Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Stainless Steel Specification

Caricato da

mariusdejDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Stainless Steel Specification

Caricato da

mariusdejCopyright:

Formati disponibili

www.limatherm.

com

TECHNICAL INFORMATION

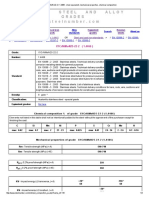

STAINLESS STEEL DIN 1.4541(V2A) , AISI 321 SPECIFICATION

COMPOSITION C 0,08% , Fe 68% , Cr 18% , Ni 11% , Mn 2% , P 0,045% , S 0,03% , Si 1% , Ti 0,15% DESCRIPTION Titanium bearing , austenic , chromium nickel steel . Stabilized against carbide precipitation and designed to work within the temperature range where carbide precipitation develops . Ti content helps prevent chromium carbide precipitation resulting from welding or elevated temperatures . Stabilized at annealing temperatures between 950 1010 C. Resist scaling and vibration fatigue. Application include aircraft exhaust stacks and manifolds , chemical processing equipment, weld equipment ,jet engine parts . PHISICAL PROPERTIES Property Unit Value Comments Density g/cm2 8 MECHANICAL PROPERTIES Hardness Rockwell B 80 Tensile Strength , Ultimate MPa 620 Tensile Strength , Yield MPa 240 Elongation at Break % 45 in 50 mm Modulus of Elasticity GPa 193 200 Charpy Impact J 165 v-notch Izod Impact J 135 ELECTRICAL PROPERTIES Electrical Resistivity ohm cm 7.2 e- 0,05 at 20 C Magnetic Permeability 1.008 at RT THERMAL PROPERTIES CTE linear 500 C m / m C 18,5 0-540 C Heat Capacity J / g C 0,5 from 0 100 C Thermal Conductivity W/ m K 16,1 100 C Melting point C 1400 - 1425 Maximum service Temperatures , Air C 870 Continuous Service Maximum service Temperatures , Air C 925 Intermittent Service

SUGGESTED APPLICATION

CORRODENT

Acetone Acetylene Alcohols Ammonia Dry Ammonium Hydroxide (Ammonia 100 212 ALL Aqua ) Asphalt 121 250 Atmosphere (Industrial and Marine ) Barium Compounds SEE CALCIUM Beer 21 70 Benzene ( Benzol ) 100 212 Butane 204 400 ALL Butyl Alcohol SEE ALCOHOLS Carbolic Acid SEE PHENOL Carbonated Water 100 212 ALL Carbonated Beverages 100 212 Carbon Disulfide 93 200 Cider 149 300 Copper Plating Solution (Cyanide ) 82 180 Copper Plating Solution (Acid ) 24 75 Corn oil 93 200 Creosole 93 200 ALL Ethyl Acetate SEE LACQUER THINNER Ethyl Chloride Dry 260 500 Ethanol SEE ALCOHOLS Ethylene Glycol ( Uninhibited ) 100 212 ALL Ethylene Oxide 24 75 Ferric Sulfate 149 300 ALL Freon 149 300 Fluorine , Anhydrous 38 100 Gasoline 149 300 Glucose 149 300 Glue ph 6-8 149 300 Hydrogen Chloride , Dry 260 500 Hydrocyanic Acid 100 212 ALL Hydrogen Fluoride , Dry 79 175 Hydrogen Peroxide 52 125 10-100% Kerosene 149 300 ALL

TEMP. TEMP. TEMP. CONC.% CORRODENT C F C 100 212 ALL Lacquers & Thinners 149 204 400 Linseed Oil 24 100 212 ALL Magnesium Hydroxide ( or Oxide ) 24 100 212 ALL Magnesium Sulfate 100 Mercury Methylene Chloride Methyl Chloride , Dry Milk , fresh or sour Molasses Natural Gas Nitric Acid Oxygen Oleic Acid Photographic Bleaching Palmitic Acid Potassium Compounds Propane Soap & Detergents Sodium Bisulphite Sodium Bisulphate Salt or Brine Sodium Cyanide Sodium Nitrate Sodium Phosphate Sodium Silicate Sodium Sulfite Sodium Thiosulfate Steam Stearic Acid Sugar Solutions Sulfur Toluene Varnish 371 100 24 82

TEMP. F 300 75 75 212 700

CONC.% ALL ALL 40% 100%

212 ALL 75 180 SEE GLUCOSE 21 70 24 75 ALL 24 75 ALL SEE FATTY ACIDS 38 100 ALL SEE FATTY ACIDS SEE SODIUM COMPOUNDS 149 300 100 212 ALL 100 212 20% 100 212 20% SEE SODIUM CHLORIDE 100 212 ALL 100 212 40% 100 212 10% 100 212 10% 100 212 30% 100 212 ALL SEE FATTY ACIDS SEE GLUCOSE 260 500 24 75 66 150

451 Limatherm Sp. z o.o., ul. Tarnowska 1, 34-600 Limanowa, Poland, tel. +48 18 337 98 20, fax +48 18 337 98 25

www.limatherm.com

TECHNICAL INFORMATION

STAINLESS STEEL DIN 1.4571 (V4A) , AISI 316 Ti SPECIFICATION

COMPOSITION C-0,08% , Fe-62% , Cr-18% , Ni-14% , Mn-2% , Mo- 3% , Ti-0,4% , P-0,045% , S-0,05% , Si-1% DESCRIPTION Molybdenum content increased resistance to marine environments. High creep strength at elevated temperatures and good heat resistance . Biocompatible . Food and pharmaceutical processing equipment , marine exterior trim , surgical implants , and industrial equipment that handles the corrosive process chemicals used to produce inks , rayons , photographic chemicals , paper , textiles , bleaches , and rubber . Resists sodium and calcium brines ; hypochlorite solutions , phosphoric acid ; and the sulfite liquors and sulfurous acid used in the paper pulp industry . PHISICAL PROPERTIES Property Unit Value Comments Density g/cm3 8 MECHANICAL PROPERTIES Hardness Rockwell B 79 Tensile strength , Ultimate MPa 580 Tensile strength , Yield MPa 290 Elongation at Break % 50 in 50 mm Modulus of Elasticity GPa 193 in tension Charpy Impact J 105 V - notch Izod Impact J 129 ELECTRICAL PROPERTIES Electrical Resistivity ohm cm 7,4e - 005 Magnetic Permeability 1,008 at RT THERMAL PROPERTIES CTE linear 500C m / m C 17,5 0-540C Heat capacity J/g C 0,5 Thermal conductivity W/m K 16,3 100C Melting point C 1370 - 1400 Maximum service Temperature , Air C 870 Continous service Maximum service Temperature , Air C 925 Intermittent service

SUGGESTED APPLICATION

CORRODENT Aluminium Sulfate Ammonia , Dry Ammonium Hydroxide (Ammonia , Aqua) Ammonium Sulfate Barium Compounds Benzene ( Benzol ) Benzoic Acid Boric Acid Butane Butyl Alcohol Calcium Hypochlorite Carbolic Acid Copper (10) Nitrate Copper (10) Sulfate Ethyl Acetate Ethyl Chloride , Dry Ethanol Ethylene Oxide Fatty Acids Formaldehyde Formic Acid Freon Furfural Gasoline Hydrogen Fluoride ,Dry Kerosene Lactic Acid Lime Linseed Oil Mercury Methyl Chloride , Dry Molasses Nitric Acid

TEMP. C 100 100 100 100

TEMP. C 212 212 212

CONC. % ALL ALL ALL

CORRODENT Oxygen Oleic Acid Palmitic Acid Phosphoric Acid Phenol Potassium Compounds Propane Rosin Sodium Bicarbonate Sodium Carbinate Salt or Brine Sodium Hydroxide Sodium Nitrite Sodium Phosphate Sodium Silicate Sodium Sulfate Sodium Sulfide Stearic Acid Sugar Solutions Sulfur Chloride Sulfur Dioxide Sulfur Trioxide Sulfuric Acid Sulfuric Acid Sulfurous Acid Titanium Tetrachloride Toluene Turpentine Varnish Zinc Sulfate

TEMP. TEMP. CONC. C C % 24 75 ALL SEE FATTY ACIDS SEE FATTY ACIDS 100 212 ALL 100 212 ALL SEE SODIUM COMPOUNDS 149 300 371 700 100% 100 212 20% 100 212 40% SEE SODIUM CHLORIDE 100 212 30% 24 75 20% 100 212 10% 100 212 10% 100 212 30% 100 212 10% SEE FATTY ACIDS SEE GLUCOSE 24 75 DRY 260 500 DRY 260 500 DRY 100 212 10% 100 212 90-100% 24 75 20% 24 75 ALL 24 75 24 75 66 150 100 212 ALL

212 ALL SEE CALCIUM 100 212 100 212 200 400 ALL 204 400 ALL SEE ALCOHOLS SEE BLEACHING POWDER SEE PHENOL 149 300 ALL 149 300 ALL SEE LACQUER TRINNER 260 500 SEE ALCOHOLS 24 75 260 500 ALL 100 212 40% 149 300 ALL 149 300 232 450 149 300 79 175 149 300 ALL 149 300 ALL 100 212 ALL 24 75 371 700 100% 24 75 SEE GLUCOSE 149 300 ALL

452 Limatherm Sp. z o.o., ul. Tarnowska 1, 34-600 Limanowa, Poland, tel. +48 18 337 98 20, fax +48 18 337 98 25

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- MMT Bohler M303extra Feature ArticleDocumento4 pagineMMT Bohler M303extra Feature ArticlegvmindiaNessuna valutazione finora

- Calculation Desk BookDocumento145 pagineCalculation Desk Bookachmaddach100% (2)

- As 5016-2004 Metallic Materials - Conversion of Hardness ValuesDocumento10 pagineAs 5016-2004 Metallic Materials - Conversion of Hardness ValuesSAI Global - APAC0% (1)

- EMTL 250 Module 1 2018Documento57 pagineEMTL 250 Module 1 2018Yeab MengistuNessuna valutazione finora

- (3 Tip Type) : Product Description Chart GradeDocumento2 pagine(3 Tip Type) : Product Description Chart GradeRodrigo E. González NavarreteNessuna valutazione finora

- HEsteel SerbiaDocumento26 pagineHEsteel SerbiaYogesh GuptaNessuna valutazione finora

- VAR 3486 - PDC UpdatedMay2014 v1.0 SM PDFDocumento32 pagineVAR 3486 - PDC UpdatedMay2014 v1.0 SM PDFpendexxNessuna valutazione finora

- AK Carbon Steel PB 201307Documento70 pagineAK Carbon Steel PB 201307SilveradoNessuna valutazione finora

- Api 6DDocumento12 pagineApi 6Dcarlosalex200050% (2)

- 2-2 Ultrasonic WeldingDocumento43 pagine2-2 Ultrasonic WeldingnavneetrNessuna valutazione finora

- Outokumpu Semifinished MaterialsDocumento12 pagineOutokumpu Semifinished MaterialsvgestantyoNessuna valutazione finora

- Heat-Affected Zone Infiltration by Dissimilar Liquid Weld MetalDocumento9 pagineHeat-Affected Zone Infiltration by Dissimilar Liquid Weld MetalshivabejugamaNessuna valutazione finora

- Results and Discussion: Sample Mark Annealing Parameters Hollomon-Jaffe ParametarDocumento1 paginaResults and Discussion: Sample Mark Annealing Parameters Hollomon-Jaffe ParametarDarko LandekNessuna valutazione finora

- Lamellar TearingDocumento36 pagineLamellar Tearingcastelino_shanNessuna valutazione finora

- Manual Treadmill Cycle": Minor Project Report ON " Submitted To Maharishi Markandeshwar Deemed To Be UniversityDocumento16 pagineManual Treadmill Cycle": Minor Project Report ON " Submitted To Maharishi Markandeshwar Deemed To Be UniversityShrwan GyawaliNessuna valutazione finora

- DIN 17007-4-1963, Material Type NumberDocumento9 pagineDIN 17007-4-1963, Material Type NumberLloyd R. PonceNessuna valutazione finora

- Malz Grup KaynakDocumento43 pagineMalz Grup KaynakÜmit Uçak100% (1)

- 3PS Gaw 003Documento5 pagine3PS Gaw 003ravi00098Nessuna valutazione finora

- Datasheet-Sandvik-253-Ma-En-V2019-08-19 09 - 46 Version 1Documento12 pagineDatasheet-Sandvik-253-Ma-En-V2019-08-19 09 - 46 Version 1mini p shendeNessuna valutazione finora

- Astm A 385 PDFDocumento9 pagineAstm A 385 PDFNizarHamrouniNessuna valutazione finora

- Komelon Full Line Catalog 2014Documento50 pagineKomelon Full Line Catalog 2014bbutros_317684077Nessuna valutazione finora

- Delta FerriteDocumento4 pagineDelta FerriteRavindra ErabattiNessuna valutazione finora

- European Steel and Alloy Grades: X1Crnimon25-22-2 (1.4466)Documento3 pagineEuropean Steel and Alloy Grades: X1Crnimon25-22-2 (1.4466)farshid KarpasandNessuna valutazione finora

- PUMA - Piping ClassesDocumento256 paginePUMA - Piping ClassesBilel Mahjoub100% (1)

- Marine BrochureDocumento8 pagineMarine Brochurepramodtry100% (1)

- TataDocumento3 pagineTataayona12340000Nessuna valutazione finora

- ChE Basic QuestionsDocumento114 pagineChE Basic QuestionsKrizzete HernandezNessuna valutazione finora

- Drill Collars Tubing and Drill Pipe NS 1 A4 WatermarkedDocumento12 pagineDrill Collars Tubing and Drill Pipe NS 1 A4 Watermarkedislam atifNessuna valutazione finora

- ASTM A 751 - 07aDocumento6 pagineASTM A 751 - 07analakasaNessuna valutazione finora

- Fluidized Bed Freezer Quotation (MELIDocumento8 pagineFluidized Bed Freezer Quotation (MELIrichardNessuna valutazione finora