Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

13.07 - Steel Structures

Caricato da

Ian GordonDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

13.07 - Steel Structures

Caricato da

Ian GordonCopyright:

Formati disponibili

Steel Structures

Structural Design for Architecture – Chapter 3

Structural Properties

Steel has high strength in tension and compression, and is therefore able to resist

bending and axial loads with equal facility. It is the strongest of the commonly used structural

materials. It is used to make the tallest buildings and the enclosures with the longest spans.

The thin columns and floors and greater spans possible with steel allow for uncluttered

interiors to be created within buildings. Skeleton frameworks channel the load of the building

into slender elements of low volume within which stress levels are high. This allows both

internal and external walls to become non-loadbearing partitions. This allows for the

development of glass-clad buildings and ‘overt use of structural elements’ (e.g. exposed

structure) which can deliver the appearance of lightness, openness and structural elegance.

Indeed the merits of steel-frame construction are often intertwined with the advantages

and disadvantages of glazing. Glass-clad buildings are visually appealing, but on its own

glass performs poorly in terms of thermal and acoustic insulation.

When a ‘space framework’ is built out of steel components it can demonstrate an even

greater strength-to-weight ratio. They can do this because their form provides a more

‘satisfactory distribution of internal forces’. Space frames demonstrate ‘high static

indeterminancy’ meaning that they can warp and bend without losing strength. Due to their

cost space frames are only economical for wide spans (20m +). Similarly when, as in tall

buildings such as the World Trade Centre, the structure is kept to the edges of the building so

as to create a tube, this allows the building to resist lateral loading from wind.

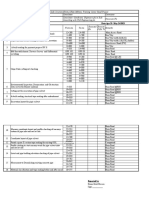

Steel components are typically bolted or welded on site. Joints between components will

either be hinge-type joints which do not transmit ‘bending moment’ (e.g. the components can

flex away from each other) and rigid joints which do (e.g. the components flex together).

Hinged joints can allow for thermal expansion and movements in the foundation, but they will

also require bracing. Where hinge joints are used bracing can be provided in the vertical

plane by masonry walls (or other solid sections like lift shafts a.k.a. self-supporting masonry

cores) and in the horizontal plane by the roof or diagonal beams.

One-way-spanning structural systems support weight in a single plane (e.g. two parallel walls

with a roof in between), whereas two-way-spanning systems support weight in two planes

(e.g. a box).

Technical Performance

Despite its strength, steel is also dense and heavy, giving it a strength-to-weight ratio which is

similar to timber.

Benefits of using steel:

• High strength means that flexibility in building plans is possible;

• High strength means smaller components which means that the structure takes up

less space;

• Consistent performance (unlike wood or concrete which can vary) meaning that small

safety factors are required;

• Standard components means fast erection of the structure on site.

Problems associated with steel:

• Construction must, in most circumstances, be specified from standard components

and can be changed very little on site. Typically this results in rectilinear buildings.

• Poor durability when exposed to weather, must be treated with corrosion-protection if

exposed;

• Poor performance in fire, must be clad in fire-proofing materials;

• Exposed elements must be also be fire-protected to prevent them from conducting

heat around the building;

• Difficult to shape into useful components;

• Heavy components, requires cranes;

• High energy consumption and pollution associated with production.

When steel is exposed to the heat of a fire the most vulnerable parts of the structure are the

compression elements and the compression flanges of beams (e.g. the top ones). Fire

protection (which can be mechanical such as at Le Centre Pompidou, but is more commonly

insulating material) reduces the rate at which the temperature of steel increases. Common

insulating materials include ‘tradition’ materials such as concrete and masonry, ‘spray-on’

materials made from rock-fibre, and ‘intumescent coating’ which is thin like paint but foams

when exposed to heat.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- LabEx No. 2 Flexural Strength of WoodDocumento6 pagineLabEx No. 2 Flexural Strength of WoodianzkieeNessuna valutazione finora

- RCC Lab ReportDocumento18 pagineRCC Lab ReportShuvanjan Dahal50% (4)

- APA LVL Hole DrillingDocumento6 pagineAPA LVL Hole DrillingJake YalongNessuna valutazione finora

- Midterm Exam - MCQ - TFQ - ENGI8690-9114 - W2019Documento5 pagineMidterm Exam - MCQ - TFQ - ENGI8690-9114 - W2019Mohammad HaqNessuna valutazione finora

- Gypsump Board Plafon Dan DindingDocumento11 pagineGypsump Board Plafon Dan DindingViViArianiNessuna valutazione finora

- Plate No.3 PlumbingDocumento1 paginaPlate No.3 PlumbingDawat JohnNessuna valutazione finora

- Ce Drawing QuestionsDocumento6 pagineCe Drawing Questionsসন্দীপ চন্দ্রNessuna valutazione finora

- EN 1993-1:2005/A1:2014, Eurocode 3: Design of Steel StructuresDocumento2 pagineEN 1993-1:2005/A1:2014, Eurocode 3: Design of Steel StructurestomicNessuna valutazione finora

- 307 - Foundation Cutoff Walls For Dams and Levees WebinarDocumento16 pagine307 - Foundation Cutoff Walls For Dams and Levees WebinarZELALEMNessuna valutazione finora

- Surveying Monthly Report MAY 2023.Documento3 pagineSurveying Monthly Report MAY 2023.AshebirNessuna valutazione finora

- 3 - Plumbing MEP - Drainage-RevDocumento57 pagine3 - Plumbing MEP - Drainage-Revsardarmkhan100% (10)

- Rock MechanicsDocumento49 pagineRock MechanicsMohamed KessyNessuna valutazione finora

- Foundation Studies - Pile GroupDocumento55 pagineFoundation Studies - Pile GroupMuhammad Fahmi AnbNessuna valutazione finora

- Bomba Inspection Guideline V2018Documento5 pagineBomba Inspection Guideline V2018kimura takuya100% (1)

- Reinforced Concrete Rectangular Beam Design To AS3600-2009Documento4 pagineReinforced Concrete Rectangular Beam Design To AS3600-2009Rron de GuzmanNessuna valutazione finora

- Astm A999-14Documento12 pagineAstm A999-14Артем ТитовNessuna valutazione finora

- Architect's Guide To FLS (NFPA)Documento29 pagineArchitect's Guide To FLS (NFPA)N V Sumanth Vallabhaneni100% (1)

- Behavior of Field Splice Details in Precast Concrete-Filled Steel Grid Bridge DeckDocumento10 pagineBehavior of Field Splice Details in Precast Concrete-Filled Steel Grid Bridge DeckIoannis BazosNessuna valutazione finora

- FHWA Geotechnical Aspects of Pavements Reference Manual: Chapter 5.0 Geotechnical Inputs For Pavement Design (Continued)Documento1 paginaFHWA Geotechnical Aspects of Pavements Reference Manual: Chapter 5.0 Geotechnical Inputs For Pavement Design (Continued)Erasmo AlexanderNessuna valutazione finora

- Etce 208Documento1 paginaEtce 208Sourabh PandeyNessuna valutazione finora

- Pages From (ASHRAE) - 2009 - ASHRAE - Handbook - Fundamentals - (SI)Documento2 paginePages From (ASHRAE) - 2009 - ASHRAE - Handbook - Fundamentals - (SI)Tran Canh HoanNessuna valutazione finora

- MAR For Single Bubble InsulationDocumento23 pagineMAR For Single Bubble InsulationResearcherNessuna valutazione finora

- Fluid Mechanics & Fluid MachinesDocumento355 pagineFluid Mechanics & Fluid MachinesSatish Kumar100% (6)

- GEOGRIDS Final ReportDocumento58 pagineGEOGRIDS Final ReportJovan BucolNessuna valutazione finora

- 1d GeomechanicsDocumento8 pagine1d GeomechanicsHamed YousifNessuna valutazione finora

- Plasticity and Structure of Soil: Shinwaray, MSCDocumento36 paginePlasticity and Structure of Soil: Shinwaray, MSCAadolf ElÿasNessuna valutazione finora

- Anexo A - Magnesium Elektron Elektron® ZRE1 Magnesium Alloy, UNS M12330 - DatasheetDocumento3 pagineAnexo A - Magnesium Elektron Elektron® ZRE1 Magnesium Alloy, UNS M12330 - DatasheetAmilton CardosoNessuna valutazione finora

- Tool Life, Tool Wear Machinability PDFDocumento9 pagineTool Life, Tool Wear Machinability PDFshivaNessuna valutazione finora

- Steel Girder Bridge With Composite Concrete DeckDocumento9 pagineSteel Girder Bridge With Composite Concrete DeckTanjil MominNessuna valutazione finora

- Converging Nozzles & Converging-Diverging NozzlesDocumento4 pagineConverging Nozzles & Converging-Diverging NozzlesSaiful ZakwanNessuna valutazione finora