Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Filtration Lab Report: Measuring Cake Resistance

Caricato da

Umesh Kumar Sharma RamamoorthiDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Filtration Lab Report: Measuring Cake Resistance

Caricato da

Umesh Kumar Sharma RamamoorthiCopyright:

Formati disponibili

Laboratory

Mechanical Process Engineering

Report on the laboratory experiment:

Filtration

Prof. Dr.-Ing. U. Grossmann

Students:

SEBASTIAN GONZLEZ GONZLEZ (29105)

UMESH KUMAR SHARMA (29189)

HENNING BOHLIUS (28386)

INGRID SNCHEZ

TURO VALKAMA (29045)

List of Content

Figures...................................................................................................................................................I

Abbreviations and Formula Signs.........................................................................................................I

1 Introduction......................................................................................................................................1

2 Lab Test............................................................................................................................................1

2.1 Measurement.............................................................................................................................2

2.2 Calculations..............................................................................................................................3

3 Discussion.........................................................................................................................................4

4 Statements.........................................................................................................................................4

Figures

Figure 1: Flow Chart of the Lab Test....................................................................................................2

Figure 2: Volume of the Filtrate............................................................................................................2

Figure 3: Filtration Line.......................................................................................................................3

Abbreviations and Formula Signs

Abbreviations

Eq Equation

PVC Polyvinyl Chloride

Formula Signs

A Area of the Filter Membrane

h Hight

L

f

Thickness of the Filter Cake

p Pressure

V Filtrate Volume

o

o

W

Filter Cake Resistance

Filter Resistance

n

f

Viscosity of the Filtrate

I

1 Introduction

Filtration is a separation method to hold back suspended solids in a gaseous or liquidize flow at a

membrane. The on the suspension side remaining particle film is the so called filter cake. With the

progressing filtration the filter cake is growing and causes an increasing pressure drop over the

filter, which leads to an higher stress.

The filter membrane is held in a filter support, because it is as itself too weak to resist an volume

flow.

There are two main ways to run a filtration:

constant pressure

constant volume flow

Constant Pressure

Advantages:

stress on the filter is limited by the applied pressure

a simple set up is possible

Disadvantages

the output volume of the filtrate is decreasing

the filtration has to be stopped to achieve an economical produktion

Constant Volume Flow

Advantages:

the output volume flow is constant

Disadvantages

the stress on the filter is increasing by the fast crowing filter cake resistance

the filtration has to be stopped faster than with constant pressure to beware a damaging of

the filter

this procedure requires advanced control technologies

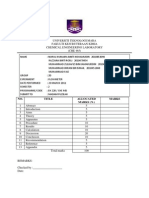

2 Lab Test

In the lab test a cake filtration under constant pressure is performed using an one percent water PVC

suspension (25 l of water and 250 g PVC). The densities of the water and the PVC are nearly the

same, which is normal for filtration, because otherwise the separation could be performed by

1

sedimentation. To keep a homogeneous suspension a stirrer is applied.

The filter is inside a vertical pipe. The water column above the filter is at a constant level of

h=2.15 m, which is secured by a level drain. The filtration is started by opening the lower valve

(Figure 1). At the end of the filtration, the filter is back washed the high concentrated suspension is

taken out at the upper valve.

Figure 1: Flow Chart of the Lab Test

2.1 Measurement

The filtrate is collected in a tank, that's placed on a balance. Every 15 s the weight of the water is

written down. During the progress of filtration the volume increase decreases (Figure 2) ,which is

related to the growing filter cake. After the filtration as itself is finished, the back washing takes

place. When the back washing is done, the time is stopped.

Figure 2: Volume of the Filtrate

2

0 s 100 s 200 s 300 s 400 s 500 s 600 s 700 s 800 s 900 s 1000 s

0

2

4

6

8

10

12

Time [s]

F

i

l

t

r

a

t

e

[

d

m

]

The filtration took 15 min and 15 s and with back washing 18 min and 35 s, so the backwashing

procedure took 3 min and 19 s.

The filter cake is 12 cm thick after 15 min of filtration.

2.2 Calculations

The filtration line is determined by a linear regression to calculate the coefficients of cake filtration.

Figure 3: Filtration Line

Taking the regression from Figure 3 and applying it to the equation (Eq.2) taken from the the

literature [1] the coefficients are calculated.

f x)=ax+b=6,0193x+15,5136 (Eq.1)

t

V t )

=

n

F

o

2A

2

Ap

V t )+

n

F

AAp

(Eq.2)

Comparing Eq.1 from Figure 3 with Eq.2 the initial point to calculate and are the slope a

(Eq.3) and the intersection b (Eq.4).

a=

n

F

o

2A

2

Ap

=6,0193

s

dm

6

(Eq.3)

b=

n

F

AA p

=15,5136

s

dm

3

(Eq.4)

Eq.3 is transposed to (Eq.5)

o=

a2A

2

Ap

n

F

=

6,0193

s

dm

6

20,0023

2

m

4

21113 Pa

0,001 Pas

(Eq.5)

o=1344564388m

2

=1,344610

9

m

2

(Eq.6)

Eq.4 is transposed to the filter resistance.

3

0 1 2 3 4 5 6 7 8 9 10 11 12

0

10

20

30

40

50

60

70

80

90

f(x) = 6,0193x + 15,5136

R = 0,9796

Volume Filtrate [dm]

t

/

V

[

s

/

d

m

]

=

bAAp

n

F

=

15,5136

s

dm

3

0,0023m

2

21113Pa

0,001Pas

(Eq.7)

=753338865m

1

=7,533410

8

m

1

(Eq.8)

The cake resistance is calculated in Eq.9.

o

W

=

V

AL

f

o=

10,95dm

0,0023m

2

0,12m

1,344610

9

m

2

(Eq.9)

o

W

=53345543478m

2

=5,334610

10

m

2

(Eq.10)

3 Discussion

The lab test was successfully performed. The amount of filtrate was measured and the typical curve

of a cake filtration under constant pressure has been recorded (Figure 2).

Furthermore the thickness of the filter cake was measured and all values were calculated. The most

interesting value is the specific filter cake resistance. With its help a statement regarding the

filterability can be made.

The determined cake resistance lies with 5,3*10

10

m

-2

in the interval 10

12

m

2

>o

W

>10

10

m

2

, that

says the suspension of PVC and water is good filterable [2].

4 Statements

Henning Bohlius

The filtration laboratory explained with the help of a constant pressure filtration the basics of

filtration. It showed me, that an filtration is non-continuous process. Also I got a feeling for the

procedure of the filtration. The filtration has to stop when the yield becomes economical ineffective,

this is an optimisation problem between the filtration as itself and the backwashing. Possible

question are the set up with more filters in parallel which are time staggered to have constant

average production.

Sebastian Gonzlez Gonzlez

As a separation process, filtration is a very important field in industry and even if it looks

apparently easy, the proper design of a filter requires a lot of study and involves several parameters

that must be evaluated in the laboratory. By means of theoretical calculations based on those

experimental data, it is possible to select the better materials for the filter and to set the parameters

in order to get the higher efficiencies in practice.

I find our practical training illustrative but I think that it would be great if we also have the

opportunity to compare theoretical data with the experimental values, measuring the concentration

of the fluid after the filter and determining in that way the real efficiency of the equipment.

4

Umesh Kumar Sharma

It was interesting to see how the needed values for a filtration can be easily determined by simple

experimental set up. This is good to know later in praxis when it's our turn to plan a filtration

process.

Ingrid Snchez

The lab test showed me, that the needed data for a filtration can be measured without big effort.

Although there are in general two types of filtration the needed data can be determined just using

the simple type with constant pressure, also when you want to perform the filtration later on with

constant volume flow. Now having these knowledge I feel confident to perform such an experiment

later on in my enterprise.

Turo Valkama

This laboratory has been really informative. It took just a few minutes to perform it and to calculate

the values. Seeing the growing filter cake and measuring the filtrate over the time, gave me a better

understanding of what is actually happening during the filtration process.

Sources

[1] Stie: Mechanische Verfahrenstechnik 2

[2] Pre discussion notes

5

Potrebbero piacerti anche

- Solid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityDa EverandSolid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityValutazione: 5 su 5 stelle5/5 (2)

- Chee Lab 2 FinalDocumento26 pagineChee Lab 2 FinalOLEBOGENG RATLHOGONessuna valutazione finora

- Ultrasound in Food Processing: Recent AdvancesDa EverandUltrasound in Food Processing: Recent AdvancesMar VillamielNessuna valutazione finora

- Constant Pressure FiltrationDocumento19 pagineConstant Pressure Filtrationmahbub1332100% (5)

- Filtration (Final Report)Documento13 pagineFiltration (Final Report)Noel Jeffrey PintonNessuna valutazione finora

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsDa EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsNessuna valutazione finora

- ACT 9 Filter Grp1Documento8 pagineACT 9 Filter Grp1Junn Edgar LibotNessuna valutazione finora

- In situ Spectroscopic Techniques at High PressureDa EverandIn situ Spectroscopic Techniques at High PressureNessuna valutazione finora

- Chemical Plant III Assignment - 1-2023Documento4 pagineChemical Plant III Assignment - 1-2023winnie FikileNessuna valutazione finora

- Gravity Filtration and Vacuum Filtration of Calcium Carbonate (CaCO3) SlurryDocumento6 pagineGravity Filtration and Vacuum Filtration of Calcium Carbonate (CaCO3) SlurryElajah ZaragozaNessuna valutazione finora

- Filtration Questions)Documento8 pagineFiltration Questions)Evan CarniyanNessuna valutazione finora

- Dewatering of iron ore slurry by a ceramic vacuum disc filterDocumento6 pagineDewatering of iron ore slurry by a ceramic vacuum disc filterReynan Giacomin Borlini100% (1)

- Manufacturing Lab REPORTDocumento7 pagineManufacturing Lab REPORTSamar AlgheetanyNessuna valutazione finora

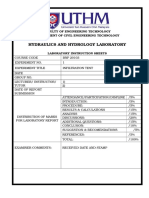

- NO. Title Allocated MARKS (%) MarksDocumento22 pagineNO. Title Allocated MARKS (%) MarksjufferyNessuna valutazione finora

- Ntsako Jason Maluleke 201209457 P2 Project Stickies TrialDocumento27 pagineNtsako Jason Maluleke 201209457 P2 Project Stickies TrialJasontsako_419568363Nessuna valutazione finora

- Rotary Vacum Drum Filter (Jurnal)Documento7 pagineRotary Vacum Drum Filter (Jurnal)Shofiyah Bannan100% (2)

- PlantDocumento5 paginePlantLucas LethukuthulaNessuna valutazione finora

- Filter ManualDocumento53 pagineFilter ManualHazem DiabNessuna valutazione finora

- Ssino 2Documento18 pagineSsino 2shuaibu abdullahiNessuna valutazione finora

- ME 414E Instrumentation and Control Engineering Practical Activity No. 6 Title: Liquid Flow Measurements ObjectivesDocumento4 pagineME 414E Instrumentation and Control Engineering Practical Activity No. 6 Title: Liquid Flow Measurements ObjectivesRoberto Yeso Jocson IIINessuna valutazione finora

- Filtration Study of Calcium Carbonate Slurry Under Vacuum PressureDocumento26 pagineFiltration Study of Calcium Carbonate Slurry Under Vacuum Pressuredrami9433% (3)

- FiltrationDocumento7 pagineFiltrationElajah ZaragozaNessuna valutazione finora

- Experiment 1: Dust Removal From Gas Using Cyclone Separator: ObjectiveDocumento16 pagineExperiment 1: Dust Removal From Gas Using Cyclone Separator: ObjectivenaquiahoNessuna valutazione finora

- Results, Discussion, Recommendations, AppendixDocumento4 pagineResults, Discussion, Recommendations, Appendixpc_renewNessuna valutazione finora

- Cross FlowDocumento14 pagineCross FlowFoong Shiuh HaurNessuna valutazione finora

- Soil Hydrometer Analysis ReportDocumento21 pagineSoil Hydrometer Analysis ReportsipilPI12Nessuna valutazione finora

- Calibration of Venturimeter and OrificemeterDocumento6 pagineCalibration of Venturimeter and Orificemeteranil chejara83% (6)

- Fisher Model 95 Manual 14311A - 296027Documento38 pagineFisher Model 95 Manual 14311A - 296027gnv7770% (1)

- ECHELON ENVIRONMENTAL ENGINEERING LABDocumento36 pagineECHELON ENVIRONMENTAL ENGINEERING LABsaurav rajNessuna valutazione finora

- Masinde Muliro University of Science and TechnologyDocumento51 pagineMasinde Muliro University of Science and TechnologyKelvho GitongaNessuna valutazione finora

- Drilling Lab Experiment on Mud Cake Thickness and Water LossDocumento7 pagineDrilling Lab Experiment on Mud Cake Thickness and Water LossAbdullwahid AhmedNessuna valutazione finora

- Differential Equation For The Rate of Capillary Action of Water On A Single Brand Tissue PaperDocumento8 pagineDifferential Equation For The Rate of Capillary Action of Water On A Single Brand Tissue Paperjohn_42494Nessuna valutazione finora

- Xpress 500 Changeover TimeDocumento3 pagineXpress 500 Changeover Timeltrevino100Nessuna valutazione finora

- Plate and Frambhhe LAB REPORTDocumento10 paginePlate and Frambhhe LAB REPORTrossangel35Nessuna valutazione finora

- Sedimentation, Filtration, and Thickening CalculationsDocumento1 paginaSedimentation, Filtration, and Thickening CalculationsDwaipayan PradhanNessuna valutazione finora

- Baghouse Design For Milk Powder CollectionDocumento262 pagineBaghouse Design For Milk Powder Collectionthalispacceli7566Nessuna valutazione finora

- Venturimeter ExpDocumento12 pagineVenturimeter ExpAmoluck BhatiaNessuna valutazione finora

- Filter Press Experiment for Chemical Engineering LabDocumento4 pagineFilter Press Experiment for Chemical Engineering Labgravity_coreNessuna valutazione finora

- Basic Laboratory Techniques CHM 138Documento12 pagineBasic Laboratory Techniques CHM 138Iffah Hazwani0% (1)

- Lab CO1: Fundamentals of Pressure, Viscosity: and Surface Tension of Fluids BMM 3521 Engineering Fluid MechanicsDocumento21 pagineLab CO1: Fundamentals of Pressure, Viscosity: and Surface Tension of Fluids BMM 3521 Engineering Fluid MechanicsIr Mathan RajNessuna valutazione finora

- W13 CIVE375 Lab4Documento7 pagineW13 CIVE375 Lab4nenephNessuna valutazione finora

- Water Filtration Lab Report AnalysisDocumento10 pagineWater Filtration Lab Report AnalysisvalerieNessuna valutazione finora

- Barometric Column Filtration V/s Filtrate Pump Filtration Comparison: Case StudyDocumento8 pagineBarometric Column Filtration V/s Filtrate Pump Filtration Comparison: Case StudyEusebio Castillo MejiaNessuna valutazione finora

- Week 3 (2) - Hydrometer (Level 0)Documento6 pagineWeek 3 (2) - Hydrometer (Level 0)Syed Zulfaizzuan AljufriNessuna valutazione finora

- Lab ReportDocumento7 pagineLab ReportMuhammed Zahir XoshnawNessuna valutazione finora

- Asee-Midwest 0008 6430aaDocumento13 pagineAsee-Midwest 0008 6430aaAysun GüvenNessuna valutazione finora

- Unit Operations Tutorial 2015-2016Documento13 pagineUnit Operations Tutorial 2015-2016hazimraad0% (1)

- Problem Set 4 - FiltrationDocumento3 pagineProblem Set 4 - FiltrationAki EspaldonNessuna valutazione finora

- Experiment 1 - Infiltration TestDocumento8 pagineExperiment 1 - Infiltration TestEiyra NadiaNessuna valutazione finora

- Experiment 3 Full Report LatestDocumento17 pagineExperiment 3 Full Report LatestChan Chun Chen100% (2)

- RECYCLEDocumento34 pagineRECYCLEEmonbeifo Efosasere100% (1)

- Concrete Group Report Term 2Documento9 pagineConcrete Group Report Term 2Andrea Rodriguez YepesNessuna valutazione finora

- 1.0 Objectives: Mass Transfer 2Documento12 pagine1.0 Objectives: Mass Transfer 2Laila Faeizah100% (1)

- Assignment (Plate and Frame Filter Press) Group A-8)Documento22 pagineAssignment (Plate and Frame Filter Press) Group A-8)Sajjad Rasool Chaudhry0% (4)

- Azeem Khan B00230817 Cstrs in Series Tht-2 Report DR Mojtaba MirzaeianDocumento11 pagineAzeem Khan B00230817 Cstrs in Series Tht-2 Report DR Mojtaba MirzaeianAzeem KhanNessuna valutazione finora

- Final Exam Soil and Water Conservation Spring 2020Documento5 pagineFinal Exam Soil and Water Conservation Spring 2020Umar iqbalNessuna valutazione finora

- DR RS Tutorial Sheet-Mechanical OperationsDocumento8 pagineDR RS Tutorial Sheet-Mechanical OperationsNguyễn Hoàng QuânNessuna valutazione finora

- Standardization of Volumetric GlasswareDocumento8 pagineStandardization of Volumetric GlasswareJIEHASMARTNessuna valutazione finora

- CHPR4405 Sample Exam2Documento7 pagineCHPR4405 Sample Exam2Elena TodorovskaNessuna valutazione finora

- Analytical ReportDocumento5 pagineAnalytical ReportUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- CPSBDocumento94 pagineCPSBNishanth MehanathanNessuna valutazione finora

- Activated SludgeDocumento13 pagineActivated SludgeUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- Adsorption LiteratureDocumento18 pagineAdsorption LiteratureUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- Waste Water Treatment SCNDocumento7 pagineWaste Water Treatment SCNUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- Catalytic Oxidation FormularsDocumento1 paginaCatalytic Oxidation FormularsUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- Layout of A Chemical Reactor FormularsDocumento1 paginaLayout of A Chemical Reactor FormularsUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- TC Tech Tree The Modific PDFDocumento18 pagineTC Tech Tree The Modific PDFWilman CuervoNessuna valutazione finora

- Ferric Iron MethodDocumento8 pagineFerric Iron MethodUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- Activited Sludge PersonalDocumento33 pagineActivited Sludge PersonalUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- Adsorption of Activated CarbonDocumento14 pagineAdsorption of Activated CarbonUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- Activated Sludge FormulaeDocumento1 paginaActivated Sludge FormulaeUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- List of IEE ExamsDocumento3 pagineList of IEE ExamsUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- Langmuir Adsorption Isotherm EquationDocumento6 pagineLangmuir Adsorption Isotherm EquationUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- Mechanism of CO Formation in Reverse Water-Gas Shift Reaction Over Cu/Al O CatalystDocumento4 pagineMechanism of CO Formation in Reverse Water-Gas Shift Reaction Over Cu/Al O CatalystUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- Modeling and simulation of methanation catalytic reactorDocumento8 pagineModeling and simulation of methanation catalytic reactorMartin NizNessuna valutazione finora

- Participants: List Your Information On These LinesDocumento1 paginaParticipants: List Your Information On These LinesUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- High-Temperature Kinetics of The Homogeneous Reverse Water-Gas Shift ReactionDocumento14 pagineHigh-Temperature Kinetics of The Homogeneous Reverse Water-Gas Shift ReactionUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- Faculty Norms For Electrical Engineering, Mechanical Engineering, Civil Engineering and Chemical EngineeringDocumento8 pagineFaculty Norms For Electrical Engineering, Mechanical Engineering, Civil Engineering and Chemical EngineeringUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- Sodasayudha StotramDocumento1 paginaSodasayudha StotramUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- PET Bottles ManufacturingDocumento7 paginePET Bottles ManufacturingUmesh Kumar Sharma Ramamoorthi100% (1)

- Amaidhiyum Aarokiyamum (Monthly Magazine) - August MonthDocumento30 pagineAmaidhiyum Aarokiyamum (Monthly Magazine) - August MonthSankara Narayanan100% (1)

- A Simple CEOSDocumento9 pagineA Simple CEOSnghiabactramyNessuna valutazione finora

- Kali KavachDocumento10 pagineKali KavachUmesh Kumar Sharma Ramamoorthi0% (1)

- Equation of StateDocumento6 pagineEquation of StateJanardhan CnNessuna valutazione finora

- ThiramDocumento4 pagineThiramUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- Greenports EnglischDocumento52 pagineGreenports EnglischUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- Properties of Gases Lecture NotesDocumento24 pagineProperties of Gases Lecture NotesVivek AgrawalNessuna valutazione finora

- Phase Equilibria and Fluid Properties in The Chemical Industry Estimation and CorrelationDocumento436 paginePhase Equilibria and Fluid Properties in The Chemical Industry Estimation and CorrelationUmesh Kumar Sharma RamamoorthiNessuna valutazione finora

- The Derivation of Van Der Waals Equation of State For Real GasesDocumento6 pagineThe Derivation of Van Der Waals Equation of State For Real GasesMike Alex50% (2)

- 9AKK101130D1664 OISxx Evolution PresentationDocumento16 pagine9AKK101130D1664 OISxx Evolution PresentationfxvNessuna valutazione finora

- Rubric - Argumentative EssayDocumento2 pagineRubric - Argumentative EssayBobNessuna valutazione finora

- IEC-60721-3-3-2019 (Enviromental Conditions)Documento12 pagineIEC-60721-3-3-2019 (Enviromental Conditions)Electrical DistributionNessuna valutazione finora

- BSC6900 UMTS V900R011C00SPC700 Parameter ReferenceDocumento1.010 pagineBSC6900 UMTS V900R011C00SPC700 Parameter Referenceronnie_smgNessuna valutazione finora

- E Learning: A Student Guide To MoodleDocumento16 pagineE Learning: A Student Guide To MoodleHaytham Abdulla SalmanNessuna valutazione finora

- BMXNRPDocumento60 pagineBMXNRPSivaprasad KcNessuna valutazione finora

- Overview for Report Designers in 40 CharactersDocumento21 pagineOverview for Report Designers in 40 CharacterskashishNessuna valutazione finora

- StsDocumento10 pagineStsSamonte, KimNessuna valutazione finora

- Maximizing modular learning opportunities through innovation and collaborationDocumento2 pagineMaximizing modular learning opportunities through innovation and collaborationNIMFA SEPARANessuna valutazione finora

- Agricultural Sciences P1 Nov 2015 Memo EngDocumento9 pagineAgricultural Sciences P1 Nov 2015 Memo EngAbubakr IsmailNessuna valutazione finora

- Consumer Behaviour Towards AppleDocumento47 pagineConsumer Behaviour Towards AppleAdnan Yusufzai69% (62)

- Published Filer List 06072019 Sorted by CodeDocumento198 paginePublished Filer List 06072019 Sorted by Codeherveduprince1Nessuna valutazione finora

- LLM DissertationDocumento94 pagineLLM Dissertationjasminjajarefe100% (1)

- Mark Dean GR6211 Fall 2018 Columbia University: - Choice Theory'Documento5 pagineMark Dean GR6211 Fall 2018 Columbia University: - Choice Theory'bhaskkarNessuna valutazione finora

- VNC Function Operation InstructionDocumento11 pagineVNC Function Operation InstructionArnaldo OliveiraNessuna valutazione finora

- English Skills BookDocumento49 pagineEnglish Skills BookAngela SpadeNessuna valutazione finora

- EE-434 Power Electronics: Engr. Dr. Hadeed Ahmed SherDocumento23 pagineEE-434 Power Electronics: Engr. Dr. Hadeed Ahmed SherMirza Azhar HaseebNessuna valutazione finora

- Hastrof Si Cantril. 1954. The Saw A Game. A Case StudyDocumento6 pagineHastrof Si Cantril. 1954. The Saw A Game. A Case Studylandreea21Nessuna valutazione finora

- Assignment 3 Part 3 PDFDocumento6 pagineAssignment 3 Part 3 PDFStudent555Nessuna valutazione finora

- Relay Coordination Using Digsilent PowerFactoryDocumento12 pagineRelay Coordination Using Digsilent PowerFactoryutshab.ghosh2023Nessuna valutazione finora

- Linguistics: Chapter 1 - 10Documento41 pagineLinguistics: Chapter 1 - 10Ahmad A. JawadNessuna valutazione finora

- Form 1 ADocumento2 pagineForm 1 ARohit Jain100% (1)

- ArtigoPublicado ABR 14360Documento14 pagineArtigoPublicado ABR 14360Sultonmurod ZokhidovNessuna valutazione finora

- Jesus - The Creator Unleashes Our Creative PotentialDocumento1 paginaJesus - The Creator Unleashes Our Creative PotentialKear Kyii WongNessuna valutazione finora

- EG-45-105 Material Information Sheet (Textura) V2Documento4 pagineEG-45-105 Material Information Sheet (Textura) V2GPRNessuna valutazione finora

- Test SessionDocumento2 pagineTest SessionMuhammad Fiaz AslamNessuna valutazione finora

- Arduino Nano based K1EL Winkeyer compatible CW contest keyerDocumento35 pagineArduino Nano based K1EL Winkeyer compatible CW contest keyerSreejith SreedharanNessuna valutazione finora

- D257272 1200 FDD 002 R1 PDFDocumento420 pagineD257272 1200 FDD 002 R1 PDFTap Toan100% (1)

- HU675FE ManualDocumento44 pagineHU675FE ManualMar VeroNessuna valutazione finora

- OROLO & W. D. GannDocumento56 pagineOROLO & W. D. GannGaurav Garg100% (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDa EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionValutazione: 4.5 su 5 stelle4.5/5 (542)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemDa EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionNessuna valutazione finora

- Asset Integrity Management for Offshore and Onshore StructuresDa EverandAsset Integrity Management for Offshore and Onshore StructuresNessuna valutazione finora

- Ramblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowDa EverandRamblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowNessuna valutazione finora

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Da EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Valutazione: 5 su 5 stelle5/5 (1)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsDa EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsValutazione: 4 su 5 stelle4/5 (1)

- 8051 Microcontroller: An Applications Based IntroductionDa Everand8051 Microcontroller: An Applications Based IntroductionValutazione: 5 su 5 stelle5/5 (6)

- Beginner's Guide to Reading Schematics, Third EditionDa EverandBeginner's Guide to Reading Schematics, Third EditionNessuna valutazione finora

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDa EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionValutazione: 4 su 5 stelle4/5 (331)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersDa Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersValutazione: 5 su 5 stelle5/5 (1)

- Build Your Own Electric Vehicle, Third EditionDa EverandBuild Your Own Electric Vehicle, Third EditionValutazione: 4.5 su 5 stelle4.5/5 (3)

- Understanding Automotive Electronics: An Engineering PerspectiveDa EverandUnderstanding Automotive Electronics: An Engineering PerspectiveValutazione: 3.5 su 5 stelle3.5/5 (16)

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsDa EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsValutazione: 5 su 5 stelle5/5 (2)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Da EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Valutazione: 4.5 su 5 stelle4.5/5 (2)

- Industrial Piping and Equipment Estimating ManualDa EverandIndustrial Piping and Equipment Estimating ManualValutazione: 5 su 5 stelle5/5 (7)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideDa EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideValutazione: 2 su 5 stelle2/5 (1)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesDa EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesValutazione: 5 su 5 stelle5/5 (1)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesDa EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertValutazione: 3 su 5 stelle3/5 (2)

- Current Interruption Transients CalculationDa EverandCurrent Interruption Transients CalculationValutazione: 4 su 5 stelle4/5 (1)

- Beginner's Guide to Reading Schematics, Fourth EditionDa EverandBeginner's Guide to Reading Schematics, Fourth EditionValutazione: 3.5 su 5 stelle3.5/5 (10)

- The Rare Metals War: the dark side of clean energy and digital technologiesDa EverandThe Rare Metals War: the dark side of clean energy and digital technologiesValutazione: 5 su 5 stelle5/5 (2)

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDa EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeValutazione: 5 su 5 stelle5/5 (8)