Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1767 Alt

Caricato da

vsen5Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1767 Alt

Caricato da

vsen5Copyright:

Formati disponibili

COMPRESSED EARTH BLOCKS (CEB)

For further information on Compressed Earth Blocks (CEB) Applications of Compressed Earth Block:

Please contact: Cost effective n Foundation, load bearing walls, arches, vaults and domes, etc.

houses – Mayotte

n Hot or cold climate

n Dry or humid areas

UNITED NATIONS CENTRE Soil Stabilization for Durability:

FOR HUMAN SETTLEMENTS n The strength of CEB is often better than country fired bricks

(UNCHS - HABITAT) A Local Material for Reducing Imports:

n CEB production is ideally made on the construction site itself

PO Box 30030, Nairobi, KENYA

Limiting Deforestation, no Need of Firing:

Phone: (254-2) 621234

Auram Press 3000 n CEB are often stabilized with cement or lime. Thus no firing is

Fax: (254-2) 624265 required, but curing is necessary for a month

E-mail: Rainer.Nordberg@unchs.org 13 apartments

on 4 floors, More Eco-Friendly than Fired Bricks:

819 m2 – Auroville, India

n 5-15 times energy savings

n 8 times less polluting

AUROVILLE BUILDING CENTRE Cost effective

house – Kerala, Cost Saving:

(AVBC / EARTH UNIT) India n CEB are most of the time cheaper than conventional materials

Auroshilpam, Auroville - 605 101 A New Market Opportunity:

Tamil Nadu, INDIA n Possibility to uplift labour skills and to offer a new product

Phone: +91 (0)413-622277 / 622168 Need of a Proper Soil Identification:

Fax: +91 (0)413-622057 Visitors Centre, 1300 m2 n It is essential to check the soil suitability before doing CEB

Auroville, India

E-mail: csr@auroville.org.in Need to Manage the Soil Resources:

Disaster resistant house

New Delhi, India Vault, 10.35 m span n It is essential to know before starting a production what to do

Auroville, India later on with the hole from where the soil was taken

SOIL SUITABILITY

The Raw Material Soil Stabilization Field Analyses for Soil Identification

n Organic soil present in the topsoil is not suitable for CEB It aims at giving long lasting properties to silt and clay ‘ Pull the cohesive ball

ΠSmell a humid soil for humus content

n Stabilization calculations are always with dry weights n A gravely soil breaks apart very easily

n It should not smell rotten

The stabilization percentage is rather low n A sandy soil breaks apart easily

n n It should not smell musty

Don’t use the topsoil ð Cement is preferably used for sandy soils (average of 5%) n A silty soil breaks apart after some length

n n It should smell agreable

n A clayey soil breaks apart after a long pull

n Lime is rather used for clayey soils with 6% as an average

Use the subsoil ð

• Look a humid or dry soil ’ Stick a knife into the ball

Soil Improvement n A gravely soil contains big pieces n A gravely soil does not stain the knife

n A sandy soil contains coarse particles n A sandy soil stains very little the knife

Don’t use the rock ð Most of the soils can be used n A silty soil is thin, with small lumps n A silty soil stains easily the knife

Often they need to be improved by simple and natural means: n A clayey soil is very thin, with big lumps n A clayey soil stains a lot the knife

n Remove the topsoil and use it for agriculture n Mixing various soils n Crushing or sieving Ž Touch a humid or dry soil “ Cut the ball with a knife

n Adding gravel n Adding sand n Adding clay A gravely soil is very rough

n A soil is an earth concrete! Soil contains gravel, sand and binders n n A gravely soil has a very rough aspect

which are silt and clay. Silt and clay are the cement of the earth but n A sandy soil is rough n A sandy soil has a rough aspect

they are not stable under water. They can be stabilized. Management of Resources n A silty soil is soft, with crumbly lumps n A silty soil has a smooth, not shiny aspect

n A clayey soil is thin, with hard lumps n A clayey soil has a smooth, shiny aspect

n Almost every soil can be used, as such or after improvement to get

the best proportions. It is essential to be aware of ecological parameters ” Do a print in the ball and pour water

• Add a little water, compress a humid ball

n Not caring for the environment creates ecological disasters Water goes very quickly in a gravely soil

n A good soil for CEB is more sandy than clayey or silty n A gravely soil needs a very short pressure n

Be conscious and respect Nature! n A sandy soil needs a short pressure n Water goes quickly in a sandy soil

n Before digging imagine how the hole can be used later on a little n A silty soil needs a medium pressure n Water goes slowly in a silty soil

Composition of the Best Soil n Holes can be created and used in many ways: water n A clayey soil needs a long pressure n Water goes very slowly in a clayey soil

Basement floor for underground storage

• Wash hands with water

Landscaped pond • Add more water to shape a cohesive ball

Rainwater harvesting to refill the water table n A gravely soil is very difficult to shape n A gravely soil does not stick, is very easy to wash

Ponds to water animals and to control water run off, etc. n A sandy soil is difficult to shape n A sandy soil sticks very little, is easy to wash

n A silty soil is easy to shape n A silty soil sticks a lot, is very difficult to wash

You can create a new harmonious and beautiful balance n A clayey soil is very easy to shape more water

n A clayey soil gives a thin film and is quite easy

15% Gravel 50% Sand 15% Silt 20% Clay between nature and buildings to wash

PRODUCTION

1. Sieving the Soil 2. Measuring 3. Mixing 4. Check the Moisture Content

n Too dry

n Good moisture

content

Mesh 1.5 x 1.5 cm

n Measure all components directly in the containers n Too wet

(wheelbarrows for soil, buckets for sand and cement) n Pour in order, soil, sand and stabilizer

n Aerate the soil n Remove lumps, stones and pebbles n Fill the containers with accuracy, as per specifications n First mix dry, 2 times n Add water and mix wet, 2 times n Drop a squeezed ball from 1m high

5. Moulding 6. Quality Control 7. Humid Curing and Stacking 8. Final Curing and Stacking

n Every block of every mix must be checked n The pile must remain covered 2 days with a plastic sheet

n Water the pile daily (on top and on the 4 sides),

n Pocket penetrometer n Block height gauge n Cover immediately every as many times as needed, for 1 month

n Mould immediately the mix: within 20 minutes! for the compression strength for the height n Stacking the fresh block row with a plastic sheet n Never let the pile dry for a full month!

MASONRY

Mortar Quality Block Laying for Single Bond Wall Pointing the Joints Guidelines for a Village House

n The mortar is stabilized 1.5 times more than the blocks n A good roof with good overhangs

n Sand (0.2 to 2 mm) should be added ΠThe course must ΠUse a piece of n RCC ring beam in U blocks

n The mortar should be prepared at a plastic state (not too liquid) be humid hose pipe, which

Conduct some test first! is soaked in water

n Mortar for wall: mix = 1 cement + 6 soil + 6 sand, by volume

n Apply 1 cm mortar on a block soaked in water

Cure the mortar 3 days under shed, let it dry 3 days under sun • Soak the block

n • Clean the joint

The test sample must be neither cracking nor crumbling into water

with a wet sponge

It is not cracking, Ž Apply mortar on n The pointing must be done every day after laying the blocks

it is not crumbling: the side of the block

n The mix 1 : 6 : 6 is OK Dimensioning the Building

n Dimension the building according to the module of the block

If cracks appeared: n Protection of the window sill

The module of the block is its dimension, plus the mortar

n Add more sand thickness (mt)

• Press the side joint

n Try 1 cement + 5 soil + 7 sand

n Rise the ground floor +/- 50 cm

n Or try 1 cement + 4 soil + 8 sand

A = (x . module) - 1 mt

• Adjust the block n RCC plinth beam in U blocks

If the mortar is crumbly: along the string line n Plaster the basement with cement

n Add more soil n Provide a good slope to drain water

B = (x . module) + 1 mt

n Try 1 cement + 7 soil + 5 sand

n Or try 1 cement + 8 soil + 4 sand n Good foundations

C = (x . module)

n Never fill the joint n Avoid water accumulation around the building

n The new trial test must be neither cracking nor crumbling after laying the block n Avoid water run offs in any part of the building

n The mortar laid in the masonry must be cured for a month n Maintain the building regularly

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Bearing Capacity SPTM27 1 2Documento5 pagineBearing Capacity SPTM27 1 2Tarek AbulailNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Printable Article Rocks On The BeachDocumento2 paginePrintable Article Rocks On The BeachPiper WalkerNessuna valutazione finora

- Pipe Culvert 1000mmDocumento8 paginePipe Culvert 1000mmgtarun22gupta100% (1)

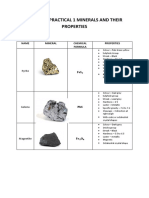

- Geology Minerals Practical 1-3Documento9 pagineGeology Minerals Practical 1-3Simiso GasaNessuna valutazione finora

- Sample Soil WorksheetsDocumento12 pagineSample Soil WorksheetsSaravanan Ramasamy100% (1)

- 1 - General GeologyDocumento60 pagine1 - General GeologyDubistWhiteNessuna valutazione finora

- Southern University Bangaladesh: Welcome To Our PresentationDocumento25 pagineSouthern University Bangaladesh: Welcome To Our PresentationJoy Chowdhury100% (1)

- SNF-Flomin Product Selection WheelDocumento1 paginaSNF-Flomin Product Selection WheelGerman Van der Olguin50% (2)

- Housing Geotechnical ReportDocumento39 pagineHousing Geotechnical ReportMfanelo Mbanjwa100% (2)

- Dindigul Bypass To Samyanallore On NH 7 in The State of Tamil Nadu Vol - Iii PDFDocumento29 pagineDindigul Bypass To Samyanallore On NH 7 in The State of Tamil Nadu Vol - Iii PDFVinay YadavNessuna valutazione finora

- 05 Weathering Soil and Mass Movements 1 2Documento40 pagine05 Weathering Soil and Mass Movements 1 2anon_293149761100% (1)

- Dakota Well - Bit Spec PDFDocumento42 pagineDakota Well - Bit Spec PDFMygroup 5544Nessuna valutazione finora

- Classification of Rocks Lecture-3Documento20 pagineClassification of Rocks Lecture-3Dr. Daljeet Singh SidhuNessuna valutazione finora

- 16 - OreOre Deposit Geology (John Ridley, 2013)Documento3 pagine16 - OreOre Deposit Geology (John Ridley, 2013)Hugo Luis HuamaníNessuna valutazione finora

- Q4 P. Task 1 - RocksDocumento2 pagineQ4 P. Task 1 - RocksJhonazel SandovalNessuna valutazione finora

- Soil ReportDocumento36 pagineSoil ReportCanaille Jonas PangilinanNessuna valutazione finora

- No. F-Dtn-M-Bhsa Agriculture Paper-I: Time Allowed Three Hours Maximum Marks: 300Documento10 pagineNo. F-Dtn-M-Bhsa Agriculture Paper-I: Time Allowed Three Hours Maximum Marks: 300Bhawesh KumarNessuna valutazione finora

- Sedimentary RocksDocumento19 pagineSedimentary Rocksvishnu.jayasangarNessuna valutazione finora

- Vetiver System Applications Technical Reference ManualDocumento98 pagineVetiver System Applications Technical Reference ManualDoan ChicuongNessuna valutazione finora

- Electro-Osmotic Enhancement of Bentonite With Reactive and Inert ElectrodesDocumento7 pagineElectro-Osmotic Enhancement of Bentonite With Reactive and Inert ElectrodesLydia DarmiyantiNessuna valutazione finora

- Soil Type Categories and Districts - Government-Of-Madhya-Pradesh, IndiaDocumento2 pagineSoil Type Categories and Districts - Government-Of-Madhya-Pradesh, IndiaMayur MittalNessuna valutazione finora

- Slope Stability Assessment of The Letlhakane (DK1) MineDocumento10 pagineSlope Stability Assessment of The Letlhakane (DK1) MineBoon FuiNessuna valutazione finora

- Numerical Simulations of Stone Column InstallationDocumento53 pagineNumerical Simulations of Stone Column InstallationlorenzaNessuna valutazione finora

- Das PoGE 8e SI LB PPT - Chapter 12 ExamplesDocumento32 pagineDas PoGE 8e SI LB PPT - Chapter 12 ExamplesTan Kai XianNessuna valutazione finora

- Field Permeability Test-2Documento1 paginaField Permeability Test-2P Allen Samuel IgnatiusNessuna valutazione finora

- Bullock Et Al-2018-Geology TodayDocumento5 pagineBullock Et Al-2018-Geology TodayABERA ERENANessuna valutazione finora

- L2 - Introduction To Advanced IrrigationDocumento98 pagineL2 - Introduction To Advanced IrrigationVirgin VinushaNessuna valutazione finora

- Methods For Evaluating Overconsolidation Ratio From Piezocone Sounding ResultsDocumento13 pagineMethods For Evaluating Overconsolidation Ratio From Piezocone Sounding ResultsBárbara RodríguezNessuna valutazione finora

- Student Exploration: Rock ClassificationDocumento4 pagineStudent Exploration: Rock Classificationjack guzman100% (2)

- And Sekar A.S.S, 2009) (Bahar Demirel, 2010)Documento3 pagineAnd Sekar A.S.S, 2009) (Bahar Demirel, 2010)rowejessicaNessuna valutazione finora