in all directions. As a result, chip dimensions have a distribution around a statistical mean value.

Pulp yield and kappa number

The yields of pulp and kappa numbers of the three hardwoods are shown in Table 3. Merbatu undersized chips had the highest total yield (47.6%) and merbatu oversize chips the lowest total yield (35.9%). Merbatu undersize and nyatoh accepted chips gave the highest screened yields (38.9%) while kekatong oversize chips, the lowest (16.3%). Kekatong oversize chips had the highest rejects (26.1%) and nyatoh undersize, the lowest (0.5%). Kekatong oversize chips

Table 2

Average diameter and thickness of chips by species and fractionation of size

Retained on screen slot 30-mm 25-mm 20-mm 15-mm Biggest size retained Smallest size retained

Wood species

Kekatong Diameter Thickness Merbatu Diameter Thickness Nyatoh Diameter Thickness

62.10 7.06 55.75 7.02 39.69 5.26

27.59 5.08 27.67 5.03 27.26 3.86

22.86 4.50 23.24 4.73 23.11 3.91

18.55 4.06 19.34 3.76 18.40 3.38

119.64 19.48 109.34 18.03 57.60 9.28

16.89 3.01 19.30 2.83 17.06 1.73

152

Journal of Tropical Forest Science 18(3): 149156 (2006)

70

60

Kekatong Merbau

50

Retained wood chips (%)

Nyatoh

40

30

20

10

0 30 mm 25 mm 20 mm Diameter of screen slot 15 mm Collector

Figure 1

Percentage of wood chips retained on screen slots by species

Table 3

Pulp yields and kappa numbers of three Malaysian tropical hardwoods

Chip size Screened yield (%) Rejects or sieves (%) Total yield (%) Kappa no.

Wood species

Kekatong

Merbatu

Nyatoh

Undersize Accepted Oversize Undersize Accepted Oversize Undersize Accepted Oversize

22.65 28.15 16.33 38.89 27.39 22.75 38.08 38.89 30.74

23.46 9.15 26.11 8.67 11.29 13.16 0.47 3.91 13.61

46.11 37.30 42.44 47.56 38.68 35.91 44.35 42.80 44.35

50.9 60.7 122.0 61.3 66.1 92.6 50.5 59.3 65.9

exhibited the highest kappa number (122.0) and nyatoh undersize chips had the lowest kappa number (50.5). The differences in yields and kappa numbers between the species are due to their chemical and physical characteristics, which affect the topochemical and diffusion processes during pulping process (Minor 1996). This study showed that pulps of the three hardwood species all had kappa numbers > 20; these made them unsuitable for bleaching (Peh et al. 1986). Some optimization studies should be done to reduce the kappa number and rejects content. High values of screened yield and low rejects

are due to high lignin dissolution. Kappa number measures the quantity of lignin left in pulp. The lower the kappa number, the more lignin dissolved, and thus, more fibres were separated and fewer fibres were bonded together (Figure 2). The selectivity of the delignification is linked to the chip size distribution (Hartler 1996, Broderick et al. 1998). Chip size strongly determines the mass transfer properties. Undersize chip overcook to a lower yield because liquor penetrates more quickly and reactions proceed more thoroughly. Delignification was retarded as the chip size increased (Figure 3).

Journal of Tropical Forest Science 18(3): 149156 (2006)

153

45 Reject 40 Screened 35

Reject and screened yields (%)

30 25 20 15 10 5 0 40 50 60 70 80 90 100 110 120 130

Kappa number

Figure 2

Relationship between kappa number and screened yield and rejects

140

120

100

Kappa number

80

60

40

20

0 K-U K-A K-O M-U M-A M-O N-U N-A N-O

Note : K = kekatong, M = merbatu, N = nyatoh, U = undersize, A = acceptable, O = oversize

Figure 3

The effects of wood species and size on kappa number

154

Journal of Tropical Forest Science 18(3): 149156 (2006)

Pulp properties

Pulp properties of the three species are shown in Table 4. Among the pulps, nyatoh oversize handsheets had the highest apparent density (0.49 g cm 3 ). Apparent density indirectly measures the flexibility of pulp. Heavy hardwood fibres are stiffer so they do not easily fill the gap in the sheet compared with medium and light hardwood fibres (Horn 1978). For mechanical properties, kekatong undersize had the highest tensile index (15.8 N m g1) and merbatu oversize, the lowest (7.1 N m g1). Handsheets made from kekatong chips of acceptable chip size gave the highest tear index (3.9 mN m2 g1) and folding endurance (5). Merbatu undersize and oversize chips had the lowest burst and tear indices (1.8 kPa m2 g1 and 1.1 mN m2 g1) respectively. Strength of paper with randomly oriented fibre is dependent on the strength of individual fibres as well as the strength and number of bonds between them. The number of bonds is the number of bonding area and is influenced by fibre flexibility. A flexible fibre will have a larger surface area for bonding. Fibre flexibility and relative bonding area can be determined by the apparent density and light-scattering coefficient of the paper. Apparent density is one of the most significant properties of paper. It influences almost all mechanical, physical, and electrical properties. Paper light-scattering coefficient is a function of both internal and inter fibre bonded area. Light-scattering coefficient indicates the extent to which an area of component fibres is bonded and is generally accepted as a measure of the degree of bonding (Clark 1985).

Pulp yield, tensile index and burst index are the main parameters used to judge whether a species is good or poor for pulp and papermaking. The tensile index and burst index of wood waste pulps after beating are shown in Figures 4 and 5. Screened yields of pulp were in the range of 16.3 to 38.9%, tensile index 10 to 32 N m g1, and burst index 2.5 to 3.5 kPa m2 g1. Based on guidelines (yield < 40%, tensile index < 65 N m g1 and burst index < 5 kPa m2 g1) by Peh et al. (1986), we conclude that the wood waste species used in this study were not suitable for pulp and paper making.

CONCLUSIONS

Wood species affected the chip distribution size. The quantity and quality of chips are different between species. Kekatong produced more acceptable chip for kraft pulping compared with merbatu and nyatoh. Some optimization studies should be done in order to reduce kappa number and rejects content. Kekatong gave the highest mechanical paper properties. As secondary raw material for pulping, wood wastes should be processed separately according to their density because uniform chips and pulp properties can be attained. In this study, we found that the three Malaysian tropical wood wastes were not suitable for pulp because of its low yield and strength.

ACKNOWLEDGMENTS

The author acknowledges the research grant provided by Universiti Sains Malaysia, Penang and the cooperation provided by the Forest Research Institute Malaysia, Kepong throughout this study.

Table 4

Species

The effects of species and chip size on properties of handsheets

Chip size Apparent density (g cm3) Tensile index (N m g )

1

Burst index (kPa m g )

2 1

Tear index (mN m g )

2 1

Folding endurance

Scattering coefficient (cm2 g1)

Kekatong

Merbatu

Nyatoh

Undersize Accepted Oversize Undersize Accepted Oversize Undersize Accepted Oversize

0.38 0.39 0.33 0.43 0.33 0.40 0.37 0.39 0.49

15.81 12.89 7.27 12.63 8.62 7.14 9.47 10.53 11.49

2.43 2.08 2.96 1.82 1.94 2.52 2.15 2.21 2.68

2.43 3.85 2.05 1.15 1.53 1.13 1.49 1.78 1.62

3 5 2 2 2 2 2 3 2

24.61 25.28 21.70 27.64 28.27 26.83 23.97 23.56 22.91

Journal of Tropical Forest Science 18(3): 149156 (2006)

155

35 Kekatong 30 Merbatu Nyatoh 25

Tensile index

20

15

10

0 0 5000 10000 Degree of beating (rev.) 15000 20000

Figure 4

Tensile index (N m g1) of three wood waste kraft pulps

3.5

2.5

Burst index

Kekatong Merbatu

1.5 Nyatoh 1

0.5

0 0 2000 4000 6000 8000 10000 12000 14000 16000 18000

Degree of beating (rev.)

Figure 5

Burst index (kPa m2g1) of three wood waste kraft pulps

156

Journal of Tropical Forest Science 18(3): 149156 (2006) MINOR, J. L. 1996. Production of unbleached pulp. Pp 25 57 in Dence, C. W. & Reeve, D. W. (Eds.) Pulp Bleaching: Principles and Practice. TAPPI Press, Atlanta. MTIB (MALAYSIAN TIMBER INDUSTRY BOARD). 2001. Directory of Timber Trade Malaysia 20012002. MTIB, Kuala Lumpur. PEH, T. B., KHOO, K. C., LEE, T. W. & MOHD NOR, M. Y. 1986. Pulp and Paper Industry & Research in Peninsular Malaysia. Malayan Forest Records No. 31. Forest Research Institute Malaysia, Kepong. SMITH, D. E. & JAVID, S. R. 1992. New approaches to fines and pins screening. Tappi 75(1): 9397. SMOOK, G. A. 1992. Handbook for Pulp and Paper Technologists. Second edition. Angus Wilde Publications, Vancouver. SOSEF, M. S. M., HONG, L. T. & KRAWIROHATMODJO, S. (EDS.). 1998. Plant Resources of South-East Asia No 5(3). Timber Trees: Lesser-known Timbers. Backhuys Publishers, Leiden. T APPI (TECHNICAL A SSOCIATION O F T HE P ULP A ND P APER INDUSTRY). 1994. TAPPI Test Methods 19941995. TAPPI Press, Atlanta. T SOUMIS, G. 1991. Science and Technology of Wood. Van Nostrand Reinhold, New York. UHMEIER, A. 1995. Some fundamental aspects of wood chipping. Tappi 78(10): 7986.

REFERENCES

ANONYMOUS. 1998. Guidelines for Management of Wood Waste From the Wood Processing Industry. FRIM Technical Information Handbook No. 23. Forest Research Institute Malaysia, Kepong. BIERMANN, C. J. 1996. Essentials of Pulping and Papermaking. Second edition. Academic Press, Inc. San Diego. BRODERICK , G., CACCHIONE , E. & H EROUT, Y. 1998. The importance of distribution statistics in characterization of chip quality. Tappi 81(2): 131 142. CLARK, J.DA. 1985. Pulp Technology and Treatment for Paper. Second edition. Miller-Freeman. Pub. Inc. San Francisco. HARTLER, N. 1996. Achievement and significance of optimal chip quality. Tappi 79(2): 259264. HOI, W. K. 2000. Wood waste utilisation in Malaysia. Pp 334 340 in Appanah, S., Safiah, M. Y., Astinah, W. J. & Khoo, K. C. (Eds.) Proceedings of the 4th Conference on Forestry and Forest Products Research. 24 October 1997. Forest Research Institute Malaysia, Kepong. HORN, R. A. 1978. Morphology of pulp fiber from hardwoods and influence on paper strength. Research Paper FPL 312. U.S. Forest Products Laboratory, Madison. KOCH, P. 1972. Utilization of the Southern Pines. Agriculture Handbook No. 420. USDA Forest Ser vice, Washington D.C. MENON, P. K. B. 2004. Structure and Identification of Malayan Woods. Malayan Forest Records No. 25. Forest Research Institute Malaysia, Kepong.

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- str-w6754 Ds enDocumento8 paginestr-w6754 Ds enAdah BumbonNessuna valutazione finora

- Naval TV SystemDocumento24 pagineNaval TV Systemsharmasandeep0010Nessuna valutazione finora

- Aristotle - OCR - AS Revision NotesDocumento3 pagineAristotle - OCR - AS Revision NotesAmelia Dovelle0% (1)

- Functions of Theory in ResearchDocumento2 pagineFunctions of Theory in ResearchJomariMolejonNessuna valutazione finora

- Control ValvesDocumento95 pagineControl ValvesHardik Acharya100% (1)

- Press Statement - Book Launching Shariah Forensic 27 Oct 2023Documento4 paginePress Statement - Book Launching Shariah Forensic 27 Oct 2023aNessuna valutazione finora

- Darkle Slideshow by SlidesgoDocumento53 pagineDarkle Slideshow by SlidesgoADITI GUPTANessuna valutazione finora

- BSS Troubleshooting Manual PDFDocumento220 pagineBSS Troubleshooting Manual PDFleonardomarinNessuna valutazione finora

- Banking Ombudsman 58Documento4 pagineBanking Ombudsman 58Sahil GauravNessuna valutazione finora

- Resume - James MathewsDocumento2 pagineResume - James Mathewsapi-610738092Nessuna valutazione finora

- SCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Documento2 pagineSCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Nguyễn Hồng AnhNessuna valutazione finora

- Logistic RegressionDocumento7 pagineLogistic RegressionShashank JainNessuna valutazione finora

- AP8 Q4 Ip9 V.02Documento7 pagineAP8 Q4 Ip9 V.02nikka suitadoNessuna valutazione finora

- solidworks ขั้นพื้นฐานDocumento74 paginesolidworks ขั้นพื้นฐานChonTicha'Nessuna valutazione finora

- CPD - SampleDocumento3 pagineCPD - SampleLe Anh DungNessuna valutazione finora

- CE162P MODULE 2 LECTURE 4 Analysis & Design of Mat FoundationDocumento32 pagineCE162P MODULE 2 LECTURE 4 Analysis & Design of Mat FoundationPROSPEROUS LUCKILYNessuna valutazione finora

- Supply List & Resource Sheet: Granulation Techniques DemystifiedDocumento6 pagineSupply List & Resource Sheet: Granulation Techniques DemystifiedknhartNessuna valutazione finora

- FINAL SMAC Compressor Control Philosophy Rev4Documento6 pagineFINAL SMAC Compressor Control Philosophy Rev4AhmedNessuna valutazione finora

- Abnt NBR 16868 1 Alvenaria Estrutural ProjetoDocumento77 pagineAbnt NBR 16868 1 Alvenaria Estrutural ProjetoGIOVANNI BRUNO COELHO DE PAULANessuna valutazione finora

- Passage To Abstract Mathematics 1st Edition Watkins Solutions ManualDocumento25 paginePassage To Abstract Mathematics 1st Edition Watkins Solutions ManualMichaelWilliamscnot100% (50)

- Code of Ethics For Civil Engineers PiceDocumento3 pagineCode of Ethics For Civil Engineers PiceEdwin Ramos Policarpio100% (3)

- Types of Chemical Reactions: Synthesis and DecompositionDocumento3 pagineTypes of Chemical Reactions: Synthesis and DecompositionAlan MartínNessuna valutazione finora

- A Short Survey On Memory Based RLDocumento18 pagineA Short Survey On Memory Based RLcnt dvsNessuna valutazione finora

- Determinant of Nurses' Response Time in Emergency Department When Taking Care of A PatientDocumento9 pagineDeterminant of Nurses' Response Time in Emergency Department When Taking Care of A PatientRuly AryaNessuna valutazione finora

- Inverter 2 chiềuDocumento2 pagineInverter 2 chiềuKhánh Nguyễn MinhNessuna valutazione finora

- KK AggarwalDocumento412 pagineKK AggarwalEnrico Miguel AquinoNessuna valutazione finora

- 28 TerminalsDocumento42 pagine28 TerminalsAlin FazacasNessuna valutazione finora

- VOTOL EMController Manual V2.0Documento18 pagineVOTOL EMController Manual V2.0Nandi F. ReyhanNessuna valutazione finora

- Pitch DeckDocumento21 paginePitch DeckIANessuna valutazione finora

- Load Chart Crane LiftingDocumento25 pagineLoad Chart Crane LiftingLauren'sclub EnglishBimbel Sd-sma100% (1)