Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Structure 201002

Caricato da

Muhammed Abdel-AzizDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Structure 201002

Caricato da

Muhammed Abdel-AzizCopyright:

Formati disponibili

A

J

o

i

n

t

P

u

b

l

i

c

a

t

i

o

n

o

f

N

C

S

E

A

|

C

A

S

E

|

S

E

I

S

T

R

U

C

T

U

R

E

February 2010

Steel

NCSEA Winter Institute

Coronado, California

March 12 & 13

Feb10 cover saddle stitch.indd 1 1/19/2010 2:46:09 PM

Powers Fasteners, Inc.

2 Powers Lane

Brewster, NY 10509

www.powers.com

P: (914) 235-6300

F: (914) 576-6483

Keep on top of the latest building code changes now

requiring code listed and compliant anchors in all states.

Powers has the products, the tools and the information you

need to help you specify compliant anchors.

Powers currently has the most code compliant anchors on the market*,

satisfying a range of needs including mechanical and adhesive anchors.

Our FREE PDA software is an anchor design interface

that puts technical data into a real-time environment

to help you visualize, consider

and specify anchors with our tabbed Design

feature, pull-down menu options, interactive

3-D graphics and anchor information bar.

Understanding the newcode is vital. Powers

makes information about compliancy a

priority, offering informational pieces,

and a hotline to connect you one-to-one with an expert who can help

answer your questions.

Get Compliant with Powers.

* AS OF DECEMBER 2009, 46 STATES INTHE USAHAVEADOPTEDEITHERTHE 2003 OR 2006

INTERNATIONAL BUILDINGCODE.

Powers can help you

make the change efficiently.

Blank.indd 1 12/11/2009 4:45:36 PM

STRUCTURE magazine February 2010

C O N T E N T S

Publication of any article, image, or advertisement in STRUCTURE

magazine does not constitute endorsement

by NCSEA, CASE, SEI, C

3

Ink, or the Editorial Board. Authors, contributors, and advertisers retain sole

responsibility for the content of their submissions.

22

20

6

The Richmond Oval is a

multipurpose sports and

recreation facility that

will serve as the Long

Track Speed Skating

venue for the 2010

Winter Olympics. This 6-acre roof structure features

composite wood-steel arches and is featured in this

months Structural Sustainability article found on

page 16. Courtesy of FII.

A

Jo

in

t P

u

b

lica

tio

n

o

f N

C

S

E

A

| C

A

S

E

| S

E

I

S

T

R

U

C

T

U

R

E

February 2010

Steel

NCSEA Winter Institute

Coronado, California

March 12 & 13

COLUMNS

FEATURES

DEPARTMENTS

IN EVERY ISSUE

ON THE COVER

3

20 Cold-Formed Steel Faade Framing

By Anthony D. Coviello, P.E., S.E.

It is important that structural engineers have a good understanding of the limitations

of Cold-formed Steel (CFS), as well as its possibilities. This article outlines some

common CFS faade framing issues and how the Engineer of Record can resolve

them with early consideration.

22 A Gem in the Mountains

By Carol A. Stevens, P.E., SECB and Phillip A. Warnock, AIA, NCARB

The Upshur County Courthouse, built in 1899, is constructed of brick with a

rock face sandstone foundation and monumental sandstone columns supporting

the portico. The dome is supported by a brick tower that draws ones eye to the

top of the structure, where decorative Corinthian cast iron columns adorn the

faade. Time and weather had taken a toll on this gem, which has suffered the

consequences of good intentions.

5 Editorial

Understanding National Standards

Provisions for Seismic Design

By James Malley, S.E.

6 Structural Design

Structural Design of Steel Pipe

Support Structures

By Kasi V. Bendapudi, P.E., S.E.

10 Construction Issues

Planning to Minimize Damage to

Buildings Adjacent to Construction

Sites in Urban Environments

By Milan Vatovec, Ph.D., P.E., Paul

Kelley, P.E., Michael Brainerd, P.E.,

and Charles Russo, P.E.

14 Structural Performance

A Solution to Seismic

Bracing Restrictions

By John W. Lawson, S.E.

16 Structural Sustainability

Can Using More Wood Reduce Your

Environmental Footprint?

By Roxane Ward

41 Structural Forum

The Failure of the Five Es

By Barry Arnold, P.E., S.E., SECB

24 InSights

Soil/Cement Slurry Strengthens

Weak Soils

By Jonathan Bussiere, E.I.T.

27 Quality Assurance Corner

Validating the Results of Structural

Engineering Software

By Clifford Schwinger, P.E., SECB

and Eric J. Heller, E.I.T.

33 Spotlight

Upholding Tradition

By Brent Bonham, P.E., S.E. and

Jeffry S. Adams, P.E.

4 Advertiser Index

30 Resource Guide Bridge

34 NCSEA News

36 SEI Structural Columns

38 CASE in Point

TOC Feb10.indd 1 1/21/2010 8:55:09 AM

Visit STRUCTURE magazine on-line at

www.structuremag.org

Visit STRUCTURE magazine on-line at

www.structuremag.org

Visit STRUCTURE magazine online at

www.STRUCTUREmag.org

STRUCTURE

(Volume 17, Number 2). ISSN 1536-4283.

Publications Agreement No. 40675118. Owned by the

National Council of Structural Engineers Associations and

published in cooperation with CASE and SEI monthly by C

3

Ink. The publication is distributed free of charge to members

of NCSEA, CASE and SEI; the non-member subscription rate is

$65/yr domestic; $35/yr student; $125/yr foreign (including

Canada). For change of address or duplicate copies, contact

your member organization(s). Any opinions expressed in

STRUCTURE magazine are those of the author(s) and do not

necessarily reect the views of NCSEA, CASE, SEI, C

3

Ink, or the

STRUCTURE Editorial Board.

STRUCTURE

is a registered trademark of

National Council of Structural Engineers Associations (NCSEA).

Published By:

C

3

Ink

A Division of Copper Creek Companies, Inc.

148 Vine St., Reedsburg WI 53959

P-608-524-1397 F-608-524-4432

publisher@STRUCTUREmag.org

C

3

Ink

ADVERTISING ACCOUNT MANAGER

Interactive Sales Associates

Chuck Minor Dick Railton

Eastern Sales Western Sales

847-854-1666 951-587-2982

sales@STRUCTUREmag.org

EDITORIAL STAFF

Executive Editor Jeanne Vogelzang, JD, CAE

execdir@ncsea.com

Editor Christine M. Sloat, P.E.

publisher@STRUCTUREmag.org

Associate Editor Nikki Alger

publisher@STRUCTUREmag.org

Graphic Designer Rob Fullmer

graphics@STRUCTUREmag.org

Web Developer William Radig

webmaster@STRUCTUREmag.org

SUPPORTING ORGANIZATIONS

National Council of Structural

Engineers Associations

Jeanne M. Vogelzang, JD, CAE

Executive Director

312-649-4600

execdir@ncsea.com

Council of American Structural Engineers

David Bixby

Director, Coalitions

202-347-7474

case@STRUCTUREmag.org

Structural Engineering Institute

John E. Durrant, P.E.

Manager

ASCE Engineering Programs

703-295-6360

sei@STRUCTUREmag.org

STRUCTURE magazine February 2010

STRUCTURAL

ENGINEERING

INSTITUTE

A

D

V

E

R

T

I

S

E

M

E

N

T

F

o

r

A

d

v

e

r

t

i

s

e

r

I

n

f

o

r

m

a

t

i

o

n

,

v

i

s

i

t

w

w

w

.

S

T

R

U

C

T

U

R

E

m

a

g

.

o

r

g

4

ADVERTISER PAGE #

American Galvanizers Association Page 30

Computers & Structures, Inc. Page 44

CTS Cement Manufacturing Corp. Page 13

Design Data Page 40

ESAB Welding and Cutting Products Page 19

Fyfe Co. LLC Page 7

Geopier Foundation Company, Inc. Page 29

Integrated Engineering Software, Inc. Page 42

KPFF Consulting Engineers Page 4

MidaSoft, Inc. Page 31

National Council of Examiners for Engineering and Surveying (NCEES) Page 17

Powers Fasteners, Inc. Page 2

QuakeWrap, Inc. Page 28

RISA Technologies Page 43

SidePlate Systems, Inc. Page 25

Simpson Strong-Tie Page 9

Steel Deck Institute Page 11

StrucSoft Solutions, Ltd. Page 32

Struware, Inc. Page 27

Valmont Tubing Page 15

Wheeling Corrugating Page 26

Advertiser Index free information from advertisers

C-Index-Ed-InFoc-Feb10.indd 1 1/19/2010 2:47:02 PM

STRUCTURE magazine February 2010

Editorial

5

Understanding National Standards

Provisions for Seismic Design

By James Malley, S.E.

Vice President, NCSEA

As a member of the committee that writes and updates the AISC

seismic design standard for structural steel in AISC document 341,

I am able to participate in the discussions and dialogues that are

held whenever a new provision is proposed, or an existing provision

is modied. This is a unique opportunity to understand both of

the fundamental philosophies for, and the detailed reasons behind,

the AISC 341 provisions. I know that every meeting held by our

committee will be a great learning experience for me, as I try to take

in all of the expertise that is shared by my fellow committee members.

Unfortunately, most practicing engineers do not have this opportunity

and therefore have to rely on other means to complete their project

designs, such as their own interpretation of the provisions, review of

the accompanying commentary, and discussion with colleagues. The

seemingly never-ending series of changes and additional complexity,

built into every edition, makes proper application of our seismic design

standards one of the signicant challenges of our profession.

If you have ever felt that this challenge was frustrating, and maybe

even a bit overwhelming, then attending the 2010 NCSEA Winter

Institute on March 12

th

and 13

th

in San Diego may be just the ticket for

you. Titled Seismic Design: Explaining the Y Factor from One Generation

to the Next, this seminar will focus on presenting the fundamental basis

for, and reasons behind, our national standards provisions for seismic

design. This Winter Institute will include seven lectures given by leading

seismic researchers and practicing engineers on such topics as the basic

seismic design provisions, requirements for the four primary structural

materials, nonstructural component design, soil-foundation-structure

interaction (SFSI), and the next generation of performance-based

design criteria. The presenters will describe recent changes and will

focus on areas of the code that have been the more frustrating or less

understood. Their emphasis will be on how to systematically implement

good fundamental seismic design concepts, to result in buildings and

structures that will meet our seismic design objectives.

NCSEA Winter Institute Presenters:

Professor Chia-Ming Uang, UCSD

ASCE 7 and Steel Design Concepts

Professor Benson Shing, UCSD

Masonry Design Methods and Issues

Professor Jose Restrepo, UCSD

Concrete Performance Factors and Design

Mr. Phil Line, URS Corporation

Wood Design Provisions, Past and Present

Professor Tara Hutchinson, UCSD

Nonstructural Components and Systems

Dr. Farzad Naeim, John A. Martin & Associates

Modeling SFSI, Easy, Difcult, or Impossible?

Mr. Ronald Hamburger, SGH

Next-Generation Performance-Based Design

In addition to the lectures, there will be a Friday afternoon tour of

the world-renowned structural testing laboratory and shake table at the

University of California at San Diego. These facilities include a strong

wall for full scale component tests, a lab specically designed for testing

base isolators, and the outdoor shaking table that can test full scale

Chair

Jon A. Schmidt, P.E., SECB

Burns & McDonnell

Kansas City, MO

chair@structuremag.org

Executive Editor

Jeanne M. Vogelzang, JD, CAE

NCSEA

Chicago, IL

execdir@ncsea.com

Craig E. Barnes, P.E., SECB

CBI Consulting, Inc.

Boston, MA

Richard Hess, S.E., SECB

Hess Engineering Inc.

Los Alamitos, CA

Mark W. Holmberg, P.E.

Heath & Lineback Engineers, Inc.

Marietta, GA

Editorial Board

Brian J. Leshko, P.E.

HDR Engineering, Inc.

Pittsburgh, PA

John A. Mercer, P.E.

Mercer Engineering, PC

Minot, ND

Brian W. Miller

AISC

Davis, CA

Mike C. Mota, P.E.

CRSI

Williamstown, NJ

Evans Mountzouris, P.E.

The DiSalvo Ericson Group

Ridgeeld, CT

Matthew Salveson, Ph.D., P.E.

Dokken Engineering

Folsom, CA

Greg Schindler, P.E., S.E.

KPFF Consulting Engineers

Seattle, WA

Stephen P. Schneider, Ph.D., P.E., S.E.

Kramer Gehlen & Associates, Inc.

Vancouver, WA

John Buddy Showalter, P.E.

AF & PA/American Wood Council

Washington, DC

buildings. We are currently planning a tour that includes observing

multiple tests in action, as well as a shaking table test.

If this isnt enticing enough, I havent even mentioned the venue, the

Marriott Coronado Island Resort and Spa, on world famous Coronado

Island across the bay from San Diego. The resort boasts a full spa,

tennis courts and three pools on site, and easy access to the beach and

downtown San Diego. Combining the hotel with the expected warm,

but not hot, weather year round in San Diego should make for an

enjoyable stay during the event.

Check out pages 34 and 35 of this issue and the NCSEA website

(www.NCSEA.com) for more details on the Winter Institute schedule,

to register, and to reserve your room at the Marriott Coronado Island

Resort. Then plan to join us in San Diego this March 12

th

and 13

th

. I

am sure that you will learn a lot, catch up with colleagues, meet new

engineers, and maybe even work on your tan before heading home!

C-Index-Ed-InFoc-Feb10.indd 2 1/21/2010 8:56:00 AM

d

e

s

i

g

n

i

s

s

u

e

s

f

o

r

s

t

r

u

c

t

u

r

a

l

e

n

g

i

n

e

e

r

s

S

T

R

U

C

T

U

R

A

L

D

E

S

I

G

N

STRUCTURE magazine February 2010

6

Structural Design of Steel Pipe Support Structures

By Kasi V. Bendapudi, P.E., S.E.

It is common to overemphasize the struc-

tural design of pipe support structures,

rather than focus on detailing for stability

or economics and practical aspects of the

steel structure and the foundations. This

is sometimes referred to as over-designing

and under-detailing. Sometimes the

hanger-type pipe supports or the trapezes

supported by another structure, such as

the main building frame, are referred to

as pipe support structures. For the pur-

poses of this discussion, the terms pipe

racks, pipe supports, and pipe support

structures are interchangeable. Essential

elements for limit states of pipe support

systems are often ignored, since these

systems are comprised of secondary ele-

ments and rarely impact the structural

integrity of any industrial facility.

Structural failures of pipe supports are

neither documented nor disseminated to

the structural community. The structural

design of pipe racks varies widely depend-

ing upon the plant operations and the

associated plant standards. However, pipe

rack failures could cause serviceability

problems for plant operations. Failures

of pipe support systems could potentially

impact the health, welfare, and safety of

plant personnel due to pipe breakage or

leaks. The following discussion includes

a review of the considerations involved

in the design, detailing, and structural

stability of pipe racks. Optimal solutions

are still governed by the judgment of the

design engineer.

Overview of piping design

In general, pipes are designed to move

freely on their supports in the longitudinal

direction (along the axis of the pipe),

except at the anchor points. Pipe anchor-

ages are required to account for expansion

and contraction of pipes due to variations

in the ambient temperatures. The expan-

sion/contraction of pipes resulting from

changes in temperature and pressure of

the contents is taken into consideration by

the piping engineers during piping design.

Anchor points will be required to maintain

the pipes in a state of equilibrium. Expan-

sion loops are also used to limit pipe stresses

and the associated failures in the piping

systems. The movements of the pipes

occur due to expansion, contraction, and

transient loads. System shutdowns and re-

starts could also cause movements in the

pipes. Transverse guides limit the lateral

displacements of the pipes.

Temperature effects

Ambient temperature differentials induce

forces in both pipes and pipe supports.

These forces are generally induced over a

period of time if they are due to variations

in the ambient temperature. However, the

forces occur more rapidly if the thermal

variations are affected by the contents in

the pipes. Particularly during the time

of plant startups and shutdowns, these

forces can occur rapidly. A pipe rack or

a pipe support is not typically subjected

to noticeable punishment under seasonal

temperature differentials, because it re-

sponds like an accordion. Thermal

variations due to the contents of the pipe

result in anchor forces that are more severe

Structural steel pipe supports are extensively utilized in

industrial and manufacturing facilities. Lack of uniform

industry standards for this topic leads to each organization

adopting its own engineering standards, at times, without

a clear understanding of the underlying theoretical concepts

and the cost implications. This is the rst of a two-part series of

articles on the behavior and design of steel support structures

for pipes. This article (Part 1) discusses the effects of ambient

temperature changes, expansion joint requirements, and an

introduction to design loads. Part 2 concludes with the continu-

ation of design loads, structure stability concepts and detailing

for stability requirements.

SYMM ABOUT C

L

SYMM ABOUT C

L

TYPICAL LOCK-IN BRACE

PREFERRED BRACE

Figure 1: Vertical bracing arrangements.

Side view of 4 tier process pipe rack with longitudinal bracing. Courtesy of Midrex Corporation,

Inc., Charlotte, NC.

X

Y

130F

60F

50F

30F

30F

D

E

S

I

G

N

R

A

N

G

E

U

S

E

D

I

N

E

X

A

M

P

L

E

MEAN TEMP. OF ERECTED

STRUCTURE (ASSUMED)

STRUCTURE

ERECTION

ASSUMED CYCLICAL ANNUAL VARIATIONS

IN ATMOSPHERIC TEMPERATURES

+ t

(EXPANSION DOMAIN)

t

(CONTRACTION DOMAIN)

Figure 2: Thermal variations of structure.

C-StructDesign-Bendapudi-Feb10.i1 1 1/19/2010 2:48:37 PM

STRUCTURE magazine February 2010

A

D

V

E

R

T

I

S

E

M

E

N

T

-

F

o

r

A

d

v

e

r

t

i

s

e

r

I

n

f

o

r

m

a

t

i

o

n

,

v

i

s

i

t

w

w

w

.

S

T

R

U

C

T

U

R

E

m

a

g

.

o

r

g

7

and should be considered in the design of the

supporting structure.

The effects of temperature change (expansion

or contraction) occur with respect to the

center of thermal stiffness of the structure. As

a matter of good practice, lock-in bracing

(Figure 1) should be avoided. Such vertical

bracing provided at the ends of the pipe rack

structure, in any given straight segment of the

structure, tends to restrain the thermal forces.

On the other hand, if the vertical bracing is

provided at the center or close to the center

of the pipe rack structure, the accordion

effect can be achieved in the structural system.

Expansion joints are not necessary for pipe

rack structures less than approximately 400 to

500 feet (125m to 155m) in length, if lock-in

bracing is avoided. Failures of pipe rack struc-

tures due to lack of expansion joints are rare,

and no recorded evidence is readily available.

The coefcient of linear expansion () is the

change in the length, per unit length, for a

change of one degree of temperature. The thir-

teenth edition of the AISC Steel Construction

Manual recommends a value of 0.0000065

for each degree Fahrenheit (F) as a reasonable

approximation of the coefcient of thermal

expansion for temperatures less than 100

degrees F.

The change in length

l = tl Equation 1

Where l is the original length of the

member and t is the change in temperature.

The force imparted (P) due to restraint

of free thermal expansion (l)

P = AE (l )/l Equation 2

Substituting tl for l in Equation 2 the

change in stress ) (psi) is expressed as

) = E t Equation 3

P = A ) = A E t , Equation 4

where A is the cross-sectional area of

the member.

The metrics for establishing ambient temper-

ature differential are to some extent subjective

and should be based on recorded historical

data of the atmospheric temperature conditions,

preferably site-specic. The variations in the

seasonal temperature with respect to the in-

place condition of the structure need not be

more than 80 F at most locations of the struc-

tural systems (Figure 2). A similar temperature

gradient diagram should be established for

each project location.

Variation of 80 F in temperature would

cause an elongation (Equation 1) of approxi-

mately -inch in a 20-foot-long structural

member and, if fully restrained, would cause

a stress of 15.1 ksi (Equation 3). For a pipe

rack longitudinal beam (W12x26), the inter-

nal force induced to restrain the elongation

would be 116 kips (Equation 4). Design con-

siderations should be segregated between the

design of the piping for its own movements

and the design of pipe rack steel for the effects

of variations in the ambient conditions. The

movements of pipes during the operating

conditions, or at the time of startups and

shutdowns, could either happen in the ex-

pansion domain or the contraction domain

(Figure 2). Any attempt to establish a design

basis for the pipe rack steel to combine both

of these effects occurring concurrently is very

cumbersome and impractical.

Any attempt to restrain such forces at each

frame of the pipe rack would also be imprac-

tical and uneconomical. Therefore, lock-in

bracing as shown in Figure 1 should be avoided.

For example, in a 440-foot-long stretch of pipe

rack with frames spaced 20 feet apart, the middle

two frames should be braced in accordance

with the preferred method as shown in Figure

1. In this arrangement, the extreme column

would be displaced approximately 1.25 inches

(0.125 x 10 bays) at the top in the longitu-

dinal direction. Column slope caused by this

expansion is H/480 for a column height of 50

feet. Typically, longitudinal drift will not cause

serviceability problems. There are no codes or

industry standards that prescribe limits on lon-

gitudinal drift. For long stretches of pipe racks,

the pipe stress engineer should be consulted

for any special requirements for longitudinal

drift control. As a matter of interest, Process In-

dustry Practice (PIP) Structural Design Criteria

2007 (STC 01015) limits transverse drift of

the pipe rack bents to H/100, which is very

lenient. Therefore, the column displacement

at the top is not signicant, and the structure

should be allowed to expand and contract due

to the variations of the ambient temperatures.

The total column displacements would be re-

duced along the longitudinal direction (see

in Figure 3) if the column bases are xed in the

longitudinal direction; however, this is neither

a common practice nor necessary. No expan-

sion joints in the pipe racks are necessary for

rack lengths less than 500 feet (approximately

155m). Under such provisions (Figure 3), the

structure is considered stable and serviceable.

SYMM ABOUT

COMPRESSION BRACE

10 BAYS @ 20 = 200

DISPLACEMENT

AT POINT A @ COL. LINE 1 H / 480

A

(

~

1

6

m

)

H

=

5

0

0

10 BAYS @ 20 = 200

OF BRACING

AND THERMAL STIFFNESS

C

L

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Figure 3: Partial elevation of pipe rack with no expansion joints.

T y f o

F i br wr ap

S y s t e ms

FYFE

Co.

LLC

NSFFFR

Certied to NSF/ANSI 61

Over 20 years ago we created the industry...

today we set the standard

Structural Strengthening

FRP Installation

Seismic Upgrade

Blast Mitigation

Concrete Retrot

Specialty Gunite

Underwater & Coastal Repairs

Expansion & Seismic Joints

Pipe Repair and Renewal

Large and Small Diameter

PCCP, RCP, Steel Structural Repairs

Carbon Fiber Structural Liners

Concrete Restoration

Epoxy Crack Injection

Spall Repair

Corrosion Protection

Advanced Fire Protection

8380 Miralani Drive, San Diego, CA 92126

Tel: 858.642.0694

z

Fax: 858.444.2982

www.fyfeco.com

continued on next page

C-StructDesign-Bendapudi-Feb10.i2 2 1/19/2010 2:48:44 PM

STRUCTURE magazine February 2010

8

Design loads

Pipe racks should be designed for all gravity

and natural hazards such as wind and seismic

loads, internal forces induced by restraint of

free thermal expansion, and the pipe anchor

and guide support loads. Gravity loads are the

largest of the operating loads during normal

plant operations or under the hydro-test con-

dition. The primary anchor forces consist of

longitudinal and transverse forces. Calculated

and identiable load paths for strength and

stability should be provided. The longitudinal

anchor forces are typically resisted by the ver-

tical bracing of the pipe rack (Figure 3, page 7).

If adequate stiffness for the bracing is provided,

it will function as a lean-on brace. Pipe

anchor supports should be stabilized in both

orthogonal planes. Bracing in the longitudinal

direction for long stretches (greater than 500

feet) are typically located at or near the center

of thermal stiffness. The transverse bracing, or

bracing perpendicular to the length of the pipe

rack, does not provide restraint to the longitu-

dinal thermal movements of the pipe rack.

Designing pipe supports for seismic conditions

consists of two parts: 1) design of connections

(anchorage or fastening) of the pipes to the

supporting structure for the seismic loads;

and, 2) design of the pipe support structure

for the seismic forces. These two cases are

independently investigated and should not be

combined. The controlling combinations for

loads are specied in the governing codes and

standards. The base shears at the pipe support

structure must be transferred to the founda-

tions by means of appropriate anchorage.

The guidance given by the building codes is

minimal in this regard, since pipe racks are not

considered to be buildings and must be treated

as Other Structures.

Design of the pipe support structure, including

the lateral-load-resisting elements, should

typically be on the basis of the equivalent

lateral force procedure. ASCE 7 and the

International Building Code (IBC) also permit

the modal analysis procedure and linear

response history analysis for non-building

structures. Dynamic analysis may not be nec-

essary unless the contents of the pipes are

hazardous to the environment and there is a

concern for public safety. Pipe support struc-

tures should maintain symmetry and uniformity.

Irregularities should be eliminated as much

as possible.

Proper fastening of the pipes to the supporting

structure is essential in the seismic design

of pipe racks. The design of connections be-

tween the pipes and the supporting structure

should be based on the seismic base shear

attributable to the dead weight of the pipes

and their contents. Such seismic force should

be applied at the centroid of the pipe, and the

associated eccentricity should be considered

in the design of the fastening system between

the pipe and the supporting structure. All pipe

support structures should be provided with

adequate bracing required for frame stability

as discussed in this article. Horizontal bracing

(plan bracing) underneath the pipes may be

required to transmit the horizontal seismic

loads applied at the centroids of the pipes

(Figure 4). The plan bracing would function

as a collector element (diaphragm) in order

to transmit the seismic loads to the vertical

bracing. The transverse force component of

anchor loads should be assumed to be shared

by the adjoining two frames on either side of the

anchor point. This load-sharing concept assumes

decay of this force beyond these ve frames. This

is only possible when the plan bracing is pro-

vided. Therefore, it is imperative that the anchor

points be located with at least two frames before

the end of the pipe support segment.

B

A

1 4

2 3

(~4.5m)

15 0 (TYP)

(~6.0m)

20 0 (TYP)

(

~

4

.

5

m

)

1

5

0

(

T

Y

P

)

PLAN BRACING

NOTE: VERTICAL BRACING FOR

PIPE RACKS II & III NOT SHOWN

SEPARATE FRAME

AT INTERSECTION

DIRECT CONNECTION TO

INTERSECTING PIPE RACK

COLUMN

S

H

E

A

R

T

R

A

N

S

F

E

R

@

C

O

L

2

8

&

3

8

PIPE RACK I

PIPE RACK II

PIPE RACK III

ELEVATION AT COL. LINE -A

PLAN

E

L

E

V

A

T

I

O

N

A

T

C

O

L

.

L

I

N

E

S

-

3

&

4

N

Figure 4: Intersecting pipe racks.

Summary

Part 1 of this two-part series discussed tem-

perature effects on pipe racks, including the

forces imparted, recommended bracing arrange-

ments, drift control requirements, and an

introduction to design loads. The upcoming

Part 2 will discuss the interaction between the

pipe support structure and the pipes, stability

requirements, and detailing for the stability of

pipe racks.

Kasi V. Bendapudi, P.E., S.E. is the Chief

Civil, Structural, and Architectural Engineer

with BE&K Inc., at Houston, Texas. He can

be reached at kasib46@yahoo.com.

The online version of this article

contains references. Please visit

www.STRUCTUREmag.org.

Elevation of multi-tier process pipe racks bridging across the roadways. Courtesy of Midrex

Corporation, Inc., Charlotte, NC.

C-StructDesign-Bendapudi-Feb10.i3 3 1/19/2010 2:48:45 PM

The only code-listed

stacked shearwall solution.

2010 Simpson Strong-Tie Company Inc. SSW10-S

If youre planning to stack prefabricated shearwalls, make sure theyre Steel Strong-Wall

shearwalls.

Simpson Strong-Tie is now the only manufacturer to have a code-listed, two-story solution. Available

in widths as narrow as 15 inches for stacked applications, our engineered walls allow you to design

multistory homes and buildings with larger windows, doors and open spaces without sacricing the

high load values required for the project.

To ensure your walls stack up, look to Simpson Strong-Tie for the widest selection of shearwalls code listed

to the 2006 IBC (see ICC-ES ESR-1679). Visit www.strongtie.com/strongwall or call (800) 999-5099.

Blank.indd 1 1/6/2010 9:20:15 AM

d

i

s

c

u

s

s

i

o

n

o

f

c

o

n

s

t

r

u

c

t

i

o

n

i

s

s

u

e

s

a

n

d

t

e

c

h

n

i

q

u

e

s

C

O

N

S

T

R

U

C

T

I

O

N

I

S

S

U

E

S

STRUCTURE magazine February 2010

10

Planning to Minimize Damage to Buildings Adjacent

to Construction Sites in Urban Environments

By Milan Vatovec, Ph.D., P.E., Paul Kelley, P.E., Michael Brainerd, P.E., and Charles Russo, P.E.

This is the second in a three-part series on the topic of planning and managing building response to adjacent construction.

The rst, Monitoring Building Response to Adjacent Construction, was published in the November 2008 issue of STRUCTURE

magazine. The third will appear in an upcoming issue.

People and businesses continue to con-

centrate in large metropolitan centers

because keen competition in a city makes

services and commerce better. As a result,

land values are typically at a premium,

requiring development of structures that

optimize use of space. Taller and deeper

structures are being constructed, existing

structures are expanded or modied, the

urban infrastructure is constantly main-

tained, replaced, and expanded, while the

existing and often historic fabric of mature

cities must be maintained. During this

continuum of urban rejuvenation, provid-

ing protection and needed maintenance

for the remaining, adjacent structures is

not a trivial task.

Common issues associated with urban

development can be political, commercial,

and technical in nature. Urban commu-

nities have multiple interests historic

preservation, trafc control, and vehicular

and pedestrian access. Developers are

often faced with signicant cost restraints,

especially when expanding into adjacent

properties, so construction alternatives

are selected by balancing risk and costs.

Adjacent neighbors are concerned with

property damage, disruption of access,

disruption to operation (noise, dust, vi-

bration), and safety. Design team members

must manage expectations of owners and

neighbors. Their role, which includes

determining the reasonable construction

methodology and evaluation of loads and

margins of safety, is extremely difcult in

urban environments. Due to unpredictable

existing conditions, tight boundaries, and

A photo of a building elevation can be used as a key map for identication of individual distress, shown separately on detailed, up-close photos.

Detailed observations from a condition survey can be shown on individual photos linked to

a key plan.

C-ConstrIssues-Vatovec-Feb10.ind1 1 1/19/2010 2:49:20 PM

STRUCTURE magazine February 2010

11

the relative imprecision of construction toler-

ances in underground work, the designers risk

exposure often is not commensurate with their

level of control and compensation.

Some of the more common issues encountered

in planning for construction in this complex

environment are described next.

Well Managed Development

Projects Limit Damage Risks

Urban structures often consist of fragile,

archaic, and not well understood construction

components and systems. They can be founded

on unknown and potentially deteriorated

foundations, or can potentially bear on inad-

equate soils or soils whose condition changed

since the original construction (e.g. due to

past dewatering or consolidation). Therefore,

most projects in urban environments can and

probably will result in some level of movement

to adjacent buildings. Properly conceived and

executed projects, however, can effectively

limit the risk of signicant damage. To achieve

that, the developer and their design team must

begin planning, communicating, and acting

long before the rst shovel hits the ground.

Some of the more critical tasks to be addressed

in the process include:

Engage the design professional to

perform (pre)condition assessments

of adjacent buildings in an attempt

to document and understand their

present condition and fragility. Share

information with adjacent building

owners and reach agreement regarding

issues contained in the survey reports.

Conduct post-construction surveys at

the appropriate time.

Evaluate the effects of excavation

and the new foundation system on

adjacent buildings using estimated or

observed information regarding existing

foundations (type and depth). Evaluation

of potential risks can be used to develop

construction methodology and plans

to mitigate damage. Sequencing of

anticipated construction processes should

be well planned and executed (all too

often excavation proceeds ahead of lateral

support work, for example).

Engage in open communication with

adjacent building owners. Provide

them descriptions of planned activities

and controls. Solicit and address their

concerns. Coordinate with them all work

affecting their property.

Establish a well-dened construction

monitoring plan (building-performance

monitoring and construction diagnostic

monitoring) that includes monitoring of

groundwater elevations, ground-borne

vibrations, movements of the excavation

support elements, and movements of

adjacent properties. Establish threshold

and limiting criteria for each aspect

of measured response. If necessary,

especially fragile components should

be braced or protected.

Require that the contractors specialty

engineer make frequent site visits to

observe conditions, review and comment

on monitoring results, and react quickly

to any unforeseen conditions.

Unfortunately, many projects in larger US

cities are not designed and planned to suc-

ceed, especially relative to maintenance, care,

and damage protection for adjacent buildings.

Too often:

Responsibility is often blurred between

the designer, contractor, and the

contractors specialty engineer;

communication channels with adjacent

building owners are non-existent or

break down;

design professionals are not retained to

perform a thorough condition assessment

or to evaluate potential risk of damage;

the preconstruction survey, monitoring,

and protection of adjacent structures are

not budgeted;

the design team does not adequately

communicate project requirements, or

such requirements are ignored;

risky excavation activities seem to be

under no ones purview; or,

the developer/contractor rely on their

insurance to cover any collateral damage.

As a result, problems arise.

Legal Responsibilities and Issues

Most building codes and common laws en-

courage construction on rightfully owned

land, with certain provisions and requirements

regarding the remaining adjacent properties.

For example, the developing party may have a

duty to inspect the adjacent property, to give

reasonable notice regarding construction ac-

tivities that affect the building next door, or

to obtain insurance to protect the adjacent

owners. Owners of adjacent buildings may

be required to grant access to perform inspec-

tions, and ready the adjacent building to resist

construction impact.

In addition, most building codes have require-

ments regarding protection of adjacent buildings

during construction activities. A frequent

common law right is to have the owned land

naturally supported. If natural soil support

is removed or modied during construction

activities, the adjacent site owners or operators

will likely be found liable for any ensuing

damage. If adjacent development requires

excavation near or at the lot line, underpin-

ning of nearby building wall foundations will

STEEL DECK

I NSTI TUTE

s

www.sdi.org

We are pleased to announce that our new

American National Standards Institute

(ANSI ) / Steel Deck Institute ( SDI )

standards for Steel Roof Deck (RD1.0),

Composite Steel Floor Deck (C1.0) and

Non-Composite Steel Floor Deck (NC1.0)

are now available for FREE download

on our website. These standards are also

highlighted in our Steel Deck Institute

Steel Deck Design Manual #31 which

can also be ordered from our website.

Set your standards high.

P.O. Box 25 Fox River Grove, IL 60021

(p) 847.458.4647

Weve got

NEW 2009

downloadable.

And now theyre

standards.

A

D

V

E

R

T

I

S

E

M

E

N

T

-

F

o

r

A

d

v

e

r

t

i

s

e

r

I

n

f

o

r

m

a

t

i

o

n

,

v

i

s

i

t

w

w

w

.

S

T

R

U

C

T

U

R

E

m

a

g

.

o

r

g

C-ConstrIssues-Vatovec-Feb10.ind2 2 1/19/2010 2:49:28 PM

STRUCTURE magazine February 2010

12

typically be required. In general, responsibility

for any damage that is shown to be a result

of adjacent-site construction will rest with

the party performing the construction. Other

building code requirements may include pro-

tection of roofs, skylights, and walls, protec-

tion against water entry, protection and lateral

support of party walls exposed as a result of

demolition, installation pedestrian bridges for

protection against falling debris, etc.

Despite common sense, common law, and

building code requirements, construction in

urban areas, once damage is alleged, seldom

goes smoothly. Adjacent owners may not be

sufciently informed, are unaware of their

rights, or are not familiar with the plans for

adjacent development until it is too late.

Sometimes building code requirements are

vague or incomplete in terms of guidance, re-

quirements, and responsibility of the involved

parties. Occasionally, owners of damaged

properties inform their insurance companies

too late, or blindly request their insurance

carriers to pay for damage that is not covered by

their policies. At other times, cause of dam-

Monitoring of vertical building displacements.

The map on the right shows areas where the

threshold limits for displacement established prior

to construction were exceeded. Early detection

of exceedance can be used to quickly develop a

mitigation plan.

age is disputed or new damage is not easily

discerned from the pre-existing damage. In

general, without well-dened and planned proj-

ect processes in place, disputes regarding

causation and amount of damage (no precondi-

tion surveys), or disruption, easily develop and

occasionally escalate, requiring involvement of

experts, consultants, and ultimately attorneys.

Ensuing litigation can in turn quickly engulf

other parties (architects, engineers, contractors,

and insurance carriers) in the dispute.

Managing the Process to

Minimize Damage to

Buildings (Anticipate)

So, how does someone avoid getting their

building damaged when faced with irrespon-

sible, under-budgeted, under-qualified, or

uncommunicative prospective developers of

a property next door? The assumption here is

that, unless one of the four adjectives above is

true, the project would be well-planned, man-

aged, implemented, and designed to minimize

damage-risks described earlier. The following

focuses on some common issues and strategies

available to building owners.

Up-front Research

At least some information regarding new

developments is typically available in the public

domain. Specically, plans for new buildings

should be on le with the building depart-

ment in the appropriate municipality. Owners

of adjacent buildings should research the

building department records, which are often

available on the internet, at the rst sign of

adjacent development (e.g. the windows of the

existing building next door are being boarded

up), especially if they have not already been

approached by the developing party next door.

Generally, even if plans related to operations

that are most likely to affect adjacent properties

(such as excavation) are not available, sufcient

information regarding the identity of involved

parties can usually be obtained from the building

department records. Additional useful infor-

mation, such as past violations associated with

the development site or with the developer in

question, may also be available.

C-ConstrIssues-Vatovec-Feb10.ind3 3 1/19/2010 2:49:28 PM

STRUCTURE magazine February 2010

13

A

D

V

E

R

T

I

S

E

M

E

N

T

-

F

o

r

A

d

v

e

r

t

i

s

e

r

I

n

f

o

r

m

a

t

i

o

n

,

v

i

s

i

t

w

w

w

.

S

T

R

U

C

T

U

R

E

m

a

g

.

o

r

g

Communication

Owners of adjacent buildings should try to

contact, and get properly informed directly

from, representatives of the adjacent devel-

opment. A savvy building owner should be

able to recognize if the development is well

planned, if due attention is given to demoli-

tion, excavation, and construction methods,

as well as how the planned activities relate to

existing adjacent building(s). For less experi-

enced owners, the appropriate contact person

on the development side should be able to

walk them through all the processes, and help

them understand and anticipate all potential

issues. However, if plans and procedures are

not made available, if the monitoring plan

and staff that will implement protection is

not dened or divulged, or if full access to all

matters pertaining to the next-door property is

not given, there should be reason for concern.

Regardless of the response from the developers

side, however, owners may choose to retain

an independent consultant (adjacent owners

engineer) to help them through the process

and help mitigate risks. The adjacent-owners

engineer would review the design approach

and preconstruction-survey data, spot-check

monitoring and quality-control programs,

review monitoring data and reports, and visit

the site periodically to review project progress

and condition of the adjacent building. If the

project is going well, the adjacent-owner engi-

neers involvement and time-commitment can

be minimal. If the project is not going well,

if damage is incurred, if information is not

forthcoming, or if any other problem arises,

the engineers role may grow. They may take

on some monitoring and evaluation duties

ordinarily belonging to the developer and

design team or the adjacent property contractor,

as well as provide engineering guidance re-

garding protection and damage management

during construction.

Unfortunately, if the adjacent-building owner

is faced with an unresponsive developer next

door, there are few pleasant options. They may

rely on their independent consultant and their

insurance company to help them navigate

through issues that may arise throughout the

project, but this typically puts them in the

reactive mode. If they dont become part of

the planning process, and if the process is not

managed well, they will only be able to deal

with issues and damage as they occur; they will

not be able to prevent them.

Agreements

One way to attract the attention of an adja-

cent (and unresponsive) developer is to involve

attorneys. This does not necessarily mean that

litigation is imminent, or that some level of

damage was already incurred. Attorneys can

typically reach the appropriate parties on the

other side, and work towards developing a

rm, contractual agreement between neigh-

boring parties even before the project is started.

Ideally, irrespective of whether attorneys are

involved or not, this agreement would typically

dene steps, procedures, and reimbursements

for design and construction review; for access,

monitoring, property protection, responsibility

for damage and repair; and, other factors

that can be anticipated during the course of

the project. Although often not ideal, this

approach offers a clean, agreed-upon method of

resolution for any issues arising from construc-

tion, and it is a better alternative to unplanned

disputes and litigation. In general, there are

three ways for an owner of the adjacent building

to get protection against damage: through

insurance (their own or the adjacent develop-

ment owners), through contractual agreement

with the adjacent development owners, or

through some form of litigation.

Conclusion

Congested urban construction is difcult and

often results in damage to adjacent structures.

Damage and associated disputes can usu-

ally be avoided if proper project planning,

monitoring, and execution are employed.

Early coordination between parties can pre-

vent disputes and reduce risks. Preconstruction

agreements, whether procured through attorneys

or not, are invariably benecial when it comes

to minimizing and resolving damage claims.

Further discussion regarding evaluation and

remediation of building damage, once it has

already incurred, will be presented in the

third article of this series.

Paul L. Kelley, P.E. is a Senior Principal

at Simpson Gumpertz and Hegers ofce in

Boston and a head of East Coast Structural

Engineering operations.

Charles Russo, P.E. is a Senior Principal with

Simpson Gumpertz & Heger Inc., and is

Head of Structural Engineering Practice in

their Washington, DC ofce.

Michael Brainerd, P.E. is a Senior Principal

with Simpson Gumpertz & Heger Inc, and is

their National Practice Leader for Structural

Repair and Rehabilitation.

Milan Vatovec, Ph.D., P.E. is a Senior

Principal with Simpson Gumpertz & Heger

Inc., and is Head of Structural Engineering

Practice in their New York ofce.

C-ConstrIssues-Vatovec-Feb10.ind4 4 1/19/2010 2:49:30 PM

p

e

r

f

o

r

m

a

n

c

e

i

s

s

u

e

s

r

e

l

a

t

i

v

e

t

o

e

x

t

r

e

m

e

e

v

e

n

t

s

S

T

R

U

C

T

U

R

A

L

P

E

R

F

O

R

M

A

N

C

E

STRUCTURE magazine February 2010

14

A Solution to Seismic Bracing Restrictions

Expanding the Acceptance of New Large HSS Sections

By John W. Lawson, S.E.

Concentric Braced Frames of steel hollow

structural sections (HSS) have a long his-

tory of providing efcient designs to resist

lateral forces especially in seismic zones.

The workhorse material standard, ASTM

A500, has provided tubular sections with

a good history of performance. However,

with the adoption of the 2006 edition of

the International Building Code (IBC) in

conjunction with the AISC 341-05 Seismic

Provisions for Structural Steel Buildings, it

has become difcult to utilize these sections

in taller clear-height buildings and heavily

loaded applications due to the current

scope of the ASTM A500 standard. Ex-

panding the scope of ASTM A500 to

include the thicker wall sections currently

being produced will provide engineers more

seismically compact sections to choose

from and result in more efcient designs.

In the seismically active Western United

States, very large distribution/warehouse

facilities of 100,000 square-feet to over

two-million square-feet incorporate large

concentric braced frames. The inverted-V-

type bracing conguration, in conjunction

with an Ordinary Concentric Braced Frame

system (OCBF), has been preferred in the

past by allowing material handling ow

beneath and simplied bracing connec-

tions at the expense of higher design base

shear. Figure 1 was taken last year at a

facility in Southern California and depicts

a completed 1,400,000 square-foot dis-

tribution warehouse for a national brand

undergarment manufacturer. This large

building consists of concrete tilt-up walls

with a hybrid panelized at roof system.

The buildings interior utilizes large Hol-

low Structural Sections for the columns

(HSS 10x10x0.3125) and for the seismic

resisting braced frame diagonals (HSS

14x14x0.500).

With the adoption of the 2006 IBC

and referenced AISC 341-05, tubular

sections larger than 10 inches no longer

meet the new limits for seismically com-

pact sections. For an OCBF as used in this

example building, the allowable width/

thickness ratio for square brac-

ing members b/t < 110(F

y

)

was relatively low under the

1997 UBC through 2003 IBC.

For these larger cross-sections,

thinner wall sections were per-

mitted under the code and

complying HSS members were

widely available. In the 2006

IBC, the braces for OCBF

and Special Concentric Braced

Frames (SCBF) both have a

limited width/thickness ratio

of b/t < 0.64(E/F

y

) for square

and rectangular bracing members.

The background of this building code

change can be traced to the Northridge

Earthquake in 1994 and the subsequent

width/thickness ratios incorporated into

the 1997 UBC. Ongoing research has

shown that brace ductility is in large part

determined by the prevention of fracture

due to local buckling behavior under low

cycle fatigue. HSS sections are suscep-

tible to localized buckling. Because both

OCBFs and SCBFs are expected to un-

dergo some limited buckling under severe

ground motions, the braces are required

to meet the special width/thickness ratios

for seismic compactness. Unlike compact-

ness dened for gravity shapes where local

buckling is prevented before the onset of

strain-hardening, seismic compactness

provides resistance to local buckling when

stressed into the inelastic range.

Initially, a new width/thickness ratio limit

was applied only to SCBF by the adop-

tion of IBC 2003, but because SCBFs

require special detailing and because large

sections meeting the seismic compactness

criteria were not available, heavily loaded

and larger clear-height buildings continued

to use OCBFs. X-type bracing congu-

rations (Figure 2b) were avoided due to

perceived erection complexity, the larger

number of connections, and brace obstruc-

tion closer to oor level. Until recently, the

inverted-V-type congurations (Figure 2a)

have been preferred in single story large

clear height buildings.

Researchers cautioned that Hollow

Structural Sections (HSS) under seismic

loading should be avoided unless more

restrictive seismic compactness limita-

tions were adopted. Under the 2006 IBC

(AISC 341-05), width/thickness ratios

for OCBFs now are identical to SCBF

systems. The use of HSS under grav-

ity and wind loading was unaffected by

these changes.

An unexpected consequence of the more

restrictive width-to-thickness ratio is the

elimination of all HSS sections larger than

10 inches square for use in concentric

braced frames. Currently, only ASTM

A500 sections are available for square

braces in seismic applications. Because

the current ASTM A500 standard limits

its scope to a maximum wall thickness of

approximately inch, 12-inch, 14-inch

and 16-inch square sections are unable to

comply with seismic compactness, despite

thicker walled sections being available

from Japan.

One Japanese manufacturer, Nippon Steel

& Sumikin Metal Products Co., Ltd

(NSMP), is producing large HSS products

and exporting them to the United States.

According to Masao Sonoda, General

Manager of Building Products Develop-

ment, NSMP is regularly producing 12-,

14-, 16-, 18-, 20- and 22-inch square sec-

tions with 0.750-inch and 0.875-inch

wall thicknesses. As Table 1 shows, these

large HSS with thicker walls could give

structural engineers a new tool to comply

with the tighter restrictions under the

2006 IBC. By providing heavier walls,

12- and 14-inch square sections can once

again be used for concentric seismic brac-

ing to accommodate heavy loads or long

bracing situations.

In gravity or wind loading situations

where braces or columns are not required

to be seismically compact, cross sections

larger than 16-inch square may be desired;

however, ASTM A500s scope currently

limits section perimeters of 64 inches

or less. While not yet being produced

by North American steel manufacturers,

Figure 1: Large HSS shapes have been common in braced frames

in the seismically active western United States. Expanding the

scope of ASTM A500 will allow use of these shapes that already

comply with the new seismic compactness requirements.

(a) (b) (c)

Figure 2: Examples of concentrically

braced frames.

C-StructPerformance-Lawson-Feb101 1 1/19/2010 3:42:58 PM

STRUCTURE magazine February 2010

A

D

V

E

R

T

I

S

E

M

E

N

T

-

F

o

r

A

d

v

e

r

t

i

s

e

r

I

n

f

o

r

m

a

t

i

o

n

,

v

i

s

i

t

w

w

w

.

S

T

R

U

C

T

U

R

E

m

a

g

.

o

r

g

15

Compactness Requirements:

Width/Thickness Ratio = b/t

(1) Earthquake loading:

b/t < 0.64(E/F

y

) Seismically Compact

(2) Gravity, Wind loading:

b/t < 1.12(E/F

y

) Compact

E= Young Modulus F

y

=Yield Strength

t = 0.93 times the nominal wall thickness

b = the clear distance of at portion between corners.

The outside corner radius equates to 1.5 times of the wall thickness.

t

HSS

t

1.5t 1.5t

B

b

Figure 3.

Japans NSMP is manufacturing 18-, 20- and 22-inch

square sections that could comply with ASTM A500

if the Standards scope were to expand. Without being

subject to the special seismic compactness restrictions,

these extra large HSS shapes provide many additional

opportunities for architects and engineers.

In an effort to continue providing concentric braced

frames in large clear-height buildings, some engineers have

experimented with using round pipes (HSS16x0.625)

as a substitute, but it is difcult to obtain seismically

complying material. And, the reduced radius of gyra-

tions in these sections increases the slenderness and thus

restricts their use to shorter applications.

Another unorthodox option is to ll the 12-, 14- and

16-inch tubes with concrete to stabilize their walls.

However, in addition to the extra material costs, it is

undesirable to bring a concrete subcontractor back out

to the job so late in the process and pump concrete

upwards of 40 feet.

A better approach to the conict between the current

ASTM A500 standard and AISCs compactness limi-

tations is to expand the standards scope of regulation.

Currently, there are applications where these large

HSS sections are being used despite being outside the

dimensional scope of ASTM A500 but equivalent in

quality. At the current time, some US service centers

have started to stock them in their warehouses for lim-

ited uses.

Unfortunately, ASTM A500 currently regulates its

scope to total periphery up to 64 inches, wall thick-

ness up to 0.625 inches. An increase in this standards

scope would once again provide a larger range of brac-

ing sections available for engineers to utilize. At this

time, NSMP has submitted a proposal to ASTM to

expand the dimensional scope to 88-inch periphery

and 0.875-inch wall thickness. With the opportunity

for foreign and domestic producers to supply larger,

thicker HSS material complying with ASTM A500,

more efcient structural systems can provide tall, open

spaces as well as accommodate heavily loaded seismic

bracing conditions.

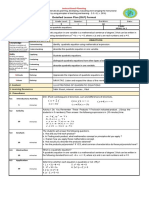

Size

(in.)

Nominal Wall thickness (in.)

0.250 0.375 0.500 0.625 0.750 0.875

4 x 4 OK OK OK

6 x 6

OK OK

8 x 8

OK OK

10 x 10

OK

12 x 12

OK

14 x 14

OK

16 x 16

18 x 18

20 x 20

22 x 22

Table 1: Seismic Compactness.

John W. Lawson S.E. is a practicing Structural Engineer and Assistant Professor in the

Architectural Engineering Department at California Polytechnic State University, San

Luis Obispo. He can be reached at jwlawson@calpoly.edu.

T u b u l a r s e c t i o n s

custom built

to the highest standards.

Yours.

SuperStruct tubular sections hold up to the strictest

design standards without holding them back.

ManuIacIurcd In a varIcIv oI sIacs and sIzcs Io

vour sccIIIcaIIons

Largc sIzcs Iron 12 u Io 4S squarcs and rccIangIcs

LcngIIs u Io 55'

WaII IIIckncss 5/16 Io 1

LxccIIcnI coIunn sIrcngII and IorsIonaI rocrIIcs

AcsIIcIIcaIIv acaIIng

S00-S25-666S vvv.vaInonI.con VaIIcv, NcLraska

ConIacI KvIc DcBusc aI VaInonI TuLIng IoII-Ircc aI 1-800-825-6668 ext. 3558 or

kld2@valmont.com Io Icarn norc on IIc dcsIgn ossILIIIIIcs oI HSS SucrSIrucI.

Shaded areas indicate availability, but not meeting the scope

of ASTM A500.

C-StructPerformance-Lawson-Feb102 2 1/19/2010 2:50:52 PM

s

u

s

t

a

i

n

a

b

i

l

i

t

y

a

n

d

p

r

e

s

e

r

v

a

t

i

o

n

a

s

t

h

e

y

p

e

r

t

a

i

n

t

o

s

t

r

u

c

t

u

r

a

l

e

n

g

i

n

e

e

r

i

n

g

S

T

R

U

C

T

U

R

A

L

S

U

S

T

A

I

N

A

B

I

L

I

T

Y

STRUCTURE magazine February 2010

16

Can Using More Wood Reduce Your Environmental Footprint?

By Roxane Ward

Building designers have long recognized

the inuence they have in addressing the

worlds most pressing environmental issues.

In the late 1970s, the oil crisis helped to

initiate what has now been 30+ years of

increasing energy efciency. Today, con-

cern about climate change is resulting in

a similar focus on carbon dioxide (CO

2

).

However, while buildings in the United

States account for approximately 39 per-

cent of the countrys energy consumption

and contribute 38 percent of its CO

2

emissions, there is growing awareness

that material choices also factor greatly

and that wood, in particular, can have

a positive impact on a buildings environ-

mental footprint.

Carbon Absorption

and Storage

The fact that wood is the only major

building material thats renewable and

sustainable is just part of the picture, says

Dwight Yochim, national director of the

WoodWorks program, which provides ed-

ucation and technical support to engineers

and architects designing non-residential

wood buildings. Sustainably managed

forests such as those in North America,

and the products made from those forests,

also have the potential to play a signicant

role in addressing climate change.

As a tree grows, it absorbs CO

2

from

the atmosphere, using the carbon (C) for

growth and releasing the oxygen (O

2

).

Thats as much as most people think

about, says Yochim. But wood is about

50 percent carbon by weight and wood

products continue to store this carbon

indenitely. In a building, for example,

its stored for many decades. But wood

buildings are also easily adaptable and

its becoming increasingly common to

see the wood reclaimed for other uses

so the carbon is actually kept out of the

atmosphere considerably longer.

According to the research rm Dovetail

Partners, Inc., the amount of carbon stored

in U.S. wood products is about 3.5 bil-

lion metric tons (including landll sites).

However, more important from a climate

change perspective is the cumulative impact

over time. Each year, new wood products

represent an estimated 60 million metric

tons of additional stored carbon. Most

of this is in the nations housing stock,

so assuming that more homes are built

than dismantled, and adding any increase

in non-residential wood buildings, the

amount of stored carbon can be expected

to grow considerably.

Given that wood is made using the suns

energy, greenhouse gas emissions are also

avoided when wood is used in place of

materials which require large amounts of

fossil fuels to manufacture. For example,

although cost and speed of construction

were the reasons that HMC Architects

chose wood as the main framing and

structural material for Harada Elementary

School in California, the building includes

more than 23,000 cubic feet of wood,

which stores an estimated 490 metric tons

of carbon and is responsible for another

990 metric tons in avoided CO

2

emis-

sions. The 2010 Olympic Speed Skating

Oval in British Columbia, which has a

six-acre free-spanning wood roof, includes

almost 135,000 cubic feet of wood, stores

an estimated 2,940 metric tons of CO

2

and is responsible for avoided emissions

of another 8,820 metric tons of CO

2

.

Two things complete the cycle, says Yochim

the use of biomass as a carbon-neutral

energy source and forest regeneration.

Forests absorb more carbon when theyre

young because thats when theyre grow-

ing most vigorously. As they get older

they absorb less, until eventually they

start to decay and begin releasing their

stored carbon back into the atmosphere.

Obviously this doesnt mean that all forests

should be managed for timber. North

American forests can and should be

sustainably managed to provide a full range

of environmental, social and economic

values. However, those that are managed

for wood products help to reduce green-

house gases in an endless cycle of carbon

absorption and storage.

Choosing Materials Based

on their Life Cycle Impacts

In terms of material choices, the green

building movement is shifting away from

a prescribed approach and toward the life

cycle evaluation of actual performance,

says Lisa Podesto, P.E., a technical director

for WoodWorks and current chair of the

Structural Engineers Association of Central

California Sustainable Design Committee.

A prescribed approach assumes that

certain materials or practices are better

for the environment regardless of the

situation, says Podesto. For example,

some people might think that recycled

Olympic Oval. Courtesy of FII.

Forest regeneration. Courtesy of Sandy McKellar.

C-StructSustainability-Ward-Feb11 1 1/19/2010 2:51:21 PM

STRUCTURE magazine February 2010

ADVERTISEMENT - For Advertiser Information, visit www.STRUCTUREmag.org

17

products are automatically preferable even

though they may require a large amount of

energy to produce and transport, and the

alternate choice may be wood from a local,

sustainably managed forest. It isnt that you

shouldnt use recycled materials, just that other

considerations may weigh more heavily on the

products life cycle environmental impacts,

depending on the situation. Its important for

designers to be able to assess the impacts of

their choices.

To compare materials, life cycle assessment

methodology, or LCA, has received strong

support from the international scientific

community and is increasingly being integrated

into green building rating systems such as the

U.S. Green Building Councils Leadership in

Energy and Environmental Design (LEED

)

system and the Green Building Initiatives

Green Globes

. The process of analysis con-

siders the environmental impacts of a material

or assembly over its lifespan from extraction

and harvesting to manufacturing, transportation,

installation, use, maintenance and disposal

or recycling.

Its an area where wood excels, said Podesto.

Using the scientic LCA approach shows that

wood buildings are better for the environment

than other materials in areas such as air and

water pollution, greenhouse gas emissions and

embodied energy. And the thing engineers

need to know because were a sceptical bunch

is that apples-to-apples are being compared

in LCA studies; wall systems with the same R

value and oor systems designed to carry the

same load.

Energy and

Resource Efciency

In the green building world, embodied energy

has received less attention than operational

energy because operational energy needs have

been so proportionally high. About a third of

the energy consumed in developed countries

goes toward heating, cooling, lighting and

the operation of appliances in non-industrial

buildings. However, as buildings become more

and more energy efcient, the signicance of

embodied energy will continue to rise because

it will represent a larger piece of the overall

energy pie.

At the same time, wood also contributes to

operational energy efciency. Because its cellular

structure has air pockets that limit its ability to

conduct heat, its a better insulator than other

materials which have higher conductivity

and must overcome lower R-values associated

with thermal bridging. As a result, they require

more insulation to meet the same level of

thermal performance.

Along similar lines, the concept of advanced

framing or optimum value engineering is

gaining popularity with engineers and as

part of green building codes because of its

impact on energy and resource efciency.

At a presentation to architects and engineers

in California, Katy Hollbacher, P.E., principal

of Beyond Efciency, Inc. said key elements of

advanced framing include optimizing the layout

for efcient material use, using structural-

rated wood materials to their full approved

capacities, eliminating structural materials where

non-structural materials are adequate and

Multi-family wood structure. Courtesy of FII.

C-StructSustainability-Ward-Feb12 2 1/19/2010 2:51:35 PM

STRUCTURE magazine February 2010

18

reducing structural redundancies inherent with

conventional stick framing. Among other

things, she suggests laying the building out on

a 2-foot module, which maximizes the ef-

ciency of 24-inch framing and 4x8 sheet

materials, sizing headers based on load, leaving

open wall corners and using ladder framing at

wall intersections.