Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hanson Railroad Crossing

Caricato da

djprasadCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hanson Railroad Crossing

Caricato da

djprasadCopyright:

Formati disponibili

Premier Modular Railroad Crossings

Product Catalog

HEIDELBERGCEMENT Group

Topic

Section.Page

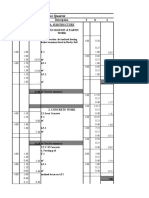

Premier Railroad Crossing ....................................................................................... 10.0 Cover Page ..................................................................................................................... 10.1 Index ............................................................................................................................... 10.2 General Notes ......................................................................................................10.3 - 10.4 Typical Section and Superelevated Section .................................................................... 10.5 Curved Alingments (Diverged Units) ............................................................................... 10.6 Curved Alingments (Tapered Units)) ............................................................................... 10.7 Boot and Optional Fillers ................................................................................................. 10.8 4' - 0" Concrete Unit (Isometric View) ............................................................................. 10.9 4' - 0" Concrete Unit (Plan View) ...................................................................................10.10 8' - 0" Concrete Unit (Isometric View) ........................................................................... 10.11 8' - 0" Concrete Unit (Plan View) ...................................................................................10.12 4' - 0" Premier Plus Unit (Isometric View) ..................................................................... 10.13 4' - 0" Premier Plus Unit (Plan View) ............................................................................. 10.14 8' - 0" Premier Plus Unit (Isometric View) ..................................................................... 10.15 8' - 0" Premier Plus Unit (Plan View) ............................................................................. 10.16

TITLE

PLANT

SECTION PAGE

DATE

Premier Modular Railroad Crossing Page Index

10.2

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossings

Premier Notes

The following notes shall apply unless noted otherwise on the plans or specifications. In the case of conflict with the plans or specifications, the more restrictive requirements shall apply.

Reference Specifications:

HIGHWAY LIVE LOADING, AASHTO LRFD Bridge Design Specifications, Section 36 Standard design capacity is HS20. RAIL LIVE LOAD AND GENERAL DESIGN AREMA MANUAL FOR RAILWAY ENGINEERING. Standard design capacity is Cooper E80.

Concrete

1. Aggregate conforms to ASTM C33. 2. Portland cement conforms to ASTM C150. 3. Fly ash conforms to ASTM C618. 4. Minimum compressive strength (at 28 days) = 7,000 p.s.i. unless greater strength is required by project specifications.

Reinforcing Steel

1. All bar reinforcing steel conforms to ASTM A706. 2. Welded wire fabric conforms to ASTM A497, 65 KSI. 3. Concrete cover of reinforcing steel conforms to AREMA Standard.

Installation

1. Prior to dismantling the track assembly, stake out the alignment for the new crossing with offsets located every four track feet. 2. Remove existing track assembly including all rail, hardware, ties, and ballast. Remove subgrade below the ballast to the hardpan. 3. Inspect for proper drainage and deficient subgrade. Remove any deficient subgrade material. The overall excavation should be at least 10 feet wide to accommodate the new construction. 4. Prepare the new subgrade with clean granular material or a controlled low strength material (CLSM or flowable fill). The top 6 inches of the subgrade is formed and screeded level. Granular material is placed in four inch lifts to finished top of subgrade. This material is compacted to 95% proctor density. Screed top of subgrade to level. The subgrade is compacted again which will typically create a 3/4 inch gap to the top of subgrade. Compact 3/8 inch minus crushed stone (screenings) to top of subgrade. The subgrade is now complete for the granular subgrade option. If using CLSM, place the CLSM to the top of the leveling form. Screed the CLSM and allow to cure. For this option, the subgrade is complete. 5. Establish the centerline of the existing track. Mark the centerline at the bottom of the premier module, For a curved alignment, use offsets from centerline at four foot increments. Reference curve data chart for proper module spacing. 6. When placing modules for tangent track use 1/4 inch shims between modules. When placing modules on a curved alignment, refer to the curved data chart. Gaps are required between modules to prevent spalling. Make note at this time if beveled ends are used in the crossing. 7. Remove both center panels together and stack outside the immediate working area. Clean threaded inserts of fallen debris and protect the inserts to prevent debris from filling the insert during installation. Pull rail into position by pulling the rail from the middle of the existing track and through the middle of the modules. This ensures that a mishandled rail does not chip the exposed portion of the module. (Notes continued on next page.)

TITLE

PLANT

SECTION PAGE

DATE

Premier Modular Railroad Crossing General Notes

10.3

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossings

Premier Notes

Installation

(Continued)

(Continued)

8. After the rail is in position, lift it high enough to install the rubber boot. Unroll the boot and position the boot under the rail. Unfold the boot. Apply the rail boot continuously from one end of the rail to the other. Applying the boot from more than one location will create a bubble between the boot and the rail. Make sure the high side edge of the rubber boot is toward the field side of the rail. 9. Apply lubrication (Module rail slick) to the rail seat of the module. 10. Place the rail snug into the rail seat. Place track jacks end-to-end and jack the rail into the rail seat. Use two sets of track jacks at 4 to 8 foot intervals and leapfrogging the jacks as you install the center panels. On extreme degree curves, leapfrog the track jacks in 4 foot intervals. 11. Install the center panels simultaneously and align the holes for the anchor bolts. 12. Install the anchor bolts by hand first, and then tighten them to 125 lbs. per foot maximum. OVER TIGHTEN. DO NOT

13. At the ends of the crossing, cut the rail boot flush and install two rail anchors per rail at each end of the module. 14. Inform the contractor placing the asphalt that roller equipment will damage the Premier Modules.

TITLE

PLANT

SECTION PAGE

DATE

Premier Modular Railroad Crossing General Notes

10.4

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossings

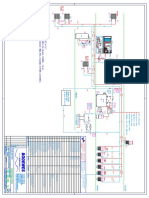

Premier Unit Leveling Gravel or Stone Dust 3/ " or Less 8

Roadway Surface Roadway Subgrade

New Granular Material Compacted Exsisting Hard Pan Compacted or Undisturbed Native Soil

Granular Material

Premier Unit CLSM or Flowable Fill

Roadway Surface Roadway Subgrade

New Granular Material Compacted

Exsisting Hard Pan

Compacted or Undisturbed Native Soil

CLSM or Flowable Fill

TITLE

PLANT

SECTION PAGE

DATE

Premier Modular Railroad Crossing Typical Section

10.5

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossings

Center Panel Anchor Bolt Typical (2) Each Panel 2 Ton Ring Clutch Lifting Anchor Typical (1) Each Panel Divergence (Gap) 4' - 0" O.D. Center Panel x 4' - 0"

8' - 0" O.D.

4' - 0" Recessed Diamond Pattern Typical (4) Places Base Panel x 4' - 0"

4' - 0" Symmetrical Units

Notes: (1.) Premier units may be laid referring to the "Curve Data

Chart" for Divergence (Gap).

(2.) Tapered sections may be used to reduce divergence. (3.) Taper shortens one side of 4' - 0" section by 1 inch.

TITLE PLANT SECTION PAGE

DATE

Premier Modular Railroad Crossing Curved Alingments (Diverged)

10.6

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossings

Center Panel Anchor Bolt Typical (2) Each Panel 2 Ton Ring Clutch Lifting Anchor Typical (1) Each Panel Divergence (Gap) 4' - 0" O.D. Center Panel x 4' - 0"

8' - 0" O.D.

3' - 11" Recessed Diamond Pattern Typical (4) Places Base Panel x 4' - 0"

4' - 0" Tapered Units

Notes: (1.) Premier units may be laid referring to the "Curve Data

Chart" for Divergence (Gap).

(2.) Tapered sections may be used to reduce divergence. (3.) Taper shortens one side of 4' - 0" section by 1 inch.

TITLE PLANT SECTION PAGE

DATE

Premier Modular Railroad Crossing Curved Alingments (Tapered)

10.7

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossing - Curve Data Chart Symmetrical Module

Curve Curve Radius (degrees) (ft.) 1 2 3 4 5 6 6 7 7 8 8 9 9 10 10 11 11 12 12 13 13 14 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 5729.7 2864.9 1910.1 1432.7 1146.3 955.4 881.9 819.0 764.5 716.8 674.7 637.3 603.8 537.7 546.4 521.7 499.1 478.3 459.3 441.7 425.4 410.3 396.2 383.1 359.3 338.3 319.6 302.9 287.9 274.4 262.0 250.8 240.5 231.0 222.3 214.2 206.7 199.7 193.2 187.1 181.4 176.0 171.0 166.3 Low Side Gap (in) 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 1/ 1/ 1/ 1/ 1/ 1/ 1/ 1/ 1/ 1/ 1/ 1/ 1/ 1/ 1/ 1/ 1/ 1/ 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

48" Tapered to 47" Module

Low Side Gap (in) 0.859 0.792 0.724 0.690 0.657 0.624 0.591 0.568 0.525 0.492 0.459 0.426 0.393 0.360 0.327 0.294 0.261 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 7/ 8 13/ 16

3/ 11/ 5/ 5/ 9/ 9/ 4 16 8 8

High Side Gap (in) 0.327 0.395 0.462 0.530 0.564 0.597 0.631 0.665 0.699 0.733 0.767 0.801 0.835 0.869 0.903 0.937 0.971 1.005 16 3/ 8 7/ 16 1/ 2 9/ 16 9/ 16 5/ 8 11/ 16 11/ 16 3/ 4 3/ 4 13/ 16 13/ 16 7/ 8 7/ 8 15/ 16 5/

High Side Gap (in) 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.250 0.327 0.386 0.453 0.519 0.586 0.653 0.719 0.786 0.852 0.919 0.985 1.051 1.118 1.184 1.250 1.317 1.382 1.448 1.514 1.580 1/ 4 1/ 4

1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 5/ 16 5/ 8 7/ 16 1/ 2 9/ 16 5/ 8 11/ 16 3/ 4 7/ 8 15/ 16

16

1 1 -

16 1/ 2 1/ 2 7/ 16 7/ 16 3/ 8 3/ 8 3/ 8 5/ 16 5/ 16 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4 1/ 4

1 1 1/16 1 1/8 1 3/16 1 1/4 1 5/16 1 3/8 1 1/2 1 5/8 1 3/4

TITLE

PLANT

SECTION PAGE

DATE

Premier Modular Railroad Crossing Curve Data Chart

10.8

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossings

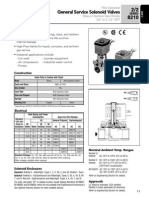

Rail

Rail Boot

Rail with Standard Boot

Standard Flangeway Filler (Optional for Transit Applications)

Rail

Rail Boot

Rail with Boot & Flangeway Filler

Walkway Flangeway Filler (Optional for Transit Applications in Walkway Area, Provides an ADA Approved Crossing)

Rail

Rail Boot

Rail with Boot & Walkway Filler

TITLE

PLANT

SECTION PAGE

DATE

Premier Modular Railroad Crossing Boot & Optional Fillers

10.9

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossings

Base Panel x 4' - 0"

2 Ton Ring Clutch Lifting Anchor Typical (1) Place Center Panel x 4' - 0" Center Panel Anchor Bolt Typical (2) Places

Recessed Diamond Pattern Typical (4) Places

4' - 0" O.D. 8' - 0" O.D.

4' - 0" O.D. Rail and Rail Boot Not Shown for Clarity 2 Ton Ring Clutch Lifting Anchor Typical (2) Places

6" Ref.

3' - 6" 2 Ton Ring Clutch Lifting Anchor Typical (2) Places

6" Ref. Varies 45

1 1/2" Lifting Hole Typical (2) Places 4' - 0" O.D.

Base Panel x 4' - 0"

Optional Beveled Edge Detail

TITLE

PLANT

SECTION PAGE

DATE

Premier Modular Railroad Crossing 4' - 0" Premier Unit (Isometric View)

10.10

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossings

8' - 0" O.D. Base Panel x 4' - 0" Center Panel x 4' - 0"

2 Ton Ring Clutch Lifting Anchor Typical (1) Each 4' - 0" O.D.

4' - 0" O.D.

Rail (Boot Not Shown for Clarity)

Plan View

Base Panel x 4' - 0" 1' - 7 3/4" 56 1/2" (4' - 8 1/2") Track Gauge 1' - 7 3/ " 4

3/ " Anchor Bolt 4 Typical (2) Each Panel

Rail (Boot Not Shown for Clarity)

3/ " Anchor Bolt 4

Typical (2) Each Panel

A 6"

Base Panel x 4' - 0" B

1/ " 2

Center Panel x 4' - 0"

Section A-A

Panel Geometry: 100 RB Pound Rail 100 RE/105 Dudly Rail 112/115 Pound Rail 132/136 Pound Rail A (in.) 5 3/4 6 6 13/16 7 5/

16

B (in.) 2' - 4 5/8 2' - 4 5/8 2' - 4 3/4 2' - 5

Base Wt. (Lbs.) 3,450 3,500 3,600 3,700

Center Wt. (ea.) (Lbs.) 525 550 600 650

TITLE

PLANT

SECTION PAGE

DATE

Premier Modular Railroad Crossing 4' - 0" Premier Unit (Plan View)

10.11

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossings

Base Panel x 8' - 0"

2 Ton Ring Clutch Lifting Anchor Typical (2) Places Center Panel x 8' - 0"

Recessed Diamond Thread Pattern Typ. (4) Places

Center Panel Anchor Bolt Typical (2) Places

8' - 0" O.D. 8' - 0" O.D. 1 1/2" Lifting Hole Typical (2) Places

Rail and Rail Boot Not Shown for Clarity

2 Ton Ring Clutch Lifting Anchor Typical (4) Places

6" Ref.

7' - 6" 2 Ton Ring Clutch Lifting Anchor Typical (4) Places

6" Ref. Varies 45

Base Panel x 8' - 0" 8' - 0" O.D.

Optional Beveled Edge Detail

TITLE

PLANT

SECTION PAGE

DATE

Premier Modular Railroad Crossing 8' - 0" Premier Unit (Isometric View)

10.12

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossings

8' - 0" O.D. Base Panel x 8' - 0" Center Panel x 8' - 0"

3/ " Anchor Bolt 4 Typical (2) Each Panel

8' - 0" O.D. 2 Ton Ring Clutch Lifting Anchor Typical (2) Each

Plan View

Rail (Boot Not Shown for Clarity) Rail (Boot Not Shown for Clarity) 1' - 7 3/4" 56 1/2" (4' - 8 1/2") Track Gauge 1' - 7 3/4"

3/ " Anchor Bolt 4 Typical (2) Each Panel

A 6"

Base Panel x 8' - 0" B

1/ " 2

Center Panel x 8' - 0"

Section A-A

Panel Geometry: 100 RB Pound Rail 100 RE/105 Dudly Rail 112/115 Pound Rail 132/136 Pound Rail A (in.) 5 3/ 6 6 13/16 7 5/16

4

B (in.) 2' - 4 5/8 2' - 4 5/8 2' - 4 3/4 2' - 5

Base Wt. (Lbs.) 6,900 7,000 7,200 7,400

Center Wt. (ea.) (Lbs.) 1,050 1,100 1,200 1,300

TITLE

PLANT

SECTION PAGE

DATE

Premier Modular Railroad Crossing 8' - 0" Premier Unit (Plan View)

10.13

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossings

Base Panel x 4' - 0"

Plastic Filler Panel Typical (2) Places

Recessed Diamond Pattern Typical (4) Places

3/ " 4

Anchor Bolt Typical (3) Each Panel

4' - 0" O.D. 8' - 0" O.D. 4' - 0" O.D. Rail and Rail Boot Not Shown for Clarity 2 Ton Ring Clutch Lifting Anchor Typical (2) Places

6" Ref.

7' - 6" 2 Ton Ring Clutch Lifting Anchor Typical (4) Places

6" Ref. 45

1 1/2" Lifting Hole Typical (2) Places 4' - 0" O.D.

Base Panel x 4' - 0"

Optional Beveled Edge Detail

TITLE

PLANT

SECTION PAGE

DATE

Premier Modular Railroad Crossing 4' - 0" Premier Plus Unit (Isometric View)

10.14

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossings

Base Panel x 4' - 0"

8' - 0" O.D.

4' - 0" O.D.

Plastic Filler Panel Typical (2) Places

Rail (Boot Not Shown for Clarity)

4' - 0" O.D.

Typical (2) Each Panel

3/ " Anchor Bolt 4

Plan View

Rail (Boot Not Shown for Clarity) 1' - 7 3/4" 56 1/2" (4' - 8 1/2") Track Gauge 1' - 7 3/4"

3/ " 4

Anchor Bolt Typical (3) Each Panel

13"

Section A-A

Rail Clip Typical (2) Each Rail

Rail Clip Pocket Typical (2) Each Panel

Center Panel Geometry: 112/115 Pound Rail 132/136 Pound Rail

A 6 13/16" 7 5/16"

Weight 4,900 lbs. 4,900 lbs.

TITLE

PLANT

SECTION PAGE

DATE

Premier Modular Railroad Crossing 4' - 0" Premier Plus Unit (Plan View)

10.15

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossings

Base Panel x 8' - 0"

Plastic Filler Panel Typical (2) Places

Recessed Diamond Pattern Typical (3) Places

3/ " 4

Anchor Bolt Typical (6) Each Panel

8' - 0" O.D.

8' - 0" O.D.

1 1/ " Lifting Hole 2 Typical (2) Places

Rail and Rail Boot Not Shown for Clarity

2 Ton Ring Clutch Lifting Anchor Typical (4) Places

6" Ref.

7' - 6" 2 Ton Ring Clutch Lifting Anchor Typical (4) Places

6" Ref. 45

Base Panel x 4' - 0" 8' - 0" O.D.

Optional Beveled Edge Detail

TITLE

PLANT

SECTION PAGE

DATE

Premier Modular Railroad Crossing 8' - 0" Premier Plus Unit (Iso. View)

10.16

03-04-08

HEIDELBERGCEMENT Group

Premier Modular Railroad Crossings

8' - 0" O.D. Base Panel x 8' - 0"

Plastic Filler Panel Typical (2) Places 8' - 0" O.D.

Rail (Boot Not Shown for Clarity)

3/ " 4

Anchor Bolt Typical (6) Each Panel

Plan View

Rail (Boot Not Shown for Clarity) 1' - 7 3/4" 56 1/2" (4' - 8 1/2") Track Gauge 1' - 7 3/4"

3/ " 4

Anchor Bolt Typical (6) Each Panel

13"

Section A-A

Rail Clip Typical (4) Each Rail

Rail Clip Pocket Typical 4) Each Panel

Center Panel Geometry: 112/115 Pound Rail 132/136 Pound Rail

A 6 13/16" 7 5/16"

B 9,800 lbs. 9,800 lbs.

TITLE

PLANT

SECTION PAGE

DATE

Premier Modular Railroad Crossing 8' - 0" Premier Plus Unit (Plan View)

10.17

03-04-08

HEIDELBERGCEMENT Group

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Take Off Sheet Service QuarterDocumento36 pagineTake Off Sheet Service Quarterelias workuNessuna valutazione finora

- Mould Release Agent Article - April 2011Documento2 pagineMould Release Agent Article - April 2011Stacey HarperNessuna valutazione finora

- 9 19 j2363 Mohamad May 2022 93Documento11 pagine9 19 j2363 Mohamad May 2022 93hadeefffasfaNessuna valutazione finora

- Asme B16.9 Int 1993Documento13 pagineAsme B16.9 Int 1993SUSEINCANessuna valutazione finora

- 616-100-402a - 00 - Central Heating SchemeDocumento1 pagina616-100-402a - 00 - Central Heating SchemeAnonymous yyjpEsydasNessuna valutazione finora

- Triad Series: 3 Piece Ball ValvesDocumento8 pagineTriad Series: 3 Piece Ball Valvesevilnemesis133Nessuna valutazione finora

- Conectori HidrauliciDocumento121 pagineConectori HidrauliciAdi AdrianNessuna valutazione finora

- Construction Manual California PDFDocumento956 pagineConstruction Manual California PDFAlexander Ponce VelardeNessuna valutazione finora

- Hoesch (Con Parametri Per Diaframmi)Documento48 pagineHoesch (Con Parametri Per Diaframmi)PinoScribdNessuna valutazione finora

- Flygt Bs 2640 MT 226 5 6 KW 7 5 HP Salida 4Documento2 pagineFlygt Bs 2640 MT 226 5 6 KW 7 5 HP Salida 4MartinTPNessuna valutazione finora

- CP Carrillo HardwareDocumento23 pagineCP Carrillo HardwarePaul ZiddyNessuna valutazione finora

- LOD Spec 2016 Part I 2016-10-19 PDFDocumento207 pagineLOD Spec 2016 Part I 2016-10-19 PDFzakariazulkifli92Nessuna valutazione finora

- Valvula SolenoideDocumento6 pagineValvula SolenoideArnezNessuna valutazione finora

- Vinyl Catalog and Technical Information 2019Documento245 pagineVinyl Catalog and Technical Information 2019prateekmuleNessuna valutazione finora

- Indonesian Law on Building RequirementsDocumento58 pagineIndonesian Law on Building RequirementsNindy Ratri KNessuna valutazione finora

- PPT-FINAL - Light HouseDocumento46 paginePPT-FINAL - Light Housesunitasanga0% (1)

- En 1053 3Documento18 pagineEn 1053 3Alper ÇelikNessuna valutazione finora

- Country Presentation: MalaysiaDocumento12 pagineCountry Presentation: MalaysiaADBI Events100% (1)

- An Investigation On The Weldability of Grey Cast Iron Using Nickel Filler MetalDocumento5 pagineAn Investigation On The Weldability of Grey Cast Iron Using Nickel Filler MetalKhin Aung ShweNessuna valutazione finora

- Checklist PMS TBDocumento3 pagineChecklist PMS TBalsitorNessuna valutazione finora

- Method Statement: Scope of WorkDocumento8 pagineMethod Statement: Scope of WorkHaitham M A BecharaNessuna valutazione finora

- Method Statement: Conbextra GP2Documento5 pagineMethod Statement: Conbextra GP2diwakar1978Nessuna valutazione finora

- STUDBOLTS, THREADED RODS, AND HEAVY HEX NUTS FOR PETROCHEMICAL AND OFFSHOREDocumento1 paginaSTUDBOLTS, THREADED RODS, AND HEAVY HEX NUTS FOR PETROCHEMICAL AND OFFSHOREKamlesh LuharNessuna valutazione finora

- Schedule 40 Steel Pipe and ANSI SCH 40 Weight - Dimensions - PriceDocumento18 pagineSchedule 40 Steel Pipe and ANSI SCH 40 Weight - Dimensions - PriceDileep ChinganNessuna valutazione finora

- 1276-R0-STP - Kalyan Sagar - MahobaDocumento41 pagine1276-R0-STP - Kalyan Sagar - MahobaSilhoutte IllusionNessuna valutazione finora

- WBS-Engineering Project PlanDocumento3 pagineWBS-Engineering Project PlanM iqbalNessuna valutazione finora

- Boiler Operating Sequence-Rev1Documento11 pagineBoiler Operating Sequence-Rev1Ran NNessuna valutazione finora

- Cement Metering ValveDocumento11 pagineCement Metering ValveWise SoNessuna valutazione finora

- Data Sheet Murfor - Type GERDocumento1 paginaData Sheet Murfor - Type GERMelo PereiraNessuna valutazione finora

- NationalStandardForConstructionWork NOHSC1016-2005 PDF PDFDocumento31 pagineNationalStandardForConstructionWork NOHSC1016-2005 PDF PDFRemer JalbunaNessuna valutazione finora