Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Uns S31803

Caricato da

Amjath PallasDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Uns S31803

Caricato da

Amjath PallasCopyright:

Formati disponibili

MATERIALSPECIFICATION

H521RevCA182F51(UNSS31803)

Rev C B A Date 02.01.08 14.03.05 01.02.05 ECN 249 119 116 Issue Revised/Reissued Revised/Reissued Revised/Reissued Preparedby T.S. N.R. A.K. Check/Approved J.S. T.K. N.R.

ProductForm Standard Grade AcceptableClass ForgedBar ASTMA182 F51(UNSS31803) Blank Ring ClosedDieForgings Scope Thisspecificationoutlinesthemodificationsandadditionalrequirementstothe relevantASTMSpecificationsforthesupplyofrawmaterialtomanufactureVector Internationalproducts. Other ASTMA370/A388/E562/G48(LatestIssues) Applicable Specifications SteelMaking ManufacturetobeinaccordancewithASTMA182(LatestIssue). HeatTreatment SolutionAnneal(1050Cminfor1hrmin)inaccordancewithASTMA182(Latest Issue).Furnacesshallbecalibratedwithcertificatesbeingavailableforreview uponrequest. Chemical Min Max Min Max Min Max Analysis% 0.02 0.03 0.15 0.20 C S N (Heat) 1.00 4.50 6.50 Si NiCr Mn Mo 21.00 23.00 PREN 35 2.00 P 0.03 2.50 3.50

Note:PREN=Cr+3.3Mo+16N

Mechanical Properties

Tensile(Rm): Yield(Rp0.2): Elongation(A%): R.ofA(Z%): Hardness:

Min 98600psi(680MPa) 65250psi(450MPa) 25 45

Max 28HRC

Note:MechanicalTestingtoASTMA370afterfinalheattreatment.MechanicalTestingrequired foreachheatandheattreatmentlot.

Impact Properties

CharpyV.70J(Ave),65J(Min)at50C. LateralExpansiontobe0.38mmmin.

MATERIALSPECIFICATION

H521RevCA182F51(UNSS31803)

Corrosion Testing Micrographic Examination CorrosiontesttobeinaccordancewithASTMG48MethodA(LatestIssue)for24 hoursatatemperatureofNOTlessthan30C.TheacceptancecriteriaisNO pitting. AMicrographicexaminationshallbecarriedoutatX400magnification.The structureshallconsistof40%60%ferritemeasuredinaccordancewithASTM E562(LatestIssue)andshallbefreefromgrainboundarycarbides,sigma,chiand lavesphases. TestCoupons(testbarsmaybeused)shallberepresentativeofproduction forgingsandshallbeheattreatedwiththeforgingsinaccordancewithASTMA182 (LatestIssue).Testcouponsshallalsoreceiveessentiallythesameforging reductionratioastheproductionforgings.Testcouponsmustbetakenfrom productionforgingswhencloseddieforgingsareused. 100%UTonOpenDieForgingsandBar(afterfinalheattreatment)inaccordance withASTMA388,tobeundertakenbysupplier.AcceptancecriteriatoASMEVIII. ForgingstobeofsufficientqualityforLPIcheck.LPIonfinishedmachinedpartsto beundertakenbyVectorInternationalLtd. Forgingstobesuppliedfreeofdefects(Slaginclusions,scale,laps,cracks). Weldrepairisnotacceptable. ForgingstobemarkedwithHeatNumber,MaterialGrade,andVector Specification. CertificationtobeinaccordancewithEN102043.1:ChemicalAnalysis,Mechanical Analysis,HeatTreatmentReport(soaktimesandcoolingmedium),MillCertificate (WetStamped). 1. RefertoPOforsupplementaldetails. 2. Anydeviationfromthisspecificationmustbeformallyraisedasaconcession requestpriortodelivery.Certificationmustincludeconcessiondocumentation.

TestSampling

N.D.E SurfaceFinish andQuality Repairof Defects Marking Certification

Notes

Potrebbero piacerti anche

- Astm A106 Ts EnglDocumento4 pagineAstm A106 Ts EnglxaviereduardoNessuna valutazione finora

- b2020-Tdc-Fas-004 Fasteners r3Documento2 pagineb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranNessuna valutazione finora

- Oil Gas Construction Factory L.L.CDocumento2 pagineOil Gas Construction Factory L.L.CRenny DevassyNessuna valutazione finora

- C43Documento1 paginaC43rudramansingh123Nessuna valutazione finora

- Flange 10 & 12 InchDocumento2 pagineFlange 10 & 12 InchreniNessuna valutazione finora

- Material Information Sheet For Plates: Erndtebrücker EisenwerkDocumento2 pagineMaterial Information Sheet For Plates: Erndtebrücker EisenwerkAhmad KamilNessuna valutazione finora

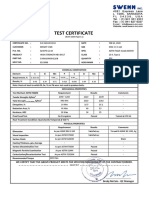

- Test Certificate: (BS EN 10204 Type 3.1)Documento1 paginaTest Certificate: (BS EN 10204 Type 3.1)Sachin NambiarNessuna valutazione finora

- TDC 004 CS Fittings r0Documento1 paginaTDC 004 CS Fittings r0samkarthik47Nessuna valutazione finora

- TDC 003 - SS Pipes - r0Documento1 paginaTDC 003 - SS Pipes - r0samkarthik47Nessuna valutazione finora

- TDC For Pipes - Sa 106 GR.BDocumento2 pagineTDC For Pipes - Sa 106 GR.BRenny DevassyNessuna valutazione finora

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Documento15 pagineFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNessuna valutazione finora

- Welding Procedure Welding Procedure Specification SpecificationDocumento2 pagineWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNessuna valutazione finora

- ST 35.8 (Germany / DIN) : Material PropertiesDocumento3 pagineST 35.8 (Germany / DIN) : Material Propertiesmohammad zareiNessuna valutazione finora

- Tube FittingsDocumento12 pagineTube FittingsspiritveluNessuna valutazione finora

- 2 PN40 (WCB)Documento2 pagine2 PN40 (WCB)siddhesh_guessNessuna valutazione finora

- QAP Seamless PipeDocumento2 pagineQAP Seamless PipeashokkahirwarNessuna valutazione finora

- API 5L GR.B SteelDocumento2 pagineAPI 5L GR.B SteelYosua Rielys PNessuna valutazione finora

- Fepa P Paper Micron μm Fepa F Grain Micron μm JIS R6001 Japan 1973 Micron μmDocumento4 pagineFepa P Paper Micron μm Fepa F Grain Micron μm JIS R6001 Japan 1973 Micron μmapi-19654224Nessuna valutazione finora

- 4 2500 (F347H)Documento2 pagine4 2500 (F347H)siddhesh_guessNessuna valutazione finora

- 0901b80380959cc7 PDFDocumento2 pagine0901b80380959cc7 PDFBonaventure NzeyimanaNessuna valutazione finora

- 3604 1Documento17 pagine3604 1Tiffany WilsonNessuna valutazione finora

- Repair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6Documento6 pagineRepair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6mohd as shahiddin jafriNessuna valutazione finora

- MTR's PO# 2113-06-12 PDFDocumento14 pagineMTR's PO# 2113-06-12 PDFAgustinaDeWinneNessuna valutazione finora

- Comparison of Flange Face Finish As Per B16-5Documento1 paginaComparison of Flange Face Finish As Per B16-5Vivi OktaviantiNessuna valutazione finora

- 163 Dimensions of Large Male Female and Small Tongue and Groove Flange Facing Ansi b165 StandardDocumento6 pagine163 Dimensions of Large Male Female and Small Tongue and Groove Flange Facing Ansi b165 StandardQiuniuNessuna valutazione finora

- Anodes in Cooling Water Exchangers PDFDocumento12 pagineAnodes in Cooling Water Exchangers PDFcbrittaivNessuna valutazione finora

- Mill Test Certificate: Customer Name/Address StampDocumento1 paginaMill Test Certificate: Customer Name/Address StampD S Sagar TripuramalluNessuna valutazione finora

- Mds-Sparkler Filter F-304Documento1 paginaMds-Sparkler Filter F-304Vipul Gandhi50% (2)

- Mi3530 B1820401Documento1 paginaMi3530 B1820401abinayaNessuna valutazione finora

- Material Product Data SheetDocumento4 pagineMaterial Product Data SheethungNessuna valutazione finora

- TDC-10B Heat Treatment For C12A Steel CastingsDocumento2 pagineTDC-10B Heat Treatment For C12A Steel CastingsGohilakrishnan ThiagarajanNessuna valutazione finora

- TDC For Flanges SA 105NDocumento2 pagineTDC For Flanges SA 105NRenny DevassyNessuna valutazione finora

- Astm A179 PDFDocumento1 paginaAstm A179 PDFgaminNessuna valutazione finora

- TDC 1150Documento3 pagineTDC 1150shazanNessuna valutazione finora

- Purchase Spec. For Tubes (Sa789 S31803)Documento6 paginePurchase Spec. For Tubes (Sa789 S31803)Daison PaulNessuna valutazione finora

- Plate Material SpecificationDocumento24 paginePlate Material SpecificationprasongNessuna valutazione finora

- Summary Paint Mix RatioDocumento1 paginaSummary Paint Mix RatioVijay Kumar Konathala100% (1)

- DCP Nde DV 297 HLT 01Documento7 pagineDCP Nde DV 297 HLT 01Chandrasekhar mishraNessuna valutazione finora

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocumento3 pagineTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanNessuna valutazione finora

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Documento4 pagineAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Dimensions of Butt Welding Equal Tee en 10253 2Documento1 paginaDimensions of Butt Welding Equal Tee en 10253 2aliNessuna valutazione finora

- MTC Sample Dia 36 Inch Heat 639914 4130Documento2 pagineMTC Sample Dia 36 Inch Heat 639914 4130emadabdelsattarNessuna valutazione finora

- Hardness Pro Form1Documento2 pagineHardness Pro Form1gst ajah100% (1)

- TubacexDocumento1 paginaTubacexMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNessuna valutazione finora

- Material Test ReportDocumento5 pagineMaterial Test ReportJuan Carlos Sua SuaNessuna valutazione finora

- T.C.L. Co. - Test & Control LaboratoriesDocumento2 pagineT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταNessuna valutazione finora

- QAP CondenserDocumento3 pagineQAP CondenserisaacNessuna valutazione finora

- Jyoti Engineering Works: Chemical AnalysisDocumento8 pagineJyoti Engineering Works: Chemical AnalysisKristin CrawfordNessuna valutazione finora

- Buried Pipes and Fittings Painting SpecDocumento5 pagineBuried Pipes and Fittings Painting SpecRohan Sharma50% (2)

- Ewf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDocumento1 paginaEwf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDries VandezandeNessuna valutazione finora

- Mill TC en 19 6.00MMDocumento1 paginaMill TC en 19 6.00MMKamal BhandariNessuna valutazione finora

- Wps Sp14 Reva PDFDocumento9 pagineWps Sp14 Reva PDFravi00098Nessuna valutazione finora

- Mill'S Test Certificate ACC. TO EN 10204 / 3.1Documento2 pagineMill'S Test Certificate ACC. TO EN 10204 / 3.1Durulsan MakinaNessuna valutazione finora

- 03CA2SAE: Specification Piping Material ClassDocumento7 pagine03CA2SAE: Specification Piping Material Classabhishek186186Nessuna valutazione finora

- S275JR PDFDocumento1 paginaS275JR PDFEmrahCayboylu100% (1)

- Severin FinalDocumento26 pagineSeverin Finalcristasocum_trans1758Nessuna valutazione finora

- 1000 Wog Ball ValveDocumento1 pagina1000 Wog Ball ValveSandi AslanNessuna valutazione finora

- Astm A 312Documento2 pagineAstm A 312Raj KumarNessuna valutazione finora

- C402 Rev A - ASTM A182 F304: All Mechanical Tests To Be Carried Out To ASTM A370 After Final Heat TreatmentDocumento2 pagineC402 Rev A - ASTM A182 F304: All Mechanical Tests To Be Carried Out To ASTM A370 After Final Heat TreatmentRajkumarNessuna valutazione finora

- C216 Rev F - AISI4140Documento2 pagineC216 Rev F - AISI4140Rama KrishnaNessuna valutazione finora

- Medicinal PlantsDocumento5 pagineMedicinal PlantsSnehasis PatraNessuna valutazione finora

- Dresser 3 Way ValveDocumento24 pagineDresser 3 Way ValveAmjath Pallas100% (1)

- Steel Casting Handbook Supplement 8 - High Alloy Data Sheets - Corrosion SeriesDocumento93 pagineSteel Casting Handbook Supplement 8 - High Alloy Data Sheets - Corrosion SeriesjosemiguelzuNessuna valutazione finora

- Penstock Butterfly Valves StandardDocumento12 paginePenstock Butterfly Valves StandardAmjath PallasNessuna valutazione finora

- 1Documento6 pagine1Amjath PallasNessuna valutazione finora

- Key Shortcuts WinDocumento26 pagineKey Shortcuts WinrockskartikNessuna valutazione finora

- Intro To RMAN-10g-okDocumento41 pagineIntro To RMAN-10g-okAnbao ChengNessuna valutazione finora

- ApolloBVM PDFDocumento41 pagineApolloBVM PDFShiva KumarNessuna valutazione finora

- (Revised) Dale Carnegie-How To Win Friends and Influence People-Simon and Schuster (1981)Documento12 pagine(Revised) Dale Carnegie-How To Win Friends and Influence People-Simon and Schuster (1981)TomasUreñaNessuna valutazione finora

- USDP Shehzore02Documento39 pagineUSDP Shehzore02Feroz GullNessuna valutazione finora

- Academic Stress ScaleDocumento3 pagineAcademic Stress Scaleteena jobNessuna valutazione finora

- ABB - Composite Station Post InsulatorsDocumento6 pagineABB - Composite Station Post InsulatorsDominic SantiagoNessuna valutazione finora

- Chapter7 Ex PDFDocumento5 pagineChapter7 Ex PDFSathish Kumar100% (1)

- Cop4600 Exam1 sp13Documento2 pagineCop4600 Exam1 sp13chavNessuna valutazione finora

- Resume MullinsDocumento4 pagineResume Mullinsapi-236735643Nessuna valutazione finora

- Mae 1202: Aerospace Practicum: Lecture 4: Introduction To Basic Aerodynamics 3Documento38 pagineMae 1202: Aerospace Practicum: Lecture 4: Introduction To Basic Aerodynamics 3زهديابوانسNessuna valutazione finora

- Equinoxes and Solstices: UttarayanamDocumento2 pagineEquinoxes and Solstices: UttarayanamRahul SharmaNessuna valutazione finora

- Purchasing Process Models Inspiration For Teac 2019 Journal of Purchasing ADocumento11 paginePurchasing Process Models Inspiration For Teac 2019 Journal of Purchasing ASunita ChayalNessuna valutazione finora

- Avenger 220 Cruise Street BS IVDocumento79 pagineAvenger 220 Cruise Street BS IVShubham AatopartsNessuna valutazione finora

- Pakistan Wapda - Power Wing: Standard Operating ProceduresDocumento8 paginePakistan Wapda - Power Wing: Standard Operating Procedureszahra batoolNessuna valutazione finora

- Centennial Tower Promotion 1Documento10 pagineCentennial Tower Promotion 1madeNessuna valutazione finora

- Sharp Service Manual Models Lc-40sh340k and Lc-40sh340e With Chassis 17mb60Documento106 pagineSharp Service Manual Models Lc-40sh340k and Lc-40sh340e With Chassis 17mb60murtibing100% (1)

- CertificateofAnalysis 2019 11 9 879766Documento2 pagineCertificateofAnalysis 2019 11 9 879766Trọng TínNessuna valutazione finora

- ch1 ProbsDocumento8 paginech1 ProbsEkrem GüldesteNessuna valutazione finora

- Procedure Issuing EtaDocumento5 pagineProcedure Issuing EtaCarlos FrançaNessuna valutazione finora

- Tavistock PrimerDocumento13 pagineTavistock PrimerSharon Schaff100% (1)

- Khairro SanfordDocumento2 pagineKhairro SanfordJezreel SabadoNessuna valutazione finora

- Wind Load On StructuesDocumento14 pagineWind Load On StructuesNasri Ahmed mohammedNessuna valutazione finora

- FZ1 Parts CatalogDocumento78 pagineFZ1 Parts CatalogAntonis Fotis100% (1)

- Symposium's Platonic LoveDocumento10 pagineSymposium's Platonic LovezkottNessuna valutazione finora

- Climate Transition Finance Handbook Related Questions: 9 December 2020Documento4 pagineClimate Transition Finance Handbook Related Questions: 9 December 2020glenlcyNessuna valutazione finora

- Hw1 2 SolutionsDocumento7 pagineHw1 2 SolutionsFrancisco AlvesNessuna valutazione finora

- Product Leaflet Seawater ElectrochlorinationDocumento4 pagineProduct Leaflet Seawater Electrochlorinationgkdora574Nessuna valutazione finora

- Orient Technologies Profile PresentationDocumento27 pagineOrient Technologies Profile PresentationNisarg ShahNessuna valutazione finora

- Amiel Houser - LévinasDocumento8 pagineAmiel Houser - Lévinaschristyh3Nessuna valutazione finora