Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

5 Pidicrete URP

Caricato da

K Sri KarthikDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

5 Pidicrete URP

Caricato da

K Sri KarthikCopyright:

Formati disponibili

Dr.

Fixit Pidicrete URP

S B R l at e x f o R w at e R P R o o f i n g a n d R e P a i R S

Description

Dr. Fixit Pidicrete URP is based on modified styrene butadiene latex supplied as a ready to use bonding agent in liquid consistency. it is used for repair of spalled concrete floors, columns, beams, chhajas, slabs & waterproofing of toilets & bathrooms, small terraces etc. as it bonds strongly to old & new concrete and to plasters. it reduces shrinkage, prevents cracking, dust pick up & improves abrasion resistance.

Areas of Application

for concrete repairs - Spalled concrete of floors, columns, beams, chhajas, slabs, parapets, etc. for waterproofing Small roof terraces, sunken portions of toilets & bathrooms, chhajas & lift pits, balconies & staircases. for waterproofing liquid & effluent tanks, car decks & walkways. as a bonding agent Bonding mortar for tiles & panels, as undercoat for special finishes such as top rendering coat for chemical resistant floors. as a bond coat for bonding of new concrete to old concrete, masonry stone work, plastering. for cladding fixing or re-fixing of slip bricks, tiles, stones & marble bedding. as external rendering weatherproof & frost resistant render, high wear & erosion resistant render. as bonding slurry coat for pinhole treatment on concrete surface & as repair mortar for overhead application.

Features & Benefits

Multipurpose it is multipurpose & economical product, easy to use. Cracking it prevents cracking by improving flexural strength. Hardness improves the hardness & prevents dust generation. Shrinkage Reduces drying & aging shrinkage cracks. Bonding Bond strongly to concrete, masonry, stonework, plasters, cementitious surfaces, asphalt & most of the building materials. erosion & corrosion improves erosion resistance & prevents corrosion. abrasion resistance improves abrasion resistance of the cement mix. grouting Reduces viscosity of cement injection grout for better fluidity & bonding.

Method of Application

1 S U R FAC E P R E PA R ATI O N

Clean the surface with wire brush or scrubber to remove hidden dirt, loose particles, laitance & dust. degrease the surface by using suitable solvents. Repair the spalled concrete portion by saw, cutting the extreme edges of the repair location to a depth of at lease 10 mm to avoid featheredging & to provide strong bond. Clean the concrete surface to remove any contamination where breaking is not possible. Roughen the surface by light scabbling or grit blasting. expose corroded rebar in the repairing area fully . Remove all loose scales & corrosion deposits and immediately clean the surface.

2 PRIMING

for priming of steel surface, apply Dr. Fixit Rust Remover to all exposed reinforcement area and wash it with water jet before applying Dr. Fixit Epoxy Zinc Rich Primer on the rebars. for priming of concrete substrate, the surface should be thoroughly saturated with potable water. Remove any excess of water prior to application. Slurry of primer coat is prepared by mixing of one part Dr. Fixit Pidicrete URP, one part of water and 3 parts of fresh oPC cement. Slowly mix cement with binder to obtain a smooth consistency. Continue mixing the slurry during application to prevent settlement.

Dr. Fixit Pidicrete URP

WATERPROOFING PRODUCTS

Dr. Fixit Pidicrete URP

S B R l at e x f o R w at e R P R o o f i n g a n d R e P a i R S

3 M IXI N G

4 A P P L I CATI O N

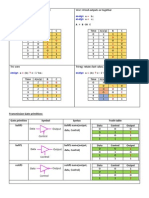

wide range of mix designs are recommended for different application using Dr. Fixit Pidicrete URP. Sl No. Application Patching & Repair Mortar 1

Composition

Quantity of Dr. Fixit Pidicrete URP 10 litres

Consistency & thickness Mortar consistency, 6-40 mm thickness

oPC 50 Kg graded sharp & washed sand 150 Kg water 10 litres oPC 50 Kg graded sharp & washed sand 75 Kg granite chips (3-6 mm) 75 Kg water 6 litres oPC 50 Kg graded sharp & washed sand 150 Kg water 6 litres oPC 50 Kg graded sharp & washed sand 125 Kg water 7 litres

Heavy duty floor screed 2

10 litres

Semi dry cohesive consistency, 10-40 mm thickness

Renders 3

10 litres

Mortar consistency, 6-9 mm thickness

Bonding Mortar for slip bricks & tiles

10 litres

Mortar consistency, 6-40 mm thickness.

Precautions & Limitations

do not add extra water or more than recommended dosage. Recommended dosage to be followed to achieve desired results.

Dr. Fixit Pidicrete URP

a forced action mixer is essential (Pan Mixer) & recommended to ensure that Dr. Fixit Pidicrete URP mortar is thoroughly mixed. Use a suitable sized drum with heavy-duty electrical drill machine fitted with spiral paddle mixer at slow speed of 400-500 rpm. Hand mixing is permissible only for 25 kg or less quantity. Charge the mixer with required quantity of clean & dry sand, cement & mix for 1-2 minutes, then add Dr. Fixit Pidicrete URP as per the dosages recommended. Mix for 2-3 minutes to avoid air entrapment. Keep on slowly adding water until the required consistency is achieved. do not add extra water.

WATERPROOFING PRODUCTS

Dr. Fixit Pidicrete URP

S B R l at e x f o R w at e R P R o o f i n g a n d R e P a i R S Technical Information

PROPERTIES SPECIFICATION RESULTS

Base Coverage total active solid content pH pot life Speciic gravity pH Compressive strength, n/mm2 7 tensile strength,n/mm2 flexural strength,n/mm2 Slant shear bond, n/mm2 Chemical resiatance to mild acids, alkalies, sulphates. Resistance to water pressure, bar freeze thaw resistance

PAC K I N G

SBR latex styerene, butadine rubber 20 22 sq ft/kg for two coats (URP + cement in ratio of 1:15) 34 2% 89 30 45 minutes at 30oC 1.01+/- 0.02 7 to 9 ( BS6319 part2:1983) ( aStM C 190-85) 35 days 3.3 11+/- 2 30 Resists mild acids, Upto 2 excellent

500 gm, 1 kg, 5 kg, 10 kg, 20 kg & 50 kg

Dosage

10 litres Dr. Fixit Pidicrete URP per 50 kg oPC cement.

Shelf Life & Storage

Shelf life is 12 months from the date of manufacturing. Store in a cool & dry place in unopened condition (Prevent from direct sunlight).

Health & Safety Precautions

Cementitious mortars & slurries modified with Dr. Fixit Pidicrete URP when mixed or when become damp, may release alkali which can be harmful to skin & eye. wear suitable protective clothings, gloves, eye protection and respiratory protective equipment during application. in case of contact with skin, rinse with plenty of clean water and then cleanse with soap water. in case of contact with eyes, rinse immediately with plenty of clean water and seek medical advise.

Dr. Fixit Pidicrete URP

WATERPROOFING PRODUCTS

Dr. Fixit Pidicrete URP

S B R l at e x f o R w at e R P R o o f i n g a n d R e P a i R S

Other Product Categories Available

dR. fixit has wide range of waterproofing & Construction chemicals which includes,

Pidilite Industries Limited

Construction Chemicals division Ramkrishna Mandir Road Post Box no. 17411 andheri (e) Mumbai 400059 india tel +91-22-2835 7000 fax +91-22-2835 7008 website www.doctor-fixit.com e-mail drfixit@pidilite.com

Toll Free No.: 1800-22-5502

DISCLAIMER the product information & application details given by the company & its agents has been provided in good faith & meant to serve only as a general guideline during usage. Users are advised to carry out tests & take trials to ensure on the suitability of products meeting their requirement prior to full scale usage of our products. Since the correct identification of the problems, quality of other materials used and the on-site workmanship are factors beyond our control, there are no expressed or implied guarantee / warranty as to the results obtained. the company does not assume any liability or consequential damage for unsatisfactory results, arising from the use of our products.

Dr. Fixit Pidicrete URP

waterproofing Products Repair Products Sealants flooring Products

exterior Coating Products tile fixing Range Concrete admixtures grouts

WATERPROOFING PRODUCTS

Potrebbero piacerti anche

- DR Fixit Pidicrete URP Waterproof CompoundDocumento4 pagineDR Fixit Pidicrete URP Waterproof CompoundjackofmanytradesNessuna valutazione finora

- Dr. Fixit Pidicrete URP 171 1 PDFDocumento4 pagineDr. Fixit Pidicrete URP 171 1 PDFManish Khaling RaiNessuna valutazione finora

- Pidicrete URPDocumento4 paginePidicrete URPsaaz adilNessuna valutazione finora

- DR Fixit Pidicrete MPB 71 1Documento3 pagineDR Fixit Pidicrete MPB 71 1vishutayalNessuna valutazione finora

- DR Fixit Floor Repair Mortar 66 1Documento3 pagineDR Fixit Floor Repair Mortar 66 1Suzaikumar R SanglikarNessuna valutazione finora

- DR Fixit SafeguardDocumento3 pagineDR Fixit SafeguardrpdeepuNessuna valutazione finora

- DR Fixit Pidiproof UrpDocumento2 pagineDR Fixit Pidiproof UrpRameshNessuna valutazione finora

- DR Fixit Super Latex 81 1Documento3 pagineDR Fixit Super Latex 81 1dapsiduNessuna valutazione finora

- Dr. Fixit Dampguard waterproof coatingDocumento3 pagineDr. Fixit Dampguard waterproof coatingManmohan SinghNessuna valutazione finora

- Damp FreeDocumento3 pagineDamp FreeblaqhaqarNessuna valutazione finora

- 60 Piditop 444Documento3 pagine60 Piditop 444Jay RajNessuna valutazione finora

- Waterproofing Membranes Under 40 CharactersDocumento4 pagineWaterproofing Membranes Under 40 CharactersshashiNessuna valutazione finora

- Dr. Fixit Pidifin 2K 177 1 PDFDocumento4 pagineDr. Fixit Pidifin 2K 177 1 PDFRameshNessuna valutazione finora

- 301 Dr. Fixit Pidicrete URPDocumento4 pagine301 Dr. Fixit Pidicrete URPAlpesh ShahNessuna valutazione finora

- Description Dr. Fixit Pidifin 2KDocumento4 pagineDescription Dr. Fixit Pidifin 2KshashiNessuna valutazione finora

- DR Fixit Rust RemoverDocumento2 pagineDR Fixit Rust RemoverSujay NahaldeNessuna valutazione finora

- Dr Fixit Pidicrete URP latex for repairs and waterproofingDocumento2 pagineDr Fixit Pidicrete URP latex for repairs and waterproofingrohit.rk2009262Nessuna valutazione finora

- DR Fixit Micro Concrete 69 1Documento3 pagineDR Fixit Micro Concrete 69 1Rahul AgarwalNessuna valutazione finora

- Damp FreeDocumento2 pagineDamp FreeShashi Bhushan SinghNessuna valutazione finora

- DR Fixit Pidiproof LWplusDocumento2 pagineDR Fixit Pidiproof LWplusvicky3k100% (1)

- DR Fixit Powder WaterproofDocumento2 pagineDR Fixit Powder Waterprooflokeshras12Nessuna valutazione finora

- 101 DR Fixit Pidiproof LW+ PDFDocumento2 pagine101 DR Fixit Pidiproof LW+ PDFRishabh VijayNessuna valutazione finora

- Dr. Fixit Pidicrete MPB acrylic concrete binderDocumento3 pagineDr. Fixit Pidicrete MPB acrylic concrete binderamandeepsuperanNessuna valutazione finora

- DR Fixit Powder Waterproof 49 1 PDFDocumento3 pagineDR Fixit Powder Waterproof 49 1 PDFSuraj SubhashNessuna valutazione finora

- Bio ShieldDocumento3 pagineBio ShieldVimal GopalakrishnanNessuna valutazione finora

- DR Fixit Polyplus CPDocumento4 pagineDR Fixit Polyplus CPLalith KumarNessuna valutazione finora

- Dr. Fixit Fastflex: DescriptionDocumento3 pagineDr. Fixit Fastflex: DescriptionmanorajcvNessuna valutazione finora

- Dr. Fixit Fastflex 108 1 PDFDocumento3 pagineDr. Fixit Fastflex 108 1 PDF41464147Nessuna valutazione finora

- RIPSTAR 130 acrylic polymer cement modifierDocumento3 pagineRIPSTAR 130 acrylic polymer cement modifierAnkita Baban GavadeNessuna valutazione finora

- 233 DR Fixit Pidicrete WPDocumento3 pagine233 DR Fixit Pidicrete WPreshmitapallaNessuna valutazione finora

- Dr. Fixit Crack - X Powder 85 1 PDFDocumento2 pagineDr. Fixit Crack - X Powder 85 1 PDF41464147Nessuna valutazione finora

- 36 Fevimate TLDocumento3 pagine36 Fevimate TLRavishankar SokkarNessuna valutazione finora

- Construction Chemical SuperplasticiserDocumento1 paginaConstruction Chemical SuperplasticiserAnup DaNessuna valutazione finora

- 7 Renderoc SP30Documento4 pagine7 Renderoc SP30samueltee212Nessuna valutazione finora

- DR Fixit General Repair Remedial Waterproofing GuideDocumento40 pagineDR Fixit General Repair Remedial Waterproofing Guidebalu119100% (1)

- Roff SupercreteDocumento3 pagineRoff Supercretehunky11Nessuna valutazione finora

- 642 DR Fixit Raincoat SelectDocumento3 pagine642 DR Fixit Raincoat Selectarchit singhNessuna valutazione finora

- DR - FIXIT - Krystalline (IMP)Documento4 pagineDR - FIXIT - Krystalline (IMP)Prasanth TalatotiNessuna valutazione finora

- Dr. Fixit Gapfill: DescriptionDocumento4 pagineDr. Fixit Gapfill: Descriptionhunky11Nessuna valutazione finora

- Dr. Fixit Dampguard 86 1 PDFDocumento2 pagineDr. Fixit Dampguard 86 1 PDF41464147Nessuna valutazione finora

- 24 Epoxy Injection GroutDocumento3 pagine24 Epoxy Injection GroutJaspreet Singh VermiNessuna valutazione finora

- DR Fixit General Repair Remedial Waterproofing Guide PDFDocumento40 pagineDR Fixit General Repair Remedial Waterproofing Guide PDFandrealeger755774Nessuna valutazione finora

- Proposal - Ayush ParkDocumento25 pagineProposal - Ayush ParkAvinash PhaseNessuna valutazione finora

- Sikagrout - 200: High Strength, Non-Shrink, None Oxidized Cementitious GroutDocumento2 pagineSikagrout - 200: High Strength, Non-Shrink, None Oxidized Cementitious Groutthe pilot100% (1)

- 1154 GB Concrete RetardersDocumento8 pagine1154 GB Concrete RetardersMadhu Priya100% (1)

- 404 Dr. Fixit Fevimate TG Tile GroutingDocumento3 pagine404 Dr. Fixit Fevimate TG Tile GroutingJoseph EzekielNessuna valutazione finora

- Pawan Enterprises: Dr. Fixit Trained ApplicatorDocumento5 paginePawan Enterprises: Dr. Fixit Trained ApplicatorMangesh GharatNessuna valutazione finora

- DR Fixit Pidifin 2 KDocumento3 pagineDR Fixit Pidifin 2 Ksubhaschandra100% (1)

- Novolac ScreedDocumento4 pagineNovolac Screedmd_kureshiNessuna valutazione finora

- Dr. Fixit RaincoatDocumento2 pagineDr. Fixit RaincoatnivasshaanNessuna valutazione finora

- Nitobond BB: Acrylic Emulsion Cement Modifier and Water Based Concrete Bonding Agent UsesDocumento4 pagineNitobond BB: Acrylic Emulsion Cement Modifier and Water Based Concrete Bonding Agent UseskalidindivenkatarajuNessuna valutazione finora

- Dr. Fixit Modern Tile Adhesive: DescriptionDocumento3 pagineDr. Fixit Modern Tile Adhesive: DescriptionkiranNessuna valutazione finora

- Polished PlasterDocumento3 paginePolished PlasterZubair IrshadNessuna valutazione finora

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsDa EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNessuna valutazione finora

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringDa EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringValutazione: 4 su 5 stelle4/5 (5)

- 4 - FunctionsDocumento23 pagine4 - FunctionsK Sri KarthikNessuna valutazione finora

- 3 - Booleans and ConditionalsDocumento26 pagine3 - Booleans and ConditionalsK Sri KarthikNessuna valutazione finora

- Functions allow code reuse in PythonDocumento2 pagineFunctions allow code reuse in Pythonbooklover2Nessuna valutazione finora

- Creating and Inheriting Classes in PythonDocumento2 pagineCreating and Inheriting Classes in Pythonbooklover2100% (1)

- 2 - Numbers - Math and CommentsDocumento24 pagine2 - Numbers - Math and CommentsK Sri KarthikNessuna valutazione finora

- Tutorial On Cadence Virtuoso - IISCDocumento8 pagineTutorial On Cadence Virtuoso - IISCK Sri KarthikNessuna valutazione finora

- Beginners Python Cheat Sheet PCC Testing PDFDocumento2 pagineBeginners Python Cheat Sheet PCC Testing PDFbooklover2Nessuna valutazione finora

- 5 - ListsDocumento41 pagine5 - ListsK Sri KarthikNessuna valutazione finora

- Python Lists in 40 CharactersDocumento2 paginePython Lists in 40 CharacterskiranNessuna valutazione finora

- Beginners Python Cheat Sheet PCC Files Exceptions PDFDocumento2 pagineBeginners Python Cheat Sheet PCC Files Exceptions PDFbooklover2Nessuna valutazione finora

- Verilog NetsDocumento2 pagineVerilog NetsK Sri KarthikNessuna valutazione finora

- E 01504456Documento4 pagineE 01504456Muhammad Yunus AndrianNessuna valutazione finora

- Digital Combinational Logic Part-IIDocumento4 pagineDigital Combinational Logic Part-IIK Sri KarthikNessuna valutazione finora

- 2D Arrays:: List (2) (List+2)Documento1 pagina2D Arrays:: List (2) (List+2)K Sri KarthikNessuna valutazione finora

- Differences Between PLL and DPLL and DLLDocumento3 pagineDifferences Between PLL and DPLL and DLLK Sri KarthikNessuna valutazione finora

- Introduction To UnixDocumento132 pagineIntroduction To UnixediklmusicNessuna valutazione finora

- Differences Between PLL and DPLL and DLLDocumento3 pagineDifferences Between PLL and DPLL and DLLK Sri KarthikNessuna valutazione finora

- UNIX IntroductionDocumento3 pagineUNIX IntroductionVysakh SreenivasanNessuna valutazione finora

- BPSK ModulatorDocumento5 pagineBPSK ModulatorTayran PrashadNessuna valutazione finora

- BPSKDocumento10 pagineBPSKMeta TumNessuna valutazione finora

- The Jindal Prize: Form 1ADocumento6 pagineThe Jindal Prize: Form 1AK Sri KarthikNessuna valutazione finora

- 2 GalanisDocumento8 pagine2 GalanisK Sri KarthikNessuna valutazione finora

- TVLSI 04 Sleep SwitchDocumento12 pagineTVLSI 04 Sleep SwitchK Sri KarthikNessuna valutazione finora

- ASIC Design CMOS Logic LatchesDocumento12 pagineASIC Design CMOS Logic LatchesK Sri KarthikNessuna valutazione finora

- Astm F139Documento5 pagineAstm F139diegomez84Nessuna valutazione finora

- Basic Mechanical Engineering MCQ PDF Part 3Documento10 pagineBasic Mechanical Engineering MCQ PDF Part 3kibrom atsbhaNessuna valutazione finora

- Application of Nanoparticles in AgricultureDocumento11 pagineApplication of Nanoparticles in AgricultureShetti Swamy PatelNessuna valutazione finora

- Chemical and Physical Prop of PetroleumDocumento35 pagineChemical and Physical Prop of Petroleumshivam tiwari100% (1)

- Chapter 3: Atomic and Ionic Arrangements: 3-1 SolutionDocumento52 pagineChapter 3: Atomic and Ionic Arrangements: 3-1 SolutionMarcos Jose100% (1)

- Construction and Building Materials: Baojian Zhan, Chi Sun Poon, Qiong Liu, Shicong Kou, Caijun ShiDocumento5 pagineConstruction and Building Materials: Baojian Zhan, Chi Sun Poon, Qiong Liu, Shicong Kou, Caijun ShiSara_ParkerNessuna valutazione finora

- M44 40seriesDocumento9 pagineM44 40seriesKaspar RapsakNessuna valutazione finora

- LIST OF TSD FACILITIESDocumento18 pagineLIST OF TSD FACILITIESAmelia SantosNessuna valutazione finora

- New Natron NXT Series Screen and Pad Printing Ink For Neoprene, Nitrile, EVA and EPDM Rubber From Boston Industrial Solutions, Inc.Documento2 pagineNew Natron NXT Series Screen and Pad Printing Ink For Neoprene, Nitrile, EVA and EPDM Rubber From Boston Industrial Solutions, Inc.PR.comNessuna valutazione finora

- Chapter Wise QuestionsDocumento6 pagineChapter Wise QuestionsDr. B. Sree Giri Prasad100% (2)

- MSDS Mindray M-30 LyseDocumento2 pagineMSDS Mindray M-30 LyseSandra HubayaNessuna valutazione finora

- Week 2 - Preparing Raw Materials For Salting and CuringDocumento36 pagineWeek 2 - Preparing Raw Materials For Salting and CuringLovely JavierNessuna valutazione finora

- Lecture 2 - Cellulose Structure PDFDocumento55 pagineLecture 2 - Cellulose Structure PDFpipers10Nessuna valutazione finora

- Astm c1161 13Documento19 pagineAstm c1161 13Taiana BonadioNessuna valutazione finora

- Partial replacement of discarded rubber tyres with coarse aggregate in concreteDocumento18 paginePartial replacement of discarded rubber tyres with coarse aggregate in concretePrasanna Gayathri VinnakotaNessuna valutazione finora

- Fisa Tehnica ROBODURDocumento1 paginaFisa Tehnica ROBODURdneprmt1Nessuna valutazione finora

- 2012 - Cosmetic Ingredient Review - Amended Safety Assessment of Alkyl Esters As Used in CosmeticsDocumento83 pagine2012 - Cosmetic Ingredient Review - Amended Safety Assessment of Alkyl Esters As Used in CosmeticsymiyazyNessuna valutazione finora

- Brochure Coating ConstructionDocumento16 pagineBrochure Coating ConstructionALİ ÖRSNessuna valutazione finora

- Toksikologi PDFDocumento134 pagineToksikologi PDFPurwani Ni NyomanNessuna valutazione finora

- Mysore Road Plastic Industry ListDocumento6 pagineMysore Road Plastic Industry ListjafarptrNessuna valutazione finora

- Calculations of Elastic Moduli of Polymer Crystals." II. TeryleneDocumento11 pagineCalculations of Elastic Moduli of Polymer Crystals." II. Teryleneapi-3733260Nessuna valutazione finora

- CBSE Class 12 Chemistry Previous Year Question Paper 2019 Set-3 QuestionDocumento6 pagineCBSE Class 12 Chemistry Previous Year Question Paper 2019 Set-3 QuestionVikram tomarNessuna valutazione finora

- Comparing antioxidant assays for estimating activity in guava extractsDocumento7 pagineComparing antioxidant assays for estimating activity in guava extractsFira KuswandariNessuna valutazione finora

- Equations of StateDocumento33 pagineEquations of StateDevika BharathanNessuna valutazione finora

- Cooling Towers: Key Design Factors and Operation PrinciplesDocumento8 pagineCooling Towers: Key Design Factors and Operation PrinciplesMade PutraNessuna valutazione finora

- NACE-MR0274 Mat Req For Polyolefin Cold-AppliedDocumento7 pagineNACE-MR0274 Mat Req For Polyolefin Cold-Appliedluis fernando beltran balderasNessuna valutazione finora

- Class 9 Matter in Our Surroundings McqsDocumento3 pagineClass 9 Matter in Our Surroundings McqsHariharan VIIA1Nessuna valutazione finora

- Sesv8002 PDFDocumento97 pagineSesv8002 PDFali100% (2)

- Pipes, Tubes, Fittings, FlangesDocumento121 paginePipes, Tubes, Fittings, FlangesCarl Jones100% (2)