Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Materials Quick Reference Guide

Caricato da

Brian AplinCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Materials Quick Reference Guide

Caricato da

Brian AplinCopyright:

Formati disponibili

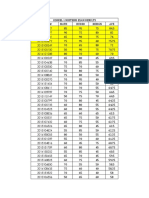

Metallic Materials Quick Reference Guide

Carbon Steel Brass

Carbon steels are the simplest form of steels, STAINLESS STEEL ALLOY FAMILY Brass is a common name for many copper-zinc

comprised of iron and carbon with a small amount of alloys. Lead is added to certain grades for enhanced

manganese. Some grades add phosphorus, sulfur, and machinability. Brass is generally corrosion resistant

sometimes lead to improve machinability. Often used 303 DUPLEX

2507

to natural (non-industrial) environments and water.

for equipment and transport lines for oil, air and gas 347 Exposure to ammonia and mercury are known to cause

applications. Carbon steels are often coated or plated 2205 stress corrosion cracking in most brass alloys.

Add niobium to reduce Add sulfur to improve machinability. Additional chromium and

for enhanced corrosion resistance.

intergranular corrosion No molybdenum. molybdenum to improve

susceptibility. Typically strength and resistance Aluminum Alloys

Alloy 400 used in elevated to pitting and crevice

Most alloys in this group are selected because of their

temperatures. corrosion.

Monel® 400 is a nickel-copper alloy widely used in Lower nickel. light weight, lower cost and satisfactory resistance to

marine environments. It offers exceptional resistance natural (non-industrial) environment conditions. Anod-

PH

to hydrofluoric acid, and is resistant to stress corrosion Add titanium to reduce 304 Add copper, titanium,

ized or coated aluminum alloys are also designated for

cracking and pitting in most fresh and industrial waters. intergranular corrosion

18 to 20 % chromium 17-4 seawater applications.

321 susceptibility. Typically

aluminum for

Stagnant seawater has been shown to induce crevice

used in elevated 8 to 10.5 % nickel precipitation hardening. 17-7

and pitting corrosion in this alloy. temperatures.

Lower nickel. Titanium

Source–Special Metals Corp. product literature

Titanium alloys have excellent resistance to corrosion in

Add Molybdenum for resistance to

pitting and crevice corrosion a wide variety of environments including seawater, salt

Alloy 600 brines, inorganic salts, bleaches, wet chlorine, alkaline

Lower carbon to reduce

Inconel® 600 is a nickel-chromium-iron alloy which is solutions, oxidizing acids and organic acids. These

intergranular corrosion

highly resistant to chloride-ion induced stress corrosion Nickel and copper NICKEL AUSTENITIC alloys have excellent resistance to crevice corrosion in

susceptibility.

316 added to improve

cracking. It also has reasonable resistance to many

16 to 18 % chromium resistance to Alloy 20 salt solutions and generally outperform stainless steels.

organic and inorganic compounds. Its high strength 304L Lower carbon to

10 to 14 % nickel

sulfuric acid and Unalloyed titanium (Grades 1, 2, 3 & 4) typically do not

and resistance to oxidation at elevated temperatures

also make it a good choice for these types of service

316L reduce intergranular

corrosion susceptibility 2 to 3 % molybdenum

increase strength suffer crevice corrosion at temperatures below 80°C

(175°F). Titanium is incompatible with fluorides, strong

and improve

conditions. reducing acids, very strong caustic solutions, and

weldability

Source–Special Metals Corp. product literature More Molybdenum anhydrous chlorine. Due to its combustibility, titanium is

Higher nickel, SUPER AUSTENITIC

not suitable for oxygen service.

Alloy 625

chromium and

254SMO

317 molybdenum; Nitrogen

added for enhanced AL-6XN

Source–Allegheny Ludlum product literature

Inconel® 625 is a nickel-chromium-molybdenum alloy corrosion resistance

with a small quantity of niobium. The alloy combination and higher strength Zirconium

of this material provides very good resistance in a The main use of zirconium is for nuclear power

wide variety of severely corrosive environments, generation applications. Reactor-grade zirconium

including hydrochloric and nitric acids. It is used Alloy 825 Alloy C-276 is essentially free of hafnium and has a low thermal

for its outstanding resistance to aggressive attack, Incoloy® 825 is a nickel-iron-chromium-molybdenum alloy de- Hastelloy® C-276 contains nickel, molybdenum and chromium neutron absorption cross-section. Zirconium is

specifically; crevice corrosion, pitting, and chloride-ion signed for a high level of resistance to general corrosion, pitting as the main elements. It is among the most corrosion resistant exceptionally resistant to corrosion by many common

stress corrosion cracking as well as high-temperature and crevice corrosion, as well as stress corrosion cracking in a alloys currently available, making it the most widely selected acids, alkalis, and sea water, and is therefore used

oxidation. It is also known for its high strength in both wide range of media. Some environments in which Incoloy 825 material for the most severe environments encountered in extensively by the chemical industry where corrosive

ambient and elevated temperatures. Resistance to is particularly useful are sulfuric acid, phosphoric acid, sulfur- chemical and petrochemical processing, flue gas desulfuriza- agents are employed. Zircaloy alloys such as Zircaloy-2

sour gas makes this alloy a popular choice for critical containing flue gases, sour gas, oil wells and seawater. tion, pulp and paper industries, sour gas, etc. The high level and Zircaloy-4, were developed specifically for nuclear

components in such environments. of molybdenum in this alloy makes it exceptionally resistant to applications. They combine the excellent corrosion

Source–Special Metals Corp. product literature

Source–Special Metals Corp. product literature, Haynes resistance of zirconium with alloying elements to

pitting and crevice corrosion. It is also one of the few materi-

International product literature

Alloy B-2 als that withstands the corrosive effects of wet chlorine gas, improve the material’s mechanical strength.

Hastelloy® B-2 is known for its excellent resistance to hypochlorite, and chlorine dioxide. This alloy is not a recom- Source–Online sources: http://periodic.lanl.gov/elements/40.

Tantalum html, http://www.wahchang.com

hydrochloric acid in all concentrations and temperatures. The mended choice for strong oxidizing environments, such as, hot

This metal is almost immune to chemical attacks and concentrated nitric acid.

nickel and elevated molybdenum content in this alloy offers

below 150°C (302°F). However, it can be attacked Source–Haynes International product literature, –Allegheny Ludlum

it excellent resistance to stress corrosion cracking as well as

by hydrofluoric acid. Its high melting point (>3000°C product literature

pitting and crevice corrosion.

(5432°F)) often makes it a choice for furnace

components. Source–Haynes International product literature Swagelok confidential for internal use and for training authorized

Swagelok distributors’ associates only.

Plastic and Elastomer Materials Quick Reference Guide

PEEK PI

Polyetheretherketone is a semi-crystalline, high- Elastomers Known commonly as Vespel®, polyimide is an amorphous

performance thermoplastic material that is insoluble in all material with good thermal stability, chemical resistance

common solvents and has excellent resistance to a very Buna-N EPR TFE/P and excellent mechanical properties. PI exhibits very low

wide range of organic and inorganic liquids. Mechanical (Nitrile Rubber) Recommended (Ethylene-Propylene Rubber) Offers Aflas® offers excellent chemical creep and high tensile strength. These properties are

properties are almost constant up to 300°F (149°C). PEEK for general purpose sealing of excellent resistance to atmospheric resistance to automotive lubricants, maintained during continuous use to temperatures of

can withstand short-term exposure to approximately 572 water, petroleum oils, solvents ageing and ozone, phosphate ester battery acids, jet fuels and oil field 450°F (232°C) and for short excursions, as high as 900°F

°F (300°C). and some alkalis. It is superior to hydraulic fluids, brake fluids, weak applications. The most common (482°C). Typically not effected by many solvents, oils and

most other elastomers with regard acids and bases. Has good wear use in plastic valves is in ozone weak acids. PI is not recommended for use in alkalis or

PFA to compression set, abrasion and resistance. Attacked by oils and water treatment systems, where inorganic acids.

Perfluoroalkoxy copolymers are melt processable, tear resistance. Typical upper use petroleum lubricants. Typical upper it is excellent. Typical upper use

semi-crystalline materials that have outstanding chemical temperature is approximately 250°F use temperature is approximately temperature is approximately PEI

resistance and can withstand a wide temperature range (121°C). 250°F (121°C). 400°F (204°C). Polyetherimide (PEI), commonly known as Ultem®, is an

from -328 to 482°F (-200 to 250°C). PFA is slightly less amorphous, amber-to-transparent thermoplastic with

chemical resistant than PTFE, but has considerably higher characteristics similar to PEEK. Relative to PEEK, PEI

Fluorocarbon (VDF/HFP) Polychloroprene Butyl is less expensive, but less temperature-resistant and

resistance to deformation under load than PTFE.

Provides chemical resistance to a Was first introduced by DuPont as Offers very low permeability and lower in impact strength. It offers good heat resistance,

wide range of chemicals including Neoprene. It resists degradation chemical resistance to hot water solvent resistance, flame resistance, high dielectric

PTFE mineral acids, salt solutions, from sun, ozone and weather and steam up to 250°F, brake strength, natural flame resistance, and exhibits extremely

Polytetrafluoroethylene is a semi-crystalline thermoplastic chlorinated hydrocarbons and and performs well in contact fluids, some acids, alcohols, and low smoke generation. PEI has excellent mechanical

material that has a melt viscosity that is significantly petroleum oils. Not recommended with hydrocarbon oils and many many other chemicals. It is not properties and performs in continuous use to 340°F

higher than most other polymers. As a result, it can not for use with steam or ammonia. chemicals. It has excellent physical compatible with mineral oil, fuels, (170°C).

be melt processed. PTFE can withstand continuous Typical upper use temperature toughness. Typical upper use or chlorinated hydrocarbons.

service temperature of 500°F (260°C) and is known to be is approximately 400°F (204°C). temperature is approximately 250°F Typical upper use temperature is

chemical resistant to almost all substances. The material’s

PAI

DuPont’s Viton® is one of many (121°C). approximately 250°F

main weakness is its poor resistance to deformation under brands of fluorocarbon elastomer. Commonly known as Torlon®, polyamide-imide is an

load. amorphous thermoplastic that has the highest strength

and stiffness of any thermoplastic up to 525°F (275°C).

Perfluoroelastomer Fluorosilicone Rubber Silicone It has outstanding resistance to wear and creep.

PCTFE

Offers chemical resistance that This elastomer is noted for its Offers good resistance to extreme PAI is virtually unaffected by aliphatic and aromatic

Polychlorotrifluoroethylene is a semi-crystalline polymer

is far superior to most other retention of flexibility, resilience high and low temperatures. hydrocarbons, chlorinated and fluorinated hydrocarbons,

whose type and degree of crystallinity depend strongly

elastomers. It can have limited and tensile strength over a wide It has excellent resistance to and most acids at moderate temperatures. The polymer,

on its molecular weight and thermal history. PCTFE

low temperature use and high temperature range. It is not, oxygen, ozone, UV and many however, may be attacked by saturated steam, strong

exceeds both PTFE and PFA in resistance to deformation

compression set. The maximum however, noted for its chemical chemicals. Low tensile strength, bases, and some high-temperature acid systems. Proper

under load but is susceptible to chemical attack by many

service temperature varies from resistance. Typically limited to static poor wear resistance and tear post-cure of PAI is necessary to achieve optimal chemical

organic materials.

428°F (220°C) to 600°F (316°C) applications. Typical upper use strength. Typically limited to static resistance. PAI can absorb a significant amount of water

It can withstand continuous exposure to 302°F (150°C).

depending on the compound used. temperature is approximately 350°F applications. Typical upper use when exposed to high humidity for extended time periods.

(177°C). temperature is approximately

PPS 400°F (204°C).

Polyphenylene sulfide is a semi-crystalline thermoplastic

commonly known as Ryton®. PPS can withstand long-

term exposure to 392°F (200°C) and short-term exposure PES POM Swagelok confidential for internal use and for training

authorized Swagelok distributors’ associates only.

to 500°F (260°C). PPS can be molded to tight tolerances Polyethersulfone, commonly known as Radel® A, is Polyoxymethylenes are semi- crystalline acetal

and will maintain dimensional integrity even at elevated an amorphous thermoplastic with exceptional high homopolymers (Delrin®) or copolymers that offer high

temperatures. PPS can be severely attacked by oxidizing Ryton—TM Chevron Phillips Chemical Company

temperature properties. PES remains in satisfactory fatigue strength, good creep resistance, toughness and Radel—TM Solvay Advanced Polymers

chemicals. condition in long-term continuous use without causing impact resistance. POM can withstand temperatures in Ultem—TM Sabic Innovative Plastics

Monel—TM Huntington Alloys Corporation

any dimensional change or physical deterioration at excess of 200°F (94°C). POM is sensitive to acid hydrolysis Inconel, Incoloy—TM Inco Alloys International, Inc.

temperatures as high as 399°F (204°C). PES has poor and oxidation. Low levels of chlorine in potable water (1-3 Hastelloy—TM Haynes International, Inc.

Viton, Vespel, Delrin—TM DuPont

weathering resistance and is attacked by some alcohols ppm) can cause stress corrosion cracking.

Torlon—TM Amoco Performance Products, Inc.

and ketones. Aflas—TM Asahi Glass Co., Ltd.

Swagelok—TM Swagelok Company © 2009 Swagelok Company

May 2009, R0 CORP-0018

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Training Matrix For TM IDocumento14 pagineTraining Matrix For TM IApril NavaretteNessuna valutazione finora

- Chemical Resistance GuideDocumento32 pagineChemical Resistance GuidevsvineeshNessuna valutazione finora

- Sip TrainingDocumento96 pagineSip Trainingronics123Nessuna valutazione finora

- Singer Basic Tote Bag: Shopping ListDocumento5 pagineSinger Basic Tote Bag: Shopping ListsacralNessuna valutazione finora

- FMDS0129Documento49 pagineFMDS0129hhNessuna valutazione finora

- Swagelok Fitting ManualDocumento120 pagineSwagelok Fitting ManualSmit ShahNessuna valutazione finora

- 000 200 1210 Guidelines For Minimum Deliverables 3 November 2011Documento22 pagine000 200 1210 Guidelines For Minimum Deliverables 3 November 2011Raul Bautista100% (1)

- Ss 400 61 orDocumento1 paginaSs 400 61 orBrian Aplin0% (1)

- Ss 400 61 0038Documento1 paginaSs 400 61 0038Brian AplinNessuna valutazione finora

- Swagelok CatalogDocumento66 pagineSwagelok Catalogfeelmybeat100% (1)

- Chemiucal Resistance Guide NIBCODocumento32 pagineChemiucal Resistance Guide NIBCOwaltliewNessuna valutazione finora

- Tube Fitters ManualDocumento275 pagineTube Fitters ManualBrian Aplin100% (2)

- Jaguar Land Rover Configuration Lifecycle Management WebDocumento4 pagineJaguar Land Rover Configuration Lifecycle Management WebStar Nair Rock0% (1)

- HFM Currency CubeDocumento2 pagineHFM Currency CubeSudhakar kNessuna valutazione finora

- F 2786538d6cdc0bb1Documento245 pagineF 2786538d6cdc0bb1Daniel HarutyunyanNessuna valutazione finora

- CBSE Class 5 Mathematics Sample Paper Set NDocumento4 pagineCBSE Class 5 Mathematics Sample Paper Set NRamanjeet KaurNessuna valutazione finora

- SPPID QuestionsDocumento2 pagineSPPID Questionsvivek83% (12)

- Module 1 Introduction To Highway and Railroad EngineeringDocumento43 pagineModule 1 Introduction To Highway and Railroad EngineeringKenneth FajardoNessuna valutazione finora

- Enzyme Inhibition and ToxicityDocumento12 pagineEnzyme Inhibition and ToxicityDaniel OmolewaNessuna valutazione finora

- DSD - Assignment 1 2018Documento3 pagineDSD - Assignment 1 2018Naveen KumarNessuna valutazione finora

- Python Programming Lecture#2 - Functions, Lists, Packages & Formatting I/ODocumento69 paginePython Programming Lecture#2 - Functions, Lists, Packages & Formatting I/OHamsa VeniNessuna valutazione finora

- Notes Measures of Variation Range and Interquartile RangeDocumento11 pagineNotes Measures of Variation Range and Interquartile RangedburrisNessuna valutazione finora

- Introduction to Continuous Optimization for Machine LearningDocumento10 pagineIntroduction to Continuous Optimization for Machine LearningMarcos OliveiraNessuna valutazione finora

- Public Key Cryptography: S. Erfani, ECE Dept., University of Windsor 0688-558-01 Network SecurityDocumento7 paginePublic Key Cryptography: S. Erfani, ECE Dept., University of Windsor 0688-558-01 Network SecurityAbrasaxEimi370Nessuna valutazione finora

- Product Presentation Nova Blood Gas AnalyzerDocumento38 pagineProduct Presentation Nova Blood Gas Analyzerlaboratorium rsdmadani100% (1)

- Front Panel & Display Technical Data: User ManualDocumento2 pagineFront Panel & Display Technical Data: User ManualJulio PorleyNessuna valutazione finora

- Hydrogen and Its Compound.1Documento10 pagineHydrogen and Its Compound.1abhishekNessuna valutazione finora

- Smart Dustbin using ArduinoDocumento22 pagineSmart Dustbin using ArduinoEr Dinesh TambeNessuna valutazione finora

- Reliability EngineeringDocumento9 pagineReliability Engineeringnvaradharajan1971Nessuna valutazione finora

- Classification of Differential Equations For Finding Their SolutionsDocumento2 pagineClassification of Differential Equations For Finding Their SolutionsakhileshNessuna valutazione finora

- Algebra Translating Algebraic Phrases 001Documento2 pagineAlgebra Translating Algebraic Phrases 001crazyomnislash25% (4)

- Developmental Morphology and Physiology of GrassesDocumento26 pagineDevelopmental Morphology and Physiology of GrassesAnonymous xGVfcqNessuna valutazione finora

- CI SetDocumento18 pagineCI Setতন্ময় ঢালি Tanmay DhaliNessuna valutazione finora

- Is A Calorie Really A Calorie - Metabolic Advantage of Low-Carbohydrate DietsDocumento6 pagineIs A Calorie Really A Calorie - Metabolic Advantage of Low-Carbohydrate DietsGustavo CastroNessuna valutazione finora

- Midterm Exam Result Ce199-1l 2Q1920Documento3 pagineMidterm Exam Result Ce199-1l 2Q1920RA CarpioNessuna valutazione finora

- 10th Term Exams Computer Science PaperDocumento2 pagine10th Term Exams Computer Science PaperMohammad Tariq JavaidNessuna valutazione finora

- Green Synthesis of Zinc Oxide Nanoparticles: Elizabeth Varghese and Mary GeorgeDocumento8 pagineGreen Synthesis of Zinc Oxide Nanoparticles: Elizabeth Varghese and Mary GeorgesstephonrenatoNessuna valutazione finora