Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Z-Carb Original SpeedFeed

Caricato da

alphatoolsDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Z-Carb Original SpeedFeed

Caricato da

alphatoolsCopyright:

Formati disponibili

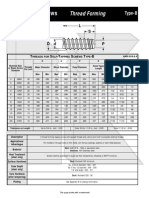

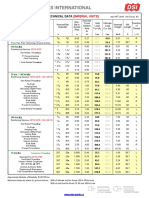

Fractional

Z-Carb Speed and Feed Recommendations

™

Cutting Diameter

Material Type Bhn 1/8 3/16 1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4 1

rpm in/min rpm in/min rpm in/min rpm in/min rpm in/min rpm in/min rpm in/min rpm in/min rpm in/min rpm in/min rpm in/min

Low Carbon Steels ~175 15,585 12 10,360 20 7,795 24 6,235 29 5,195 39 4,455 38 3,895 37 3,465 35 3,115 33 2,600 31 1,950 25

Low Carbon Steels ~275 12,835 10 8,150 17 6,420 20 5,135 24 4,280 32 3,665 31 3,210 30 2,850 29 2,565 27 2,140 25 1,605 21

Med Alloy Steels ~275 10,695 8 6,790 14 5,350 17 4,280 20 3,565 27 3,055 26 2,675 25 2,375 24 2,140 23 1,785 21 1,335 17

Mold And Die Steels ~275 5,500 4 3,490 8 2,750 8 2,200 10 1,835 13 1,570 13 1,375 13 1,220 12 1,100 11 915 11 690 9

Cast Iron - Gray ~200 14,515 11 9,215 19 7,260 23 5,805 27 4,840 36 4,145 35 3,630 34 3,225 32 2,905 31 2,420 29 1,815 24

Cast Iron - Ductile ~300 7,335 5 4,655 9 3,665 11 2,935 14 2,445 18 2,095 18 1,835 17 1,630 16 1,465 15 1,220 14 915 12

Cast Iron - Malleable ~300 4,585 4 2,910 6 2,290 7 1,835 8 1,530 11 1,310 11 1,145 11 1,020 10 915 9 765 9 575 7

Stainless 300 Series ~275 9,170 7 5,820 12 4,585 14 3,665 16 3,055 16 2,620 16 2,290 16 2,035 20 1,835 16 1,530 15 1,145 15

Stainless 400 Series ~185 12,835 10 8,245 17 6,420 22 5,135 25 4,280 25 3,665 25 3,210 25 2,850 29 2,565 25 2,140 22 1,605 22

Stainless PH Series ~325 7,640 5 4,850 10 3,820 12 3,055 14 2,545 14 2,185 14 1,910 14 1,700 17 1,530 14 1,275 12 955 12

Titanium Alloys ~295 9,170 9 5,820 14 4,585 16 3,665 18 3,055 18 2,620 18 2,290 18 2,035 20 1,835 18 1,530 16 1,145 16

High Temp. Alloys ~300 2,445 2 1,550 3 1,220 3 980 4 815 4 700 4 610 4 545 6 490 4 410 4 305 3

Profiling: Radial Width .5 x Diameter (max.) Profiling: Axial Depth 1.5 x Diameter (max.) Slotting: Axial Depth 1 x Diameter (max.)

Avoid re-milling chips

Tool holders with adequate gripping pressure are required

Stub length solid holders are recommended for heavy stock removal

Ramping or spiral plunging are the preferred entry methods into pockets (approximately 6 degrees @ 50% normal feed)

Radial Width of Cut (Rw)

Axial Depth of Cut (Ad)

Tool Diameter (D)

18 Z-Carb Solid Carbide End Mills

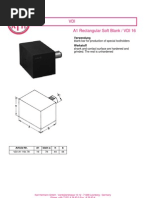

Metric

Z-Carb Speed and Feed Recommendations

™

Cutting Diameter

Material Type Bhn 3 5 6 8 10 12 14 16 18 20

rpm mm/min rpm mm/min rpm mm/min rpm mm/min rpm mm/min rpm mm/min rpm mm/min rpm mm/min rpm mm/min rpm mm/min

Low Carbon Steels ~175 16,500 335 9,895 502 8,250 586 6,185 754 4,950 955 4,125 963 3,535 890 3,095 817 2,750 809 2,475 804

Low Carbon Steels ~275 13,585 276 8,150 413 6,795 483 5,095 620 4,075 786 3,395 793 2,910 733 2,545 672 2,265 667 2,040 662

Med Alloy Steels ~275 11,320 230 6,790 345 5,660 403 4,245 517 3,395 656 2,830 661 2,425 592 2,125 561 1,885 556 1,700 552

Mold And Die Steels ~275 5,820 118 3,490 177 2,910 207 2,185 266 1,745 337 1,455 340 1,250 314 1,090 288 970 285 875 283

Cast Iron - Gray ~200 15,365 300 9,215 468 7,680 546 5,760 702 4,610 889 3,840 897 3,290 829 2,880 761 2,560 754 2,305 749

Cast Iron - Ductile ~300 7,765 158 4,655 236 3,880 276 2,910 354 2,330 449 1,940 453 1,665 419 1,455 384 1,295 381 1,165 378

Cast Iron - Malleable ~300 4,850 98 2,910 147 2,425 173 1,820 221 1,455 280 1,215 283 1,040 262 910 240 810 238 730 236

Stainless 300 Series ~275 9,705 175 5,820 300 4,850 355 3,640 405 2,910 405 2,425 405 2,080 405 1,820 405 1,615 380 1,455 380

Stainless 400 Series ~185 13,585 250 8,245 430 6,795 560 5,095 635 4,075 635 3,395 635 2,910 635 2,545 635 2,265 560 2,040 560

Stainless PH Series ~325 8,085 125 4,850 250 4,045 300 3,030 355 2,425 355 2,020 355 1,735 355 1,515 355 1,350 300 1,215 300

Titanium Alloys ~295 9,705 225 5,820 355 4,850 405 3,640 455 2,910 455 2,425 455 2,080 455 1,820 455 1,615 405 1,455 405

High Temp Alloys ~300 2,590 50 1,550 75 1,295 75 970 100 775 100 645 100 555 100 485 100 430 100 390 100

Profiling: Radial Width .5 x Diameter (max.) Profiling: Axial Depth 1.5 x Diameter (max.) Slotting: Axial Depth 1 x Diameter (max.)

Avoid re-milling chips

Tool holders with adequate gripping pressure are required

Stub length solid holders are recommended for heavy stock removal

Ramping or spiral plunging are the preferred entry methods into pockets (approximately 6 degrees @ 50% normal feed)

Radial Width of Cut (Rw)

Axial Depth of Cut (Ad)

Tool Diameter (D)

WWW.SGSTOOL.COM 19

Potrebbero piacerti anche

- Diffusion Make Welding ElectrodeDocumento9 pagineDiffusion Make Welding ElectrodeSarah FrazierNessuna valutazione finora

- Reinforcement Steel WorksDocumento28 pagineReinforcement Steel WorksPooja PawarNessuna valutazione finora

- A Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesDa EverandA Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesValutazione: 4 su 5 stelle4/5 (1)

- Star Core 6Documento2 pagineStar Core 6jmur10Nessuna valutazione finora

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersDa EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersValutazione: 3.5 su 5 stelle3.5/5 (2)

- Indian Rolled Sections 756Documento1 paginaIndian Rolled Sections 756sfsffNessuna valutazione finora

- ARIEL JG AND JGA COMPRESSOR SPECSDocumento4 pagineARIEL JG AND JGA COMPRESSOR SPECSparathasiNessuna valutazione finora

- Z-Carb JetStream SpeedFeedDocumento2 pagineZ-Carb JetStream SpeedFeedalphatoolsNessuna valutazione finora

- JG JgaDocumento4 pagineJG Jgaivan.mehanikNessuna valutazione finora

- Cilindros de Aluminio: 220 - 100 ToneladasDocumento1 paginaCilindros de Aluminio: 220 - 100 ToneladasLukas EzequielNessuna valutazione finora

- MURAFLEX 2020 Low RizeDocumento4 pagineMURAFLEX 2020 Low RizeanisyariskiNessuna valutazione finora

- Double-Sphere Connectors: FeaturesDocumento4 pagineDouble-Sphere Connectors: FeaturesArya WisnuNessuna valutazione finora

- Rule No. 1Documento64 pagineRule No. 1Albert AliminNessuna valutazione finora

- SD II PDF - OCRDocumento18 pagineSD II PDF - OCRSuraj KumarNessuna valutazione finora

- V GAVETA - Grooved Resilient OSY Gate ValveDocumento1 paginaV GAVETA - Grooved Resilient OSY Gate ValveGabriel TapiaNessuna valutazione finora

- V GAVETA - Grooved Resilient OSY Gate Valve - Ficha TécnicaDocumento1 paginaV GAVETA - Grooved Resilient OSY Gate Valve - Ficha TécnicaGabriel TapiaNessuna valutazione finora

- Sttype BDocumento1 paginaSttype BSean YangNessuna valutazione finora

- Self Tapping ScrewsDocumento1 paginaSelf Tapping ScrewsGulfstream Data, IncNessuna valutazione finora

- Carbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, IncDocumento2 pagineCarbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, Incsemarasik_651536604Nessuna valutazione finora

- EvolutionTekDatasheet PDFDocumento1 paginaEvolutionTekDatasheet PDFRobNessuna valutazione finora

- Ffe Brtpctbends 210407Documento2 pagineFfe Brtpctbends 210407api-3725163Nessuna valutazione finora

- Heavy Hex Bolts Screws ASTM A307 Gr.ADocumento1 paginaHeavy Hex Bolts Screws ASTM A307 Gr.AENGR 414Nessuna valutazione finora

- TorqueDocumento2 pagineTorquestaedtlerpNessuna valutazione finora

- U.S. Tsubaki Bs/Din Roller ChainDocumento6 pagineU.S. Tsubaki Bs/Din Roller ChainAnandhi ChidambaramNessuna valutazione finora

- TornilleriaDocumento26 pagineTornilleriacorpSIG corpSIGNessuna valutazione finora

- Pole Sheets: Cold-Rolled Steel StripDocumento2 paginePole Sheets: Cold-Rolled Steel StripL Mahender ReddyNessuna valutazione finora

- Minimum Bolt Tension Per AISC 360-16, Table J3.1: Bolt Diameter, In. A325 Bolts A490 BoltsDocumento2 pagineMinimum Bolt Tension Per AISC 360-16, Table J3.1: Bolt Diameter, In. A325 Bolts A490 Boltsrob westoverNessuna valutazione finora

- Strip Cladding StripsDocumento20 pagineStrip Cladding StripsMahesh DeshmukhNessuna valutazione finora

- FF ReportDocumento6 pagineFF ReportAbdur Rehman MarwatNessuna valutazione finora

- Shapes (HEB) Designacao de MaterialDocumento25 pagineShapes (HEB) Designacao de MaterialGabriel DimaNessuna valutazione finora

- Electrode CalculationDocumento2 pagineElectrode CalculationVarun MalhotraNessuna valutazione finora

- Design of Monorail SystemsDocumento2 pagineDesign of Monorail SystemsedwraulNessuna valutazione finora

- Rotator PipeDocumento4 pagineRotator PipetisnaNessuna valutazione finora

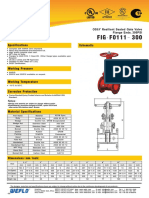

- OS&Y Resilient Seated Gate Valve, Flanged Ends, 300PSI FIG.F0111-300Documento1 paginaOS&Y Resilient Seated Gate Valve, Flanged Ends, 300PSI FIG.F0111-300Fight FireNessuna valutazione finora

- Non Return Valve-ShieldDocumento3 pagineNon Return Valve-ShieldNOMANNessuna valutazione finora

- Lloyds SteelDocumento10 pagineLloyds Steelsahil_484498Nessuna valutazione finora

- RAPTOR Cone CrusherDocumento4 pagineRAPTOR Cone CrusherLuis Miguel La TorreNessuna valutazione finora

- Specification FOR Stranded Galvanized Steel Wire For FencingDocumento3 pagineSpecification FOR Stranded Galvanized Steel Wire For FencingNarasimha DvlNessuna valutazione finora

- PL Wrenches 1Documento39 paginePL Wrenches 1Mc Louie BasaNessuna valutazione finora

- Techweld BrochureDocumento12 pagineTechweld BrochurekratingdiengNessuna valutazione finora

- Rolled Steel Sections - Indian (Bis) (Refr. Hanbook For Structural Engineers Sp:6 (1) - 1964 Rolled Steel BeamsDocumento1 paginaRolled Steel Sections - Indian (Bis) (Refr. Hanbook For Structural Engineers Sp:6 (1) - 1964 Rolled Steel BeamsSundara MoorthyNessuna valutazione finora

- Obtegachi 1 PDFDocumento4 pagineObtegachi 1 PDFSvetoslav SpasovNessuna valutazione finora

- FL6003 PDFDocumento4 pagineFL6003 PDFMauricio Barrios CastellanosNessuna valutazione finora

- 621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Documento2 pagine621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Anonymous GxpR56RZgNessuna valutazione finora

- Dewpoint Copper DPC-0521-DDocumento4 pagineDewpoint Copper DPC-0521-DTengku MunzirNessuna valutazione finora

- Sucker Rod Specifications and Torque RatingsDocumento2 pagineSucker Rod Specifications and Torque RatingsMichelangeloTiberiiNessuna valutazione finora

- CSE-CSG-23 Crimp Station Reference GuideDocumento7 pagineCSE-CSG-23 Crimp Station Reference GuideJoel DobbsNessuna valutazione finora

- Product CatalogDocumento24 pagineProduct CatalogRenan MolinaNessuna valutazione finora

- CatalogFilename Gearing Catalog Form HSB MB0029E B9-B-10Documento2 pagineCatalogFilename Gearing Catalog Form HSB MB0029E B9-B-10The Maison MaidsNessuna valutazione finora

- Threaded Rod Product Data Sheet Features Strengths MaterialsDocumento1 paginaThreaded Rod Product Data Sheet Features Strengths MaterialsFILID MADNessuna valutazione finora

- SG Sheet Piling Products Catalogue 2020/2021Documento20 pagineSG Sheet Piling Products Catalogue 2020/2021nurfirdausfadzilNessuna valutazione finora

- TDSWE 5356 Wire TSDocumento2 pagineTDSWE 5356 Wire TSbalamuruganNessuna valutazione finora

- Plugs and ReceptaclesDocumento2 paginePlugs and ReceptaclesAslamNessuna valutazione finora

- Sttype ABDocumento1 paginaSttype ABSean YangNessuna valutazione finora

- Bfs-Co-Ltd 29959 YezyivDocumento28 pagineBfs-Co-Ltd 29959 YezyivHisham ABD ALRASOULNessuna valutazione finora

- IMI TRUFLO RONA Fully Welded Ball ValvesDocumento12 pagineIMI TRUFLO RONA Fully Welded Ball ValvesAlexandra HarperNessuna valutazione finora

- NUTDocumento13 pagineNUTIDTR JamshedpurNessuna valutazione finora

- Ai Cylinders - Heavyduty PDFDocumento15 pagineAi Cylinders - Heavyduty PDFGM HerbalsNessuna valutazione finora

- Wafer Cast Steel Check Valve150Lb/300Lb: Applicable Standards: Design DescriptionsDocumento2 pagineWafer Cast Steel Check Valve150Lb/300Lb: Applicable Standards: Design Descriptionsmigaspro energiaNessuna valutazione finora

- Threadbars (Imperial Units) : Dywidag - Technical DataDocumento1 paginaThreadbars (Imperial Units) : Dywidag - Technical Dataradi_ashrafNessuna valutazione finora

- SINTCOMDocumento58 pagineSINTCOMalphatoolsNessuna valutazione finora

- BondhusDocumento52 pagineBondhusalphatoolsNessuna valutazione finora

- SAITDocumento166 pagineSAITalphatoolsNessuna valutazione finora

- Z-CARB MD SpeedFeedDocumento1 paginaZ-CARB MD SpeedFeedalphatoolsNessuna valutazione finora

- Z-Carb Corner Radius SpeedFeedDocumento2 pagineZ-Carb Corner Radius SpeedFeedalphatoolsNessuna valutazione finora

- DELFERDocumento81 pagineDELFERalphatoolsNessuna valutazione finora

- Z Carb MDDocumento4 pagineZ Carb MDalphatoolsNessuna valutazione finora

- Z-Carb Original End Mills: Revolutionizes MillingDocumento4 pagineZ-Carb Original End Mills: Revolutionizes MillingalphatoolsNessuna valutazione finora

- Ti NAMITEDocumento2 pagineTi NAMITEalphatoolsNessuna valutazione finora

- Z-Carb HTADocumento2 pagineZ-Carb HTAalphatoolsNessuna valutazione finora

- Tri CarbDocumento2 pagineTri CarbalphatoolsNessuna valutazione finora

- Z-Carb Corner RadiusDocumento4 pagineZ-Carb Corner RadiusalphatoolsNessuna valutazione finora

- Z-Carb JetStreamDocumento4 pagineZ-Carb JetStreamalphatoolsNessuna valutazione finora

- The Finishing Touch: Expect More From A Finishing MillDocumento4 pagineThe Finishing Touch: Expect More From A Finishing MillalphatoolsNessuna valutazione finora

- HPC Flyer UnzippedDocumento8 pagineHPC Flyer UnzippedalphatoolsNessuna valutazione finora

- Turbo CarbDocumento2 pagineTurbo CarbalphatoolsNessuna valutazione finora

- Ski CarbDocumento4 pagineSki CarbalphatoolsNessuna valutazione finora

- Osborn EZ-Flex CatalogueDocumento1 paginaOsborn EZ-Flex CataloguealphatoolsNessuna valutazione finora

- SCarb 012004Documento12 pagineSCarb 012004alphatoolsNessuna valutazione finora

- Power CarbDocumento3 paginePower CarbalphatoolsNessuna valutazione finora

- Osborn Pro CatalogueDocumento1 paginaOsborn Pro CataloguealphatoolsNessuna valutazione finora

- Osborn Novoflex-B CatalogueDocumento1 paginaOsborn Novoflex-B CataloguealphatoolsNessuna valutazione finora

- Ice-Carb High Performance Internal Coolant Drills For Drilling Depths Up To 7XdDocumento4 pagineIce-Carb High Performance Internal Coolant Drills For Drilling Depths Up To 7XdalphatoolsNessuna valutazione finora

- AD-Coated End MillsDocumento2 pagineAD-Coated End MillsalphatoolsNessuna valutazione finora

- OSBORN Retail & Trading ConceptsDocumento1 paginaOSBORN Retail & Trading ConceptsalphatoolsNessuna valutazione finora

- Osborn Load Runners CatalogueDocumento1 paginaOsborn Load Runners CataloguealphatoolsNessuna valutazione finora

- VDI enDocumento110 pagineVDI enalphatoolsNessuna valutazione finora

- Osborn Top CatalogueDocumento1 paginaOsborn Top CataloguealphatoolsNessuna valutazione finora