Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tank Manual2 Of2

Caricato da

AlbertDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tank Manual2 Of2

Caricato da

AlbertCopyright:

Formati disponibili

& & TANK

Manual Sponsor: D. M. Bosi / CTN 242-7218 / E-mail: bosd@chevron.com

50 Using This Manual

100 Gener al Infor mation

200 Fir e Pr otection

300 Mater ials Consider ations

400 Tank Design

500 Foundations and Gr oundwater Pr otection

600 Appur tenance Design

700 Instr umentation/Measur ement

800 Evapor ation Losses

900 Constr uction

1000 Inspection and Testing

1100 Maintenance

1200 Special Types of Tanks

Glossar y

Appendix A - Tank Appur tenance Vendor s

Appendix B - Conver sion Tables

Appendix C - Guidelines For Seismically Evaluating And Retr ofitting

Existing Tanks

800 EVAPORATION LOSSES

This section of the Tank Manual has been deferred. For information and details about evaporation, please consult

the sponsor of this manual. More information may also be obtained from the documents listed below. They can

be ordered directly from API.

API Bulletin 2516 Evaporation Loss from Low-pressure Tanks

API Publication 2517 Evaporation Loss from External Floating Roof Tanks

API MPMS19.1 Evaporative Loss from Fixed Roof Tanks

API Publication 2519 Evaporation Loss from Internal Floating Roof Tanks

API Bulletin 2521 Use of Pressure-vacuum Vent Valves for Atmospheric Pressure Tanks to Reduce

Evaporation Loss

Tank Manual 800 Evaporation Losses

June 1994 800-1

T

O

C

O

N

T

E

N

T

S

900 CONSTRUCTION

Abstract

This section is designed for the Company representative or engineer responsible for construction of a new tank

or replacement of major components (bottom and/or roof) of an existing tank. More than any other factors, good

communication with the contractor and careful dimensional checks, especially early in construction, influence the

success of the job. A useful tank hold points checklist is included. Appendix A lists suppliers of appurtenances

and other tank materials.

Contents Page Page

910 Foundations 900-2

911 Concrete Work

912 Installing the Secondary Containment

and Leak Detection System

913 Bottom-to-Foundation Seal

920 Bottom Construction 900-4

921 Bottoms for New Tanks

922 Bottom Replacement

930 Shell Construction 900-6

940 Roofs 900-7

941 Aluminum Dome Roofs

950 Tank Hold Points Checklist 900-17

990 References 900-17

Tank Manual 900 Construction

June 1994 900-1

T

O

C

O

N

T

E

N

T

S

910 FOUNDATIONS

The Company has installed many types of tank foun-

dations over the years: oiled sand or dirt pads, plank,

crushed rock, rock, brick and concrete ringwalls, etc.

More recently it has used the ringwall design with sec-

ondary containment and leak detection. This section

will discuss what to watch out for during the construc-

tion of the latter design, although most of the critical

factors and checks will apply to other designs as well.

The remarks below apply both to new foundations and,

during bottom replacement, to the spacer installed be-

tween the old and the new bottom.

The foundation consists of a concrete ring on which

the tank shell will rest. Inside the ring is a layer of

compacted fill. An HDPE membrane liner is stretched

over the fill and impaled on the reinforcing bars that

stick up from the ring about 1-1/2 inches. For bottom

replacement, the membrane is placed on top of the old

bottom (see Section 912).

A concrete pad (or spacer, for bottom replacements) is

poured on top of the membrane liner. If the pad is to

be reinforced with polypropylene fiber or wire mesh,

this material is placed on the membrane before the

concrete is poured. After the pour, grooves in a pie

shape arrangement are cut in the pad to drain any liq-

uid leaking from the tank to the outside where it can

be seen.

Standard Drawings GD-D1120 and GF-S1121 provide

excellent illustrations of the requirements for new leak

detection bottoms and foundations.

911 Concrete Work

Dimension Checks

During construction of the foundation, critical dimen-

sions such as diameters, depths, levels, ringwall depth,

fill depth, waterdraw basin dimensions, telltale line lo-

cation, etc., must be checked for accuracy against the

drawings.

Excavation and Fill

Before Concrete is Poured. Any backfilling of the ex-

cavation made for the foundation should be well

tamped into place. The bottom of the excavation

should be checked for adequate compacting. Forming

for the vertical walls of the foundation should extend

below the grade specified.

After Concrete is Poured. Backfill around the ring-

wall and waterdraw basin after removal of forms

should be well compacted.

Concrete for Foundation

Before ordering the concrete, check mix proportions

and mix timing with concrete subcontractor. Chloride

salts should not be added to the mix to accelerate hard-

ening, and soluble chlorides should not exceed 0.15%,

as recommended by the American Concrete Institutes

publication 201.2R-77 Guide to Durable Concrete.

Also check proportion of concrete to polypropylene fi-

ber reinforcement material, where used for the pad.

Before Pouring

Slump Test. Be sure you have cylinders on hand

to perform slump tests.

Ringwall Forms. Before concrete is poured, the

top of the ringwall forms should be checked for

level by survey: the elevation of the top of the con-

crete must be within 1/2 inch of the specified ele-

vation at all points. In addition, elevations should

not vary by more than 1/8 inch in any 30-foot cir-

cumferential length, nor more than 1/4 inch about

the entire circumference.

Reinforcing Bars. Before concrete is poured,

check that the bars are the correct size and dimen-

sions and that they are placed according to the

drawings and specifications. The bars must be at

least 1-1/2 inches away from the foundation forms

for adequate coverage when the concrete is poured.

Concrete Pad. If wire mesh is used as a concrete

pad reinforcement instead of the recommended

polypropylene fiber, check that there are sufficient

chairs to hold the wire the proper distance above

the fill or old bottom. Before pouring, check the

slope to ensure there will be sufficient concrete

over the wire reinforcement.

During Pouring

Mix Consistency. Perform slump test and check

that concrete is worked into all areas so there are

no voids or trapped bubbles of air.

Coverage, Concrete Pad. The minimum concrete

coverage depth should be checked against the

specification.

After Pouring

Concrete Ringwall. Immediately after the ringwall

is poured, elevations and tolerances should be

900 Construction Tank Manual

900-2 June 1994

checked by survey. Swelling of the formed area

usually results in a slight lowering of the top edge

of the form. A slight variation in the ringwall di-

ameter is not critical but any variation in the top

of the ringwall and pad elevation is. The height (top

elevation) of the pad edge form should be checked

for elevation by survey, not by measuring from the

top of the ringwall pour.

Check that drain pipes through the concrete ring-

wall are clear, not plugged.

Exposed Edges. All exposed edges of final pours

should be chamfered. Minimum thicknesses should

be checked immediately following the pour.

Concrete Pad. After the forms are removed and

needed patching completed on the outside edge of

the pad, check that the concrete patches or grout

adhere properly.

When to Cut the Leak Detection Grooves. Saw-

cutting of the grooves in the concrete pad should

be done as soon as the concrete is cured enough

for foot traffic. Usually this is 24 to 48 hours after

the pour. This is the optimum time for ease of cut-

ting and to avoid broken edges. See Section 912

below for the proper method for saw-cutting the

grooves.

912 Installing the Secondary Containment

and Leak Detection System

Together, the membrane liner and the grooves cut into

the concrete pad are the secondary containment and

leak detection system. This section tells you what to

watch for during membrane liner installation. Also re-

fer to the following additional sources of information

in the Tank Manual: Section 500, Foundations and

Groundwater Protection; Specification TAM-MN-1,

Tank Bottom Replacement and Membrane Place-

ment; and Specification TAM-MS-4763, Membrane

Liner for New Tanks.

When to Install the Membrane Liner

New foundations: the membrane is placed after

completion of the concrete ringwall, removal of the

internal ring forms, and backfilling and compacting

(to the proper slope) of the area inside the ringwall.

Cone up bottom foundations: the membrane is in-

stalled under the waterdraw basin prior to its pour.

Cone down bottom foundations: the center sump

and sump liner along with the telltale line from the

sump liner to the standpipe outside the tank are

placed prior to membrane installation.

How the Membrane Liner is Attached

New foundations: the membrane liner is impaled

over the concrete ring foundation reinforcing bars

extending vertically from the foundation (see

Standard Drawing GF-S1121).

Replacement bottoms: the membrane is attached to

the old bottom at the shell by adhesive/sealant and

by impaling (see Standard Drawing GD-D1120).

The old center sump is cut out and replaced with

a new sump and sump liner, and telltale line run to

a standpipe outside the tank for cone down bot-

toms.

Forming the Membrane Liner. The membrane liner

should be level, smooth and free of wrinkles as prac-

tical before the sheets are extrusion welded (or bonded)

together. Check extrusion welds (or lap joint adhesion)

for bond and leakage. Bond can be checked with a

dulled ice pick, and leakage by vacuum test similar to

that used for welded steel plate seams.

On replacement bottoms, the membrane at the rat

holes should be well sealed with adhesive/sealant. (On

bottom replacement jobs, rat holes are the cutouts in

the old shell that allow leaks to drain from the grooves

in the concrete pad and out to a gutter.)

Telltale Pipes. These pipes carry the liquid from leaks

away from the tank to where an operator can see it.

On cone down bottoms, telltale pipes should be

checked for level and tested for leakage. The backfill

should be tamped. On replacement bottom installation

of the telltale line, the area under the concrete ringwall

(or area under the shell) should be back filled with

concrete to avoid local settlement.

Sump. Center sump elevation should be exactly to

specification. The sump should rest fully on well com-

pacted soil. If the base under the center sump has any

tendency to shift or settle, an unformed, polypropylene

fiber reinforced 4-inch thick pad should be installed

and checked for elevation before the basin is installed.

Leak Detection Grooves. Follow the rules below for

grooves:

Grooves in the concrete pad are best made by saw-

cutting.

Grooves should line up and extend to the rat

holes cut in the existing shell on cone up bottom

Tank Manual 900 Construction

June 1994 900-3

replacements. The last 12 to 15 inches will have to

be chiseled. On cone down bottoms, grooves shall

stop 12 to 15 inches from the shell, which will not

have ratholes.

Grooves should extend to the distance from the

shell that the concrete saw can cut on replacement

cone down bottoms.

The groove layout should be checked against

proper drawing detail. Note the difference between

the cone up and cone down groove pattern.

913 Bottom-to-Foundation Seal

Before placing the new bottom plates (or annular ring),

a band of sealant is placed at the edge of the founda-

tion or pad. This sealant prevents groundwater from

entering under the tank.

920 BOTTOM CONSTRUCTION

This section covers field installation of steel bottoms.

921 Bottoms for New Tanks

Bottoms Not Requiring Annular Rings. The new

bottom sheets are tacked into place, then welded.

Watch for excessive overlapping of plates and grinding

down of the upper plate to hide a less-than-full fillet

weld. Before welding, check that enough plate extends

beyond the outside edge of the shell radius to meet the

specified overlap.

Cone up Bottoms Requiring Annular Rings. The an-

nular ring plate should be installed first. Annular plate

must be welded with full penetration welds. As many

plates as can be handled may be back welded into a

single section for installation. Welding these assembled

sections together in place requires the use of backup

strips (see Figure 900-1). After installation of the an-

nular ring, the bottom plate is tack welded in place and

then welded. The plates should shingle toward the low

point, i.e., the outside row of plates should be installed

first with the higher center plate row installed last.

Cone down Bottoms with Annular Rings. The pre-

ferred method of installing a new cone down bottom

with annular ring is to install the bottom deck plate

first, shingled toward the center (i.e., the row of plates

running through the center is placed first). The annular

ring is then placed on top of the deck plate with its

installation being the same as detailed above. Installing

the annular ring first traps a small amount of liquid

near the edge of the shell. The finished fillet weld at-

taching the annular ring to the bottom deck plate

should, as a minimum, be equal to the bottom deck

plate thickness. If the surface is to be coated, the weld

should be ground to a smooth radius.

922 Bottom Replacement

For a complete description of the requirements for re-

placing tank bottoms, see the commented version of

Maintenance Specification TAM-MN-1, Tank Bottom

Replacement, and the discussion above. Below is a

summary of the procedure to follow for tank bottom

replacement for small and large tanks.

Small Tanks

Small tank bottom replacement is best done by lifting

(or jacking up) the tank, placing a prefabricated bottom

on the foundation, then lowering the tank to within 2

inches of the new bottom, cutting the tank shell just

above the old bottom weld, sliding the old bottom out

and then lowering the shell and roof into place. The

shell is then welded into place and tested.

Large Tanks

For replacing the bottoms of large tanks, follow the

steps described below for each of the replacement

phases: preparation, bottom-to-shell welding, weld

seam testing, and welding of pads and reinforcing

plates to bottom.

Preparation Phase

To prepare the shell for bottom replacement follow

these steps:

X22844.DXF

TAM900-1.GEM

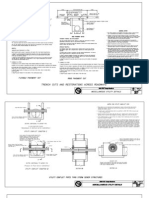

Fig. 900-1 Details of Annular Ring Butt Weld and

Backup Strip Installation

900 Construction Tank Manual

900-4 June 1994

1. Remove internal appurtenances, supports, and

brackets.

2. Cut horizontal slots in the shell. These slots are

usually about 5-1/2 to 8-1/2 feet long with 6

inches of shell left between the slots. The height

of the slot should be 3/4 inch. The lower face of

the slot should be relieved (notched out) for butt

welded annular ring backup strips. The bottom

edge of the slot will act as a form for the concrete

spacer. See Figure 900-2.

3. Weld square C-shaped support clamps (or dogs)

of heavy steel to the shell so that the open area of

the C allows the new bottom plate to slip

through the shell with the required overhang. See

Figure 900-2.

4. Install membrane under roof supports. Form

around fixed roof supports and wrap floating roof

legs as discussed in Specification TAM-MN-1.

5. Install the membrane liner as discussed in Section

910 and shown on Drawing GD-D1120.

6. Install the concrete spacer. Complete concrete

around supports as discussed in the specification.

7. Remove 6-inch spacers between slots, install annular

ring through shell slots and install bottom plate.

Relieving Shell over Bottom Plate Weld. A portion

of the shell plate directly over the field welded bottom

lapped plate or butt welded annular ring joint should

be notched in order to permit completion of the weld

under the tank shell. Each of the lap welded bottom

plates or butt welded annular ring joints under the shell

should be inspected before the notch can be welded up.

Failure in this weld joint can produce a bottom leak

almost impossible to track down. See Figure 900-1.

Bottom-to-Shell Weld Seam

Minimum weld thickness is specified in API 650, Para-

graph 3.1.5.7. There is no increase in strength by ex-

ceeding the thinner plate thickness dimension with the

weld. However, since this particular weld is subject to

considerable potential corrosion, on cone up bottoms

in particular, some extra corrosion allowance in the

weld is useful.

X25508.DXF

TAM900-2.GEM

Fig. 900-2 Slot Configuration for Replacement Bottom

Tank Manual 900 Construction

June 1994 900-5

Procedure. The ideal step-by-step procedure in making

and testing the bottom-to-shell welds is to weld the in-

side weld first, leak test the weld by applying diesel

oil or penetrant to the weld side and visually inspecting

for leakage on the exterior of the shell. The exterior

weld is then made. This method ensures a leak-free

stockside weld. It should be used wherever the bottom

design does not include a thick welded annular ring.

Bottoms equipped with annular rings cannot be welded

this way. Making the stockside weld first causes the

annular ring plate to rotate about the bottom edge of

the shell. For this reason, the outer weld must be made

first and tested before the inner weld is made.

Verify that all traces of diesel oil or penetrant are re-

moved by detergent washing from the opposite side

prior to making the weld.

Replacement Bottoms. After the bottom-to-shell weld

has been completed and tested, the dogs supporting

the shell are removed and the tank permitted to settle

down on the spacer pad.

Vacuum Testing of Weld Seams

Vacuum testing of weld seams is often done as the bot-

tom seam welding progresses; however, this practice is

not recommended. Sometimes slag inclusions occur in

the welds, particularly at stop and start weld points.

Vacuum testing immediately after welding does not

give these inclusions enough time to open up. For this

reason, vacuum testing of bottom welds should be de-

layed for 4 or more days (if possible) after welding.

Failure due to hydrogen cracking should be evident af-

ter 1 day.

Pads and Reinforcing Plates

All pads or reinforcing plates welded to the tank bot-

tom should be, as a minimum, seal welded all around.

No clip, support, bracket, etc., should be welded to the

bottom plate without a pad between the item welded

on and the bottom plate. This precaution avoids con-

centrated loads that might tear the bottom.

930 SHELL CONSTRUCTION

Building a tank shell round and plumb is of critical

importance for all floating roof tanks and for those

fixed roof tanks that might have internal floating roofs

installed in the future. A round and plumb shell mini-

mizes the annular space variation between the shell and

floating roof and, therefore, gives better sealing and

less maintenance of the seal. The key to constructing

a truly round and plumb tank is to ensure that the top

edges of the shell courses are level, especially the edge

of the first course.

Plate Preparation and Shop Inspection

Tank erectors have fabrication shops where tank plate

is processed and tank appurtenances are fabricated.

Plate processing includes:

Cutting each plate square to size

Beveling edges for field welds

Forming plate to required curvatures

Abrasive blasting and priming the plate

A Company representative should inspect work done

at the shop. A checklist for shop inspectors is included

in Section 1040.

Leveling

Leveling the top of the first course is critical for shell

roundness. The smaller the degree of variation from level,

the more perfectly round the tank will be, and the remain-

der of the shell will be easier to erect. The shell level

should be checked after the plate is tack welded or

dogged in place. The level of the top of the first course

may be corrected by wedges placed between the tank

steel bottom and foundation. The level of the remainder

of the courses should also be checked. Squared plates will

reduce out-of-level problems.

Welding

Peaking and Banding

API 650, Paragraphs 5.5.4. and 5.5.5, cover peaking

and banding. These terms refer to the distortion or

dimpling of shell plate and seams inward or outward.

Ideally, the welding of shell horizontal and vertical

seams should be done with alternating weld bead in-

side and outside to avoid peaking and banding. The

weld joint should be closely checked by use of a

straight edge on horizontal seams and by a board cut

to the exact tank radius on the vertical seams. If peak-

ing or banding is detected, no further welding should

be done on that seam until a procedure is developed

that will not worsen the condition.

900 Construction Tank Manual

900-6 June 1994

Improper shop forming of the shell plates and inade-

quate cribbing of the rolled plates during shipping and

storage can also contribute to peaking and banding.

Welding and Welder Qualification

Section 7 of API 650 covers welding procedure and

welder qualifications. In addition, most operating

companies have extensive welding specifications and

welder qualification documents.

Weld Quality Control

Onsite weld quality control by a knowledgeable and

experienced welding inspector is strongly recom-

mended. Most major operating organizations have

their own welding inspection capability. Smaller or-

ganizations that do not should either arrange for that

service from a nearby Company organization or con-

tract the service.

Wind Girders and Preventing Wind

Damage During Erection

All open-top tanks over 50 feet in diameter have wind

girders to stabilize the shell. Wind girders are covered

in API 650, Section 3.9. All plate-to-plate junctures

should be seal welded to prevent corrosion product

from breaking welds.

Preventing Wind Damage

Before the fixed roof is installed (and for open-top

tanks, before the wind girder is installed), failure to

protect the shell from wind-caused buckling can result

in major damage and delay in tank erection.

Protection against buckling should begin with the

erection of the third course.

Protection can be in the form of temporary clips

installed at the top of the shell and connected by

steel cables to ground anchors.

On floating roof and open-top tanks, the wind

girder can be raised and temporarily attached to

each shell course as the shell is erected. It then

can act as not only protection against wind dam-

age, but as a work platform and walkway.

Dimensional Checks During Erection

Shell Plate

As mentioned earlier, the level of each shell plate and

course should be checked during erection. The level

of each plate should be checked as it is set in place

with corrections made by adjusting the thickness of the

wedges placed between plates on the horizontal seam.

Plate surfaces should be flush with lower and upper

plates on the stockside.

Tank Diameter

The tank diameter is checked by measuring the tank

circumference as each course is erected. Hourglass

or barrel shaped shells are not an unusual occur-

rence. This problem is prevented by adhering strin-

gently to the gap specification between plates,

checking individual plate lengths, and using scribed

points for lineup at the top edge of the shell course

plate being installed. Often the last plate on a course

being installed is designated to be trimmed to fit in

the field to adjust for errors. At other times weld spac-

ing is used.

Peaking and Banding Checks

These checks should be made during the placing and

weld up of each shell plate. The checks are made us-

ing a long straight edge (held vertically on the stock-

side surface) or a board cut to the exact shell radius

(held horizontally across the vertical weld seam).

940 ROOFS

This section discusses the construction of fixed and

floating roofs and roof drains.

Fixed Roof

A fixed roof is constructed after the bottom and shell

are erected. Lap welded roof deck plate should be laid

in reverse shingle orientation to prevent capture of

condensate in the stockside overlapped seam. The

fixed roof should be built with a frangible joint (roof-

deck-plate-to-top-angle weld) as described in Section

400. Excess weld material should be removed by

grinding. This joint is critical to protect the shell and

bottom-to-shell seam during internal overpressure.

Floating Roof

Some tank builders prefabricate sections of the pon-

toon for assembly inside the tank while others merely

cut plates and assemble the roof in place. Erection of

the floating roof usually begins after completion of the

first shell course. An even annular space all around the

roof is of primary importance. The roof is usually as-

sembled on low temporary supports (see Figure 900-3).

The roof is then raised by air or is floated on water to

the high leg position where the leg assemblies are in-

stalled. Once the roof leg assemblies have been in-

Tank Manual 900 Construction

June 1994 900-7

stalled and entry to the tank under the roof is possible,

the roof leg or guide assembly should be welded to the

reinforcing pad or roof deck plate from the underside

of the roof. See Figure 900-4.

All floating roof pontoon compartment bulkheads

should be welded so as to make the pontoon vapor

tight. This requires that each inspection hatch cover be

equipped with a gooseneck vent.

Roof Drains

General

At all times during floating roof construction and while

the tank is out of service for repair or rebuilding, a

drain system for the floating roof must be operational.

This can be done by leaving the flexible section of the

drain system unconnected, permitting rainwater from

the roof to drain into the tank. It also can be done by

leaving the drain system open (unplugged at the roof

basin and with the valve on the shell open).

Articulated Joint Roof Drains

Roof drain systems consisting of rigid pipe sections

and articulated joints (such as the externally sealed

Chicksan) must be installed accurately to the drawing

dimensions.

The drain system must be designed to accommodate

the floating roof at any position, from its resting posi-

tion on low legs to its design safe oil height.

Two common errors made by people unfamiliar with

articulated joint roof drains is to adjust the dimensions

to better fit the high leg position, and to get the articu-

lated joints with their counterbalance bosses in the

wrong orientation.

Flexible Pipe Roof Drains

The lay pattern of the flexible pipe roof drain

(Coflexip or Mesa brands) and the twist in the pipe

when connecting the flange are critical to proper op-

eration. The flexible pipe manufacturers design and

dimensions must be followed. If an error is apparent

even though construction dimensions were accurately

followed, the manufacturer of the flexible pipe should

be notified and any re-dimensioning delayed until the

manufacturer has corrected the discrepancy in design.

The lay pattern and installation dimensions and orien-

tation must be designed to avoid obstructions, particu-

larly roof legs, at both the low or operating roof

level and at the high or out-of-service level. The de-

sign is peculiar to each tank.

941 Aluminum Dome Roofs

Introduction

This section covers the aluminum dome roof, its appli-

cations, use guidelines, and a comparison of alternative

tank-covering methods. Figure 900-5 shows an alumi-

num geodesic dome plan and elevation.

Aluminum geodesic dome roofs, or storage tank cov-

ers, offer two unique advantages over other covering

material:

1. They are clear-span structures meaning that the

support of the structure is provided at the periph-

ery only, without the need for column supports in-

x25478.DXF

TAM900-3.GEM

Fig. 900-3 Temporary SupportsNew Floating Roof

X25479.DXF

TAM900-4.GEM

Fig. 900-4 Welding of Roof Leg to Roof Deck

Plate

900 Construction Tank Manual

900-8 June 1994

side the projected plan area of the roof. Clear

spans of up to 300 feet or more are possible.

2. They are economically competitive and in many

cases the lowest cost option for covering a tank.

Originally aluminum geodesic dome roofs were used

to convert external floating-roof tanks to internal float-

ing-roof tanks, minimizing the effects of weather on

maintenance and operation. By the late 1970s the alu-

minum geodesic dome roof gained widespread use as

a cover for both retrofitted and new tanks. Following

the implementation of the Clean Air Act, the aluminum

dome roof enjoyed a resurgence as a means of reduc-

ing air emissions. Today there are several thousand

dome roof tanks in existence.

Applications

Weather Covers

Tank covers or roofs are used to reduce many weather

related problems associated with external floating roof

tanks. External floating roof tanks must be periodically

drained to eliminate the bottom water layers that form

when rainwater runs down the inside wall of the tank

shell and past the roof seals. This water must then be

treated to remove environmentally unacceptable mate-

rials before it is discharged. Additionally, external roof

drains are subject to freezing, plugging with debris, and

require frequent inspection to assure that they are

working. An aluminum dome roof eliminates all of

these problems. Figure 900-6 shows this schematically.

Product Purity

Many diesel fuel tanks are covered to reduce water in-

filtration. Too much water in the tank can lead to tur-

bidity and off-spec material. To purge the fuel of

water, the tank must be allowed to settle then water

coalescing units (or other types of water removal sys-

tem) must be used.

Keeping water out of fuels is particularly important for

materials which do not easily phase-separate in tanks.

Examples include alcohols, such as motor fuel oxygen-

ates. It is preferable to store products such as MTBE

(Methyl Tertiary Butyl Ether, a gasoline oxygenate ad-

ditive) in covered tanks because water content may

cause the product not to meet specifications.

If aluminum is compatible with the product being

stored, these domes should be considered for fixed roof

tanks that have been internally coated to eliminate

product contamination problems resulting from iron,

iron salts or rust contamination as a result of shell cor-

rosion.

X47216.HPG

TAM9005.GEM

Fig. 900-5 Aluminum Dome Roof

X47205.HPG

TAM9006.GEM

Fig. 900-6 Weather Related Problems of External

Floating Roof Tanks

Tank Manual 900 Construction

June 1994 900-9

External Corrosion Resistance

Because aluminum dome roofs are corrosion resistant

in most atmospheres, they can be used in any geo-

graphical area. However, in marine environments the

aluminum roof must be located at least 200 yards from

seawater or shoreline.

Internal Corrosion Resistance

Due to its corrosion resistance to hydrogen sulfide, an

aluminum dome roof is useful for sour product service,

sour crudes, sour waste water, and many other corro-

sive environments.

In steel roof applications where underside corrosion is

a problem, corrosive vapors condense and get into the

crevices of lap welded joints, initiating corrosion. To

prevent corrosion in these applications, steel roofs are

designed as follows:

A reverse shingle layout is often used to minimize

condensing liquid on the underside of plates and in

crevices.

Seal welding the laps on the bottom side is another

alternative.

Some roofs use external rafters so that the there are

no crevices (API 650 does not allow welding the

roof plates to the rafters). In all the above cases,

the use of an aluminum dome roof should be con-

sidered.

Emission Reduction

An internal floating roof tank suffers less evaporation

loss and emissions than a comparable external floating

roof tank. Emission and losses from roof seals are ef-

fected by wind speed. Since the wind speed above the

seals in an internal floating roof is almost zero, the

emission of air pollutants is minimized. Either a con-

ventional steel roof or a dome roof will have the same

effect on emissions. However, the geodesic dome has

an advantage that is not available with a conventional

roof. Large steel roofs, on internal floating roof appli-

cations, must be supported by columns. These support

columns must penetrate the roof. At each penetration

there are some emissions. Because the geodesic dome

roof is a clear-span structure, or a structure that is sup-

ported entirely at the perimeter, there is no internal

roof penetration. See Figures 900-7 and 900-8.

Figure 900-9 shows some typical emissions compari-

sons for covered tanks.

Pressurized Applications

Applications that may involve pressure are usually

fixed-roof tank applications with inert gas blanketing

under some small pressure (less than 2" wc) or in va-

por recovery systems. Although API 650, (Appendix

G) allows pressures under the dome of up to 9 inches

wc, this is never used in practice. The typical values

are around 2 inches of water column maximum. Prob-

lems with leakage have been significant above this

pressure and larger tanks are not designed to handle

X47209.HPG

TAM9007.GEM

Fig. 900-7 Wind Effect on External Floating Roof

Emissions

X47206.HPG

TAM9008.GEM

Fig. 900-8 Aluminum vs Cone Roof Emissions

900 Construction Tank Manual

900-10 June 1994

more pressure. Dome manufacturers are, however,

making improvements to the joint details of domes,

and increased pressure allowances are becoming more

common.

In vapor tight, pressurized-hydrocarbon services, or

fuel-gas blanketed services, silicone seal materials

should not be used. The migration of hydrocarbon into

the joints has caused many problems. Neoprene or Se-

coflex polysulfide used around hub covers and baton

strips work well as sealants.

Fire Susceptibility

Because external floating roof tanks are subject to rim-

seal fires caused by lightning strikes, covering the tank

reduces the possibility of fires. However, lightning-

caused fires have occurred in aluminum dome covered

tanks. Such fires occur because flammable vapors ac-

cumulate above the floating roof and are ignited by a

lightning strike to the circulation vents. This occur-

rence is extremely rare and is usually caused by some

kind of plant upset. Normally the venting specified by

Appendix H of API 650 is adequate, even under low

wind conditions, to maintain all flammable petroleum

products well under the lower flammable limit.

It should be noted that no fires have occurred that have

significantly heated the interior vapor space of an in-

ternal floating roof tank. Because aluminum loses its

strength at relatively low temperatures compared to

carbon steels, a temperature rise in the vapor space

could cause the dome to collapse onto the floating roof.

Because fire probability in dome-covered floating roof

tanks is low, fixed fire fighting equipment need not be

installed on these tanks. If they do occur, fires may be

fought through the hatches or light panels in the roof.

In spite of having a dome roof, some fire regulations

call for installation of fixed foam systems on tanks

with flammable materials.

Design Requirements

Standards

API 650 (Appendix G) is the only aluminum dome

standard that sets out design criteria for structurally sup-

ported aluminum dome roofs. However, the domes, be-

ing part of a larger structure, are often regulated as

building structures and are subject to local building per-

mit and fire department requirements. Live and dead

loadings, as well as maximum height requirements, are

often regulated by the building permit authorities. API

650, (Appendix G) recognizes the following applica-

tions of aluminum domes on tanks:

For new tanks

For atmospheric pressure

For internal pressure up to nine inches water column

However, there are numerous practical design consid-

erations that are not covered by the standard, some of

which are covered below.

Physical Characteristics

Dome size is not limited; however, the radius of the

aluminum dome must be within 0.7 - 1.2 times the di-

ameter of the tank. For carbon steel dome roofs the ac-

ceptable dome radius is 0.8 - 1.2 times the diameter of

the tank. The flatter dome (1.2D) is the same as the

carbon steel dome, however, the allowed steeper alumi-

num dome has been limited arbitrarily to a steepness of

0.7D. Steeper domes can be built.

Skylights are sometimes used on tank domes. When

they are used, a typical usage is at a ratio of 1% of the

projected area of the dome. They can be used to let in

light and to do visual inspections required by EPA. The

use of skylights is optional, but when used they must

be constructed of 0.25 inch minimum thickness clear

acrylic or polycarbonate plastics.

Materials

The structural members are typically 6061-T6. The pan-

els are series 3000 or 5000 aluminum with a required

minimum thickness of 0.05 inch. Fasteners are alumi-

num or stainless steel. All aluminum must be electri-

cally isolated from carbon steel by an austenitic

TAM900-9.TIF

Fig. 900-9 Emission Loss Comparison Covered

Tanks - No Guide-Pole

Tank Manual 900 Construction

June 1994 900-11

stainless steel spacer or elastomeric isolator bearing

pad. The aluminum dome must be electrically bonded

to the tank shell using 1/8 inch stainless steel cable

conductors at every third support.

Coatings

It is very rare for domes to be coated or painted inter-

nally or externally because the cost is quite high. As-

thetic considerations would be the only reason to paint

a dome. If painted, the surfaces must be first degreased

and etched for good adhesion.

Two Basic Dome Designs

The weight of the aluminum dome structure generates

an outward thrust as shown in Figure 900-10. The flat-

ter the structure the greater the outward radial thrust.

To handle this force, the dome manufacturers have

standardized on two basic type of roof designs:

1. Fixed Base Design. In this design the tank shell

absorbs the horizontal thrust caused by the domes

weight.

This is the preferred method of construction for new

tanks. Since there is no tension ring, the radial thrust

is taken by the top of the tank, requiring less struc-

tural aluminum. However, the dome manufacturer

must supply the load conditions that the tank will be

required to handle as a result of the horizontal thrust

from the dome. Additionally, the tank must have

some stiffening at the top to withstand the dome is

horizontal thrust loads, often a wind girder.

This design has one other advantage. The dome

flexes less due to a given load because the base is

restrained by the tank shell. Less movement in the

dome means less possibility for fatigue or leaks.

2. Sliding Base Design. In this configuration, the out-

ward thrust is handled by a tension ring in the

structure. The only force acting on the tank is

gravity. This design works well when modifying

existing tanks because there is no need to modify

the shell which is already designed to handle the

dead weight of the dome. A detail of the tension

ring is shown in Figure 900-11.

Attachment of Dome To Tank Shell

The dome is attached to the tank shell for both the

fixed and sliding base design by means of support

points as shown in Figures 900-12A and 900-12B. The

specific details of attachment vary from one manufac-

turer to another. The detail for the fixed or sliding

base design is similar, but in the sliding base design

(where the support points must be free to move ra-

dially) a sheet of teflon is used as the bearing surface

and a slotted-bolt hole allows the radial movement.

Elevation Of Aluminum Dome

Figure 900-13 shows typical dome mounting details for

existing tanks. To provide ventilation the dome is ele-

vated slightly above the top of the tank. The support

points (sliding type) transfer the loading through col-

umns to wind girders so that the top of the tank shell

will not be over-stressed at the points of attachment.

Figure 900-13 appears on page following.

A retrofitted tank dome poses a business decision:

either lose some tank capacity or spend the extra

money to add sufficient height to the dome so that no

tank space is lost. Tank space is lost due to floating

roof appurtenances, such as seals or floating roof legs

that project upward. This can vary up to several feet.

To raise the roof high enough to avoid loss of tank

space, free-board must be installed above the top of the

tank shell to support the dome. Any open space must

be covered. This is usually done with aluminum roll

formed into sidewall panels.

Design Loadings

The minimum dead loading is the weight of the roof

itself and all accessories attached to it. Typically, alu-

X47210.HPG

TAM90010.GEM

Fig. 900-10 Forces on Dome Structures

900 Construction Tank Manual

900-12 June 1994

X47204.HPG

TAM90011.GEM

Fig. 900-11 Tension Ring

X47200.HPG

TAM90012A.GEM

Fig. 900-12 Support Point

X47208.HPG

TAM90012B.GEM

Tank Manual 900 Construction

June 1994 900-13

minum dome roofs average 2.5 psf (

1

2

inch wc), which

is about 1/3 the weight of conventional 3/16 inch thick

carbon steel roofs.

The live load is 25 psf or greater if required by the

regulatory agencies or building codes. API 650, Ap-

pendix G includes requirements for unbalanced loads,

panel loading, and concentrated loading. It also gives

requirements for the load combinations such as dead-

load-plus-seismic. The suppliers are required to run

through a series of load combinations to assure that

the roof is structurally adequate for the application. If

there is any internal pressure, that number must be in-

cluded in the load calculations.

One of the design-loading conditions that requires

good communication between the purchaser and the

supplier is the means of transferring the roof loads

to the tank shell. The tank and foundation must be

checked to assure that they are adequate to assume

the increased loading from the added roof. Since the

top of an existing tank is rarely round, the dome

must be constructed to accommodate this tolerance

problem. This is done by the allowance for large tol-

erances made at the support points. It must also accom-

modate thermal expansion of the roof within a

temperature range of 120F. For existing tanks, the

easiest way to handle some of these problems is to de-

sign the roof to shell junction with a sliding surface so

that only vertical loads are transferred to the tank shell.

For new tanks, the tank rim is often strengthened suf-

ficiently so that the roof is rigidly attached to the shell

which is designed to take all of the roof loadings. When

tanks have internal pressure, the preferred design is to rig-

idly affix the roof to the shell. If a sliding joint is used,

a sealing fabric must be installed to contain the internal

pressure. This design is more subject to failure than the

fixed-base design.

Shell Buckling

Local and general shell buckling must have a mini-

mum safety factor of 1.65. General shell buckling

can be determined from:

NOTES:

1. SUPPORT POST TRANSFERS REACTIONS

TO THE WINDGIRDER TO PREVENT OVER-

STRESSING OF THE TOP OF THE TANK

SHELL AT POINTS OF ATTACHMENT.

2. FREEBOARD IS ENCLOSED BY ROLL

FORMED SIDEWALL PANELS WHICH ARE

ATTACHED TO SUPPORT POSTS.

3. POST ELEVATES DOME ABOVE TOP OF

TANK.

X47207.HPG

TAM90013.GEM

Fig. 900-13 Tension Ring

900 Construction Tank Manual

900-14 June 1994

W 2258 x 10

6

I

x

A

(SF) LR

2

(Eq. 900-1)

where:

W = allowable live load, psf

I

x

= moment of inertia of beam about the

strong axis, in

2

A = cross section area of beam, in

2

R = spherical radius of dome, in

L = average dome beam length, in

SF = safety factor

= 1.65

Tension Ring Area

The minimum tension ring area is determined from:

A 11

D

2

ntansin

|

.

180

n

`

,

F

t

(Eq. 900-2)

where

A = net area of tension beam, in

2

D = tank diameter, ft

n = number of dome supports

=

1

2 the central angle of the dome or

the roof slope at the tank shell

F

t

= allowable stress of the tension ring, psi

Roof-Shell Junction

A dome roof is never considered to be frangible. How-

ever, internal pressure would probably blow out dome

panels or destroy the roof long before the shell or bot-

tom would be affected and could therefore be an ef-

fective means of preserving the integrity of the tank

contents during an over-pressure situation.

Temperature Limits

API establishes a maximum operating temperature for

aluminum dome roofs of 200F.

Wind Loading

Unless specified by the tank/owner operator, the de-

fault wind loading condition is 100 mph.

Seismic Loading

The seismic loading is presumed to act uniformly over

the dome and the design basis for the dome is:

F .24ZIW

r

(Eq. 900-3)

where

F = horizontal force

Z = zone coefficient

I = essential facilities factor

= 1.0 for most cases

W

r

= weight of tank roof, lb

Testing

For atmospheric applications the roof is simply hosed

down and checked on the underside for the evidence

of leakage. When the tank is designed for internal pres-

sure, it should be pressurized with air and soap-bubble,

and leak tested.

Appurtenances

Roof hatches are optional. However, most tank appli-

cations use only 1 hatch. If there is a rolling ladder

left in a tank, a hatch is often supplied for it. Figure

900-14 shows the details of a roof hatch.

Roof nozzles should be constructed per Figure 900-15.

They are used for high level alarms or for thief hatch

purposes. Many applications do not have any roof noz-

zles.

Skylights are optional See Figure 900-16. However,

they provide natural lighting for the interior and also

provide a means to do visual inspection of roof seals

that are required to be performed annually by EPA.

They are recommended and they should be provided at

a rate of 1% of the projected area of the dome.

Tank Manual 900 Construction

June 1994 900-15

Dome roofs are vented by the gap between the roof

and the shell, making peripheral shell vents unneces-

sary. One center vent at the top is required per API

650 (Appendix 11), usually an 8 inch vent. Typically,

there is no special access provided for this hatch.

Internal Rolling Ladders

When an existing tank is retrofitted with a dome, the

existing rolling ladder can be left in place. Because the

dome usually interferes with the operation at the top

of the ladder, the dome manufacturers often reattach

the ladder to the structural members of the dome. This

requires that the bottom of the rolling ladder be ex-

tended to suit the modifications.

Often the tank owner/operator does not wish to make

the modifications or there are no modifications that can

be made to accommodate the new dome and the full

travel range of the floating roof. In these cases the lad-

der is removed and tank owners do one of two things

for access to the internal roof:

1. They use a rope ladder for access when needed.

2. They wait until the floating roof is at its high level

X47201.HPG

TAM90014.GEM

Fig. 900-14 Typical Access Hatch Detail

X47202.HPG

TAM900-15.GEM

Fig. 900-15 Typical Nozzle Section at Duct

Penetration with Flanged Connection

X47203.HPG

TAM900-16.GEM

Fig. 900-16 Skylight Panel Detail

900 Construction Tank Manual

900-16 June 1994

in the tank and simply access the top of the roof

by stepping onto it.

Access to the internal roof is required periodically for

seal, appurtenance and roof condition inspections.

Platforms and Walkways

In existing tanks retrofitted with domes, some problems

related to the tank gagers platform often arise. In these

cases modification must be made to raise or relocate

the platform to clear the dome.

Walkways are rarely used on domes as there is really

no reason to access the top of the dome. The center

vent at the top does not need maintenance in most

cases. However, when many tanks are located near one

another, walkways have been used to provide access

as shown in Figure 900-17.

Construction

Domes can be constructed on operating tanks that are

filled with flammable materials since there is no hot-

work involved. The typical construction sequence be-

gins with the loading of the structural materials and

sheet panels onto the top of the floating roof. The roof

structure is assembled using jackstands with bolted and

other types of fasteners. The entire roof fits within the

shell space. The roof can be raised until the dome is

higher than the top of the tank shell and then lowered

onto its support points. The support points have suffi-

cient radial adjustment to accommodate the typical out-

of-round that exists in tank shells near the top.

Typical construction times will be according to Figure

900-18.

Costs. For rough estimating purposes for aluminum

domes, refer to Figure 900-19.

950 TANK HOLD POINTS CHECKLIST

Figure 900-20 is a tank hold points checklist to be used

when constructing a tank.

990 REFERENCES

1. Morovich, The Use of Aluminum Dome Tank

Roofs, Proceedings of the 2nd International Sym-

posium on Aboveground Storage Tanks, January

14-16, 1992, Houston Texas, Materials Technology

Institute, 1992

2. Barnes, New Tank Roofs Capture Evaporating Va-

pors, Louisiana Contractor, 12/1992

3. Barrett, Geodesic-dome Tank Roof Cuts Water

Contamination, Vapor Losses, Oil and Gas Journal,

7/10/1989

Diameter, ft Time, Weeks

30 - 70 1

70 - 100 2

100 - 120 3

TAM9018.WP

Fig. 900-18 Aluminum Dome Roof Construction

Period

Diameter, ft Installed Cost, $/ft

3

0 - 50 20 - 40

50 - 100 15 - 20

100 - 200 10 - 15

Fig. 900-19 Costs for Aluminum Domes

TAM90019.WP

TAM90017.TIF

Fig. 900-17 Aluminum Dome Roof Walkways

(Courtesy of Conservatek)

Tank Manual 900 Construction

June 1994 900-17

TANK HOLD POINTS CHECKLIST

The items below are inspection hold points for the construction of ____ Tank in the ____________ Tank Field

and are part of the contract. Company Engineer or Company Representative will initial this checklist after each

item has been satisfactorily completed. Contractor will notify Company when these items are ready for inspec-

tion. Company will have the time length indicated to inspect and approve or disapprove each item. Repairs

and/or delays necessary to make each installation satisfactory will be at Contractors expense and will not

constitute delay by Company.

Item Engr. Initial

Company Rep.

Initial

1. Ringwall Installation

(8 Dayshift hours after completion)

2. Soil Compaction & Sand Fill

(8 Dayshift hours after completion)

3. Membrane Installation

(8 Dayshift hours after completion)

4. Concrete Pad Placement

(8 Dayshift hours after completion)

5. Concrete Cure Time/Clean Up

(8 Dayshift hours after completion)

6. Bottom Plate Vacuum Test

(8 Dayshift hours after completion)

7. Annular Ring Diesel Test

(48 Dayshift hours after completion)

8. Shell 1st Course Inserts Installation and X-Ray

(8 Dayshift hours after completion)

9. Shell 2nd Course Installation and X-Ray

(8 Dayshift hours after completion)

10. Shell 3rd Course Installation and X-Ray

(8 Dayshift hours after completion)

11. Shell 4th Course Installation and X-Ray

(8 Dayshift hours after completion)

12. Shell 5th Course Installation and X-Ray

(8 Dayshift hours after completion)

13. Shell 6th Course Installation and X-Ray

(8 Dayshift hours after completion)

14. Shell 7th Course Installation and X-Ray

(8 Dayshift hours after completion)

15. Shell 8th Course Installation and X-Ray

(8 Dayshift hours after completion)

16. Roof Plate Vacuum Test

(8 Dayshift hours after completion)

17. Hydrotest Tank & Install Roof Seal

(8 Dayshift hours after completion)

18. AQMD Roof Seal Inspection

(8 Dayshift hours after completion)

TAM90020.WP

Fig. 900-20 Tank Hold Points Checklist

900 Construction Tank Manual

900-18 June 1994

1000 IN-SERVICE ABOVEGROUND STORAGE TANKS: GUIDELINES

FOR INSPECTION, REPAIR, ALTERATION, AND

RECONSTRUCTION

Abstract

This section covers the inspection, repair, alteration, and maintenance of in-service, aboveground storage tanks

(ASTs) welded and riveted, non-refrigerated, and atmospheric and focuses on the American Petroleum In-

stitutes (API) Standard 653 relating to these activities. A synopsis of this recently released standard is included

as Figure 1000-1 of this chapter.

Contents Page Page

1010 Background 2

1011 Industry Standards

1012 Intent of API 653

1013 Responsibility and Compliance

1014 Implementation: Time and Costs

1015 Other Considerations

1016 Recommended Implementation

1020 Preventing Failures: API 653 6

1030 Assessing Suitability for Service 6

1031 Reasons for Assessing Suitability for

Service

1032 Physical Considerations

1040 Inspection 7

1041 Inspection Philosophy

1042 Three Types of Periodic Inspections

1043 General Requirements for

Post-installation Inspections

1044 Inspection Methods

1045 Typical AST Bottom Inspection

Techniques

1046 Other Inspection Methods and Tools

1047 Leak Detection Methods of Inspection

1050 API 653 Repair and Alteration

Guidelines

24

1051 Repairs of AST Components

1052 Welding

1053 Shell Plates and Penetrations

1054 Bottom Plates and Slumps

1055 Roofs and Foundations

1056 Hot Taps

1057 Hydrostatic Testing of Repaired,

Altered, or Reconstructed ASTs

1058 Dismantling and Reconstruction

1060 The Mechanical Integrity Element

of OSHA 29 CFR 1910.119

34

1070 API Recommended Practice RP 575 35

1080 References 35

1090 Other Resources 35

Tank Manual 1000 Inspection and Testing

March 1993 1000-1

T

O

C

O

N

T

E

N

T

S

1010 BACKGROUND

Recent incidents involving ASTs have caused public

and legislative bodies to view them as environmentally

hazardous equipment. The most notable event occurred

in 1988 in Floreffe, PA, when a sudden and cata-

strophic spill released over one million gallons of fuel

oil into the Monagahela river, a drinking water source

for several municipalities.

Such episodes have contributed to the current attitude

of local, state, and federal agencies toward ASTs: i.e.,

any leak or spill that contaminates subsurface or navi-

gable waters often results in:

Severe financial and legal penalties, and

The potential for new and stricter regulations (cor-

rective, not preventive) that specify secondary con-

tainment or post-incident regulatory requirements.

Recently, API issued several, new, preventive stand-

ards and recommended practices (RPs) for in-service

ASTs.

1011 Industry Standards

Many standards (e.g., API 620 and 650, AWWA D-100,

UL-142), based on industry experiences, assist engineers

in the design or construction of ASTs and assure a rea-

sonably failure-free AST at installation. There were,

however, no industry standards or practices for the in-

spection or maintenance of in-service ASTs until API re-

cently issued:

1. API 653, Tank Inspection, Repair, Alteration, and

Reconstruction. (See synopsis in Figure 1000-1.)

2. API RP 651, Cathodic Protection.

3. API RP 653, Interior Linings.

These documents are intended to reduce AST failures

and their associated environmental problems.

Note: Figure 1000-1 appears on page following.

1012 Intent of API 653

API 653, in conjunction with the several other API

publications (see 1080 References), provides a compre-

hensive AST spill-or-release-protection plan. This

standard is, in fact, an inspection document that out-

lines a program of minimum maintenance require-

ments for the foundations, bottoms, shells, structures,

roofs, appurtenances, and nozzles of in-service ASTs.

While it does not provide AST owners with cookbook

answers to all problems, this standard does offer the

best and most cost-effective current technology to en-

sure that in-service ASTs:

1. Do not leak.

2. Do not fail catastrophically because of brittle frac-

ture or structural breakdown.

1013 Responsibility and Compliance

Responsibility

Owner/Operator. The owner/operator of the AST has

the ultimate responsibility for complying or not com-

plying with the provisions of API 653. This standard

places the burden of determining long-range suitability

of service on the owner/operator and defines the degree

of quality by:

Establishing the qualifications of inspection personnel.

Requiring that findings be documented at the time

of inspections.

The Company. The Company can assign certain tasks

such as repairs or data collection to others, but must

define clearly the limits of responsibility for these tasks

before the work commences.

Compliance

For most facilities, a standard in itself is rarely man-

dated under law, except by implication; i.e., to comply

with local, state, or federal authorities references to in-

dustrial standards or good engineering practice.

OSHAs Process Safety Management Regulation

1910.119 states, for example, that employers must

maintain written on-going integrity procedures, follow

generally accepted good engineering practices, and

document each inspection.

API 653 sets minimum requirements for ASTs and,

therefore, authorities having jurisdiction may impose

this standard because nothing better exists. Such is the

case with EPAs Spill Prevention Control and Coun-

termeasures (SPCC) regulations that require regularly

scheduled, documented inspections of ASTs in facili-

ties near navigable waterways. While EPAs SPCC

program does not mandate API 653, it is prescribed by

default unless the owner/operator is already complying

with all requirements of API 653.

1000 Inspection and Testing Tank Manual

1000-2 March 1993

1014 Implementation: Time and Costs

Implementation Timeframe

API 653 does not specify a deadline for compliance

but does require owner/operators to perform internal

inspections at ten-year intervals (longer ones being an

exception). All in-service ASTs should, therefore, be

scheduled for an initial, comprehensive, internal in-

spection within ten years. (See also Cost of Internal

Inspections later in this section.) Many companies may

complete this work within a three- to five-year period,

depending on the size of their facilities.

A standard does exist; therefore, any delay in compli-

ance translates into an unnecessary risk for the

owner/operator. A major AST failure now in a facility

that has not begun to initiate API 653 would most

probably:

Outrage the public and devastate the owner/opera-

tors image.

Raise jurisdictional inquiries into the owner/opera-

tors reasons for non-compliance with an industry

standard.

Incur environmental penalties and liabilities in civil

and possibly in criminal courts.

Suggestions for Mitigating Costs

Planning can mitigate the cost of implementing API

653, particularly in three broad areas: cost of internal

inspections, assessing suitability for service, estab-

lishing and maintaining recordkeeping systems.

Cost of internal inspections. Attributed to preparing

ASTs for internal inspections and to interrupting their

operations, these costs can reach millions of dollars per

year for a large, integrated oil company. API 653 sug-

gests ways to increase the interval between internal in-

spections to as many as 20 years, thus reducing the

cost dramatically.

Assessing suitability for service. Engineering evalu-

ations of ASTs can lower the costs of attaining fit-for-

service status. For a AST with many violations of the

current standard, the difference in cost is appreciable

between simply correcting everything and correcting

only those items an engineering evaluation deems nec-

essary.

Establishing and maintaining recordkeeping sys-

tems. Establishing a Companywide standard for re-

cordkeeping a standardized system, including

software would be cost-effective, particularly if API

653 were to become a Company policy in the future.

There are other, less obvious items that have an impact

on controlling the overall cost of complying with API

653:

Recouping costs. The costs associated with instituting

API 653 are more than recouped by ensuring that the

owner/operator does not:

Incur post-incident costs of site remediation and

heavy EPA-imposed fines.

Experience costly business interruption.

Expend additional funds to ensure that ASTs al-

ready involved in incidents now comply with the

many new AST regulations.

Note: The standards fitness-for-service program

could, in itself, have prevented many notable

AST catastrophes.

Cost-saving, new designs. Operating costs of ASTs can

be expected to benefit from new AST designs which

should incorporate those factors that will extend the pe-

riod between internal inspections: e.g., liners, corrosion

allowance, cathodic protection, and leak detection.

1015 Other Considerations

Assuming that the decision or policy is made to com-

ply with API 653, there are several issues to consider

before launching the program, including establishing:

A budget for compliance

An inspection team of employees, contractors, or a

combination (see Inspection Agencies later in this

section)

The procedures for

Recordkeeping

Inspections

* Operators monthly (required by API 653)

* Periodic external

* Internal (and the means of safe entry to

ASTs)

A compilation of data on all in-service ASTs: ages,

last inspections, problems, construction data, draw-

ings, etc.

Tank Manual 1000 Inspection and Testing

March 1993 1000-3

API Standard 653 is based upon and extends the principles of API 650.

Section 1 - Summary

API 653 provides minimum requirements for maintaining the integrity of in-service, aboveground storage tanks (ASTs). These

requirements includes inspection, repairs, alterations, relocation, and reconstruction. The owner/operator is responsible for comply-

ing with these standards and for following safe working practices.

Section 2 - Suitability for Service

General: When a change occurs in the original condition of the AST, personnel experienced in tank design must evaluate

the ASTs suitability for service.

Tank Roof Evaluation: When roof plates corrode to an average thickness of less than .09 inch per 100 square inches of

area, they must be repaired or replaced. The principles in API 650, Appendix C offer guidance for evaluating an existing

floating roof but upgrading is not mandatory.

Change of Service: Any change of service involving internal pressure, operating temperatures or venting requirements must

be evaluated according to the principles of API 650.

Tank Shell Evaluation: API 653 describes methods of determining the minimum thickness of corroded areas for evaluation

for suitability for service. Distortions, flaws, cracks, shell welds and shell penetrations must be assessed and evaluated on

an individual basis.

Tank Bottom Evaluation: As leaks in tank bottoms are unacceptable, the causes of any potential failure mechanism (such

as settlement and corrosion) must be considered. If a tank bottom is being replaced, consider installing a leak-detection

system. Lining and cathodic protection of bottoms is covered by API RP 652.

During internal inspections, AST bottoms must be measured and the thickness determined. The minimum thickness of AST

bottoms is 0.1 inch unless the tank is lined in accordance with API RP 652 or has leak detection and containment for which

the minimum thickness is decreased to 0.05 inch.

The minimum thickness of annular plates is usually greater than 0.1 inch; however, thicker values may be required for

seismic reasons. (See API 653, Table 2-2 for minimum thicknesses.)

Section 3 - Brittle Fracture Considerations

This section provides a means of assessing an ASTs susceptibility to brittle fracture. Owner/operators must evaluate any

change of service (such as operation at a lower temperature) to determine if it increases the risk of failure due to brittle

fracture. Industrial experience indicates the risk of brittle fracture is minimal if:

The shell is less than 1/2-inch thick;

The shell metal temperature is 60 degrees F or above;

The shell stresses are less than 7 ksi; or

The AST was hydrostatically tested at the lowest operating temperature.

The decision tree in API 653, Figure 3.1 helps determine susceptibility to brittle fracture.

Section 4 - Inspection

Three inspections are required:

1. Routine in-service inspection: This inspection must be performed monthly and can be performed by anyone. It includes

a visual inspection of the ASTs exterior surface to check for leaks, shell distortions, settlement, corrosion, and any

other deleterious conditions.

2. Formal external inspection: This inspection must be performed at every five years of service or the quarter corrosion-

rate life of the shell, whichever is less. (See checklist in API 653, Appendix C.) An API 653 certified inspector must

do the inspection.

3. Formal internal inspection: The inspection interval is based on corrosion rates. The minimum thickness of the bottom

plate at the next inspection cannot be less than 0.1 inch for ASTs without leak detection or leak containment and 0.05

for ASTs with leak detection and leak containment or ASTs with reinforced linings greater than 0.05 inch thick in

accordance with API RP 652. An API 653 certified inspector must do the inspecting.

For each AST in service, the owner/operator must retain construction records, inspection history, and repair/alteration history

records, and the results of any material tests and analyses.

Inspectors must have the following education:

1. A degree in engineering plus one years experience.

2. A two-year certificate in engineering plus two years experience.

TA1000-1.WP

Fig. 1000-1 Synopsis API Standard 653, Edition 1, January 1991

Tank Inspection, Repair, Alteration, and Reconstruction (1 of 2)

1000 Inspection and Testing Tank Manual

1000-4 March 1993

3. A high school diploma and three years experience.

Section 5 - Materials

All new materials used in repairs, alterations or reconstruction must conform to the current applicable standard. For recon-

structed tanks, the material must be identified.

Section 6 - Design Considerations for Reconstructed Tanks

Reconstructed tanks are not common; therefore, this section is not included in this summary

Section 7 - Tank Repair and Alteration

The basis for repairs and alterations is equivalent to those in API 650. The minimum dimension of shell plate repairs is 12

inches or 12 times the shell thickness, whichever is greater. Shell plates must be welded with complete penetration and

complete fusion. Fillet-welded, lapped patches are not allowed. Details are given for shell penetration repairs/additions and

defective weld repairs.

Information about repairs for AST bottoms includes the critical zone. This area is defined as being within 12 inches of the

shell or the inside edge of the annular plate where no welding or patching is allowed except for repairing widely scattered

pits or cracks. In the critical zone, defective areas must be replaced with new plate.

When replacing the ASTs bottom, a new bottom may be installed, separated from the old bottom with a non-corrosive

material cushion. Consider providing a means of preventing galvanic corrosion. Shell penetrations may have to be raised.

The old bottom may be removed.

Rules for repairing fixed roofs, self-supported roofs, and floating roofs are given.

Hot taps must be carried out in accordance with API 2201.

Section 8 - Dismantling and Reconstruction

This section provides procedures for dismantling and reconstructing existing welded ASTs that are to be relocated from their

original site.

Section 9 - Welding

Welding procedures, welders, and operators are required or must be qualified in accordance with Section 9 of the ASME

Code.

The weldability of the existing AST steel must be verified.

Welders identification mark must be hand- or machine stamped next to completed welds at three-foot intervals.

Section 10 - Examination and Testing

The methods of NDE for visual, magnetic particle, liquid penetrant, ultrasonic, and radiography must follow API 650 and

the supplemental requirements of API 653. Any welding on the shell-to-bottom joint must be inspected along its entire length

by the vacuum box method. Rules for inspection of other repairs are given.

A full 24-hour hydrostatic test must be performed on reconstructed ASTs or any AST that has undergone major repairs or

alterations, including:

Shell penetrations larger than 12 inches

New bottoms

Repairs to the critical zone near the shell to bottom joint

Shell jacking

API 653, Section 10.3.2 gives cases where hydrostatic testing may be exempted.

AST settlement shall be surveyed before and after a hydrostatic test.

Section 11 - Marking and Recordkeeping

Reconstructed tanks must be identified by a nameplate with the information given in this section.

When an AST is evaluated, repaired, altered, or reconstructed in accordance with API 653, the owner/operator must retain

the following information as part of the records: calculations, construction and repair drawings, examinations, and test data.

API 653: Appendices

Appendix A Background on Past Editions of API Welded Storage Tank Standards

Appendix B Evaluation of Tank Bottom Settlement

Appendix C Checklists for Tank Inspection

Appendix D Reserved for Future Material

Appendix E Technical Inquiries

TA1000-1.WP

Fig. 1000-1 Synopsis API Standard 653, Edition 1, January 1991

Tank Inspection, Repair, Alteration, and Reconstruction (2 of 2)

Tank Manual 1000 Inspection and Testing

March 1993 1000-5

Inspection Agencies

As API 653 was issued recently, there are few people

experienced in inspecting in-service ASTs. The

owner/operator may choose to contract this work or to

handle it within the Company. The considerations are

cost (employee vs. contractor) and availability of

trained and experienced inspectors.

If the owner/operator chooses to select an in-house in-

spector, that individual must have not only experience

in inspecting in-service ASTs but also the necessary

freedom and authority to carry out the intended pur-

pose of API 653.

1016 Recommended Implementation

We recommend implementing a program to ensure the

integrity of ASTs by complying with API 653 for the

reasons stated above and also because most Opcos:

Take a highly responsible attitude towards environ-

mental protection.

Will want to comply with Company Policy 530,

Operating Facilities Safety, Fire, Health, and En-

vironment.

1020 PREVENTING FAILURES:

API 653

In API 653, there are three basic mechanisms to pre-

vent potential AST failures:

1. Assessing suitability of service

2. Inspection

3. Repair and alteration guidelines

1030 ASSESSING SUITABILITY FOR

SERVICE

API 653 emphasizes that organizations that maintain

or have access to engineering and inspection personnel