Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Production Manager

Caricato da

api-792595050 valutazioniIl 0% ha trovato utile questo documento (0 voti)

53 visualizzazioni2 pagineProduction Manager with 12 years experience looking for a Middle Management position.

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

TXT, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoProduction Manager with 12 years experience looking for a Middle Management position.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato TXT, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

53 visualizzazioni2 pagineProduction Manager

Caricato da

api-79259505Production Manager with 12 years experience looking for a Middle Management position.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato TXT, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

GREGORY JAMES WILSON

5440 North Santa Monica Boulevard

Whitefish Bay, WI 53217

(414) 967-0121, gw10f8ea4@westpost.net

CAREER HIGHLIGHTS AND ACHIEVEMENTS

Production Supervisor (10 years)

Seasoned manufacturing supervisor with the following assignments:

Heavyweight/Middleweight Transmission Gear Machining, Harley-Davidson Motor Comp

any

Interim Area Manager Facilities and Maintenance, Harley-Davidson Motor Company

Middleweight Transmission Gear & Shaft Machining, Harley-Davidson Motor Company

Middleweight Cam, Flywheel, & Conn Rod Machining, Harley-Davidson Motor Company

Heat Treat, Tool Grind and Tool Room Supervision, Harley-Davidson Motor Company

Middle & Heavyweight Carrier/Case Assembly & Machining, American Axle & Manufact

uring

Middle & Heavyweight Carrier/Case Assembly & Machining, Visteon Corporation

Recruited by Joe Prodehl, Director-Steel Machining to Work Group Advisor III-Mid

dleweight & Heavyweight Transmission Gear Machining.Mr. Prodehl stated you have

proven yourself versatile and successful across all areas of the plant, you are

one of the few that can be placed anywhere and will be a success.Successfully re

duced middleweight cam unit cost at Harley-Davidson by eliminating 100% magna-fl

uxing of cams, which cost the company $1.2M in 2007.Consistently delivered depar

tmental metrics on quality, cost, delivery, and safety for over 5 years with Har

ley-Davidson. Recommended by my peers and selected by Plant Manager-Capitol Driv

e, as Interim Area Manager for Facilities and Maintenance, during consolidation

of Pilgrim Road and Capitol Drive Plants.Key member of 2009 Consolidation Team t

hat delivered 700+ machines to Pilgrim Road facility on-time and under budget wi

th no recordable injuries.Achieved production record at American Axle & Manufact

uring on 9.25 Rear Axle Assembly Line, defined to be capable of producing 800 ax

les in an 8 hour period.Achieved 900+ axles in same 8 hour period by developing

a cross-training and assembly rotation schedule for 23 UAW employees.Record prod

uction rates were maintained with daily incremental increases in output achievin

g an all time rate of 912 axles with no quality issues recorded.

Production Scheduler (3 years)

Proficient with material requirement planning to establish production schedules

for automotive drive systems and axle assemblies for Ford Motor Company Vehicle

Assembly Plants.Analyzed and compared bill of material to master production sche

dule, making manual adjustments to support changes in customer demand.Maintained

daily cycle counts and investigated any material shortages or non-receipt of ma

terials required to support production schedule. Became skilled at color codes o

f drive-shafts with no formal training or written guide, to understand complex f

loor processes, for on-time delivery.Through this, achieved inventory reduction

of $863,400 at Ford Motor Company-Sterling Heights Plant.Promoted to 9.25/9.75 A

xle Scheduler for assembly line capable of producing 2800 axles per day for Mich

igan and Kentucky Truck Plants. After three-years as a Scheduler, I requested an

d was approved to become a Production Supervisor at the Sterling Heights Plant.

Logistics and Material Management (2 years)

Experienced member of an automotive logistic and kanban implementation team with

Ryder Integrated Logistics.Our team was tasked with developing logistic routes,

management of raw and finished inventories, inbound and outbound shipments, cre

ating, monitoring and management of kanban system at Ford and Visteon manufactur

ing facilities.Developed a broad understanding across different product lines an

d plant layouts of implementing logistic and kanban system at vehicle and compon

ent manufacturing facilities. Experience includes the following: St. Louis Vehic

le Assembly, Dearborn Vehicle Assembly, Romeo Engine Assembly, Rawsonville Power

train Control Systems Assembly, and Sterling Heights Axle Plant.Permanently assi

gned to the Sterling Heights Axle Plant as Logistic Manager. Our team delivered

a one-year savings of $2.1M thru cost reduction of expediting, reduction in raw

material, and axle inventories.Maintained an on-time dispatch and delivery rate

for outbound product to Ford facilities 6.2% above goal at 91.2%.Based on perfor

mance as Logistic Manager, was recruited by Ford Motor Company-Sterling Heights

Plant Manager to become a Production Scheduler for Drive Components.

CAREER HISTORY

Work Group Advisor III Harley-Davidson Motor Company Novembe

r 2005 - Present

Production Supervisor American Axle & Manufacturing June 20

02 - November 2005

Production Supervisor Visteon Corporation May 200

0 - June 2002

Production Scheduler Ford Motor Company & Visteon July 1997

- May 2000

Logistic & Materials Manager Ryder Integrated Logistics Jun

e 1995 - July 1997

EDUCATION

Walsh College Bachelor of Business Administration June 1993

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 5 L 40 eDocumento9 pagine5 L 40 eRichard Andrianjaka Lucky100% (1)

- Motor Vehicle - WikipediaDocumento9 pagineMotor Vehicle - WikipediaCarlos de la CallejaNessuna valutazione finora

- Swot Analysis of Tesla: StrengthsDocumento3 pagineSwot Analysis of Tesla: StrengthsSanjida RituNessuna valutazione finora

- Tire Catalog Dunlop Sportmax Roadsmart 2Documento3 pagineTire Catalog Dunlop Sportmax Roadsmart 2Exclusivo1Nessuna valutazione finora

- Start CircuitDocumento1 paginaStart CircuitKer ToppNessuna valutazione finora

- Diagramas Eléctricos CHEVROLET AVEO 1.6L 4 CIL 2009-1 PDFDocumento105 pagineDiagramas Eléctricos CHEVROLET AVEO 1.6L 4 CIL 2009-1 PDFJose Hrdz100% (1)

- Mahindra & Mahindra: An AdvertisementDocumento19 pagineMahindra & Mahindra: An AdvertisementTanushree SethNessuna valutazione finora

- About Ashok LeylandDocumento6 pagineAbout Ashok LeylandIyyan ParamanandamNessuna valutazione finora

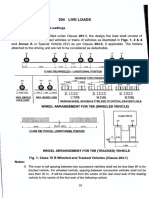

- 70R Track Live LoadDocumento1 pagina70R Track Live LoadSrinivasulu Reddy KoduruNessuna valutazione finora

- Technical Data: Pneumatic Tyred Rollers BW 28 RHDocumento4 pagineTechnical Data: Pneumatic Tyred Rollers BW 28 RHDreve MariusNessuna valutazione finora

- V3i901 PDFDocumento7 pagineV3i901 PDFIJCERT PUBLICATIONSNessuna valutazione finora

- ClioDocumento13 pagineCliodentaltzNessuna valutazione finora

- Camisa Motor LercDocumento58 pagineCamisa Motor LercJose Antonio Jareda ArreolaNessuna valutazione finora

- BT CSX10 20 30 40Documento233 pagineBT CSX10 20 30 40Socma ReachstackersNessuna valutazione finora

- Gmb Timing Kit Catalogue - final CoDocumento129 pagineGmb Timing Kit Catalogue - final CoAkachat ToufikNessuna valutazione finora

- Dokumen - Tips Daewoo Service Manual Instrument Cluster Matiz-2023Documento23 pagineDokumen - Tips Daewoo Service Manual Instrument Cluster Matiz-2023urexalg AlgériaNessuna valutazione finora

- Ficha Técnica DR650 XF650Documento6 pagineFicha Técnica DR650 XF650Andres HiguitaNessuna valutazione finora

- Maintenance Tables - Normal Service Maintenance Items 5,000 10,000 15,000 20,000 25,000 30,000 35,000 40,000 45,000Documento4 pagineMaintenance Tables - Normal Service Maintenance Items 5,000 10,000 15,000 20,000 25,000 30,000 35,000 40,000 45,000apNessuna valutazione finora

- Glysantin G64 FolderDocumento1 paginaGlysantin G64 FolderPía RivadeneiraNessuna valutazione finora

- 1.0 PM (CC) Toyota Hiace Price List May 2022Documento1 pagina1.0 PM (CC) Toyota Hiace Price List May 2022saarizal samsudinNessuna valutazione finora

- (TM) Cadillac Manual de Taller Cadillac XLR 2009 en InglesDocumento158 pagine(TM) Cadillac Manual de Taller Cadillac XLR 2009 en InglesJorge Casanova miralles0% (1)

- Memoirs of A Hack Mechanic by Rob Siegel - Table of ContentsDocumento5 pagineMemoirs of A Hack Mechanic by Rob Siegel - Table of ContentsBentley Publishers100% (3)

- 7425 and 7525 Tractors Mexican Edition Introduction PDFDocumento6 pagine7425 and 7525 Tractors Mexican Edition Introduction PDFmiguelcastillo100% (1)

- Activa125 BS VIDocumento6 pagineActiva125 BS VIAshuNessuna valutazione finora

- Sedan 1600 GSR: 1974 - 1976 Chrysler Valiant Lancer (LA) GL Sedan (Australia, A72A)Documento2 pagineSedan 1600 GSR: 1974 - 1976 Chrysler Valiant Lancer (LA) GL Sedan (Australia, A72A)lawkarlNessuna valutazione finora

- DirectWire 2015 Honda CR-V Xha27zk298Documento6 pagineDirectWire 2015 Honda CR-V Xha27zk298Pedro ToribioNessuna valutazione finora

- 4x4 Accessories Catalogue 2016Documento196 pagine4x4 Accessories Catalogue 2016SteveNessuna valutazione finora

- 07 Ford EV PresentationDocumento25 pagine07 Ford EV PresentationPat ClosserNessuna valutazione finora

- User'S Guide: Rev LampDocumento4 pagineUser'S Guide: Rev LampRicky PanderadjaNessuna valutazione finora

- Seat Belt YarisDocumento189 pagineSeat Belt YarisMiguel Guerra100% (1)